Professional Documents

Culture Documents

Piping

Uploaded by

zidaaanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Piping

Uploaded by

zidaaanCopyright:

Available Formats

Piping - Wikipedia, the free encyclopedia

https://en.wikipedia.org/wiki/Piping

Piping

From Wikipedia, the free encyclopedia

For other uses, see Internal erosion, Piping (sewing), Bagpipes, Pipe (fluid conveyance), or Pipe (disambiguation). Within industry, piping is a system of pipes used to convey fluids (liquids and gases) from one location to another. The engineering discipline of piping design studies the efficient transport of fluid.[1][2] Industrial process piping (and accompanying in-line components) can be manufactured from wood, fiberglass, glass, steel, aluminum, plastic, copper, and concrete. The in-line components, known as fittings, valves, and other devices, typically sense and control the pressure, flow rate and temperature of the transmitted fluid, and usually are included in the field of Piping Design (or Piping Engineering). Piping systems are documented in piping and instrumentation diagrams (P&IDs). If necessary, pipes can be cleaned by the tube cleaning process. "Piping" sometimes refers to Piping Design, the detailed specification of the physical piping layout within a process plant or commercial building. In earlier days, this was sometimes called Drafting, Technical drawing, Engineering Drawing, and Design but is today commonly performed by Designers who have learned to use automated Computer Aided Drawing / Computer Aided Design (CAD) software. Plumbing is a piping system with which most people are familiar, as it constitutes the form of fluid transportation that is used to provide potable water and fuels to their homes and businesses. Plumbing pipes also remove waste in the form of sewage, and allow venting of sewage gases to the outdoors. Fire sprinkler systems also use piping, and may transport nonpotable or potable water, or other fire-suppression fluids. Piping also has many other industrial applications, which are crucial for moving raw and semi-processed fluids for refining into more useful products. Some of the more exotic materials of construction are Inconel, titanium, chrome-moly and various other steel alloys.

Large-scale piping system in an HVAC mechanical room

Contents

1 Engineering subfields 2 Stress analysis 3 Wooden piping history 4 Materials 5 Standards 6 See also 7 References 8 Further reading 9 External links

Engineering subfields

Generally, industrial piping engineering has three major subfields: Piping material Piping design Stress analysis

Stress analysis

Process piping and power piping are typically checked by pipe stress engineers to verify that the routing, nozzle loads, hangers, and supports are properly placed and selected such that allowable pipe

1 4 01 4 ! 2: 2 6 13/03/10 #

PDF created with pdfFactory Pro trial version www.pdffactory.com

Piping - Wikipedia, the free encyclopedia

https://en.wikipedia.org/wiki/Piping

stress is not exceeded under different situation such as sustain, operating, pressure testing etc., as per the ASME B31, EN 13480 or any other applicable codes and standards. It is necessary to evaluate the mechanical behavior of the piping under regular loads (internal pressure and thermal stresses) as well under occasional and intermittent loading cases such as earthquake, high wind or special vibration, and water hammer.[3][4] This evaluation is usually performed with the assistance of a specialized (finite element) pipe stress analysis computer program. In cryogenic pipe supports, most steel become more brittle as the temperature decreases from normal operating conditions, so it is necessary to know the temperature distribution for cryogenic conditions. Steel structures will have areas of high stress that may be caused by sharp corners in the design, or inclusions in the material.[5]

