Professional Documents

Culture Documents

Student Review Welding

Uploaded by

martinimartiiniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Student Review Welding

Uploaded by

martinimartiiniCopyright:

Available Formats

TWO WELDING CATEGORIES Fusion welding - accomplished by melting the two parts to be joined, in some cases adding filler

metal to the joint Examples: arc welding, resistance spot welding, oxyfuel gas welding Solid state welding - heat and/or pressure are used to achieve joining, but no melting of base metals occurs and no filler metal is added Examples: forge welding, diffusion welding, friction welding ARC WELDING Joining by an arc between electrode and parts being joined Heat from electric energy at 10,000 F (5500 C), Process usually adds filler metal for added strength ELECTRIC ARC The discharge of current across a gap making a circuit Molten metal solidifies in the wake of electrode making the weld Basic types of electrodes Consumable-filler metal Weld rods, welding wire Non-consumable-filler metal added separately Made of melt resistant material (tungsten) FLUX Coating on weld wire, core inside the weld wire or pouring flux onto weld operation Shields weld from air Reduces spatter AC or DC power supply AC restricted to ferrous CONSUMABLE WELDING PROCESSES (SMAW)Shielded Metal Arc Welding (stick welding) -filler rod with flux core -Used for steels, stainless steels, cast irons, and certain nonferrous alloys (GMAW)Gas Metal Arc Welding -bare wire fed from spool through gun -shielding provided by gas directed onto weld -argon and helium for aluminum CO2 for steel Flux-Cored Arc Welding -electrode contains flux in its core -self shielded-core includes material that produces gas -gas shielded-gas is supplied externally

Electrogas Welding -continuous wire supply, bare or flux coated Submerged Arc Welding -continuous wire supply -shielded by blanket of flux from a hopper NONCONSUMABLE Gas Tungsten Arc Welding -tungsten electrode -used with or without filler metal Plasma Arc Welding -form of GTAW Resistance Welding -used mostly on thin metal sheets -electrodes touched linearly to opposite sides of parts to be joined -used widely in automobiles, appliances, products made of sheet metal Laser beam welding -fusion created by heat from intense light beam -filler metal not usually added

SOLID STATE WELDING -joining is achieved by pressure alone -heat and pressure -no filler metal Forge welding -metal heated and then forged by hammering Cold welding -high pressure between surfaces at room temperature Roll welding -pressure applied by rolling metals together causing cohesion Diffusion welding -uses heat and pressure

Explosion welding -joining caused by energy from detonation Friction welding -heat from friction between two surfaces to cause weld Ultrasonic welding -ultrasonic frequency applied to cause cohesion

WELD QUALITY Welding defects

You might also like

- VA1400 DataSheetDocument2 pagesVA1400 DataSheetVikram DewanganNo ratings yet

- MotoSim EGDocument2 pagesMotoSim EGHermis BuitrónNo ratings yet

- XRC ControllerDocument2 pagesXRC ControllersengcyanNo ratings yet

- Training Topics XRCDocument5 pagesTraining Topics XRCmartinimartiiniNo ratings yet

- NXC100 ControllerDocument2 pagesNXC100 ControllermartinimartiiniNo ratings yet

- Motoman Services OverviewDocument7 pagesMotoman Services OverviewmartinimartiiniNo ratings yet

- Moto Sim TouchDocument2 pagesMoto Sim TouchmartinimartiiniNo ratings yet

- STEM EducationAndWorkforceDevelopmentDocument3 pagesSTEM EducationAndWorkforceDevelopmentmartinimartiiniNo ratings yet

- Kinetiq TeachingDocument1 pageKinetiq TeachingmartinimartiiniNo ratings yet

- SPI Pendant InterfaceDocument2 pagesSPI Pendant InterfacemartinimartiiniNo ratings yet

- Motoman Inform Vim Syntax Jbi VimDocument3 pagesMotoman Inform Vim Syntax Jbi VimmartinimartiiniNo ratings yet

- Cs 246 Listing XRC ModuleDocument4 pagesCs 246 Listing XRC ModulemartinimartiiniNo ratings yet

- JobEditor Manual en 01Document68 pagesJobEditor Manual en 01martinimartiiniNo ratings yet

- InformDocument297 pagesInformmartinimartiiniNo ratings yet

- Cs 303 Listing Nx100 ModuleDocument7 pagesCs 303 Listing Nx100 ModulemartinimartiiniNo ratings yet

- Lincoln 158051-1CD-R3Document485 pagesLincoln 158051-1CD-R3martinimartiiniNo ratings yet

- FS100 ControllerDocument2 pagesFS100 ControllermartinimartiiniNo ratings yet

- Ea1900n en 08Document4 pagesEa1900n en 08martinimartiiniNo ratings yet

- CS-287 Why AdvancedDocument1 pageCS-287 Why AdvancedmartinimartiiniNo ratings yet

- Inform LanguageDocument297 pagesInform Languagemartinimartiini100% (1)

- S4CPlus-IRB7600 M2000A Electrical Maintenance Training ManualDocument1,070 pagesS4CPlus-IRB7600 M2000A Electrical Maintenance Training Manualmartinimartiini100% (1)

- S4-Irb 2400 M94a ProductDocument493 pagesS4-Irb 2400 M94a ProductmartinimartiiniNo ratings yet

- 1Document68 pages1martinimartiiniNo ratings yet

- S4CPlus-IRB6600 M2000A Electrical Maintenance Training ManualDocument1,020 pagesS4CPlus-IRB6600 M2000A Electrical Maintenance Training Manualmartinimartiini100% (1)

