Professional Documents

Culture Documents

1kd FTV Overhaul

Uploaded by

Jehuty88Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1kd FTV Overhaul

Uploaded by

Jehuty88Copyright:

Available Formats

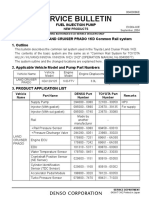

1420703

G39212

G39213

A51295

G39214

144

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

OVERHAUL

1. REMOVE OIL FILLER CAP SUBASSY

(a) Remove the oil filler cap from the cylinder head cover.

2. REMOVE NOZZLE HOLDER SEAL

(a) Pry out the 4 nozzle holder seals with a screwdriver.

3. REMOVE CYLINDER HEAD COVER SUBASSY

(a) Remove the 10 bolts, 2 nuts, cylinder head cover and

gasket.

4. REMOVE NOZZLE HOLDER CLAMP

(a) Remove the 4 bolts, 4 washers and 4 nozzle holder

clamps.

G39215

G39216

A69849

A51380

A51300

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

145

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

5. REMOVE NOZZLE LEAKAGE PIPE ASSY

(a) Remove the union bolt, 4 hollow screws, nozzle leakage

pipe and 5 gaskets from the cylinder head and injector.

6. REMOVE INJECTOR ASSY

(a) Remove the 4 injectors from the cylinder head.

HINT:

Remember the installed locations of each injector before re-

moving them from the cylinder head.

7. REMOVE CAMSHAFT TIMING PULLEY

(a) Remove the bolt, the timing pulley and the set key while

holding the hexagon portion of the camshaft with a

monkey wrench.

(b) Rotate the crankshaft about 90_ counterclockwise from

the TDC position to lower the piston.

8. REMOVE TIMING BELT NO.2 COVER

(a) Remove the 4 bolts, nut and timing belt No.2 cover.

A51301

A51302

A51303

A51304

146

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

9. REMOVE NO.2 CAMSHAFT

(a) Uniformly loosen the 15 bearing cap bolts in the order in-

dicated in the illustration and then remove them in the

same order.

(b) Remove the 5 bearing caps.

(c) Remove the camshaft No.2.

10. REMOVE CAMSHAFT

(a) Remove the camshaft from the cylinder head.

11. REMOVE CAMSHAFT SETTING OIL SEAL

(a) Remove the oil seal from the camshaft.

A51306

A51307

A51308

A51309

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

147

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

12. REMOVE CYLINDER HEAD SUBASSY

(a) Uniformly loosen the 18 cylinder head bolts in the order

indicated in the illustration and then remove them in the

same order.

NOTICE:

Removing in incorrect order will cause the cylinder head to

be warped.

(b) Remove the cylinder head and cylinder head gasket from

the cylinder block.

HINT:

Prevent the removed cylinder head from being damaged.

13. REMOVE WATER PUMP ASSY

(a) Remove the 5 bolts, 2 nuts, water pump and gasket.

14. REMOVE TIMING GEAR CASE

(a) Remove the 14 bolts and 2 nuts.

(b) Separate the timing gear case softly with a slottedscrew-

driver.

A51376

A51407

A51310

A69865

A69866

148

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

(c) Secure the idler subgears to the idler gear with a service

bolt.

(d) Remove the injection gear.

(e) Remove the Oring.

15. REMOVE TIMING GEAR CASE OR TIMING CHAIN

CASE OIL SEAL

(a) Remove the oil seal with a slottedscrewdriver and ham-

mer.

16. REMOVE TIMING CHAIN OR BELT COVER OIL SEAL

(a) Remove the oil seal with a slottedscrewdriver and ham-

mer.

A51313

A69867

A51315

A51316

A69830

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

149

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

17. REMOVE CRANKSHAFT POSITION SENSOR PLATE

NO.1

(a) Remove the crank angle sensor plate No.1.

18. REMOVE CRANKSHAFT TIMING GEAR OR

SPROCKET

(a) Using SST, remove the crankshaft timing gear.

SST 0995050013 (0995105010, 0995205010,

0995305020, 0995405010)

19. REMOVE IDLE GEAR THRUST PLATE

(a) Remove the 2 bolts and idle gear thrust plate.

20. REMOVE IDLE GEAR NO.1

(a) Remove the idle gear No.1.

21. REMOVE IDLE SUB GEAR NO.1

(a) Set the idle gear No.1 and idle sub gear No.2 in a vise.

NOTICE:

Be careful not to damage the gears.

A69831

Service Bolt

SST

A69832

A69833

Wave

Washer

Idle

Gear

Spring

Idle Sub

Gear No.1

A51322

A69834

1410

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

(b) Using SST, turn the idle sub gear No.1 clockwise and re-

move the service bolt.

SST 0996010010 (0996201000, 0996300600)

(c) Using snap ring pliers, remove the shaft snap ring.

(d) Remove the wave washer.

(e) Remove the idle sub gear No.1.

(f) Remove the idle gear spring.

(g) Remove the idle gear No.1 from the vise.

22. REMOVE IDLE SUB GEAR NO.2

(a) Reverse the idle gear No.1 and reset it in the vise.

NOTICE:

Be careful not to damage the gear.

(b) Using snap ring pliers, remove the shaft snap ring.

A69835

Wave

Washer

Idle

Gear

Spring

Idle Sub

Gear No.2

A51317

A74126

Z04119

A74127

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1411

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

(c) Remove the wave washer.

(d) Remove the idle sub gear No.2.

(e) Remove the idle gear spring.

23. REMOVE IDLE GEAR SHAFT NO.1

(a) Remove the idle gear shaft No.1.

24. REMOVE OIL PAN SUBASSY NO.2

(a) Remove the 11 bolts and 2 nuts.

(b) Remove the oil pan No.2 with SST.

SST 0903200100

25. REMOVE OIL STRAINER SUBASSY

(a) Remove the 2 nuts, oil strainer subassy and gasket.

A74128

Z04119

A51329

A51330

A52300

1412

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

26. REMOVE OIL PAN SUBASSY

(a) Remove the 22 bolts and 2 nuts.

(b) Remove the oil pan subassy with SST.

SST 0903200100

(c) Remove the oil pan gasket.

27. REMOVE TIMING GEAR CASE ASSY

(a) Remove the 8 bolts and union bolt.

(b) Using a plasticfaced hammer, tap out the timing gear

case.

(c) Remove the oil pump gasket.

(d) Remove the stud bolt.

A69840

A51346

A51332

A51333

A51347

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1413

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

(e) Remove the 2 Orings.

28. INSPECT NO.1 BALANCESHAFT SUBASSY

(a) Using a dial indicator, measure the thrust clearance by

moving the balanceshaft back and forth.

Standard thrust clearance:

0.065 to 0.140 mm (0.0026 to 0.0055 in.)

Maximum thrust clearance: 0.25 mm (0.0098 in.)

If the thrust clearance is greater than the maximum clearance,

replace the balanceshaft thrust washer.

If the thrust clearance would still be greater than the maximum

clearance, replace the balanceshaft.

