Professional Documents

Culture Documents

Uni 15316-4-7 - 2009

Uploaded by

Stefano SquadraniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uni 15316-4-7 - 2009

Uploaded by

Stefano SquadraniCopyright:

Available Formats

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009.

Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

Impianti di riscaldamento degli edifici

NORMA E U R OP E A

Metodo per il calcolo dei requisiti energetici e dei rendimenti dellimpianto

Parte 4-7: Sistemi di generazione per il riscaldamento degli ambienti, sistemi di combustione a biomassa

UNI EN 15316-4-7

MARZO 2009 Heating systems in buildings

Method for calculation of system energy requirements and system efficiencies

Part 4-7: Space heating generation systems, biomass combustion systems La norma fa parte di una serie di norme per il calcolo della prestazione energetica e il rendimento energetico dei sistemi di riscaldamento e produzione di acqua calda sanitaria. La norma definisce i dati di input, il metodo di calcolo e i risultati di output per i sistemi di combustione a biomassa a caricamento manuale. La norma si applica anche ai sistemi combinati per il riscaldamento e la produzione di acqua calda sanitaria. I sistemi per la sola produzione di acqua calda sanitaria sono trattati nella UNI EN 15316-3-3.

TESTO INGLESE

La presente norma la versione ufficiale in lingua inglese della norma europea EN 15316-4-7 (edizione novembre 2008).

ICS

UNI Ente Nazionale Italiano di Unificazione Via Sannio, 2 20137 Milano, Italia

91.140.10

UNI Riproduzione vietata. Tutti i diritti sono riservati. Nessuna parte del presente documento pu essere riprodotta o diffusa con un mezzo qualsiasi, fotocopie, microfilm o altro, senza il consenso scritto dellUNI. www.uni.com UNI EN 15316-4-7:2009 Pagina I

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

PREMESSA NAZIONALE

La presente norma costituisce il recepimento, in lingua inglese, della norma europea EN 15316-4-7 (edizione novembre 2008), che assume cos lo status di norma nazionale italiana. La presente norma stata elaborata sotto la competenza dellente federato all UNI CTI - Comitato Termotecnico Italiano La presente norma stata ratificata dal Presidente dellUNI ed entrata a far parte del corpo normativo nazionale il 19 marzo 2009.

Le norme UNI sono elaborate cercando di tenere conto dei punti di vista di tutte le parti interessate e di conciliare ogni aspetto conflittuale, per rappresentare il reale stato dellarte della materia ed il necessario grado di consenso. Chiunque ritenesse, a seguito dellapplicazione di questa norma, di poter fornire suggerimenti per un suo miglioramento o per un suo adeguamento ad uno stato dellarte in evoluzione pregato di inviare i propri contributi allUNI, Ente Nazionale Italiano di Unificazione, che li terr in considerazione per leventuale revisione della norma stessa. Le norme UNI sono revisionate, quando necessario, con la pubblicazione di nuove edizioni o di aggiornamenti. importante pertanto che gli utilizzatori delle stesse si accertino di essere in possesso dellultima edizione e degli eventuali aggiornamenti. Si invitano inoltre gli utilizzatori a verificare lesistenza di norme UNI corrispondenti alle norme EN o ISO ove citate nei riferimenti normativi. UNI EN 15316-4-7:2009 UNI Pagina II

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EUROPEAN STANDARD NORME EUROPENNE EUROPISCHE NORM

ICS 91.140.10

EN 15316-4-7

November 2008

English Version

Heating systems in buildings - Method for calculation of system energy requirements and system efficiencies - Part 4-7: Space heating generation systems, biomass combustion systems

Systmes de chauffage dans les btiments - Mthode de calcul des besoins nergtiques et des rendements des systmes - Partie 4-7 : Systmes de gnration de chauffage des locaux, systmes de combustion de la biomasse Heizungsanlagen in Gebuden - Verfahren zur Berechnung der Energieanforderungen und Nutzungsgrade der Anlagen - Teil 4-7: Wrmeerzeugung fr die Raumheizung, Biomasseverbrennungssystem

This European Standard was approved by CEN on 30 September 2008. CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member. This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions. CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION COMIT EUROPEN DE NORMALISATION EUROPISCHES KOMITEE FR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels

2008 CEN

All rights of exploitation in any form and by any means reserved worldwide for CEN national Members.

Ref. No. EN 15316-4-7:2008: E

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

Contents

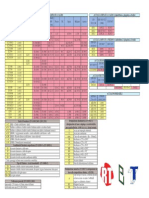

page Foreword ..............................................................................................................................................................4 Introduction .........................................................................................................................................................6 1 2 3 3.1 3.2 4 4.1 4.1.1 4.1.2 4.2 4.3 4.4 4.5 4.6 4.7 5 6 7 7.1 7.2 7.2.1 7.2.2 7.2.3 7.2.4 7.2.5 7.3 7.3.1 7.3.2 7.3.3 7.3.4 7.3.5 7.3.6 7.3.7 7.3.8 7.4 7.4.1 7.4.2 7.4.3 7.4.4 7.4.5 7.4.6 7.4.7 Scope ......................................................................................................................................................6 Normative references ............................................................................................................................6 Terms, definitions, symbols and units ................................................................................................7 Terms and definitions ...........................................................................................................................7 Symbols and units .............................................................................................................................. 10 Principle of the method ...................................................................................................................... 11 Heat balance of the biomass combustion sub-system, including control of heat generation ............................................................................................................................................ 11 Physical factors for biomass combustion sub-system ( biomass boiler ) taken into account ................................................................................................................................................ 11 Calculation structure (input and output data) ................................................................................. 12 Generation sub-system basic energy balance ................................................................................ 13 Auxiliary energy .................................................................................................................................. 14 Recoverable, recovered and unrecoverable system thermal losses ............................................ 14 Calculation steps ................................................................................................................................ 15 Using net or gross calorific values ................................................................................................... 15 Boundaries between distribution and generation sub-system ...................................................... 15 Biomass combustion sub-system calculation ................................................................................ 16 Calculation method for boilers with automatic stocking................................................................ 16 Calculation method for boilers with stocking by hand ................................................................... 16 Available methodologies ................................................................................................................... 16 Operation periods ............................................................................................................................... 16 General ................................................................................................................................................. 16 Heating up operation cycle ................................................................................................................ 17 Boiler heating operation cycle .......................................................................................................... 17 Cooling down operation cycle........................................................................................................... 17 Boiler non operation cycle ................................................................................................................. 18 Case specific boiler efficiency method ............................................................................................ 18 Principle of the method ...................................................................................................................... 18 Input data to the method .................................................................................................................... 19 Load of the boiler ................................................................................................................................ 20 Biomass boiler thermal losses .......................................................................................................... 21 Total auxiliary energy ......................................................................................................................... 23 Recoverable generation system thermal losses ............................................................................. 24 Fuel input ............................................................................................................................................. 25 Operating temperature of the biomass boiler .................................................................................. 25 Boiler cycling method ........................................................................................................................ 26 Principle of the method ...................................................................................................................... 26 Input data for the calculation method............................................................................................... 28 Load factor .......................................................................................................................................... 29 Specific thermal losses ...................................................................................................................... 29 Total thermal losses ........................................................................................................................... 33 Auxiliary energy .................................................................................................................................. 33 Recoverable system thermal losses ................................................................................................. 34

