Professional Documents

Culture Documents

Installation Procedure D13 MH MCC: MCC Electrical Connection Box MCC Electrical Connection Box

Uploaded by

mxnoxnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Procedure D13 MH MCC: MCC Electrical Connection Box MCC Electrical Connection Box

Uploaded by

mxnoxnCopyright:

Available Formats

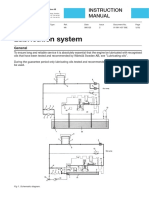

Installation Procedure: D13 MH MCC Document number: 47701344 Release date: 11-2012

Installation Procedure D13 MH MCC

MCC Electrical connection box

Switch for backlight

To use a switch to alternate between adjusted brightness and 100% brightness connect it as following: Cables Category A

BL Remote Panel

Connect to PC Tool DriveConfig*2 Connect to PC Tool DriveMonitor

Communication is connected here. Use a RS232-RS485 converter to extend length from 10 meters up to 2/900 meters.

External system MODBUS

Cables Category E

* Jumper settings

The jumpers factory setting show below. If application requires additional sensors then change jumper settings. Refer to Installation Manual MCU jumper settings

4 3 2 1

*

Remote Panel Remote Panel

Aux. I/O equipment

Jumper settings according to application

Cables Category B

Relay connection (24 V Only)

Cables Category B

Set the jumpers as following:

X1 X2

Override indication Local mode indication Spare (Set function in DriveConfig) EMS communication failure Start failure

AI1 AI2 AI3 AI4

AI5

AI6

AI7

AI8

CAN H CAN L CAN H CAN L

Voltage measurement

Resistance measurement Current measurement

BL

BL

5 9

5 9

X3 X4 X5

BL

X6 Horn X7 Common shutdown Common alarm Derate alarm Ready to start engine Engine running indication Load sharing Clutch Connect [internal use] Spare relay Spare relay X18 Pin 15,16 Connect to 0V if X15 and X16 shall be used

SDU jumper settings

ON OFF ON OFF

Loadsharing Operation (- Engine #2, #3...)

When using loadsharing connect the COM module to the remote panel in the end of the chain. The CAN2 bus is terminated with the COM module. To enable load sharing refer to Installation Manual.

X8

The jumpers should be set as following:

ON OFF ON OFF ON OFF ON OFF

S1 S2 S3 S4 S5* S6 * Should be on if used as emergency stop

Aux. I/O equipment

X9 X10 X11 X12 X13 X14 X15

Remote Panel Jumper settings

If only one remote panel is used then leave the jumper as is. Remote panels CAN2 bus is terminated with 120 Ohm inside Remote Panel via jumper. If more than one remote panel is used this jumper needs to be changed to open. Only the remote panel last in the chain do not need jumper changes.

Input Connections (24 V only)

(to sec. battery) SEC. B+ (From engine) (to sec. battery) SEC. B- (From engine)

X16

Secondary battery backup via Input connections

Relays X1 - X16

3. Normally Closed (NC) 2. Normally Open (NO) 1. Common

Connecting the external stop via input connection

Use category A cable on all inputs The figure above shows the board with the cover removed. (to external stop) STOP+ (From engine) (to external stop) STOP- (From engine)

VODIA connection

Used for configuration and maintainance. Note! The VODIA tool can download software to EMS only

Lever Control 4-20 mA A5+ A5Inputs external binary Shutdown Override B6 Aux Stop B7 Start blocking B8 Ackowledge B9 Backup Speed B10 Remote Start B11 Remote Stop B12 Spare B13 Spare B14 External Stop switch S5* 2 Ignition key +15 (Closed=on, Open=off) 1

Cut the jumper, see the manual.

The jumper under the rubber plug is used when updating the Remote Panel software. The jumper should be set to on. When done updating the jumper should be set to off again.

Ground should applied with a short cable as possible and with a diameter of equal or greater than 2.5mm2

Connector A

Connector B

BL

MCC connections

Connector B

External stop switch - Optional

The external stop can be connected via the Input Connections

The switch shall be of open contact type (NO) (stop switch not included).

Remote Panel CAN2 Connection

CAN H - 5

The D-Sub (CENTRAL UNIT interface) uses the following pins:

CAN L - 9

Connect to + at the back of the back of the remote panel. Connect to - at the back of the back of the remote panel.