Wooden piping history

Early wooden pipes were constructed out of logs that had a large hole bored lengthwise through the center. Later wooden pipes were constructed with staves and hoops similar to wooden barrel construction. Stave pipes have the advantage that they are easily transported as a compact pile of parts on a wagon and then assembled as a hollow structure at the job site. Wooden pipes were especially popular in mountain regions where transport of heavy iron or concrete pipes would have been difficult. Wooden pipes were easier to maintain than metal, because the wood did not expand or contract with temperature changes as much as metal and so consequently expansion joints and bends were not required. The thickness of wood afforded some insulating properties to the pipes which helped prevent freezing as compared to metal pipes. Wood used for water pipes also does not rot very easily. Electrolysis, that bugbear of many iron pipe systems, doesn't affect wood pipes at all, since wood is a much better electrical insulator. In the Western United States where redwood was used for pipe construction, it was found that redwood had "peculiar properties" that protected it from weathering, acids, insects, and fungus growths. Redwood pipes stayed smooth and clean indefinitely while iron pipe by comparison would rapidly begin to scale and corrode and could eventually plug itself up with the corrosion. [6]

Materials

The material with which a pipe is manufactured often forms as the basis for choosing any pipe. Materials that are used for manufacturing pipes include: Carbon steel Low temperature service carbon steel Stainless steel Nonferrous metals, e.g. cupro-nickel Nonmetallic, e.g. tempered glass

Standards

There are certain standard codes that need to be followed while designing or manufacturing any piping system. Organizations that promulgate piping standards include: ASME - The American Society of Mechanical Engineers - B31 series ASME B31.1 Power piping (steam piping etc.) ASME B31.3 Process piping ASME B31.4 Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids ASME B31.5 Refrigeration piping and heat transfer components ASME B31.8 Gas transmission and distribution piping systems ASME B31.9 Building services piping ASME B31.11 Slurry Transportation Piping Systems ASME B31.12 Hydrogen Piping and Pipelines ASTM - American Society for Testing and Materials API - American Petroleum Institute EN 13480 - European metallic industrial piping code EN 13480-1 Metallic industrial piping - Part 1: General EN 13480-2 Metallic industrial piping - Part 2: Materials EN 13480-3 Metallic industrial piping - Part 3: Design and calculation

2 4 01

PDF created with pdfFactory Pro trial version www.pdffactory.com

4 ! 2: 2 6 13/03/10 #

Piping - Wikipedia, the free encyclopedia

https://en.wikipedia.org/wiki/Piping

EN 13480-4 Metallic industrial piping - Part 4: Fabrication and installation EN 13480-5 Metallic industrial piping - Part 5: Inspection and testing EN 13480-6 Metallic industrial piping - Part 6: Additional requirements for buried piping PD TR 13480-7 Metallic industrial piping - Part 7: Guidance on the use of conformity assessment procedures EN 13480-8 Metallic industrial piping - Part 8: Additional requirements for aluminium and aluminium alloy piping EN 1993-4-3 Eurocode 3 Design of steel structures - Part 4-3: Pipelines AWS - American Welding Society AWWA - American Water Works Association MSS ! Manufacturers' Standardization Society ANSI - American National Standards Institute NFPA - National Fire Protection Association EJMA - Expansion Joint Manufacturers Association

See also

Firestop Gasket Hydraulic machinery Hydrogen piping Hydrostatic test Pipe network analysis Piping and plumbing fittings Coupling (piping) Double-walled pipe Elbow (piping) Nipple (plumbing) Pipe cap Street elbow Union (plumbing) Valve Victaulic Plumbing Plastic pipework Plastic Pressure Pipe Systems Riser clamp Thermal insulation

Pipeline pre-commissioning

References

1. 2. 3. 4. 5. 6. ^ Editors: Perry, R.H. and Green, D.W. (1984). Perry's Chemical Engineers' Handbook (6th Edition ed.). McGraw-Hill Book Company. ISBN 0-07-049479-7. ^ Editor: McKetta, John J. (1992). Piping Design Handbook. Marcel Dekker, Inc. ISBN 0-8247-8570-3. ^ Process Piping: ASME B31.3 (http://catalog.asme.org/books/PrintBook/Process_Piping_Complete_Guide.cfm) ^ Power Piping: ASME B31.1 (http://catalog.asme.org/Codes/PrintBook/B311_2004_Power_Piping.cfm) ^ Temperature & Stress Analysis (http://www.pipingtech.com/technical/pdf/tempstress-cryoshoes.pdf) Piping Technology and Products, (retrieved February 2012) ^ Piping water through miles of Redwood, Popular Science monthly, December 1918, page 74, Scanned by Google Books: http://books.google.com/books?id=EikDAAAAMBAJ&pg=PA74