- IRC5-IRB340 Prod Man 3HAC022546-001 Reference Rev - en RefDocument25 pagesIRC5-IRB340 Prod Man 3HAC022546-001 Reference Rev - en Refadriano_falavinha9186No ratings yet

- S4CPlus-IRB 940 M2000 Electrical Maintenance Training ManualDocument556 pagesS4CPlus-IRB 940 M2000 Electrical Maintenance Training Manualmartinimartiini100% (1)

- IRC5-IRB7600 Prod Man Part13HAC022033-001 Procedures RevB enDocument384 pagesIRC5-IRB7600 Prod Man Part13HAC022033-001 Procedures RevB enmartinimartiiniNo ratings yet

- IRC5-IRB4400 Prod Man Part2 3HAC022032-001 - References - Rev - enDocument57 pagesIRC5-IRB4400 Prod Man Part2 3HAC022032-001 - References - Rev - enmartinimartiiniNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Low Alloy13Document5 pagesLow Alloy13Branko FerenčakNo ratings yet

- Salamander Energy Sales Gas Metering Package Fabrication ProcedureDocument25 pagesSalamander Energy Sales Gas Metering Package Fabrication ProcedureHandri Puri100% (1)

- Syncrowave 250 ManualDocument48 pagesSyncrowave 250 ManualRob Hall100% (1)

- Oerlikon Competence 3 Grade 92 2008Document32 pagesOerlikon Competence 3 Grade 92 2008Claudia MmsNo ratings yet

- Welder Job Clearance Card: Nesma/TanmiaDocument8 pagesWelder Job Clearance Card: Nesma/TanmiaMohamed Reda Hussein SengarNo ratings yet

- Glossary of Process Piping TerminologyDocument28 pagesGlossary of Process Piping Terminologysayafrands6252No ratings yet

- Asme Sec Ix Guide PDFDocument144 pagesAsme Sec Ix Guide PDFCHARLES Anthonyraj100% (1)

- Welding (Cadet Training)Document41 pagesWelding (Cadet Training)Kyaw Bhone WinNo ratings yet

- Welding Complete by S K MondalDocument50 pagesWelding Complete by S K MondalVipul RanaNo ratings yet

- Catalogue Welding EquipmentDocument12 pagesCatalogue Welding EquipmentRico CayampatNo ratings yet

- Code of Practice: Normalisation Renault Automobiles Service 65810 Section Normes Et Cahiers Des ChargesDocument42 pagesCode of Practice: Normalisation Renault Automobiles Service 65810 Section Normes Et Cahiers Des ChargesLica EmilNo ratings yet

- Lincoln ArcLink Interface and Weld Editor - ENGDocument48 pagesLincoln ArcLink Interface and Weld Editor - ENGDrekal WarlockNo ratings yet

- Introduction To Arc WeldingDocument36 pagesIntroduction To Arc WeldingKetan VaghosiNo ratings yet

- Effect of Heat Treatment On Corrosion Behaviour of Welded AA6061 Aluminium Alloy in SeawaterDocument9 pagesEffect of Heat Treatment On Corrosion Behaviour of Welded AA6061 Aluminium Alloy in SeawaterMohamed RamadanNo ratings yet

- Welding ElectrodesDocument19 pagesWelding Electrodesraju100% (1)

- B2 1-B2 1M-2009PVDocument7 pagesB2 1-B2 1M-2009PVRobert Johnson14% (7)

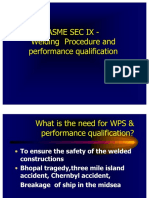

- Asme Sec IxDocument46 pagesAsme Sec Ixmurshid badshahNo ratings yet

- Procedure Qualification RecordDocument10 pagesProcedure Qualification Recordlamia97No ratings yet

- Tig-Katalog Pro w137 GB 2 0-v1 Web PDFDocument28 pagesTig-Katalog Pro w137 GB 2 0-v1 Web PDFMarioNo ratings yet

- Busbar TightnessDocument11 pagesBusbar Tightnesssanjeev267No ratings yet

- WedingDocument75 pagesWedingSrinivasan MuthuvelNo ratings yet

- Smarty 220 XLDocument132 pagesSmarty 220 XLFaycel OuerdienNo ratings yet

- Terminologies SmawDocument18 pagesTerminologies SmawMarwin NavarreteNo ratings yet

- Trailblazer 325 Trailblazer 275: Eff W/serial No. MC180915R Thru MH451163RDocument12 pagesTrailblazer 325 Trailblazer 275: Eff W/serial No. MC180915R Thru MH451163RCoordinador - MantenimientosNo ratings yet

- KEL Industrial Visit ReportDocument18 pagesKEL Industrial Visit ReportAnoopAsokan0% (1)

- Rotary PipeCLADDocument7 pagesRotary PipeCLADsafari7No ratings yet

- ArcWeld Varias PDFDocument84 pagesArcWeld Varias PDFSistemcan Productivo100% (4)

- Chapter-1: Welding RobotsDocument22 pagesChapter-1: Welding RobotsPranayNo ratings yet

- Types of Welding Machines: A Guide to 12 Common MachinesDocument10 pagesTypes of Welding Machines: A Guide to 12 Common MachinesLibin K B LeonNo ratings yet

- Q-Chem Ethylene Project welding procedure specificationDocument1 pageQ-Chem Ethylene Project welding procedure specificationS GoudaNo ratings yet