29. REMOVE NO.1 BALANCESHAFT SUBASSY

(a) Remove the 2 bolts and balanceshaft No.1.

30. REMOVE BALANCESHAFT DRIVEN GEAR NO.1

(a) Mount the balanceshaft in a vise.

NOTICE:

Be careful not to damage the balanceshaft.

(b) Remove the bolt, balanceshaft driven gear No.1 and ba-

lanceshaft thrust washer.

31. INSPECT NO.2 BALANCESHAFT SUBASSY

(a) Using a dial indicator, measure the thrust clearance by

moving the balanceshaft back and forth.

Standard thrust clearance:

0.065 to 0.140 mm (0.0026 to 0.0055 in.)

Maximum thrust clearance: 0.25 mm (0.0098 in.)

If the thrust clearance is greater than the maximum clearance,

replace the balance shaft thrust washer.

If the thrust clearance would still be greater than the maximum

clearance, replace the balanceshaft.

A51334

A51335

A52295

A69869

A75703

1414

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

32. REMOVE NO.2 BALANCESHAFT SUBASSY

(a) Remove the 2 bolts and balanceshaft No.2.

33. REMOVE BALANCESHAFT DRIVEN GEAR NO.2

(a) Mount the balanceshaft in a vise.

NOTICE:

Be careful not to damage the balanceshaft.

(b) Remove the bolt, balanceshaft driven gear No.2 and ba-

lanceshaft thrust washer.

34. REMOVE ENGINE REAR OIL SEAL RETAINER

(a) Remove the 5 bolts.

(b) Separate the engine rear oil seal retainer from the cylin-

der block with a slottedscrewdriver.

35. REMOVE ENGINE REAR OIL SEAL

(a) Using a screwdriver and a hammer, tap out the oil seal.

36. INSPECT CYLINDER HEAD SET BOLT

(a) Using vernier calipers, measure the outer diameter of the

thread.

Standard outer diameter:

11.76 to 11.97 mm (0.4630 to 0.4713 in.)

Minimum outer diameter: 11.6 mm (0.457 in.)

If the outer diameter is less than the minimum, replace the bolt.

(b) Check for damage to the threads of the cylinder head bolt.

(c) Check for damage to the threads of the cylinder block.

A51339

A69870

A51341

A51336

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1415

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

(d) Check that the 18 cylinder head bolts are installed to the

cylinder block smoothly.

37. INSPECT INJECTION GEAR

(a) Check the bearing condition.

Replace the bearing if it is worn.

38. REPLACE INJECTION GEAR BEARING

(a) Using SST, remove the bearing.

SST 0995040011 (0995104020, 0995204010,

0995304030, 0995404010, 0995504061,

0995704010, 0995804011), 0995060010

(0995100480)

(b) Using SST and a press, press in a new bearing.

SST 0922300010, 0922315020,

0950212010

39. INSPECT IDLE GEAR NO.1

(a) Using a dial indicator, measure the thrust clearance.

Standard thrust clearance:

0.06 to 0.11 mm (0.0024 to 0.0043 in.)

Maximum thrust clearance: 0.30 mm (0.0118 in.)

If the thrust clearance is greater than the maximum clearance,

replace the thrust plate. If the thrust clearance would still be

greater than the maximumclearance, replace the idle gear and/

or idle gear shaft.

A51342

A51343

1416

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

(b) Using a cylinder gauge, measure the diameter of the idle

gear.

Inside diameter of the idle gear:

44.000 to 44.025 mm (1.7323 to 1.7333 in.)

(c) Using a micrometer, measure the diameter of the idle

gear shaft.

Idle gear shaft diameter:

43.955 to 43.990 mm (1.7305 to 1.7319 in.)

(d) Subtract the idle gear shaft diameter fromthe insidediam-

eter of the idle gear.

Standard oil clearance:

0.010 to 0.070 mm (0.0004 to 0.0028 in.)

Maximum oil clearance: 0.20 mm (0.0079 in.)

If the clearance is greater than the maximumclearance, replace

the gear and shaft.

A69837

Balanceshaft No.1 x Oil Pump

Balanceshaft No.2 x Injection Pump

Crankshaft x Idler

Oil Pump x Crankshaft

Injection Pump x Idler

A61820

SST

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1417

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

40. INSPECT BACKLASH

(a) Using a dial indicator, measure the backlash.

Standard gear backlash:

0.02 to 0.15 mm (0.0008 to 0.0060 in.)

Maximum gear backlash: 0.20 mm (0.0079 in.)

If the gear backlash is greater than the maximum backlash, re-

place the gears as a set.

41. INSTALL ENGINE REAR OIL SEAL

(a) Using SSTand a hammer, tap in a newoil seal until its sur-

face reaches the rear oil seal retainer.

SST 0922315030, 0995070010 (0995107100)

(b) Apply MP grease to the oil seal lip.

A59935

Width: 4 mm (0.16 in.)

Seal Packing

A51412

A51335

A51334

A51333

1418

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

42. INSTALL ENGINE REAR OIL SEAL RETAINER

(a) Remove old seal packing (FIPG) from the rear oil seal re-

tainer and cylinder block.

(b) Apply seal packing to the specific places described in the

illustration.

Seal packing: Part No. 0882600080 or equivalent

NOTICE:

Install the engine rear oil retainer within 3 minutes and

tighten its bolts within 15 minutes after applying FIPG is

competed.

(c) Install the retainer with the 5 bolts.

Torque: 13 Nm (133 kgfcm, 10 ftlbf)

43. INSTALL BALANCESHAFT DRIVEN GEAR NO.2

(a) Mount the balanceshaft in a vise.

NOTICE:

Be careful not to damage the balanceshafts.

(b) Align the balanceshaft knock pin with the knock pin hole,

and install the balanceshaft thrust washer and balance-

shaft driven gear No.2.

(c) Install and torque the bolt.

Torque: 36 Nm (367 kgfcm, 27 ftlbf)

44. INSTALL NO.2 BALANCESHAFT SUBASSY

(a) Install the balanceshaft No.2 with the 2 bolts.

Torque: 13 Nm (133 kgfcm, 10 ftlbf)

45. INSTALL BALANCESHAFT DRIVEN GEAR NO.1

(a) Mount the balanceshaft in a vise.

NOTICE:

Be careful not to damage the balanceshafts.

(b) Align the balanceshaft knock pin with the knock pin hole,

and install the balanceshaft thrust washer and balance-

shaft driven gear No.1.

(c) Install and torque the bolt.

Torque: 36 Nm (367 kgfcm, 27 ftlbf)

A51332

A69840

New

ORing

A52300

A51330

New Gasket

A69871

Width: 4 mm (0.16 in.)

Seal Packing

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1419

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

46. INSTALL NO.1 BALANCESHAFT SUBASSY

(a) Install the balanceshaft No.1 with the 2 bolts.

Torque: 13 Nm (133 kgfcm, 10 ftlbf)

47. INSTALL TIMING GEAR CASE ASSY

(a) Install 2 new Orings to the cylinder block.

(b) Install the stud bolt.

Torque: 8.0 Nm (82 kgfcm, 71 in.lbf)

(c) Place a new gasket into the groove of the timing gear

case as shown in the illustration.