Further reading

ASME B31.3 Process Piping Guide, Revision 2 (http://engstandards.lanl.gov/esm/pressure_safety/process_piping_guide_R2.pdf) from Los Alamos National Laboratory Engineering Standards Manual OST220-03-01-ESM Seismic Design and Retrofit of Piping Systems, July 2002 (http://www.americanlifelinesalliance.org/pdf/Seismic_Design_and_Retrofit_of_Piping_Systems.pdf) from American Lifelines Alliance website Engineering and Design, Liquid Process Piping. Engineer manual, entire document (http://publications.usace.army.mil/publications/eng-manuals/EM_1110-1-4008_sec/EM_1110-1-4008.pdf) " (index page) (http://publications.usace.army.mil/publications/eng-manuals/EM_1110-1-4008_sec/toc.htm) " U.S. Army Corps of Engineers, EM 1110-l-4008, May 1999

4 ! 2: 2 6 13/03/10 #

3 4 01

PDF created with pdfFactory Pro trial version www.pdffactory.com

Piping - Wikipedia, the free encyclopedia

https://en.wikipedia.org/wiki/Piping

External links

Building services piping links (http://www.dmoz.org//Construction_and_Maintenance/Materials_and_Supplies/Mechanical/Building_Services_Piping/) on the Open Directory Project Retrieved from "http://en.wikipedia.org/w/index.php?title=Piping&oldid=597658207" Categories: Piping Plumbing Chemical engineering Mechanical engineering Building engineering This page was last modified on 1 March 2014 at 12:29. Text is available under the Creative Commons Attribution-ShareAlike License; additional terms may apply. By using this site, you agree to the Terms of Use and Privacy Policy. Wikipedia# is a registered trademark of the Wikimedia Foundation, Inc., a non-profit organization.

4 4 01

PDF created with pdfFactory Pro trial version www.pdffactory.com

4 ! 2: 2 6 13/03/10 #

You might also like

- PIPING SYSTEM DESIGN GUIDEDocument6 pagesPIPING SYSTEM DESIGN GUIDEMananNo ratings yet

- PipingDocument4 pagesPipingramthecharm_46098467No ratings yet

- 1 PipelineDocument69 pages1 PipelineEhab MohammedNo ratings yet

- Distillation Column Nozzle Location Guidelines PDFDocument21 pagesDistillation Column Nozzle Location Guidelines PDFShyam MurugesanNo ratings yet

- Piping Engineering Course OverviewDocument2 pagesPiping Engineering Course Overviewmayur_lanjewar0% (1)

- HOBAS Pressure Pipes SystemsDocument40 pagesHOBAS Pressure Pipes Systemsu_florinNo ratings yet

- 2007 Catalog Constant SpringDocument36 pages2007 Catalog Constant Springinfo592No ratings yet

- Introduction to Piping Materials Department ActivitiesDocument23 pagesIntroduction to Piping Materials Department Activitiesvikas2510100% (1)

- Basics of Piping Engineering - Online Certificate CourseDocument2 pagesBasics of Piping Engineering - Online Certificate CourseSharjeel Aslam FaizNo ratings yet

- Piping Engineering NotesDocument46 pagesPiping Engineering NoteslightsonsNo ratings yet

- Spring Support Used in PipingDocument7 pagesSpring Support Used in Pipingashish.mathur1No ratings yet

- 7hfkqlfdouhsruw Dvnhwvirusro/Hwk/Ohqh3 (SLSHFRQQHFWLRQV: A Technical Paper Presented by James Walker Australia Pty LTDDocument16 pages7hfkqlfdouhsruw Dvnhwvirusro/Hwk/Ohqh3 (SLSHFRQQHFWLRQV: A Technical Paper Presented by James Walker Australia Pty LTDthmaraishriNo ratings yet