Connector A

Engine connections Switch - Water in Fuel

EasyLink connector The connector is supporting engine mounted gauges (not supplied with engine). ( Not approved in classified application) CONN. B CONN. A

* Use 10 kOhms for broken wire detection The jumper for S5 needs to be set to enabled.

Water in fuel switch B

Cable for DriveConfig/DriveMonitor *2

The Connector used for PC Tool (DriveConfig/DriveMonitor ) has the following wiring:

Primary Battery

5 3 2

5 3 2

Water in fuel switch A

PC

MCU Water in fuel extension cable

Spare Relay

Relays marked with Spare Relay are allowed to use as desired. Activate by 0V. Note that it may require special settings to make them operational. Refer to installation manual for details.

Cables Category D

Secondary Battery (Backup) +

24 V

+ 24 V

Note! On the single turbo charged engine version connect the battery directly to the starter motor.

16 A slow Fuse

Cables Category C Pin 1

From engine

Pin 2 Use Crimp Tool 951 2653 to crimp contact

Components and Cables

Cables

Components

Front View

Rear View

MCU Marine Control Unit Part no. 3818237

BL

ID-COM Part no. 3818364

Steel box MCC Part no. 3843541

MCC to engine extension cable, 8-pin Feet Meter Part no. 9.8 3 16.4 5 22.9 7 29.5 9 36.1 11 874414 874119 874386 874387 874388

Water in fuel cable harness, 3-pin Feet Meter Part no. 9.8 3 21415866 16.4 5 21415883

Water in fuel Y-Split cable harness, 3-pin Feet Meter Part no. 21495971

External stop switch cable, 2-pin Feet Meter Part no. 32.8 10 3840677

External Stop Switch Part no. 3589458 NO/NC contacts Cable not included. Use External Stop Switch Cable 3840677

Remote Panel

Category A

Crosscut area minimum 1,5mm2 type approved low voltage (30V or more) ship cable , Max 50 meters

Category B

BL

Shielded, partwisted, Crosscut area min. 0,25mm2, 120 Ohm nominal impedance, Maximal attenuation (at 1 MHz) 2 dB / 100m, Max 900 meter

Front View

Rear View

Category C

Crosscut area 2,5mm2 type approved low voltage (30V or more) ship cable, Max 15 meters

Remote Panel Part no. 3888244

Category D

Battery cables

Category E

Use RS-TS twisted RS232 cable (Max 10 meter)

Secondary Battery (backup) Connection

1 2 3 4

Input Connection Tool

Tool Crimping parts Part Part no. 1, Housing* 1307049 2. Isolator* 1608765 3. Pin* 969832 (2,5mm2) Max. insulation diam. 3,1mm (Included in engine harness) Pin 948291 (2,5mm2) Max. insulation diam. 4,5 mm (not included) 4. Crimping tool 951 2653 * Included in engine delivery. Note! Remove the blind plugs before crimping. Part Tool Part no. Included in Steel box MCC

Connector dimensions

D

D H

Part no. 21350704

Part no. 3818362

Part no. 21350693 Spare part no. (included in Installation Instructions) 3819845

2-pin H = 15 mm (0.59) W = 24 mm (0.94)

3-pin male H = 18 mm (0.71) W = 26 mm (1.02) D = 26 mm (1.02)

3-pin female H = 20 mm (0.79) W = 25 mm (0.98)

8-pin female H = 20 mm (0.78) W = 37 mm (1.45)

8-pin male H = 20 mm (0.78) W = 37 mm (1.45) D = 43 mm (1.69)

47701344 11-2012

Input Connection

Relay Connection

SDU - Shutdown Unit

W W

You might also like

- Regolatore Europa - Manual MH02-07Document73 pagesRegolatore Europa - Manual MH02-07Sandro Sammori100% (1)

- KDGC Control Panel Manual PDFDocument92 pagesKDGC Control Panel Manual PDFÁngel aguilarNo ratings yet

- Murphy Genset ControllerDocument183 pagesMurphy Genset ControllerUmar RajputNo ratings yet

- Peter Barr: Technical Specification and Scope of Supply MTU 20V4000 GS GG20V4000A1Document27 pagesPeter Barr: Technical Specification and Scope of Supply MTU 20V4000 GS GG20V4000A1Milad KerramatiNo ratings yet