2

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

7.4.8

Calculation procedure for a modulating biomass boiler (fan assisted) ........................................ 34

Annex A (informative) Additional formulas and default values for parametering the case specific boiler efficiency method ..................................................................................................................... 35 A.1 Information on the method ................................................................................................................. 35 A.1.1 Basic assumptions and intended use ............................................................................................... 35 A.1.2 Known approximations ....................................................................................................................... 35 A.2 Boiler efficiencies and stand-by heat losses.................................................................................... 35 A.2.1 Default values for boiler efficiency at full load and intermediate load as a function of the boiler power output ............................................................................................................................. 35 A.2.2 Stand-by heat losses........................................................................................................................... 36 A.2.3 Correction factor taking into account variation of efficiency depending on boiler average water temperature ............................................................................................................................... 37 A.3 Auxiliary energy ................................................................................................................................... 38 A.4 Recoverable boiler thermal losses .................................................................................................... 38 A.4.1 Auxiliary energy ................................................................................................................................... 38 A.4.2 Thermal losses (boiler envelope) ...................................................................................................... 39 A.4.3 Default data according to boiler location .......................................................................................... 39 Annex B (informative) Additional formulas and default values for parametering the boiler cycling method .................................................................................................................................................. 40 B.1 Information on the method ................................................................................................................. 40 B.1.1 Basis assumptions and intended use ............................................................................................... 40 B.1.2 Known approximations ....................................................................................................................... 40 B.2 Default specific losses ........................................................................................................................ 40 B.2.1 Default data for calculation of thermal losses through the chimney with boiler on .................... 40 B.2.2 Default values for calculation of thermal losses through the boiler envelope ............................. 41 B.2.3 Default values for calculation of thermal losses through the chimney with the boiler off .......... 42 B.3 Default values for calculation of auxiliary energy ........................................................................... 43 B.4 Additional default data for modulating burners ............................................................................... 43 Annex C (informative) Storage systems for biomass combustion systems .............................................. 45 C.1 General ................................................................................................................................................. 45 C.1.1 Accumulator storage system ............................................................................................................. 45 C.1.2 Load balancing storage system ......................................................................................................... 45 C.2 Sizing of storage systems for biomass combustion systems........................................................ 45 C.2.1 Sizing of the volume of the accumulator storage tank .................................................................... 45 C.2.2 Sizing of the volume of the load balancing tank .............................................................................. 46 C.3 System thermal losses of storage systems...................................................................................... 46 C.3.1 Thermal losses .................................................................................................................................... 46 C.3.2 Auxiliary energy of the circulation pump .......................................................................................... 47 Annex D (informative) Calculation procedure with an example for biomass boiler with stocking by hand - Case specific boiler efficiency method ................................................................................. 48 Annex E (informative) Calculation procedure with an example for biomass boiler with stocking by hand (Cycling method)........................................................................................................................ 50 Bibliography ...................................................................................................................................................... 53

3

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

Foreword

This document (EN 15316-4-7:2008) has been prepared by Technical Committee CEN/TC 228 Heating systems in buildings, the secretariat of which is held by DS. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by May 2009, and conflicting national standards shall be withdrawn at the latest by May 2009. This document has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association (Mandate M/343), and supports essential requirements of EU Directive 2002/91/EC on the energy performance of buildings (EPBD). It forms part of a series of standards aimed at European harmonisation of the methodology for calculation of the energy performance of buildings. An overview of the whole set of standards is given in CEN/TR 15615. The subjects covered by CEN/TC 228 are the following: design of heating systems (water based, electrical etc.); installation of heating systems; commissioning of heating systems; instructions for operation, maintenance and use of heating systems; methods for calculation of the design heat loss and heat loads; methods for calculation of the energy performance of heating systems.

Heating systems also include the effect of attached systems such as hot water production systems. All these standards are systems standards, i.e. they are based on requirements addressed to the system as a whole and not dealing with requirements to the products within the system. Where possible, reference is made to other European or International Standards, a.o. product standards. However, use of products complying with relevant product standards is no guarantee of compliance with the system requirements. The requirements are mainly expressed as functional requirements, i.e. requirements dealing with the function of the system and not specifying shape, material, dimensions or the like. The guidelines describe ways to meet the requirements, but other ways to fulfil the functional requirements might be used if fulfilment can be proved. Heating systems differ among the member countries due to climate, traditions and national regulations. In some cases requirements are given as classes so national or individual needs may be accommodated. In cases where the standards contradict with national regulations, the latter should be followed. EN 15316 Heating systems in buildings Method for calculation of system energy requirements and system efficiencies consists of the following parts: Part 1: General

4

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

Part 2-1: Space heating emission systems Part 2-3: Space heating distribution systems Part 3-1: Domestic hot water systems, characterisation of needs (tapping requirements) Part 3-2: Domestic hot water systems, distribution Part 3-3: Domestic hot water systems, generation Part 4-1: Space heating generation systems, combustion systems (boilers) Part 4-2: Space heating generation systems, heat pump systems Part 4-3: Heat generation systems, thermal solar systems Part 4-4: Heat generation systems, building-integrated cogeneration systems Part 4-5: Space heating generation systems, the performance and quality of district heating and large volume systems Part 4-6: Heat generation systems, photovoltaic systems Part 4-7: Space heating generation systems, biomass combustion systems According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

5

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

Introduction

This European Standard presents methods for calculation of the additional energy requirements of a heat generation system by biomass combustion in order to meet the distribution and/or storage sub-system demand. The calculation is based on the performance characteristics of the products given in product standards and on other characteristics required to evaluate the performance of the products as included in the system. This method can be used for the following applications: judging compliance with regulations expressed in terms of energy targets; optimisation of the energy performance of a planned heat generation system, by applying the method to several possible options; assessing the effect of possible energy conservation measures on an existing heat generation system, by calculating the energy use with and without the energy conservation measures.

The user needs to refer to other European Standards or to national documents for input data and detailed calculation procedures not provided by this European Standard.