- 436 Piping Course DescriptionDocument2 pages436 Piping Course DescriptionAnonymous q9eCZHMuS100% (1)

- Fully and Partially Jacketed Piping SystemsDocument15 pagesFully and Partially Jacketed Piping SystemsSUKANTA DALAI100% (1)

- OMV Piping Design PhilosophyDocument41 pagesOMV Piping Design PhilosophyHedi Ben MohamedNo ratings yet

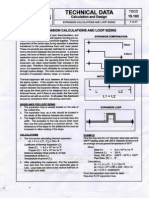

- Expansion Calculation and Loop Sizing001Document2 pagesExpansion Calculation and Loop Sizing001Joseph R. F. DavidNo ratings yet

- Underground Piping EngineeringDocument4 pagesUnderground Piping Engineeringsammar_10No ratings yet

- Fluor Piping TraingTOCDocument1 pageFluor Piping TraingTOCSergio SmithNo ratings yet

- Typical Arrangement of Air Cooler PipingDocument4 pagesTypical Arrangement of Air Cooler Pipingvedadon100% (1)

- Process Plant Layout & Piping Design FundamentalsDocument2 pagesProcess Plant Layout & Piping Design FundamentalsSamer Houzayn50% (2)

- Smith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureDocument8 pagesSmith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureWong Chung MengNo ratings yet

- Surge Analysis: Mostafa Ajjawi, Jr. Engineer 16230 Mr. Barry Howe, Head of Piping StressDocument17 pagesSurge Analysis: Mostafa Ajjawi, Jr. Engineer 16230 Mr. Barry Howe, Head of Piping StressprashantNo ratings yet

- Implementation of Expansion LoopsDocument13 pagesImplementation of Expansion LoopsSSSNo ratings yet

- Best Practices For Flexible Pipe Integrity EvolveDocument6 pagesBest Practices For Flexible Pipe Integrity Evolvebello imamNo ratings yet

- Technical Bid Evaluation of Vendor Spring Hanger Offers With PDFDocument3 pagesTechnical Bid Evaluation of Vendor Spring Hanger Offers With PDFAmjadali ChoudhariNo ratings yet

- HDPE CatalogueDocument98 pagesHDPE Cataloguemohamed fathiNo ratings yet

- Piping Scope of Work FEEDDocument2 pagesPiping Scope of Work FEEDAfolabi OlaniyiNo ratings yet

- NORSOK Standard Piping Details L-CR-003Document41 pagesNORSOK Standard Piping Details L-CR-003Thiên KhánhNo ratings yet

- Piping EngineeringDocument15 pagesPiping EngineeringRANJITHNo ratings yet

- Piping Designers Vessel OrientationDocument13 pagesPiping Designers Vessel OrientationkazishidotaNo ratings yet

- Thumb RuleDocument42 pagesThumb RuleShabeer KiblaalamNo ratings yet

- PIPING PROCEDURESDocument9 pagesPIPING PROCEDURESippon_osotoNo ratings yet

- Pipe Stress Manhours Estimation (Node Wise)Document7 pagesPipe Stress Manhours Estimation (Node Wise)pipestressNo ratings yet

- Piping Engineering Certification CourseDocument22 pagesPiping Engineering Certification Courseshiraz ahmedNo ratings yet

- Wavistrong Product CatalogueDocument114 pagesWavistrong Product CatalogueBINODH DNo ratings yet

- BL Responsibilities TemplateDocument3 pagesBL Responsibilities TemplateAbdul MalikNo ratings yet

- Checklist of Support DesignDocument2 pagesChecklist of Support DesignSakshi AgrawalNo ratings yet

- Flare Line Stress AnalysisDocument7 pagesFlare Line Stress AnalysisdhurjatibhuteshNo ratings yet