- Alphatronic Remote Control SystemDocument29 pagesAlphatronic Remote Control SystemrecutuNo ratings yet

- V-ACT D16E Brochure 22 A 100 3523 - 2007-07Document2 pagesV-ACT D16E Brochure 22 A 100 3523 - 2007-07Rolando Mancilla FloresNo ratings yet

- Engine Range en MANDocument24 pagesEngine Range en MANAsik JosNo ratings yet

- Instruction Book L2738ed080120Document252 pagesInstruction Book L2738ed080120GiovanniJaraNo ratings yet

- C10751289 PDFDocument16 pagesC10751289 PDFIrfan ZidniNo ratings yet

- Marine Diesel Engine Service Manual 6LY2-STE 6LY2A-STP 6LYA-STPDocument234 pagesMarine Diesel Engine Service Manual 6LY2-STE 6LY2A-STP 6LYA-STPJuniorJavier Olivo Farrera100% (1)

- 27 MDKDU New-EnDocument4 pages27 MDKDU New-Enabduallah muhammadNo ratings yet

- InteliGen 200 Datasheet r7Document4 pagesInteliGen 200 Datasheet r7Julius CalimagNo ratings yet

- 5-MAN Diesel 32-40 Twin Medium Speed EngineDocument218 pages5-MAN Diesel 32-40 Twin Medium Speed Engineİsmail YazıcıNo ratings yet

- Installation Instructions D2676LE4xxDocument224 pagesInstallation Instructions D2676LE4xxherreman100% (1)

- V8 900 Marine LightDocument4 pagesV8 900 Marine LightNoui BouzidNo ratings yet

- Marine Generator Set: 30.0 Ekw (60 HZ) at 1800 RPM 24.5 Ekw (50 HZ) at 1500 RPMDocument2 pagesMarine Generator Set: 30.0 Ekw (60 HZ) at 1800 RPM 24.5 Ekw (50 HZ) at 1500 RPMByron CheleNo ratings yet

- 1.2.4 MAN Marine Commercial EnginesDocument56 pages1.2.4 MAN Marine Commercial EnginesAdrian Chacon Molina100% (1)

- MAN Low Speed Engine S40MC C Mk9 PapersDocument363 pagesMAN Low Speed Engine S40MC C Mk9 PapersAbdulachim EminNo ratings yet

- Yanmar Datasheet 6LY3 ETPDocument2 pagesYanmar Datasheet 6LY3 ETPCornelius Sebastian100% (1)

- Parametros y FormulasDocument56 pagesParametros y FormulasinforlexNo ratings yet

- Marex OS II-Optimized For REINTJES Trolling Gearboxes With v-ADSDocument4 pagesMarex OS II-Optimized For REINTJES Trolling Gearboxes With v-ADSMohammed Saber100% (1)

- N45sm1a 51 To 59KWDocument3 pagesN45sm1a 51 To 59KWsaiyedasadNo ratings yet

- EMS-GC10 - Genset Controller Unit - Operator S Manual - 00-02-0878 - March 2013 - FW MURPHY PDFDocument183 pagesEMS-GC10 - Genset Controller Unit - Operator S Manual - 00-02-0878 - March 2013 - FW MURPHY PDFpevareNo ratings yet

- Doosan Infracore Generator Engine: Ratings (KWM/PS)Document4 pagesDoosan Infracore Generator Engine: Ratings (KWM/PS)Luis CuellarNo ratings yet

- Presentation DIESELWORXDocument12 pagesPresentation DIESELWORXovidiuserbanNo ratings yet

- Wood Ward GovernorDocument38 pagesWood Ward Governornack89No ratings yet

- UG 10 MAS Governor P7: ApplicationsDocument4 pagesUG 10 MAS Governor P7: Applicationsabelsg100% (1)

- MANDocument12 pagesMANNirwana GroupNo ratings yet

- Engine RatingDocument9 pagesEngine Ratingbayu190284No ratings yet

- D12 MH Volvo Penta Inboard Diesel Engine Technical SpecsDocument4 pagesD12 MH Volvo Penta Inboard Diesel Engine Technical Specszulu800% (1)

- Perkins Control PanelDocument122 pagesPerkins Control PanelAemy100% (1)