(d) Remove old seal packing (FIPG) from the timing gear

case and cylinder block.

(e) Apply seal packing to the specific places described in the

illustration.

Seal packing: Part No. 0882600080 or equivalent

NOTICE:

Install the timing gear casewithin 3 minutes andtightenthe

bolts within 15 minutes after applying FIPG is competed.

A69841

A69842

A74129

Width: 4 mm (0.16 in.)

Seal Packing

A74128

A74127

1420

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

(f) Align the matchmark on the balanceshaft driven gear

No.1 with the 2 mark on the pump drive gear.

(g) Align the mark on the oil pump drive gear with the mark

on the timing gear case.

(h) Install the 8 bolts and union bolt.

Torque:

13 Nm (130 kgfcm, 9 ftlbf) for Bolt

16 Nm (160 kgfcm, 12 ftlbf) for Union bolt

48. INSTALL OIL PAN SUBASSY

(a) Remove old seal packing (FIPG) from the oil pan sub

assy and cylinder block.

(b) Apply seal packing to the specific places described in the

illustration.

(c) Set a new oil pan gasket to the oil pan subassy.

Seal packing: Part No. 0882600080 or equivalent

NOTICE:

Install the oil pan within 3 minutes and tighten its bolts

within 15 minutes after applying FIPG is competed.

(d) Install the oil pan with the 22 bolts and 2 nuts.

Torque: 15 Nm (150 kgfcm, 11 ftlbf)

49. INSTALL OIL STRAINER SUBASSY

(a) Set a new gasket, and install the oil strainer with the 2

nuts.

Torque: 8.0 Nm (82 kgfcm, 71 in.lbf)

A71172

Width: 4 mm (0.16 in.)

Seal Packing

A74126

A51354

A51355

A51354

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1421

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

50. INSTALL OIL PAN SUBASSY NO.2

(a) Remove old seal packing (FIPG) from the oil pan sub

assy and cylinder block.

(b) Apply seal packing to the specific places described in the

illustration.

Seal packing: Part No. 0882600080 or equivalent

NOTICE:

Install the oil pan No. 2 within 3 minutes and tighten its

bolts and nuts within 15 minutes after applying FIPG is

competed.

(c) Install the oil pan No. 2 with the 11 bolts and 2 nuts.

Torque: 9.0 Nm (92 kgfcm, 80 in.lbf)

(d) Remove the plug and gasket.

(e) Pour approx. 50 cc (1.7 fl. oz) of engine oil into the oil

pump.

(f) Set a new gasket and install the plug.

Torque: 44 Nm (449 kgfcm, 33 ftlbf)

51. INSTALL INJECTION GEAR

(a) Install a new Oring to the injection pump assy.

(b) Fit the spline with the matchmark on the pump housing.

A77139

A69843

A69844 New ORing

A69845

SST

SST

A51372

1422

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

(c) Temporarily install the injection pump assy with the 2 nuts.

(d) Tighten the 2 nuts on the injection pump assy.

Torque: 21 Nm (214 kgfcm, 16 ftlbf)

(e) The matchmarks on the balanceshaft driven gear No.2

should be aligned with the 3 marks.

(f) Install a new Oring to the injection gear.

(g) Install the injection gear set nut.

(h) Using SST, tighten the nut.

SST 0996010010 (0996201000, 0996301000)

Torque: 64 Nm (653 kgfcm, 47 ftlbf)

52. INSTALL CRANKSHAFT TIMING GEAR OR

SPROCKET

(a) The matchmarks on the oil pump drive gear should be

aligned with the 1 marks.

(b) Using SST and a hammer, tap in the timing gear.

SST 0922300010

A69846

Engine Oil

A51409

A69847

Cutoff Mark

A69848

Wave

Washer

Idle

Gear

Spring

Idle Sub Gear

No.2

A69834

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1423

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

53. INSTALL IDLE GEAR SHAFT NO.1

(a) Coat the idle gear shaft No.1 with engine oil as shown in

the illustration.

(b) Install the idle gear shaft No.1 to the cylinder block.

54. INSTALL IDLE SUB GEAR NO.2

(a) Set the idle gear No.1 in a vise.

HINT:

The cutoff mark of the idle gear faces down.

NOTICE:

Be careful not to damage the gear.

(b) Install the idle gear spring.

(c) Install the idle sub gear No.2.

(d) Install the wave washer.

HINT:

Fit the pins on the gears to the spring ends.

(e) Using snap ring pliers, install the snap ring.

A69850

SST

Service Bolt

A69851

Upward

A69852

Service Bolt

A69853

Wave

Washer

Idle

Gear

Spring

Idle Sub Gear

No.1

A69832

1424

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

(f) Using SST, align the holes of the idle gear No.1 and idle

sub gear No.2 by turning the idle sub gear No.2 clockwise,

and install a service bolt.

SST 0996010010 (0996201000, 0996300600)

(g) Remove the idle gear No.1 fromthe vise and turn it upside

down.

55. INSTALL IDLE SUB GEAR NO.1

(a) Set the idle gear No.1 and idle sub gear No.2 in a vise.

NOTICE:

Be careful not to damage the gears.

(b) Remove the service bolt.

(c) Install the idle gear spring.

(d) Install the idle sub gear No.1.

(e) Install the wave washer.

HINT:

Fit the pins on the gears to the spring ends.

(f) Using snap ring pliers, install the snap ring.

A69854

Upward

SST

Service Bolt

A51373

A69855

A51410

A51411

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1425

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

(g) Using SST, align the holes of the idle gear No.1 and idle

sub gear No.1 by turning the idle sub gear No.1 clockwise,

and install a service bolt.

SST 0996010010 (0996201000, 0996300600)

56. INSTALL IDLE GEAR NO.1

(a) Align mark 4 of the idle gear No.1 with marks 4 of the

injection gear.

Align mark 5 of the idle gear No.1 with marks 5 of the

crankshaft timing gear.

57. INSTALL IDLE GEAR THRUST PLATE

(a) Align the holes for the idle gear thrust plate set bolt .

(b) Install the idle gear thrust plate with the 2 bolts.

Torque: 50 Nm (510 kgfcm, 37 ftlbf)

58. INSTALL CRANKSHAFT POSITION SENSOR PLATE

NO.1

(a) Install the crankshaft position sensor plate No.1.

A69856

SST

A69857

SST

A51376

A51408

A69873

FIPG

Width: 4 mm (0.16 in.)

1426

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

59. INSTALL TIMING CHAIN OR BELT COVER OIL SEAL

(a) Using SSTand a hammer, tap in a newoil seal until its sur-

face reaches the timing gear case.

SST 0922378010

(b) Apply MP grease to the oil seal lip.

60. INSTALL TIMING GEAR CASE OR TIMING CHAIN

CASE OIL SEAL

(a) Using SSTand a hammer, tap in a newoil seal until its sur-

face reaches the timing gear case.

SST 0921476011

(b) Apply MP grease to the oil seal lip.

61. INSTALL TIMING GEAR CASE

(a) Remove the service bolt.