Scope

This European Standard is part of a series of standards on the method for calculation of system energy requirements and system efficiencies of space heating systems and domestic hot water systems. The scope of this specific part is to standardise the: required inputs; calculation method; resulting outputs,

for space heating generation by biomass combustion sub-systems (boilers) with stocking by hand, including control. This European Standard is also intended for the case of generation for both domestic hot water production and space heating. The case of generation only for domestic hot water production is treated in EN 15316-3-3.

Normative references

The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 303-5, Heating boilers Part 5: Heating boilers for solid fuels, hand and automatically stocked, nominal heat output of up to 300 kW Terminology, requirements, testing and marking EN ISO 7345:1995, Thermal insulation Physical quantities and definitions (ISO 7345:1987)

6

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

EN 15316-2-3, Heating systems in building Method for calculation of system energy requirements and system efficiencies Part 2-3: Space heating distribution systems EN 15316-3-2, Heating systems in building Method for calculation of system energy requirements and system efficiencies Part 3-2: Domestic hot water systems, distribution EN 15316-3-3, Heating systems in building Method for calculation of system energy requirements and system efficiencies Part 3-3: Domestic hot water systems, generation EN 15316-4-1:2005, Heating systems in building Method for calculation of system energy requirements and system efficiencies Part 4-1: Space heating generation systems, combustion systems (boilers)

3

3.1

Terms, definitions, symbols and units

Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 7345:1995 and the following apply. 3.1.1 space heating process of heat supply for thermal comfort 3.1.2 domestic hot water heating process of heat supply to raise the temperature of the cold water to the intended delivery temperature 3.1.3 heated space room or enclosure which for the purposes of the calculation is assumed to be heated to a given set-point temperature or set-point temperatures 3.1.4 system thermal loss thermal loss from a technical building system for heating, cooling, domestic hot water, humidification, dehumidification, ventilation or lighting that does not contribute to the useful output of the system

NOTE Thermal energy recovered directly in the subsystem is not considered as a system thermal loss but as heat recovery and is directly treated in the related system standard.

3.1.5 auxiliary energy electrical energy used by technical building systems for heating, cooling, ventilation and/or domestic hot water to support energy transformation to satisfy energy needs

NOTE This includes energy for fans, pumps, electronics etc. Electrical energy input to the a ventilation system for air transport and heat recovery is not considered as auxiliary energy, but as energy use for ventilation.

3.1.6 heat recovery heat generated by a technical building system or linked to a building use (e.g. domestic hot water) which is utilised directly in the related system to lower the heat input and which would otherwise be wasted (e.g. preheating of the combustion air by flue gas heat exchanger) 3.1.7 total system thermal loss total of the technical system thermal loss, including recoverable system thermal losses

7

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

3.1.8 recoverable system thermal loss part of the system thermal loss which can be recovered to lower either the energy need for heating or cooling or the energy use of the heating or cooling system 3.1.9 recovered system thermal loss part of the recoverable system thermal loss which has been recovered to lower either the energy need for heating or cooling or the energy use of the heating or cooling system 3.1.10 gross calorific value quantity of heat released by a unit quantity of fuel, when it is burned completely with oxygen at a constant pressure equal to 101 320 Pa, and when the products of combustion are returned to ambient temperature

NOTE 1 This quantity includes the latent heat of condensation of any water vapour contained in the fuel and of the water vapour formed by the combustion of any hydrogen contained in the fuel. NOTE 2 NOTE 3 According to ISO 13602-2, the gross calorific value is preferred to the net calorific value. The net calorific value does not take into account the latent heat of condensation.

3.1.11 net calorific value gross calorific value minus latent heat of condensation of the water vapour in the products of combustion at ambient temperature 3.1.12 calculation step discrete time interval for the calculation of the energy needs and uses for heating, cooling, humidification and dehumidification

NOTE Typical discrete time intervals are one hour, one day, one month or one heating and/or cooling season, operating modes, and bins.

3.1.13 calculation period period of time over which the calculation is performed

NOTE The calculation period can be divided into a number of calculation steps.

3.1.14 external temperature temperature of external air

NOTE 1 For transmission heat transfer calculations, the radiant temperature of the external environment is supposed equal to the external air temperature; long-wave transmission to the sky is calculated separately. NOTE 2 The measurement of external air temperature is defined in EN ISO 15927-1.

3.1.15 boiler gas, liquid or solid fuelled appliance designed to provide hot water for space heating. It may (but need not) be designed to provide domestic hot water heating as well 3.1.16 combustion power product of the fuel flow rate and the net calorific power of the fuel

8

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

3.1.17 condensing boiler boiler designed to make use of the latent heat released by condensation of water vapour in the combustion flue products. The boiler needs to allow the condensate to leave the heat exchanger in liquid form by way of a condensate drain

NOTE Boilers not so designed, or without the means to remove the condensate in liquid form, are called noncondensing.

3.1.18 modes of operation various modes in which the heating system can operate (set-point mode, cut-off mode, reduced mode, setback mode, boost mode) 3.1.19 modulating boiler boiler with the capability to vary continuously (from a set minimum to a set maximum) the fuel burning rate whilst maintaining continuous burner firing 3.1.20 accumulator (storage) system part of the generation system tank which stores excess heat during operation time (resulting from the difference between the boiler output and the actual heat input to the heating system) 3.1.21 load balancing (storage) system part of the generation system tank which improves the operation conditions during operation time (resulting in reducing the starting intervals and increasing the running time of automatic fired biomass boilers (see EN 15316-4-1) 3.1.22 biomass boiler biomass fuelled appliance designed to provide heating medium (e.g. water, fluid) for space heating 3.1.23 load factor ratio between the time with the boiler ON and the total generator operation time 3.1.24 operation cycle time period of the operation cycle of a boiler

9

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

3.2

Symbols and units

For the purposes of this document, the following symbols and units (Table 1) and indices (Table 2) apply. Table 1 Symbols and units Symbol b c c Name of quantity temperature reduction factor coefficient

c c

Unit various J/kgK or a Wh/kgK J or a Wh J/mass unit or b Wh/mass unit

c

specific heat capacity energy in general (except quantity of heat, mechanical work and auxiliary (electrical) energy expenditure factor factor

c c

E e f H H k m n N P Q t V V' W

calorific value heat transfer coefficient factor mass exponent number of items power in general including electrical power quantity of heat time, period of time volume volume flow auxiliary (electrical) energy, mechanical work loss factor load factor prefix for difference efficiency factor Celsius temperature heat flow rate, thermal power

c

W/K kg integer W J or a Wh s or a h L m/s or a m/h J or a Wh % -

a b c

% C W

If seconds (s) is used as the unit of time, the unit for energy needs to be J; If hours (h) is used as the unit of time, the unit for energy needs to be Wh. Mass unit for fuel may be Stm, Nm or kg. Coefficients have dimensions; factors are dimensionless.