- TAD1241GE: Volvo Penta Genset EngineDocument2 pagesTAD1241GE: Volvo Penta Genset EngineMuhammad rizki100% (1)

- Mak 3032Document253 pagesMak 3032Fatah FatanNo ratings yet

- Diesel engines for fast vessels with high load factorsDocument1 pageDiesel engines for fast vessels with high load factorsghostt123No ratings yet

- Pgeg 200Document4 pagesPgeg 200Carlos Alberto Cunha100% (1)

- Engine Display GEMDocument20 pagesEngine Display GEMAlvaro PradaNo ratings yet

- Barber ColmanDocument61 pagesBarber ColmanrepelindNo ratings yet

- Man B&W K90Me9-Tii: Project Guide Electronically Controlled Two Stroke EnginesDocument347 pagesMan B&W K90Me9-Tii: Project Guide Electronically Controlled Two Stroke EnginesNguyễn Công HùngNo ratings yet

- Specifications For Connecting Rods in 3500 Family of Engines (0761, 0767, 1218)Document19 pagesSpecifications For Connecting Rods in 3500 Family of Engines (0761, 0767, 1218)ariel avalos100% (1)

- ZPG SpecDocument8 pagesZPG SpecandesNo ratings yet

- Slow Turning WartsilaDocument2 pagesSlow Turning WartsilaJosé Antonio Curado EscozNo ratings yet

- Volvo Penta - Diagrama de Calibração e Ajustes D3 - D4 - D6 - Evcec-C3 PDFDocument2 pagesVolvo Penta - Diagrama de Calibração e Ajustes D3 - D4 - D6 - Evcec-C3 PDFJorge LopesNo ratings yet

- Warship 10 BrochureDocument4 pagesWarship 10 Brochurehamid moaieriNo ratings yet

- Mp8 Export 400 CDocument2 pagesMp8 Export 400 CLuis M. Valenzuela Arias100% (1)

- 15 18 049 0H - Notice - 8M26.2 - ENDocument119 pages15 18 049 0H - Notice - 8M26.2 - ENsxturboNo ratings yet

- Service Drawings: KTA38 Engine PlatformDocument19 pagesService Drawings: KTA38 Engine PlatformMehdi Chakroune100% (1)

- Nogva Marine Gearbox Ver.3.1Document30 pagesNogva Marine Gearbox Ver.3.1cezar frasao67% (3)

- C10752596 PDFDocument103 pagesC10752596 PDFmohamedIGCMONo ratings yet

- Diesel Engines 8V 4000 M53/M63 SpecsDocument2 pagesDiesel Engines 8V 4000 M53/M63 Specsroberttv374No ratings yet

- Reduction Gearbox 1500 AGSC KPDocument1 pageReduction Gearbox 1500 AGSC KPΣπύρος ΛελούδαςNo ratings yet

- MAN D2876 Medium Duty Marine EnginesDocument4 pagesMAN D2876 Medium Duty Marine Enginesfajar saputra100% (1)

- Mercedes ADE 366 Specs, Bolt Torques and ManualsDocument12 pagesMercedes ADE 366 Specs, Bolt Torques and ManualsRadek BabuszkiewiczNo ratings yet

- Installion Electrical Interface Specification Marine Engines D9, D13, D16 EMSDocument36 pagesInstallion Electrical Interface Specification Marine Engines D9, D13, D16 EMSGiangDo100% (1)

- Mitsubishi Engine WoodwardDocument9 pagesMitsubishi Engine WoodwardRath AsypadenNo ratings yet

- BMW Stern Drive Workshop ManualDocument36 pagesBMW Stern Drive Workshop Manualstrumf381No ratings yet

- Kohler Tt1584PIMDocument20 pagesKohler Tt1584PIMJohn ElyNo ratings yet

- CMF 300Document2 pagesCMF 300AGA30No ratings yet

- CPC2+ WiringDocument27 pagesCPC2+ Wiringalejandro sanchez100% (7)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Ex-Proof RTD Temperature SensorDocument1 pageEx-Proof RTD Temperature SensormxnoxnNo ratings yet

- UUU (Universal Update Utility)Document28 pagesUUU (Universal Update Utility)mxnoxnNo ratings yet

- Leak Detector LAG-14 ER: BenefitsDocument2 pagesLeak Detector LAG-14 ER: BenefitsmxnoxnNo ratings yet