- Pipeline Leak Repair Solutions for Corrosion, Damage and TheftsDocument6 pagesPipeline Leak Repair Solutions for Corrosion, Damage and TheftsGhufran Ahmed BalaNo ratings yet

- Pipeline Lowering Analysis at Limited SpaceDocument2 pagesPipeline Lowering Analysis at Limited SpaceArvin PutrantoNo ratings yet

- FuturePipe Installation Manual 18-7-05 PDFDocument25 pagesFuturePipe Installation Manual 18-7-05 PDFPaul WoworNo ratings yet

- Codes and Standards: Piping EngineeringDocument23 pagesCodes and Standards: Piping EngineeringAnnieMalikNo ratings yet

- Standard Pipe SupportsDocument73 pagesStandard Pipe SupportsSaad Ahmad Siddiqui100% (1)

- Overview of GRP PipesDocument14 pagesOverview of GRP PipesMD IBRARNo ratings yet

- Pipe SupportDocument19 pagesPipe SupportScarlet Shwe50% (2)

- Piping Material Specification - Tsmto 99fu M 99 Pt0 001 Rev0!3!65Document64 pagesPiping Material Specification - Tsmto 99fu M 99 Pt0 001 Rev0!3!65epbamdad100% (1)

- Pipe Support ProcedureDocument21 pagesPipe Support ProcedureEfrain PonseNo ratings yet

- An Introduction To Pipe Supports PDFDocument22 pagesAn Introduction To Pipe Supports PDFrajuksk_piping100% (1)

- F681-82 (2014) Standard Practice For Use of Branch ConnectionsDocument5 pagesF681-82 (2014) Standard Practice For Use of Branch ConnectionsCarlos Guillermo Somoza AlvarengaNo ratings yet

- Steps For The Procurement of Piping / Mechanical ItemsDocument2 pagesSteps For The Procurement of Piping / Mechanical ItemsSanjeev KumarNo ratings yet

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988From EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionFrom EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNo ratings yet

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- Piping - WikipediaDocument6 pagesPiping - Wikipediaramthecharm_46098467No ratings yet

- Piping Stress 123Document8 pagesPiping Stress 123Arun NambiarNo ratings yet

- Piping: For Other Uses, See,, Bagpiping, Or, orDocument4 pagesPiping: For Other Uses, See,, Bagpiping, Or, orHarlon BartolomeNo ratings yet

- Piping 2Document7 pagesPiping 2Jeffrey SsalonNo ratings yet

- Piping: Piping Sometimes Refers To Piping Design, The Detailed Specification of TheDocument5 pagesPiping: Piping Sometimes Refers To Piping Design, The Detailed Specification of ThesiswoutNo ratings yet

- Experimental Analysis of TIG Welding and Comparison Between Activated-TIG and TIG On Duplex Stainless Steel (2205)Document8 pagesExperimental Analysis of TIG Welding and Comparison Between Activated-TIG and TIG On Duplex Stainless Steel (2205)zidaaanNo ratings yet

- Effect of Welding On Microstructure and Mechanical Properties of An Industrial Low Carbon Steel PDFDocument5 pagesEffect of Welding On Microstructure and Mechanical Properties of An Industrial Low Carbon Steel PDFzidaaanNo ratings yet

- Friction Stir Welding A Brief DiscrptionDocument7 pagesFriction Stir Welding A Brief DiscrptionzidaaanNo ratings yet

- Eagle PDFDocument6 pagesEagle PDFzidaaanNo ratings yet

- Cobalt - The silvery-gray metal elementDocument6 pagesCobalt - The silvery-gray metal elementzidaaanNo ratings yet

- Self Help Handbook 2015 PDFDocument30 pagesSelf Help Handbook 2015 PDFHomitchi SorinaNo ratings yet