10

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

Table 2 Indices acc aux avg brm accumulator auxiliary average boiler room gen gnr grs H hup i, j, k in ins int lob ls m max mass min net off generation subsystem generator gross heating heating up indices input to subsystem insulation intermediate load balancing losses mean maximum massic minimum net off on op out P0 Pint Pn Px rbl ref rvd s sby ta test W w z on operation output from subsystem at zero load at intermediate load at nominal load at x load recoverable reference recovered gross (calorific value) in stand-by operation tank test conditions heating system water water indices

cham chamber ch ci cmb cod cor ctr dis em fa fib fg ge chimney calculation step combustion cooling down corrected / correction control distribution emission factor fire bed flue gas generator envelope

The indices specifying symbols for sub-system energy balance quantities are in the following order: the first index represents the use (H = space heating, W = domestic hot water etc.); the second index represents the sub-system (gen = generation, dis = distribution etc.); the third index represents the balance item (ls= losses, in = input, aux = auxiliary etc.).

Other indices may follow for more details (rvd = recovered, rbl = recoverable etc.).

4

4.1

Principle of the method

Heat balance of the biomass combustion sub-system, including control of heat generation

Physical factors for biomass combustion sub-system ( biomass boiler ) taken into account

4.1.1

The calculation method of the boiler takes into account heat losses and/or recovery due to the following physical factors: heat losses to the chimney (or flue gas exhaust) during total time of boiler operation (running and stand-by); heat losses through the boiler envelope during total time of boiler operation (running and stand-by); auxiliary energy.

11

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

The relevance of these effects on the energy requirements depends on: type of the boiler; location of the boiler; part load ratio; operating conditions (temperature, control etc.); control strategy (on/off, modulating). Calculation structure (input and output data)

4.1.2

The calculation method of this European Standard shall be based on the following: heat demand of the distribution sub-system(s) for space heating, QH,dis,in, calculated according to EN 15316-2-3; heat demand of the distribution sub-system(s) for domestic hot water, QW,dis,in, calculated according to EN 15316-3-2, where appropriate.

The performance of the boiler may be characterised by additional input data to take into account: type and characteristics of the boiler; boiler settings; type of the boiler control system; location of the boiler; operating conditions; heat requirement.

Based on these data, the following output data are determined by calculations according to this European Standard: fuel heat requirement, EH,gen,in; total generation thermal losses (flue gas and boiler envelope), QH,gen,ls; recoverable generation thermal losses, QH,gen,ls,rbl; generation auxiliary energy, WH,gen,aux.

Figure 1 shows the calculation inputs and outputs of the generation sub-system.

12

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

Key

SUB HF QH,gen,out EH,gen,in WH,gen,aux QH,gen,aux,rvd QH,gen,ls QH,gen,ls,rbl QH,gen,rbl,th QH,gen,rbl,aux QH,gen,nrbl,th QH,gen,nrbl,aux NOTE generation sub-system balance boundary heating fluid balance boundary (see Equation (1)) generation sub-system heat output (input to distribution subsystem(s)) generation sub-system fuel input (energyware) generation sub-system total auxiliary energy generation sub-system recovered auxiliary energy generation sub-system total thermal losses generation sub-system thermal losses recoverable for space heating generation sub-system thermal loss (thermal part) recoverable for space heating generation sub-system recoverable auxiliary energy generation sub-system thermal loss (thermal part) non recoverable generation sub-system non recoverable auxiliary energy

Figures shown are sample percentages.

Figure 1 General generation sub-system inputs, outputs and energy balance

4.2

Generation sub-system basic energy balance

The basic energy balance of the generation sub-system is given by:

E H,gen,in = Q H,gen,out Q H,gen,aux,rvd + Q H,gen,ls

where EH,gen,in QH,gen,out heat requirement of the generation sub-system (fuel input); heat supplied to the distribution sub-systems (space heating);

(1)

13

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

QH,gen,aux,rvd auxiliary energy recovered by the generation sub-system (e.g. pumps, burner fan); QH,gen,ls total thermal losses of the generation sub-system (e.g. through the chimney, generator envelope).

NOTE 1 QH,gen,ls takes into account flue gas and boiler envelope losses, part of which may be recoverable for space heating according to location of the boiler. See A.4.2. NOTE 2 If the boiler provides heat for space heating and domestic hot water, the index H needs to be replaced by HW. In the following (apart from Equation 2), only H is used for simplicity. NOTE 3 Generally biomass boilers are not designed for controlling the emission part of heating systems.

If there is only one boiler, the heat output from the boiler equals the sum of heat input to the connected distribution systems:

Q HW,gen,out =

Q

i

H,dis,in,i

Q

j

W,dis,in, j

(2)

4.3

Auxiliary energy

Auxiliary energy is the energy, other than fuel, required for operation of the burner, the primary pump and any equipment whose operation is related to operation of the heat generation sub-system. Auxiliary energy is accounted for in the generation part as long as no transport energy from the auxiliary equipment is transferred to the distribution sub-system (example: zeropressure distribution array). Such auxiliary equipment can be (but need not be) an integral part of the boiler. Auxiliary energy, normally in the form of electrical energy, may partially be recovered as heat for space heating or for the generation sub-system. Examples of recoverable auxiliary energy:

electrical energy transmitted as heat to the water of the primary circuit; part of the electrical energy for the boiler fan.

Example of non-recoverable auxiliary energy:

electrical energy for electric panel auxiliary circuits, if the boiler is installed outside the heated space.

4.4

Recoverable, recovered and unrecoverable system thermal losses

Not all of the calculated system thermal losses are necessarily lost. Some of the losses are recoverable and part of the recoverable system thermal losses are actually recovered. Example of recoverable system thermal losses:

thermal losses through the envelope of a boiler installed within the heated space.

Examples of non-recoverable system thermal losses:

thermal losses through the envelope of a boiler installed outside the heated space; thermal losses (flue gas losses) through the chimney.

Recovery of system thermal losses to the heated space can be accounted for:

either as a reduction of total system thermal losses within the specific part (simplified method);

14

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

or by taking into account recoverable system thermal losses as gains (holistic method) or as a reduction of the energy use according to EN 15603.

This European Standard allows both approaches. Generation system thermal losses recovered by the generation sub-system are directly taken into account in the generation performance.

EXAMPLE Combustion air preheating by flue gas losses.