- Fault Codes Working GensetDocument1 pageFault Codes Working GensetmxnoxnNo ratings yet

- DKG 705 UserDocument22 pagesDKG 705 UsermxnoxnNo ratings yet

- FDOOTC241 Neural Fire Detector: Technical ManualDocument84 pagesFDOOTC241 Neural Fire Detector: Technical ManualmxnoxnNo ratings yet

- Emko - Esm-3710-N 01 v04 07 - 14Document2 pagesEmko - Esm-3710-N 01 v04 07 - 14mxnoxnNo ratings yet

- Textoor 22Document2 pagesTextoor 22mxnoxnNo ratings yet

- All IncludedDocument2 pagesAll IncludedmxnoxnNo ratings yet

- Lorem IpsumDocument2 pagesLorem Ipsumhomeslice123No ratings yet

- BookDocument2 pagesBookYussuf 'Totti' SiddiqueNo ratings yet

- Wrking Genset Engine ParamDocument1 pageWrking Genset Engine ParammxnoxnNo ratings yet

- EBA2004-A1 Booster Amplifier Mainboard (100 W) : Mounting InstallationDocument52 pagesEBA2004-A1 Booster Amplifier Mainboard (100 W) : Mounting InstallationmxnoxnNo ratings yet

- DKG 705 UserDocument22 pagesDKG 705 UsermxnoxnNo ratings yet

- DKG-329 Ats Controller: 2 Gensets + MainsDocument2 pagesDKG-329 Ats Controller: 2 Gensets + MainsmxnoxnNo ratings yet

- Engineering Installation Bulletin: Cooling SystemDocument43 pagesEngineering Installation Bulletin: Cooling SystemmxnoxnNo ratings yet

- Automatic Transfer Switch Control Unit Operation ManualDocument42 pagesAutomatic Transfer Switch Control Unit Operation ManualmxnoxnNo ratings yet

- DKG-329 Ats Controller: 2 Gensets + MainsDocument2 pagesDKG-329 Ats Controller: 2 Gensets + MainsmxnoxnNo ratings yet

- Engineering Installation Bulletin: Electrical SystemDocument7 pagesEngineering Installation Bulletin: Electrical Systemmxnoxn100% (1)

- FDMH293-x / FDMH297-R FDME223 / FDME224: Installation Montage Montage Montaje MontaggioDocument8 pagesFDMH293-x / FDMH297-R FDME223 / FDME224: Installation Montage Montage Montaje MontaggiomxnoxnNo ratings yet

- fn2006 A1enDocument354 pagesfn2006 A1enmxnoxnNo ratings yet

- Automatic Transfer Switch Control Unit Operation ManualDocument42 pagesAutomatic Transfer Switch Control Unit Operation ManualmxnoxnNo ratings yet

- Sinteso - Panels, Network and AccessoriesDocument2 pagesSinteso - Panels, Network and AccessoriesmxnoxnNo ratings yet

- Engineering Installation Bulletin: Cold Weather StartingDocument13 pagesEngineering Installation Bulletin: Cold Weather StartingmxnoxnNo ratings yet

- FS20 FT2040 / FC2020 / FC2030 FC2040 / FC2060: Montage Installation Montage Montaje MontaggioDocument10 pagesFS20 FT2040 / FC2020 / FC2030 FC2040 / FC2060: Montage Installation Montage Montaje MontaggiomxnoxnNo ratings yet

- Hilti PROFIS Cable Transit Report Collection: CFS-T SS-4x1 FrameDocument4 pagesHilti PROFIS Cable Transit Report Collection: CFS-T SS-4x1 FramemxnoxnNo ratings yet

- Engineering Installation Bulletin: Air Intake SystemDocument14 pagesEngineering Installation Bulletin: Air Intake Systemmxnoxn100% (1)

- Hilti PROFIS Cable Transit reportDocument5 pagesHilti PROFIS Cable Transit reportmxnoxnNo ratings yet

- Engineering Installation Bulletin: Belt Drive SystemDocument7 pagesEngineering Installation Bulletin: Belt Drive Systemmxnoxn100% (1)

- Option C4 Block Differential Current Protection 4189340397 UKDocument12 pagesOption C4 Block Differential Current Protection 4189340397 UKmxnoxnNo ratings yet