(b) Install a new Oring to the timing gear case.

(c) Apply FIPG (seal packing) to the timing gear case as

shown in the illustration.

Seal packing: Part No. 0882600080 or equivalent

NOTICE:

Install the timing case cover within 3 minutes and tighten

its bolts and nuts within 15 minutes after applying FIPG is

competed.

A51308

A51307

A69859

A69858

G39569

Front

X Measuring Point

Measuring

Tip

Protrusion

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1427

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

(d) Install the timing gear cover with the 14 bolts and 2 nuts.

Torque: 13 Nm (133 kgfcm, 10 ftlbf)

62. INSTALL WATER PUMP ASSY

(a) Install the 5 bolts, 2 nuts, water pump and gasket.

Torque: 13 Nm (133 kgfcm, 10 ftlbf)

63. INSTALL CYLINDER HEAD SUBASSY

(a) Check each piston head protrusion.

(1) Using a dial indicator, measure the amount of each

piston head protrusion, between the top surfaces of

each cylinder head and piston head.

(2) Perform the measurement at 2 places for each cyl-

inder as shown in the illustration, making a total of

8 measurements.

(3) For the piston protrusion value of each cylinder, use

the average of the 2 measurements of each cylin-

der.

Protrusion: 0.005 to 0.255 mm(0.00020 to 0.01004 in.)

HINT:

Measurement should be done at 2 locations, right and left sides

of each piston head.

A71150

Center

A: 26.5 mm (1.043 in.)

B: 18.5 mm (0.728 in.)

C: 10.5 mm (0.413 in.)

D: 115.0 mm (4.528 in.)

E: 123.0 mm (4.843 in.)

A51380

A51381

1428

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

(b) Select an appropriate cylinder head gasket.

HINT:

Each cylinder head gasket A to E has a unique notch position

at its backend, which helps you to identify an individual gasket.

(1) Find the maximum value among all the measured

piston head protrusion length to select an appropri-

ate cylinder head gasket from A to E.

Gasket size Piston protrusion mm (in.)

A 0.005 to 0.054 (0.0002 to 0.00213)

B 0.055 to 0.104 (0.00217 to 0.00409)

C 0.105 to 0.154 (0.00413 to 0.00606)

D 0.155 to 0.204 (0.00610 to 0.00803)

E 0.205 to 0.255 (0.00807 to 0.01004)

Cylinder heard gasket thickness:

Gasket size Gasket thickness mm (in.)

A 0.80 to 0.90 (0.0315 to 0.0354)

B 0.85 to 0.95 (0.0335 to 0.0374)

C 0.90 to 1.00 (0.0354 to 0.0394)

D 0.95 to 1.05 (0.0374 to 0.0413)

E 1.00 to 1.10 (0.0394 to 0.0433)

(c) Place a new cylinder head gasket in position on the cylin-

der block.

(d) Lower the piston by rotating the crankshaft about 90_

counterclockwise from the TDC position.

(e) Install the cylinder head bolts.

HINT:

The cylinder head bolts are tightened in 3 progressive steps.

(f) Apply a light coat of engine oil to the threads and under

the heads of the cylinder head bolts.

(g) Step 1

(1) Install and uniformly tighten the 18 cylinder head

bolts, in several passes in the sequence shown.

Torque: 85 Nm (867 kgfcm, 63 ftlbf)

G36575

Painted

Mark

Front

90_

90_

Step 2 Step 3

A51380

A74299

Upward

Key Groove

A69874

Dot Mark

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1429

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

(h) Step 2

(1) Mark the front of the cylinder head bolt with paint.

(2) Retighten the cylinder head bolts 90_ in the order

shown.

(i) Step 3

(1) Retighten the cylinder head bolts by an additional

90_.

(2) Check that the painted mark is nowfacing rearward.

64. INSPECT VALVE CLEARANCE

(a) Install the camshaft and camshaft No.2.

(1) Set the crankshaft and turn it 90_ counterclockwise

from the TDC position.

(2) Place the camshaft to the cylinder head as shown

in the illustration.

(3) Align the dot marks of the camshaft and camshaft

No.2 by meshing the 2 gears before placing the

camshaft No.2.

A51386

A51300

A69875

A51389

A72848

EX

IN

1430

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

(4) Install the camshaft bearing cap as shown in the il-

lustration.

(5) Tighten the 15 bolts for the camshaft bearing cap in

the specified order described in the illustration.

Torque: 19 Nm (194 kgfcm, 14 ftlbf)

(b) Install the timing belt No.2 cover with the 4 bolts and nut.

Torque: 10 Nm (102 kgfcm, 7 ftlbf)

(c) Install the camshaft timing pulley.

(1) Install the set key to the key groove of the camshaft.

(2) Align the set key with the key groove of the timing

pulley.

(3) Hold the hexagonal portion of the camshaft, and

install the timing pulley with the bolt.

Torque: 98 Nm (1,000 kgfcm, 72 ftlbf)

(d) Inspect the valve clearance.

(1) Lower the piston by rotating the crankshaft about

90_ counterclockwise from the TDC position.

(2) Align the timing mark of the camshaft timing pulley

with the arrow mark of the timing belt No.2 cover.

(3) Using a feeler gauge, measure the clearance be-

tween the valve lifter and camshaft.

(4) Record the outofspecification valve clearance

measurements. They will be used later to determine

the required replacement valve lifter.

Valve clearance (cold):

Intake: 0.20 to 0.30 mm (0.0079 to 0.0118 in.)

Exhaust: 0.35 to 0.45 mm (0.0138 to 0.0177 in.)

A72849

EX

IN

A51380

A69875

A51300

A51301

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1431

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

(5) Turn the crankshaft 360_ to set the No.4 cylinder to

the TDC position.

(6) Check only the valves indicated in the illustration.

Measure the valve clearance (See procedure (C)

above).

65. ADJUST VALVE CLEARANCE

(a) Set the crankshaft and turn it 90_ counterclockwise from

the TDC position.

(b) Remove the camshaft timing pulley.

(1) Hold the hexagon portion of the camshaft with a

monkey wrench, and remove the bolt, timing pulley

and set key.

(c) Remove the 4 bolts, nut and timing belt No.2 cover.

(d) Remove the camshaft and camshaft No.2.

(1) Uniformly loosen the 15 bearing cap bolts in order

indicated in the illustration and remove them in the

same order.

(2) Remove the 5 bearing caps.

A51302

A51303

A01082

1432

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

(3) Remove the camshaft No.2 from the cylinder head.

(4) Remove the camshaft from the cylinder head.

(e) Adjust the valve clearance.

HINT:

Determine the size of the valve lifter to be installed according

to the following formula or charts:

(1) Using a micrometer, measure the thickness of the

removed lifter.

(2) Calculate the thickness of a new lifter so the valve

clearance comes within the specified value.

A Thickness of new lifter

B Thickness of used lifter

C Measured valve clearance

Valve clearance:

Intake A = B + (C 0.25 mm (0.0098 in.))

Exhaust A = B + (C 0.40 mm (0.0158 in.))