4.5

Calculation steps

The objective of the calculation is to determine the energy input of the heating generation sub-system and the system losses for the entire calculation period (usually one year). This may be done in one of the following two different ways:

by using average data for the entire calculation period and performing the calculations using average values (usually annual data and values); by dividing the calculation period into a number of calculation steps (e.g. months, weeks, bins, operation modes as defined in EN ISO 13790), performing the calculations for each step using step-dependent values and sum up the results for all the steps over the calculation period;

For biomass boilers with stocking by hand, the calculation period shall be 24 h.

4.6

Using net or gross calorific values

Calculations described in Clause 7 may be performed according to net or gross calorific values. All parameters and data shall be consistent with this option. If the calculation of the boiler energy performance is performed according to data based on net calorific values Hi, total losses QH,gen,ls,net, non recoverable thermal losses QH,gen,ls,th,nrbl,net and generation sub-system energyware EH,gen,in,net (i.e. fuel input for combustion systems) based on net calorific values may be converted to values QH,gen,ls,grs, QH,gen,ls,th,nrbl,grs and EH,gen,in,grs based on gross calorific values Hs by addition of the latent heat of condensation Qlat according to the following:

Qlat = E H,gen,in,net

Hs Hi Hi

(3)

E H,gen,in,grs = E H,gen,in,net + Qlat QH, gen, ls,grs = QH, gen,ls, net + Qlat QH, gen, ls, th, nrbl,grs = QH, gen,ls, th, nrbl, net + Qlat

(4) (5) (6)

NOTE The latent heat of condensation Qlat varies extremely depending on the type of biomass fuel, place of origin, quality of storing etc. Therefore reference values should be given in a national annex.

4.7

Boundaries between distribution and generation sub-system

Boundaries between generation sub-system and distribution sub-system should be defined according to the principles described in 4.8 of EN 15316-4-1:2005.

15

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

Biomass combustion sub-system calculation

The performance calculation methods for biomass combustion systems differ with respect to:

type of stocking device (automatic or by hand); type of biomass fuel (pellets, chipped wood or log wood).

Calculation method for boilers with automatic stocking

The calculation method for biomass boilers with automatic stocking is comparable to the methods used for automatically fired boilers using oil or gas. The performance calculation methods for biomass boilers with automatic stocking are described in EN 15316-4-1.

NOTE 1 Biomass boilers with automatic stocking fired by pellets or chipped wood.

NOTE 2 For improving the efficiency and reduction of pollution, it is recommended to operate biomass boilers with automatic stocking by a load balancing storage system. For details on the calculation of load balancing storage systems, see Annex C.

7

7.1

Calculation method for boilers with stocking by hand

Available methodologies

In this European Standard, two performance calculation methods for biomass boilers with stocking by hand are described. The calculation methods differ with respect to:

required input data; operating conditions (operation cycles) taken into account; calculation period applied.

The first method (see 7.3, case specific boiler efficiency method) is based on the data related to the test procedures according to EN 303-5, but supplementary data are needed in order to take into account the specific operation conditions during the heating period. The second method (see 7.4, boiler cycling method) distinguishes in an explicit way the losses of the boiler which occurs during the boiler cycling (i.e. combustion losses). Some of the parameters can be measured on site.

NOTE 1 Biomass boilers with stocking by hand fired by logwood.

NOTE 2 According to EN 303-5 it is recommended to operate biomass boilers with stocking by hand with an accumulator storage system. For details on the calculation of accumulator storage systems, see Annex C or EN 303-5.

7.2

7.2.1

Operation periods

General

The operation periods for biomass boilers with stocking by hand are divided into two main periods according to the different types of operation cycles as follows:

boiler in operation tgnr,on consisting of 3 sub-periods:

16

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

boiler heating up boiler heating operation boiler cooling down

tgnr,hup tgnr,op tgnr,cod

boiler in non operation tgnr,off consisting of 2 sub-periods: boiler in fire bed operation boiler in non operation tgnr,fib tgnr,non

The total operation period tgnr,tot of the boiler is given by: tgnr,tot = tgnr,on + tgnr,off

NOTE Boiler in fire bed operation is only relevant for boilers with fan assistance.

(7)

7.2.2

Heating up operation cycle

The operation period for the heating up operation cycle tgnr,hup is influenced by:

quality of the biomass fuel applied; quantity of the biomass fuel applied (according to the required quantity of the loaded biomass fuel). Boiler heating operation cycle

7.2.3

The operation period for the heating operation cycle tgnr,op is influenced by:

quality of the biomass fuel applied; quantity of the biomass fuel applied (according to the required quantity of the loaded biomass fuel); intermediate load of the boiler.

The running time of the boiler in heating operation cycle, tgnr,op,d is calculated by:

t gnr ,op ,d =

where tgnr,op,,d QH,dis,in,d

QH ,dis ,in ,d H , gnr ,out ,avg ,d

(h)

(8)

running time in heating operation cycle within a 24 h operation period in h; heat to be supplied to the distribution system within a 24 h operation period in kWh;

H,gnr,out,avg,d average heat output from the biomass boiler within a 24 h operation period in kW. 7.2.4 Cooling down operation cycle

The operation period for the cooling down operation cycle tgnr,cod is influenced by:

time when the operation cycle starts again; mass of the relevant parts of the boiler;

17

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

water content of the boiler; heat loss of the envelope.

NOTE By a permanent operation cycle it is assumed, that the next heating up operation cycle starts immediately after the end of the cooling down operation cycle.

7.2.5

Boiler non operation cycle

Depending on the heat to be supplied to the distribution system during a 24 h operation period, two different types of non operation cycles are to be considered:

boiler in fire bed operation cycle - operation period tgnr,fib

In this case, the boiler temperature is the same as the regular boiler operating temperature.

NOTE 1

boiler in non operation cycle - operation period tgnr,non

In this case, the boiler temperature is the same as the ambience temperature (no heat loss).