- Lecture1 PDFDocument7 pagesLecture1 PDFarunNo ratings yet

- Butterfly: Butterflies Butterflies Are Part of The Class of Insects in The Order Lepidoptera, Along With The Moths. AdultDocument2 pagesButterfly: Butterflies Butterflies Are Part of The Class of Insects in The Order Lepidoptera, Along With The Moths. AdultzidaaanNo ratings yet

- Lecture1 PDFDocument7 pagesLecture1 PDFarunNo ratings yet

- Machine Design Jindall (Part Of)Document187 pagesMachine Design Jindall (Part Of)zidaaanNo ratings yet

- Fatigue Life Estimates Using Goodman DiagramsDocument11 pagesFatigue Life Estimates Using Goodman Diagramsloveleshvarma100% (1)

- Eagle PDFDocument6 pagesEagle PDFzidaaanNo ratings yet

- SnakeDocument12 pagesSnakezidaaanNo ratings yet

- Aluminium OxideDocument3 pagesAluminium OxidezidaaanNo ratings yet

- Antenna: Science and EngineeringDocument1 pageAntenna: Science and EngineeringzidaaanNo ratings yet

- SulfurDocument20 pagesSulfurzidaaanNo ratings yet

- PlasterDocument3 pagesPlasterzidaaanNo ratings yet

- Tungsten CarbideDocument3 pagesTungsten CarbidezidaaanNo ratings yet

- PoisonDocument7 pagesPoisonzidaaanNo ratings yet

- BainiteDocument3 pagesBainitezidaaanNo ratings yet

- Very Important On Bead GeometryDocument10 pagesVery Important On Bead GeometryzidaaanNo ratings yet

- Electrical Discharge MachiningDocument6 pagesElectrical Discharge MachiningzidaaanNo ratings yet

- Eddy-Current Testing - Wikipedia, The Free Encyclopedia PDFDocument3 pagesEddy-Current Testing - Wikipedia, The Free Encyclopedia PDFzidaaanNo ratings yet

- CarbonDocument19 pagesCarbonzidaaanNo ratings yet

- Eddy-Current Testing - Wikipedia, The Free Encyclopedia PDFDocument3 pagesEddy-Current Testing - Wikipedia, The Free Encyclopedia PDFzidaaanNo ratings yet

- TinDocument16 pagesTinzidaaanNo ratings yet

- CNC G-Code Programming Tutorial, Course, Examples, and ProgramsDocument5 pagesCNC G-Code Programming Tutorial, Course, Examples, and Programszidaaan0% (1)

- TitaniumDocument17 pagesTitaniumzidaaanNo ratings yet

- ZincDocument29 pagesZinczidaaanNo ratings yet

- Polarity (Mutual InductanceDocument3 pagesPolarity (Mutual InductancezidaaanNo ratings yet

- Mechanics of Material Lab ManualDocument64 pagesMechanics of Material Lab ManualMOAZNo ratings yet

- Ejercicios CORIOLIS PDFDocument2 pagesEjercicios CORIOLIS PDFAlejandro CGNo ratings yet

- (865 VHP) - Motor Grader Tier 3 (Na) - Asn N8AF04429 (7/05-12/08) (02-16 (01) ) - AIR CLEANER - ASSEMBLY Case ConstructuionDocument3 pages(865 VHP) - Motor Grader Tier 3 (Na) - Asn N8AF04429 (7/05-12/08) (02-16 (01) ) - AIR CLEANER - ASSEMBLY Case ConstructuionRjg EarthmoversNo ratings yet

- Climate Control PDFDocument80 pagesClimate Control PDFArivup PavalanNo ratings yet

- Properties of Fluids ExplainedDocument13 pagesProperties of Fluids ExplainedGie Andal0% (3)

- Accra Technical University: Index NumberDocument6 pagesAccra Technical University: Index NumberMoro Adams100% (1)

- Section D Grilles and RegistersDocument227 pagesSection D Grilles and RegistersacrisostoNo ratings yet