(3) Select a new lifter with a thickness as close as pos-

sible to the calculated values.

HINT:

Valve lifters are available in 35 sizes in increments of 0.020 mm

(0.0008 in.), from 5.060 mm (0.1992 in.) to 5.740 mm (0.2260

in.).

(4) Install the selected valve lifter.

A72845

V

a

l

v

e

L

i

f

t

e

r

S

e

l

e

c

t

i

o

n

C

h

a

r

t

(

E

x

h

a

u

s

t

)

R

e

m

o

v

e

d

l

i

f

t

e

r

N

e

w

L

i

f

t

e

r

T

h

i

c

k

n

e

s

s

m

m

(

i

n

.

)

t

h

i

c

k

n

e

s

s

m

m

(

i

n

.

)

M

e

a

s

u

r

e

d

c

l

e

a

r

a

n

c

e

m

m

(

i

n

.

)

N

o

.

T

h

i

c

k

n

e

s

s

N

o

.

T

h

i

c

k

n

e

s

s

N

o

.

T

h

i

c

k

n

e

s

s

E

x

h

a

u

s

t

v

a

l

v

e

c

l

e

a

r

a

n

c

e

(

C

o

l

d

)

:

0

.

3

5

t

o

0

.

4

5

m

m

(

0

.

0

1

3

8

t

o

0

.

0

1

7

7

i

n

.

)

E

X

A

M

P

L

E

:

T

h

e

5

.

3

4

0

m

m

(

0

.

2

1

0

2

i

n

.

)

l

i

f

t

e

r

i

s

i

n

s

t

a

l

l

e

d

,

a

n

d

t

h

e

m

e

a

s

u

r

e

d

c

l

e

a

r

a

n

c

e

i

s

0

.

4

8

0

m

m

(

0

.

0

1

8

9

i

n

.

)

.

R

e

p

l

a

c

e

t

h

e

5

.

3

4

0

m

m

(

0

.

2

1

0

2

i

n

.

)

s

h

i

m

w

i

t

h

a

n

e

w

N

o

.

4

2

l

i

f

t

e

r

.

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1433

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

A72846

V

a

l

v

e

L

i

f

t

e

r

S

e

l

e

c

t

i

o

n

C

h

a

r

t

(

I

n

t

a

k

e

)

R

e

m

o

v

e

d

l

i

f

t

e

r

N

e

w

L

i

f

t

e

r

T

h

i

c

k

n

e

s

s

m

m

(

i

n

.

)

t

h

i

c

k

n

e

s

s

m

m

(

i

n

.

)

M

e

a

s

u

r

e

d

c

l

e

a

r

a

n

c

e

m

m

(

i

n

.

)

N

o

.

T

h

i

c

k

n

e

s

s

N

o

.

T

h

i

c

k

n

e

s

s

N

o

.

T

h

i

c

k

n

e

s

s

I

n

t

a

k

e

v

a

l

v

e

c

l

e

a

r

a

n

c

e

(

C

o

l

d

)

:

0

.

2

0

t

o

0

.

3

0

m

m

(

0

.

0

0

7

9

t

o

0

.

0

0

1

1

8

i

n

.

)

E

X

A

M

P

L

E

:

T

h

e

5

.

2

5

0

m

m

(

0

.

2

0

6

7

i

n

.

)

l

i

f

t

e

r

i

s

i

n

s

t

a

l

l

e

d

,

a

n

d

t

h

e

m

e

a

s

u

r

e

d

c

l

e

a

r

a

n

c

e

i

s

0

.

4

0

0

m

m

(

0

.

0

1

5

8

i

n

.

)

.

R

e

p

l

a

c

e

t

h

e

5

.

2

5

0

m

m

(

0

.

2

0

6

7

i

n

.

)

s

h

i

m

w

i

t

h

a

n

e

w

N

o

.

4

0

l

i

f

t

e

r

.

1434

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

A51380

A74299

Upward

Key Groove

A69874

Dot Mark

A69863

Oil Passage

Seal Packing

8 mm

(0.31 in.)

Width: 4 mm (0.16 in.)

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1435

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

66. INSTALL CAMSHAFT

(a) Install the camshaft and camshaft No.2.

(1) Set the crankshaft and turn it 90_ counterclockwise

from the TDC position.

(2) Place the camshaft to the cylinder head as shown

in the illustration.

(3) Align the dot marks of the camshaft and camshaft

No.2 by meshing both of the two gears before plac-

ing the camshaft No.2.

(4) Remove old seal packing (FIPG) from the camshaft

bearing cap and cylinder head.

(5) Apply seal packing to the specific places described

in the illustration.

Seal packing: Part No. 0882600080 or equivalent

Thickness: 1.0 mm (0.04 in.)

NOTICE:

S Be careful not to adhere FIPGto the oil passage of the

bearing cap.

S After applying FIPG is completed, install the cam-

shaft bearing cap within 3 minutes and tighten its

bolts within 15 minutes.

S Do not start the engine within 2 hours after the instal-

lation.

A51386

A51387

A69864

Seal

Packing

Width:

4 mm (0.16 in.)

A51300

1436

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

(6) Install the camshaft bearing cap as shown in the il-

lustration.

(7) Tighten the 15 bolts for the camshaft bearing cap in

the specified order described in the illustration.

Torque: 19 Nm (194 kgfcm, 14 ftlbf)

67. INSTALL CAMSHAFT SETTING OIL SEAL

(a) Install the oil seal.

(1) Apply a small amount of MP grease to a newoil seal

lip.

NOTICE:

Keep the lip clean. Prevent dirt and dust from adhering to

that area.

(2) Fit the oil seal using SST and a hammer.

SST 0960806041

Oil seal depth from the flatend surface :

0.5 to 1.5 mm (0.020 to 0.060 in.)

68. INSTALL TIMING BELT NO.2 COVER

(a) Remove old packing (FIPG) from the timing gear case.

(b) Apply seal packing to the specific places described in the

illustration.

Seal packing: Part No. 0882600080 or equivalent

NOTICE:

Install the timing belt No.2 cover within 3 minutes andtight-

en its bolts and nut within 15 minutes after applying FIPG

is competed.

(c) Install the timing belt No.2 cover with the 4 bolts and nut.

Torque: 10 Nm (102 kgfcm, 7 ftlbf)

A69875

A76599

A69876

G38646

ORing

G39216

A76600

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1437

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

69. INSTALL CAMSHAFT TIMING PULLEY

(a) Install the set key to the key groove of the camshaft.

(b) Align the set key with the key groove of the timing pulley.

(c) Hold the hexagon portion of the camshaft, and install the

timing pulley with the bolt.

Torque: 98 Nm (1,000 kgfcm, 72 ftlbf)

70. INSTALL INJECTOR ASSY

(a) Install the common rail with the 2 bolts.

Torque: 38 Nm (387 kgfcm, 28 ftlbf)

(b) Apply a light coat of engine oil to a new Oring for each

injector.

(c) Install 4 new nozzle seats to the cylinder head.

(d) Install the injector to the cylinder head.

NOTICE:

S At this time, insert the injector until it touches the

nozzle sheet surface.