NOTE 2

7.3

7.3.1

Case specific boiler efficiency method

Principle of the method

This method is related to the test values according to relevant European Standards. If no values are available, default values are given in Annex A or in a national annex. a) data are collected for three basic load factors or power outputs:

b)

gnr,Pn efficiency at 100 % load; gnr,Pint efficiency at intermediate load; gnr,ls,P0 heat losses at 0 % load. efficiencies and heat losses data are corrected according to actual boiler operating conditions (temperature); thermal losses at 100 % load, gnr,ls,Pn, and at intermediate load, gnr,ls,Pint, are calculated according to the temperature corrected efficiencies; calculation of thermal losses corresponding to the actual power output is made by linear or polynomial interpolation between thermal losses determined for the three basic power outputs;

NOTE For the case specific boiler efficiency method, thermal losses and the load factor gnr are referred to boiler output.

c)

d)

e) f)

auxiliary energy is calculated taking into account the actual power output of the boiler; recoverable boiler envelope thermal losses are calculated according to a tabulated fraction of stand-by heat losses and boiler location; recoverable auxiliary energy is added to recoverable boiler envelope thermal losses to provide the total recoverable thermal losses.

g)

18

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

7.3.2 7.3.2.1

Input data to the method Boiler data

The boiler is characterised by the following data:

Pn gnr,Pn gnr,w,test,Pn fcorr,Pn Pint gnr,Pint gnr,w,test,Pint fcorr,Pint gnr,ls,P0

boiler output at full load; boiler efficiency at full load; boiler average water temperature at test conditions for full load; correction factor for full-load efficiency; boiler output at intermediate load; boiler efficiency at intermediate load; boiler average water temperature at test conditions for intermediate load; correction factor for intermediate load efficiency; stand-by heat loss at test temperature difference gnr,test,P0; difference between mean boiler temperature and test room temperature at test conditions; power consumption of auxiliary devices at full load; power consumption of auxiliary devices at intermediate load; stand-by power consumption of auxiliary devices; minimum operating boiler temperature.

gnr,test,P0

Paux,gnr,Pn Paux,gnr,Pint Paux,gnr,P0 gnr,w,min

Data to characterise the boiler shall be taken from one of the following sources, listed in priority order: a) b) product data from the manufacturer, if the boiler has been tested according to EN 303-5; default data from the relevant national annex.

If no data according to a) or b) are available, default data are given in Annex A. It shall be recorded whether or not the efficiency values include auxiliary energy recovery. 7.3.2.2 Actual operating conditions

Actual operating conditions are characterised by the following data:

QH,gnr,out heat output to the heat distribution sub-system(s);

gnr,w,m i,brm

bbrm

average water temperature in the boiler; boiler room temperature; temperature reduction factor depending on the location of the boiler.

19

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

7.3.3 7.3.3.1

Load of the boiler Boiler average power

Boiler average power H,gnr,out is given by:

H , gnr , out =

where tgnr,tot 7.3.3.2 is the total time of boiler operation. Load ratio

QH , gnr , out t gnr , tot

(9)

The load ratio factor gnr during the heating operation cycle is given by:

gnr =

where Pn H,gnr,out

H , gnr ,out Pn

(10)

is the nominal power output of the boiler (kW); is the average boiler output (kW).

The average boiler output is calculated by:

gnr ,out =

where gnr,cham

gnr ,cham gnr ,cham, ref

(11)

is the heat output for each filling of the combustion chamber in kW. If the performance of the boiler has been tested according to relevant EN 303-5, it can be taken into account. If no values are available, default values should be given in the relevant national annex;

gnr,cham,ref is the reference combustion power in kW. 7.3.3.3 Boiler with double service (space heating and domestic hot water production)

During the heating season, the boiler may produce energy for the space heating installation and the domestic hot water (double service). For a biomass boiler it is not necessary to consider a specific calculation of the operating temperature.

NOTE The minimum operating temperature of biomass boilers are always higher than the required running temperature of the domestic hot water production.

20

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

7.3.4 7.3.4.1

Biomass boiler thermal losses Biomass boiler thermal loss calculation at full load

The efficiency at full load gnr,Pn is measured at a reference biomass boiler average water temperature gnr,w,test,Pn. This efficiency has to be adjusted to the actual boiler average water temperature of the individual installation. The temperature corrected efficiency at full load gnr,Pn,corr is calculated by:

gnr ,Pn ,corr = gnr , Pn + f corr ,Pn ( gnr ,w,test , Pn gnr ,w,m )

where gnr,Pn

(12)

boiler efficiency at full load. If the performance of the boiler has been tested according to relevant European Standards, it can be taken into account. If no values are available, default values are given in A.2.1 or in the relevant national annex; correction factor taking into account variation of the full load efficiency as a function of the boiler average water temperature. The value should be given in a national annex. In the absence of national values, default values are given in A.2.1. If the performance of the boiler has been tested according to relevant European Standards, it can be taken into account; boiler average water temperature at test conditions for full load (see A.2.3); average water temperature in the boiler, as a function of the specific operating conditions (see 7.3.8).

fcorr,Pn

gnr,w,test,Pn gnr,w,m

In order to simplify the calculations, the efficiencies and heat losses determined at test conditions are adjusted to the actual boiler average water temperature. This is allowed, as it is physically correct to adjust the performance at each load to the actual boiler average water temperature of each load. The corrected biomass boiler thermal loss at full load gnr,ls,Pn,corr is calculated by:

gnr ,ls , Pn ,corr =

where Pn 7.3.4.2 boiler output at full load.

(100 gnr , Pn ,corr )

gnr ,Pn ,corr

Pn

(13)

Biomass boiler thermal loss calculation at intermediate load

gnr,w,test,Pint. This efficiency has to be adjusted to the actual boiler average water temperature of the individual

installation. The temperature corrected efficiency at intermediate load gnr,Pint,corr is calculated by:

The efficiency at intermediate load gnr,Pint is measured at a reference boiler average water temperature

gnr , P int,corr = gnr , P int + f corr , P int ( gnr ,w,test ,P int gnr ,w,m )

where gnr,Pint

(14)

boiler efficiency at intermediate load. If the performance of the boiler has been tested according to relevant European Standards, it can be taken into account. If no values are available, default values are given in A.2.1 or in the relevant national annex;

21

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

fcorr,Pint

correction factor taking into account variation of the efficiency as a function of the boiler average water temperature. The value should be given in a national annex. In the absence of national values, default values are given in A.2.1. If the performance of the boiler has been tested according to relevant European Standards, it can be taken into account;

gnr,w,test,Pint, boiler average water temperature at test conditions for intermediate load (see A.2.3); gnr,w,m average water temperature in the boiler, as a function of the specific operating conditions (see 7.3.8).