- 18Pph204: Statistical Mechanics and Thermodynamics: SRM Institute of Science and TechnologyDocument3 pages18Pph204: Statistical Mechanics and Thermodynamics: SRM Institute of Science and TechnologyVijayNo ratings yet

- ARE 301-Strength-of-Materials-ver-2021Document8 pagesARE 301-Strength-of-Materials-ver-2021Ferlyn MendezNo ratings yet

- Slip and Crystallographic TexturesDocument34 pagesSlip and Crystallographic TexturesSunkulp GoelNo ratings yet

- Reinforced Concrete Water Tank: Chapter EightDocument40 pagesReinforced Concrete Water Tank: Chapter Eightshna jabarNo ratings yet

- Acom85 - 4 High Temperature Behaviour of The Austenitic SS UNS S30815 (253 MA) & Weldments PDFDocument16 pagesAcom85 - 4 High Temperature Behaviour of The Austenitic SS UNS S30815 (253 MA) & Weldments PDFpipedown456No ratings yet

- Experienciasd en La Inspeccion de Calentadores de Aceite Termico Segun API RP573Document10 pagesExperienciasd en La Inspeccion de Calentadores de Aceite Termico Segun API RP573edgarmerchanNo ratings yet

- Ninja Part PDFDocument105 pagesNinja Part PDFErlangga AlamNo ratings yet

- 207ACBH-2-SS Parker Brass FittingDocument24 pages207ACBH-2-SS Parker Brass FittingMROstop.comNo ratings yet

- Non-Uniform Torsional Behavior and Stability of Thin-Walled Elastic Beams With Arbitrary Cross SectionsDocument25 pagesNon-Uniform Torsional Behavior and Stability of Thin-Walled Elastic Beams With Arbitrary Cross SectionsSimon TileNo ratings yet

- Soils and Foundations - Failure behavior of soil nail reinforced slopesDocument13 pagesSoils and Foundations - Failure behavior of soil nail reinforced slopesRivaiNo ratings yet

- SSK DUZCE HOSPITAL CENTRAL MEDICAL GAS SUPPLY SYSTEM DESIGNDocument6 pagesSSK DUZCE HOSPITAL CENTRAL MEDICAL GAS SUPPLY SYSTEM DESIGNAhmed Abo RashedNo ratings yet

- UTDocument346 pagesUTramdhani100% (1)

- Analysis of Water Hammering in Pipeline and Its CFD SimulationDocument6 pagesAnalysis of Water Hammering in Pipeline and Its CFD SimulationDuzzysNo ratings yet

- 08.precommissioning Checklist GeneralDocument19 pages08.precommissioning Checklist GeneralAnujGarg100% (1)

- Syphon For Pressure Measuring Instruments Model 910.15: ApplicationsDocument4 pagesSyphon For Pressure Measuring Instruments Model 910.15: Applicationsluis carlos martin contrerasNo ratings yet

- TM 5-3805-255-14 Ihc Model 100CDocument1,460 pagesTM 5-3805-255-14 Ihc Model 100CAdvocate100% (2)

- Marcet Boiler Final Lab ReportDocument14 pagesMarcet Boiler Final Lab ReportHerschelle ShongweNo ratings yet

- Air Handling Units GuidelineDocument5 pagesAir Handling Units GuidelineImam MansyurNo ratings yet

- Ed FTV-B PDFDocument32 pagesEd FTV-B PDFChâu Văn KhánhNo ratings yet

- Automotive Steering System Day 1Document49 pagesAutomotive Steering System Day 1Amrit TiwariNo ratings yet

- Lg956l&Lg958l&Lg959 Service ManualDocument367 pagesLg956l&Lg958l&Lg959 Service ManualAimHigh100% (1)

- Earthquake DescriptorsDocument13 pagesEarthquake DescriptorsDiane Demariano Torcuator60% (5)

- 2014 BMW R 1200 GS AdventureDocument176 pages2014 BMW R 1200 GS AdventurePelijuha100% (1)