S Wheninstalling the injector tothe cylinder head, if the

injector comes to float up with the reaction of Oring,

pull out the injector and install it again.

S Do not exchange the injector.

(e) Temporarily install the 4 injection pipes.

B12460

G39217

G39218

G39219

Union Bolt

#2

#3

#4

#1

Hollow Screw

1438

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

(f) Before installing the nozzle leakage pipe, check that there

is no scratch and deformation (dent) on the seal surface

of the unions (at five positions) using a straight edge.

HINT:

If there is any scratch or deformation, replace it to a new one.

(g) Place the nozzle leakage pipe and 5 new gaskets.

(h) Apply a light coat of engine oil to the 4 hollow screws and

union bolt.

(i) Temporarily install the leakage pipe with the 4 hollow

screws and union bolt.

(j) Set the spring to each injector as shown in the illustration.

(k) Set a new washer on the nozzle holder clamp as shown

in the illustration.

(l) Tighten the bolt.

Torque: 22 Nm (220 kgfcm, 16 ftlbf)

NOTICE:

S Clip the injector at the fork portion with a clampwhich

is set on the head of the cam cap bolt. At this time,

check that the clamp does not hold the injector at the

part where the spring is attached.

S To tighten the clamp bolt, temporarily tighten it by

hand until the bearing surface of the bolt touches the

washer, then tighten to the specified torque.

S Whentighteningtothe specifiedtorque, payattention

not to tilt the bolt and the clamp.

S The washer can not be reused.

S If overtightening the washer, replace it with a new

one.

(m) Tighten the 4 hollow screws from #1 to #4 in order.

Torque: 16 Nm (163 kgfcm, 12 ftlbf)

NOTICE:

If any of the screws are overtightened, replace the nozzle

leakage pipe assy with a new one.

(n) Tighten the union bolt.

Torque: 13 Nm (130 kgfcm, 9 ftlbf)

NOTICE:

If the bolt is overtightened, replace the nozzle leakage pipe

assy with a new one.

A76603

A76607 G37171

SST

A76608

A74354

G37172

A69877

Seal Packing

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1439

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

(o) Remove the 4 injection pipes.

(p) Remove the 2 bolts and common rail.

(q) Check that there are no leaks from the nozzle leakage

pipe connection.

(1) Using SST, install the nozzle leakage pipe No.2 and

new gasket to the cylinder head.

SST 0928000010

Torque: 21 Nm (214 kgfcm, 16 ftlbf)

(2) Apply a light coat of engine oil (any fluid to detect

fuel leakage) to the nozzle leakage pipe connec-

tion.

(3) Using SST (turbo charger pressure gauge), set the

SST to the leakage pipe No.2 and maintain 250 kPa

(2.5 kgf/cm

2

, 37 psi) of pressure for 60 seconds to

check that there are no leaks from the leakage pipe

No.1.

SST 0999200242

NOTICE:

Be sure to keep specified pressure, preventing from leak-

age.

HINT:

S (Apply a coat of engine oil to the leakage pipe connec-

tion,) and check that no bubbles come from the leakage

pipe connection or each nozzle leakage pipe connection.

S Check that the indication on the SST (turbo charger pres-

sure gauge) does not go down while pressure is applied.

(4) After checking fuel leaks, wipe off engine oil from

the leakage pipe connection.

(r) Remove the SST, union bolt, bolt and nozzle leakage pipe

No.2.

71. INSTALL CYLINDER HEAD COVER SUBASSY

(a) Remove old seal packing (FIPG) from the cylinder head.

(b) Apply seal packing to the specific places described in the

illustration.

Seal packing: Part No. 0882600080 or equivalent

NOTICE:

After applying the seal packing, parts must be assembled

within 3 minutes, and then tighten themwithin 15 minutes.

A51295

G39220

G39212

1440

ENGINE MECHANICAL PARTIAL ENGINE ASSY (1KDFTV)(From August,

2004)

1KDFTV ENGINE REPAIR MANUAL (RM1153E)

(c) Install the gasket to the cylinder head cover.

(d) Install the cylinder head cover with the 10 bolts and the

2 nuts. Uniformly tighten the bolts and nuts.

Torque: 9.0 Nm (92 kgfcm, 80 in.lbf)

72. INSTALL NOZZLE HOLDER SEAL

(a) Install 4 new nozzle holder seals.

73. INSTALL OIL FILLER CAP SUBASSY

(a) Install the oil filler cap to the cylinder head cover.

You might also like

- 1KD FTVDocument10 pages1KD FTVnicamarcos100% (7)

- Engine - 1VD-FTV EngineDocument33 pagesEngine - 1VD-FTV EnginePablo Pérez100% (3)

- JCB Drivetrain System 9803-9240 Service ManualDocument108 pagesJCB Drivetrain System 9803-9240 Service ManualMarcin Marszałek100% (1)

- CE302-1 1KD Engine RM Jun.2014Document488 pagesCE302-1 1KD Engine RM Jun.2014Ahmad Bik Elhays100% (6)

- 2Kd-Ftv Engine Mechanical Torque Specifications: Part Tightened N M KGF CM Ft. LBFDocument3 pages2Kd-Ftv Engine Mechanical Torque Specifications: Part Tightened N M KGF CM Ft. LBFdaniel_ting_182% (45)

- Honda XR50R Service Manual 2000 2003Document197 pagesHonda XR50R Service Manual 2000 2003aurongayNo ratings yet

- Control Engine - 1kd-Ftv and 2kd-FtdDocument25 pagesControl Engine - 1kd-Ftv and 2kd-FtdEulicer Armengol93% (73)

- Technician guide to 1VD-FTV diesel engine features and specificationsDocument53 pagesTechnician guide to 1VD-FTV diesel engine features and specificationsMurugan K93% (15)

- Denso Toyota Hilux Common RailDocument68 pagesDenso Toyota Hilux Common RailRonald Yanes93% (71)

- Toyota HiluxDocument76 pagesToyota HiluxVictor Javier91% (11)

- ENGINE - 1KD-FTV AND 2KD-FTV ENGINES Supply Pump OperationDocument8 pagesENGINE - 1KD-FTV AND 2KD-FTV ENGINES Supply Pump OperationSultan Ahmed Khan100% (23)

- Hilux 1kd 2kdDocument5 pagesHilux 1kd 2kdmiguelcastillo91% (35)

- Toyota 1kd 2kdDocument31 pagesToyota 1kd 2kdMispa Serv100% (2)

- Toyota Matrix Timing Chain Removal and Installation GuideDocument16 pagesToyota Matrix Timing Chain Removal and Installation GuideGesco EscobarNo ratings yet

- 2004-2015 Toyota Hilux Fuse Box DiagramDocument12 pages2004-2015 Toyota Hilux Fuse Box DiagramJunior Salazar100% (2)

- Engine: 1Kd-Ftv and 2Kd-Ftv EnginesDocument46 pagesEngine: 1Kd-Ftv and 2Kd-Ftv EnginesJorge Luis Garcia ArevaloNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Engine 1KD 2KDDocument72 pagesEngine 1KD 2KDJavier Espinosa100% (8)