The intermediate load depends on the boiler type. Default values are given in A.1. The corrected biomass boiler thermal loss at intermediate load gnr,ls,Pint,corr is calculated by:

gnr ,ls , P int,corr =

where Pint 7.3.4.3

(100 gnr , P int,corr )

gnr ,P int,corr

P int

(15)

boiler output at intermediate load. Biomass boiler thermal loss calculation at 0 % load

The boiler heat loss at 0 % load gnr,ls,P0 is determined for a test temperature difference according to relevant tests. If no manufacturer or national annex data are available, default values are given in A.2.2. The temperature corrected boiler thermal loss at 0 % load gnr,ls,P0,corr is calculated by:

gnr ,ls , P 0,corr

where gnr,ls,P0 gnr,w,m

i ,brm = gnr ,ls , P 0 gnr ,w,m , , 0 gnr test P

1, 25

(16)

heat loss at 0 % load at test temperature difference gnr,test,P0; average water temperature in the boiler, as a function of the specific operating conditions (see 7.3.8); indoor temperature of the boiler room. Default values are given in A.4.3; difference between mean boiler temperature and test room temperature at test conditions. Default values are given in A.2.2. Boiler thermal loss at specific load ratio gnr and power output Px

i,brm

gnr,test,P0

7.3.4.4

The specific load ratio gnr of the boiler is calculated according to 7.3.3. The actual power output Px of the boiler is given by

Px = Pn gnr

(17)

If Px is between 0 (gnr = 0) and Pint (intermediate load, gnr = int = Pint/Pn), the boiler thermal loss gnr,ls,Px is calculated by:

22

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

gnr ,ls , Px =

Px ( gnr ,ls , P int,corr gnr ,ls , P 0,corr ) + gnr ,ls , P 0,corr P int

(18)

If Px is between Pint and Pn (full load, gnr = 1), the boiler thermal loss gnr,ls,Px is calculated by:

gnr ,ls , Px =

Px P int ( gnr ,ls , Pn ,corr gnr ,ls , P int,corr ) + gnr ,ls , P int,corr Pn P int

(19)

gnr,ls,Px may also be calculated by 2nd order polynomial interpolation. An equation for such interpolation is

given in Annex B of EN 15316-4-1:2005. The total boiler thermal loss Qgnr,ls during the considered time of operation tgnr,tot of the biomass boiler is calculated by:

Qgnr , ls = gnr ,ls , Px t gnr , tot

7.3.4.5 Total generation thermal losses

(20)

The total generation sub-system thermal losses are the sum of the boiler thermal losses:

QH,gen,ls = Qgnr,ls

7.3.5 Total auxiliary energy

(21)

The total auxiliary energy for a biomass boiler is given by:

Wgnr,aux = Paux, Px tgnr, tot + Paux, off (tci tgnr, tot )

where Paux,Px Paux,off tci tgnr,tot

(22)

auxiliary power consumption corresponding to the actual power output Px of the boiler; auxiliary power consumption when the boiler is not operating; calculation interval; total time of boiler operation within the calculation interval.

The average auxiliary power consumption for each boiler Paux,Px is calculated by linear interpolation, according to the boiler load gnr, between:

Paux,Pn Paux,Pint Paux,P0

auxiliary power consumption of the boiler at full load (gnr = 1); auxiliary power consumption of the boiler at intermediate load (gnr = int); auxiliary power consumption of the boiler at stand-by (gnr = 0);

If 0 gnr int then Paux,Px is given by:

Paux ,Px = Paux , P 0 +

If int < gnr 1 then Paux,Px is given by:

gnr int

(Paux ,P int Paux ,P 0 )

(23)

23

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

Paux , Px = Paux ,P int +

gnr int (Paux , Pn Paux , P int ) 1 int

(24)

The generation sub-system auxiliary energy WH,gen,aux is given by:

WH,gen,aux = Wgnr,aux

(25)

In the absence of detailed values, the power consumption of the auxiliary equipment can be calculated according to A.3. 7.3.6 7.3.6.1 Recoverable generation system thermal losses Auxiliary energy

For the recoverable auxiliary energy, a distinction is made between:

recoverable auxiliary energy transmitted to the heating medium (e.g. water). It is assumed, that the auxiliary energy transmitted to the energy vector is totally recovered; recoverable auxiliary energy transmitted to the heated space.

The recovered auxiliary energy transmitted to the heating medium Qgnr,aux,rvd is calculated by:

Qgnr ,aux ,rvd = W gnr ,aux f rvd ,aux

where frvd,aux

(26)

part of the auxiliary energy transmitted to the distribution sub-system. The value should be given in a national annex. In the absence of national values, a default value is given in A.4.1.

Recovered auxiliary energy already taken into account in efficiency data shall not be calculated for recovery again. It has to be calculated for auxiliary energy need only.

NOTE Measured efficiency according to relevant standards usually includes the effect of heat recovered from auxiliary energy for combustion air fan, control devices, primary pump (i.e. heat recovered is measured with the useful output).

The recoverable auxiliary energy transmitted to the heated space Qgnr,aux,rbl is calculated by:

Qgnr ,aux ,rbl = W gnr ,aux (1 bbrm ) f rbl ,aux

where frbl,aux

(27)

part of the auxiliary energy not transmitted to the distribution sub-system. The value should be given in a national annex. In the absence of national values, a default value is given in A.4.1. If the performance of the boiler has been certified, it can be taken into account; temperature reduction factor depending on location of the boiler. The value of bbrm should be given in a national annex. In the absence of national values, a default value is given in A.4.3. Boiler thermal loss (boiler envelope)

bbrm

7.3.6.2

Only the thermal losses through the boiler envelope are considered as recoverable. The thermal losses through the boiler envelope are expressed as a fraction of the total stand-by heat losses.

24

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

The recoverable thermal losses through the boiler envelope Qgnr,ls,env,rbl are calculated by:

Qgnr ,ls ,env , rbl = gnr ,ls , P 0 ,corr (1 bbrm ) f gnr ,env t gnr ,tot

where fgnr,env

(28)

thermal losses through the boiler envelope expressed as a fraction of the total stand-by heat losses. The value of fgnr,env should be given in a national annex. In the absence of national values, default values are given in A.4.2. If the performance of the boiler has been tested, it can be taken into account; temperature reduction factor depending on location of the boiler. The value of bbrm should be given in a national annex. In the absence of national values, a default value is given in A.4.3; total time of boiler operation. Total recoverable generation system thermal losses

bbrm tgnr,tot 7.3.6.3

The total recovered auxiliary energy QH,gen,aux,rvd is calculated by:

QH,gen,aux,rvd = Qgnr,aux,rvd

The total recoverable generation system thermal losses QH,gen,ls,rbl are calculated by:

(29)

QH, gen, ls, rbl = Qgnr,ls, env, rbl + Qgnr,aux, rbl

7.3.7 Fuel input

(30)

Fuel heat input EH,gen,in is calculated according to Equation (1). 7.3.8 Operating temperature of the biomass boiler

The operating temperature of the boiler depends on:

type of control (taken into account by a correction factor); technical limit of the boiler (taken into account by the temperature limitation); temperature of the distribution sub-system connected to the generator.

The effect of control on the boiler is assumed to be a varying average temperature of the heat emitters. Therefore two types of boiler control are taken into account:

constant water temperature; variable water temperature depending on the operating range.