- 64-2103 Tweco Flux Core SEFCDocument2 pages64-2103 Tweco Flux Core SEFCcarlosNo ratings yet

- Genius 5.1 Speakers GHT-V150Document2 pagesGenius 5.1 Speakers GHT-V150Bogdan Ceaca100% (1)

- NJQS Product and Service Code GuidanceDocument40 pagesNJQS Product and Service Code GuidanceAF Dowell MirinNo ratings yet

- MBDCDocument2 pagesMBDCRachel RobinsonNo ratings yet

- High Voltage Spike (DV - DT) and Motor Protection MethodsDocument5 pagesHigh Voltage Spike (DV - DT) and Motor Protection MethodsAnonymous V6y1QL6hnNo ratings yet

- GBH 2 SR Manual 160841Document94 pagesGBH 2 SR Manual 160841RobertAragónLduNo ratings yet

- Green-Mode PWM Controller Reduces Audio NoiseDocument18 pagesGreen-Mode PWM Controller Reduces Audio NoisePaulo Roberto s freireNo ratings yet

- Peki Adzokoe J.H.S Information and Comunication Technology Form 1, Test IiDocument2 pagesPeki Adzokoe J.H.S Information and Comunication Technology Form 1, Test IiPelsin VisualsNo ratings yet

- Microchip MCP6006 6R 6U 7 9 Data Sheet 20006411BDocument46 pagesMicrochip MCP6006 6R 6U 7 9 Data Sheet 20006411BMiguel BaixauliNo ratings yet

- Service Manual: 17" LCD Monitor IBM L170Document54 pagesService Manual: 17" LCD Monitor IBM L170Yonny MunozNo ratings yet

- Nissan Sentra 2016Document20 pagesNissan Sentra 2016wilder0l0pezNo ratings yet

- PDX z9 Rrv3755Document107 pagesPDX z9 Rrv3755GustavoLopezGuardadoNo ratings yet

- monitoringAyIguide (EMCP3 Softwr Instln Guide)Document61 pagesmonitoringAyIguide (EMCP3 Softwr Instln Guide)xmel82100% (2)

- SONY LCD TV Bravia KLV-S26A10Document80 pagesSONY LCD TV Bravia KLV-S26A10Ricardo Chaman ChavezNo ratings yet

- HD44780 CommandsDocument3 pagesHD44780 CommandsPhani ChakravarthiNo ratings yet

- 2015 DTC Colour Displays v2.0Document305 pages2015 DTC Colour Displays v2.0Hitesh VashistNo ratings yet

- 2SA1568Document13 pages2SA1568raquelNo ratings yet

- Shimadzu MC100L30 MC125L 30Document37 pagesShimadzu MC100L30 MC125L 30anon_524582163100% (1)

- LD ProfileDocument5 pagesLD ProfileAnumanchipalli MadhubabuNo ratings yet

- Safety inspection checklist for bar cutting and bending machineDocument14 pagesSafety inspection checklist for bar cutting and bending machinepartha50% (2)

- Digital B&W Copier (D159-NA) Parts CatalogDocument128 pagesDigital B&W Copier (D159-NA) Parts CatalogJ Enrique BlancoNo ratings yet

- Power OneDocument10 pagesPower Onesteva037No ratings yet

- Serp4874 07 2Document999 pagesSerp4874 07 2Arbey GonzalezNo ratings yet

- Harga Bahan 2020Document16 pagesHarga Bahan 2020T Rahmat Putra JauhariNo ratings yet

- Engine Mechanical-Part 3Document45 pagesEngine Mechanical-Part 3Juan Camilo Chavez BolañosNo ratings yet

- Spare Parts List for Electric Stacker PS 16NDocument81 pagesSpare Parts List for Electric Stacker PS 16NMuhammad KhalidNo ratings yet

- MOC3042Document7 pagesMOC3042Sunu PradanaNo ratings yet

- Daihatsu DK 20 Injection Timing MeasurementDocument5 pagesDaihatsu DK 20 Injection Timing MeasurementStathis Moumousis100% (3)

- F9540n Datasheet PDFDocument1 pageF9540n Datasheet PDFDanielNo ratings yet

- Wärtsilä lubrication system manualDocument10 pagesWärtsilä lubrication system manualLIVIANo ratings yet