- 1kd FTVDocument2 pages1kd FTVGregory Ashley87% (15)

- Engine 1KD, 2KDDocument72 pagesEngine 1KD, 2KDjimmy_huamancayo97% (60)

- Automatic Transaxle System: PrecautionDocument21 pagesAutomatic Transaxle System: PrecautionJorge NegrettiNo ratings yet

- 5l-E Engine EletricalDocument246 pages5l-E Engine EletricalMagno Dias96% (23)

- Yanmar Excavator Yb40-2 Service Manual + Electrical Wiring Diagrams + Parts CatalogDocument188 pagesYanmar Excavator Yb40-2 Service Manual + Electrical Wiring Diagrams + Parts CatalogJonas Svidinskas100% (1)

- Optimize engine performance with intake and exhaust systemsDocument11 pagesOptimize engine performance with intake and exhaust systemsCarlos Eduardo Zelidon100% (2)

- Hydrostatic Testing GuideDocument10 pagesHydrostatic Testing Guidepraveentien100% (1)

- Lexus - GS300 - GS430 - Service - Manual 15Document38 pagesLexus - GS300 - GS430 - Service - Manual 15seregap84100% (2)

- TOYOTA Hi Lux FaultCodes 0692Document1 pageTOYOTA Hi Lux FaultCodes 0692yargen100% (1)

- Common Rail System (CRS) : Toyota 1Kd/2Kd EngineDocument31 pagesCommon Rail System (CRS) : Toyota 1Kd/2Kd EngineJuan Alberto Bucaro100% (30)

- Adjust Valve Clearance 1ZZ-FE EngineDocument11 pagesAdjust Valve Clearance 1ZZ-FE EngineAlan Dell SnyderNo ratings yet

- Toyota Corolla+c52 Shift ManualDocument221 pagesToyota Corolla+c52 Shift Manualdaswine100% (4)

- Plano Electrico Excavadora Caterpillar 330c CyaDocument2 pagesPlano Electrico Excavadora Caterpillar 330c CyaEdwin Vaca100% (1)

- Cylinder Head 3sfeDocument27 pagesCylinder Head 3sfePham Huy83% (18)

- Toyota 2kd Engine ContrlDocument25 pagesToyota 2kd Engine ContrlKamal Semboy67% (3)

- Partial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulDocument26 pagesPartial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulNelson Caño Basalo100% (3)

- KD Series Engine Technical OverviewDocument72 pagesKD Series Engine Technical OverviewCarlos Andres Guzman Salamanca75% (4)

- Electrical Insulation and Thermal Measurements For Motors and Drives AnDocument4 pagesElectrical Insulation and Thermal Measurements For Motors and Drives Anmu_ignoreNo ratings yet

- 1KD-FTV and 2KD-FTV EnginesDocument25 pages1KD-FTV and 2KD-FTV EnginesSergio Olivares Cortes100% (6)

- Hilux GD SeriesDocument17 pagesHilux GD SeriesNging Yu100% (6)

- D Transmission2010Document37 pagesD Transmission2010Akrae AcrNo ratings yet

- ACI 309R 05 Guide For Consolidation of Concrete PDFDocument36 pagesACI 309R 05 Guide For Consolidation of Concrete PDFJaniosPereiraNo ratings yet

- ACI 309R 05 Guide For Consolidation of Concrete PDFDocument36 pagesACI 309R 05 Guide For Consolidation of Concrete PDFJaniosPereiraNo ratings yet

- Optimize cylinder head gasket selectionDocument5 pagesOptimize cylinder head gasket selectionwilliam_senati20057051No ratings yet

- Motor 1AZ-FE OverhaulDocument29 pagesMotor 1AZ-FE OverhaulfredhNo ratings yet

- Valve Clearance 1KDFTVDocument6 pagesValve Clearance 1KDFTVFrans Metin86% (7)

- Sienna Timing Belt ReplacementDocument8 pagesSienna Timing Belt ReplacementGlenn MartinNo ratings yet

- Tork Tech Crown VicDocument55 pagesTork Tech Crown Vicnyinterceptor0% (1)

- H15B PLUS-2 Parts ManualDocument158 pagesH15B PLUS-2 Parts ManualАлексей50% (2)

- F7 A2 F8 B1 E1 F6 F5 G1 E4: Position of Parts in Engine CompartmentDocument3 pagesF7 A2 F8 B1 E1 F6 F5 G1 E4: Position of Parts in Engine CompartmentEtienne van Tonder100% (3)

- Standard Practice For The Use of Shrinkage-Compensating ConcreteDocument26 pagesStandard Practice For The Use of Shrinkage-Compensating ConcreteAntu IsabelNo ratings yet

- GV51790UDocument178 pagesGV51790Usaiful0% (1)

- Sampling SolutionsDocument6 pagesSampling SolutionsSrikanth MankalaNo ratings yet

- Clspro600 Operating-Manual enDocument98 pagesClspro600 Operating-Manual enluizlou5308100% (4)

- Unc Unf Metric Thread Chart Northwest FastenerDocument1 pageUnc Unf Metric Thread Chart Northwest FastenerthailanNo ratings yet

- 2rz - Valve Clearance InspectionDocument5 pages2rz - Valve Clearance Inspectionberdeaberdea100% (1)

- Astm C-494 PDFDocument9 pagesAstm C-494 PDFvelmurug_bala100% (4)

- Astm C-494 PDFDocument9 pagesAstm C-494 PDFvelmurug_bala100% (4)

- Kalmar DRD-S Tchnical HandbookDocument298 pagesKalmar DRD-S Tchnical HandbookMark Andres JuncoNo ratings yet

- 1KDFTVL P2Document4 pages1KDFTVL P2julio797No ratings yet

- 1KD Engine Coolan Drain PlugDocument2 pages1KD Engine Coolan Drain Plugkampee100% (1)

- 007008Document22 pages007008susanta_kumarNo ratings yet

- Remo TBDocument5 pagesRemo TBTyler MacNo ratings yet

- RAV Engine ManualDocument24 pagesRAV Engine ManualIsaac Okorie zakuNo ratings yet

- Timing Chain Components & Instalation Toyota Hilux 22R-E: Preparation of RemovalDocument7 pagesTiming Chain Components & Instalation Toyota Hilux 22R-E: Preparation of RemovalPablo FernandezNo ratings yet

- Transfer PDFDocument51 pagesTransfer PDFAndrey GladyshevNo ratings yet

- MT-TITLEDocument66 pagesMT-TITLERolfs Almonte DiazNo ratings yet

- Sm-Caterpillar Cat 950h Wheel Loader j5j01501Document25 pagesSm-Caterpillar Cat 950h Wheel Loader j5j01501Daniel Vanegas100% (1)

- Timing Chain Oil SealDocument2 pagesTiming Chain Oil SealEduardo Segundo Gonzalez MuñozNo ratings yet

- Toyota Highlander Timing Chain Replacement GuideDocument14 pagesToyota Highlander Timing Chain Replacement GuideOscar jhonyffer Pereda RiscoNo ratings yet