The operating temperature of the boiler is considered as

gnr , w, m = max( gnr , w, min , H , dis , m )

(31)

25

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

where gnr,w,min H,dis,m minimum operating boiler temperature for each boiler. The values should be given in a national annex. In the absence of national values, default values are given in A.2.1; temperature for heat distribution and storage system (if required) during the considered period.

7.4

7.4.1

Boiler cycling method

Principle of the method General

7.4.1.1

This calculation method is based on the following principles. 7.4.1.2 Thermal losses of the boiler

Thermal losses of the boiler are taken into account separately for the five operation periods distinguished in 7.2. During the boiler heating up operation, the following thermal losses are taken into account:

heat of flue gas of the boiler according the intermediate load; heat losses through the boiler envelope.

During the boiler heating operation, the following thermal losses are taken into account:

heat of flue gas of the boiler according the intermediate load; heat losses through the boiler envelope at the running temperature.

During the boiler cooling down operation, the following thermal losses are taken into account:

no heat of flue gas of the boiler; heat losses through the boiler envelope.

During the boiler fire bed operation, the following thermal losses are taken into account:

heat of flue gas of the boiler at fire bed load; heat losses through the boiler envelope.

During the boiler non operation, the following thermal losses are taken into account:

no heat of flue gas of the boiler; no heat losses through the boiler envelope.

26

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

7.4.1.3

Auxiliary energy

Auxiliary energy is considered separately for appliances before and after the boiler:

Wbr is the auxiliary energy required by components and devices that are installed before the combustion chamber following the energy path (typically boiler fan, see Figure 2);

NOTE 1 Typically these components and devices are running only when the boiler is on, i.e. during tgnr,on

Waf is the auxiliary energy required by components and devices that are installed after the combustion chamber following the energy path (typically primary pump, see Figure 2).

NOTE 2 Typically these components and devices are running during the entire operation period of the boiler i.e. during tgnr,tot = tgnr,on + tgnr,off.

7.4.1.4

Recovered auxiliary energy

Part of the auxiliary energy will be recovered and considered in the energy balance. Calculation methods are available if detailed information can be used. Default formulas and default values are given in Annex A and Annex B.

NOTE Auxiliary energy transformed into heat and emitted to the heated space may be considered separately and is added to the recoverable heat losses.

7.4.1.5

Basic energy balance

The basic energy balance of the generation sub-system (biomass boiler) is:

QH,gen,out = Qcmb + Qbr + Qpmp Qch,on Qch,off Qgnr, env

NOTE This is the same as equation (1) where:

(32)

and

QH,gen,ls = Qch,on + Qch,off + Qgnr, env , E H,gen,in = Qcmb

QH,gen,aux,rvd = Qbr + Qpmp .

A schematic diagram of the energy balance of the generation sub-system is shown in Figure 2.

27

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

Figure 2 Schematic energy balance of generation sub-system 7.4.2 7.4.2.1 Input data for the calculation method Biomass boiler data

The biomass boiler is characterised by the following data:

cmb cmb,min ref

Pch,on,min

combustion power of the boiler, which is the reference power for Pch,on (either design or actual value); minimum combustion power of the boiler; reference power for the heat loss factors Pch,off and Pgnr,env (usually ref = cmb); heat loss factor Pch,on at minimum combustion power cmb,min; electrical power consumption of auxiliary appliances (before the boiler) ; recovery factor of br; electrical power consumption of auxiliary appliances (before the boiler) at minimum combustion power cmb,min; electrical power consumption of auxiliary appliances (after the boiler); recovery factor of af; average boiler water temperature at test conditions for Pch,on; flue gas temperature at test conditions for Pch,on; temperature of test room for Pgnr,env and Pch,off;

Pch,on, Pch,off , Pgnr,env heat loss factors at test conditions;

br

kbr

br,min af

kaf

gnr,w,m,test ch,test i,brm,test

gnr,env,test difference between average boiler temperature gnr,w,m,test and test room temperature i,brm,test at test conditions for Pgnr,env and Pch,off;

n, m, p

NOTE

exponents for the correction of heat loss factors.

Fan assisted biomass boilers operate in a modulating mode regularly.

28

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

7.4.2.2

Actual operation conditions

Actual operation conditions are characterised by the following data: Qgnr,out net heat output to the heat distribution sub-system(s); average water temperature in the boiler; boiler room temperature; reduction factor taking into account recovery of heat losses through the boiler envelope depending on location of the boiler; load factor.

All powers and the load factor FC refer to boiler input (combustion power).

gnr,w,m i,brm

kgnr,env FC

NOTE

7.4.3

Load factor

The load factor FC is the ratio between the time with the boiler in operation and the total time of boiler operation:

FC =

where tgnr,tot tgnr,on total time of boiler operation

t gnr ,on t gnr ,tot

t gnr ,on t gnr ,on + t gnr ,off

(33)

(h); (h); (h); (h).

(h).

time with the boiler ON (pre- and post-ventilation are not considered)

NOTE 1 The boiler time in operation tgnr,on = tgnr,hup + tgnr,op

tgnr,off

time with the boiler OFF

NOTE 2 The boiler time in non operation tgnr,off = tgnr,cod + tgnr,fib + tgnr,non

The load factor shall either be calculated according to the actual energy, Qgnr,out, to be supplied by the boiler or be measured (e.g. by time counters) on existing systems.

NOTE 3 The boiler heating up time tgnr,hup depends on: - total mass of the boiler ( metal + refractory + insulating materials ) - net calorific value of the fuel ( logwood ). The boiler cooling down time tgnr,cod depends on: - total mass of the boiler ( metal + refractory + insulating materials ) - quality of the insulating materials of the boiler..

NOTE 4

7.4.4 7.4.4.1

Specific thermal losses General

Specific heat losses of the boiler are given at standard test conditions. Test conditions are identified by a quote. Heat losses at test conditions are expressed as a percentage (Pch,on, Pch,off and Pgnr,ge) of a reference power at test conditions.

29

UNI EN 15316-4-7:2009

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2009. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-4-7:2008 (E)

Test values shall be adjusted according to actual operation conditions. This applies both to standard test values and to field measurements. 7.4.4.2 Thermal losses through the chimney with the boiler on, Pch,on

The correction method for this loss factor takes into account the effects of:

average water temperature in the boiler; load factor; boiler settings (power and excess air changing the heat exchange efficiency).

Actual specific thermal losses through the chimney with the boiler on Pch,on are given by:

Pch, on = P'ch, on + ( gnr , w, m gnr , w, m ,test ) f corr FC n

where Pch,on

(34)