- Gear Pump (Transmission Charging and Scavenge) - Disassemble (KENR8443-06)Document3 pagesGear Pump (Transmission Charging and Scavenge) - Disassemble (KENR8443-06)Guido Emanuel SteinbachNo ratings yet

- Overhaul Partial Engine Assembly 2AZ-FSEDocument36 pagesOverhaul Partial Engine Assembly 2AZ-FSEHenry SilvaNo ratings yet

- 07 - Timing Chain - RemovalDocument4 pages07 - Timing Chain - Removal08088338No ratings yet

- Reglaje de ValvulasDocument15 pagesReglaje de ValvulasJuan Antonio Ochoa PadronNo ratings yet

- 8 7 PDFDocument54 pages8 7 PDFHector Renzo Zarate RodriguezNo ratings yet

- Overhaul: Partial Engine Assy (1Gr Fe)Document50 pagesOverhaul: Partial Engine Assy (1Gr Fe)Islam AttiaNo ratings yet

- D6NXL Transmission Disassembly Step-by-Step GuideDocument32 pagesD6NXL Transmission Disassembly Step-by-Step Guidehgjrujtnt srthytntynNo ratings yet

- Cylinder Head Removal and Installation GuideDocument7 pagesCylinder Head Removal and Installation GuideMohamad ZuhailiNo ratings yet

- How to Optimize Your Website for Search EnginesDocument49 pagesHow to Optimize Your Website for Search EnginestfphoenixNo ratings yet

- Procedimietos CulataDocument15 pagesProcedimietos CulataSERVICIO TECNICO AUTOMOTRIZ TONATONo ratings yet

- Aci 117 R90Document11 pagesAci 117 R90Rafael Elgueta Aravena100% (1)

- ACI 304-Bombeo-De-ConcretopdfDocument46 pagesACI 304-Bombeo-De-ConcretopdfJehuty88No ratings yet

- Hot Weather ConcreteDocument2 pagesHot Weather ConcreteJehuty88No ratings yet

- HEAVITAS font EULA - Use for free or donate $15Document1 pageHEAVITAS font EULA - Use for free or donate $15Jehuty88No ratings yet

- Aci 117 R90Document11 pagesAci 117 R90Rafael Elgueta Aravena100% (1)

- HowTo PrintLayouts PLD 88Document61 pagesHowTo PrintLayouts PLD 88Ricardo CANo ratings yet

- Zapata Velasquez Ronny Alexander DISC and MotivatorsDocument10 pagesZapata Velasquez Ronny Alexander DISC and MotivatorsJehuty88No ratings yet

- Aci 117 R90Document11 pagesAci 117 R90Rafael Elgueta Aravena100% (1)

- ALAS FormDocument1 pageALAS FormJehuty88No ratings yet

- Water PlantDocument1 pageWater PlantJehuty88No ratings yet

- Elixir European FormulaDocument1 pageElixir European FormulaJehuty88No ratings yet

- What Is ISO 9001Document16 pagesWhat Is ISO 9001Rayvathy ParamatemaNo ratings yet

- Applications Drive Tire StrategiesDocument4 pagesApplications Drive Tire StrategiesJehuty88No ratings yet

- Amalie Wearable CatalogDocument10 pagesAmalie Wearable CatalogJehuty88No ratings yet

- Amalie ServiceDocument1 pageAmalie ServiceJehuty88No ratings yet

- T30 - Model - 2340Document20 pagesT30 - Model - 2340Jehuty88No ratings yet

- 9852 0918 01a Setting COP 1238ME 07 Bench DrillingDocument1 page9852 0918 01a Setting COP 1238ME 07 Bench DrillingJehuty88No ratings yet

- Dexos 1Document2 pagesDexos 1Jehuty88No ratings yet

- 5 Factors of Refurbishment Win 2011Document3 pages5 Factors of Refurbishment Win 2011Jehuty88No ratings yet

- G-176 Sonic Plus Automatic Grade ControlDocument1 pageG-176 Sonic Plus Automatic Grade ControlJehuty88No ratings yet

- 330d L HarnessDocument1 page330d L HarnessJehuty88No ratings yet

- PAI Industries, IncDocument1 pagePAI Industries, IncJehuty88No ratings yet

- T30 - Model - 2340Document20 pagesT30 - Model - 2340Jehuty88No ratings yet

- SRI Fire FigthingDocument62 pagesSRI Fire Figthingjbor0029No ratings yet

- Godwin HL 100 MDocument14 pagesGodwin HL 100 MmuahdibNo ratings yet

- Trek Domane 2020 Quick ReferenceDocument12 pagesTrek Domane 2020 Quick ReferenceSharkykzn100% (1)

- Air-Oxygen Blender: Service ManualDocument34 pagesAir-Oxygen Blender: Service ManualJames de LunaNo ratings yet

- CMC 8000-9000 Toothed Belt ReplacementDocument6 pagesCMC 8000-9000 Toothed Belt ReplacementkarlwizardNo ratings yet

- Pole structure details sheetDocument1 pagePole structure details sheetarlene borborNo ratings yet

- GTU BE Semester IV Machine Design & Industrial Drafting ExamDocument3 pagesGTU BE Semester IV Machine Design & Industrial Drafting ExamhukNo ratings yet

- GS12-0393 KL32GT616U SKD Working InstructionDocument16 pagesGS12-0393 KL32GT616U SKD Working InstructionJorge Fernando de TivantaNo ratings yet

- G64C Maintenance CardDocument6 pagesG64C Maintenance CardBogar PinedaNo ratings yet

- TB2044XP ManualDocument48 pagesTB2044XP ManualWormy0% (1)

- Shear Connections Notes: (1) The Beams Considered With Coped ConditionDocument9 pagesShear Connections Notes: (1) The Beams Considered With Coped ConditionSrikanth SikhaNo ratings yet

- 2 WaydistributorDocument53 pages2 WaydistributormbhaditNo ratings yet

- WPC Bruchure Revised Price List November 7 2020Document10 pagesWPC Bruchure Revised Price List November 7 2020Michael FutolNo ratings yet

- MCGS Series Twin-Guide Cylinder with φ6 and φ10 Tube IDsDocument9 pagesMCGS Series Twin-Guide Cylinder with φ6 and φ10 Tube IDsMicky CeceñaNo ratings yet

- IHF Standard Fasteners - Englisch - 19.10.2010Document20 pagesIHF Standard Fasteners - Englisch - 19.10.2010Tamer Elsebaei EbarhimNo ratings yet

- Qcs 2010 Part 8.05 Valves, Penstocks and AppurtenancesDocument18 pagesQcs 2010 Part 8.05 Valves, Penstocks and AppurtenancesRotsapNayrbNo ratings yet

- 13 - Check ValvesDocument14 pages13 - Check ValvesSiles LimberdsNo ratings yet

- RD-4601 RD-4601: SHIMANO TIAGRA Rear Derailleur (10-Speed)Document1 pageRD-4601 RD-4601: SHIMANO TIAGRA Rear Derailleur (10-Speed)fvandongenNo ratings yet