Professional Documents

Culture Documents

Reverseengineeringprojectreport

Uploaded by

api-249141434Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reverseengineeringprojectreport

Uploaded by

api-249141434Copyright:

Available Formats

Computer Mouse Reverse Engineering Project

Daniel Kane

Engineering Foundations Mr. Hendricks September 16 2013 B5

Many simple everyday objects are often taken for granted without any thought going into why or how it works. This report will analyze the process of reverse

engineering a simple computer mouse. To reverse engineer an object is to take it apart and determine how it was assembled and what it is made of. The computer mouse that was disassembled was a basic two-button ballcontrolled mouse with no scroll wheel measuring roughly 115mm X 62mm. The purpose of the project was to determine how the mouse operates, what materials make up the mouse and how the mouse is constructed. All measurements were measured with callipers. The function of the mouse is simply to move the cursor and click two buttons to send information to the computer. The smooth adjusting cursor is controlled by a ball with a diameter of 21.2mm. The ball is made of hard rubber to increase friction against the pad (or any other surface to operate the mouse on). The ball is located in the center of the mouse with small plastic 2.45mm bars on two sides of the ball, 90 to each other, which rotate 17.7mm gears which send information to the computer. The gears send information to the computer by way of an infrared sensor that detects the presence of infrared light shining through the teeth of the gear. Each tooth on the gear moves in between the infrared light and the infrared sensor. When the detector senses that the infrared light is blocked or if the detector is illuminated, it will send a signal to the computer to move the cursor. The teeth on the gear are spaced apart little enough and the gear moves fast enough to make a smooth path of the cursor. The ball-gear system is shown below with a photograph of the mouse in the dark. Human eyes cannot detect

infrared but a digital camera can. The mouse is made of mostly hard plastic on the outside with some metal electrical components and the rubber ball. The main body of the mouse is plastic because the plastic is lightweight, inexpensive and fairly durable. Plastic is a good choice for electronics in general because metal conducts electricity which could potentially lead to electrical problems. The ball that controls the cursor position is made of solid rubber to provide adequate friction but hard enough to not stick to parts inside the mouse. There are also many metal electrical components that send information to the computer.

The mouse is held together with a single screw with two plastic latches in front by the two keys. The mouse isnt very likely to fall apart in the way it is held together, the engineers did a good job designing it in that sense. While the mouse is very durable, it is still easy to open it with just a screwdriver to clean it. The screw is in the back of the under-side of the mouse with two latches in the front to hold it down. The mouse was easily disassembled with a philips screwdriver. The process of reverse engineering the computer mouse showed just how carefully and well thought out the design and manufacture of the mouse must be to accomplish its purpose. While the mouse is complex in some ways, it is still fairly simple compared to more modern computer controls.

You might also like

- Weight & Bolting - Rev0Document32 pagesWeight & Bolting - Rev0Nasrul Adli100% (1)

- Computer MouseDocument15 pagesComputer Mouserichad villanuevaNo ratings yet

- Cubase 6 Manual Español e Inglés PDFDocument117 pagesCubase 6 Manual Español e Inglés PDFJorge William Rueda CanoNo ratings yet

- Understanding Optical Mice White PaperDocument6 pagesUnderstanding Optical Mice White PaperSiulfer MosqueiraNo ratings yet

- Hardware Research - Mouse 2Document20 pagesHardware Research - Mouse 2api-510494936No ratings yet

- How to Profit and Protect Yourself from Artificial IntelligenceFrom EverandHow to Profit and Protect Yourself from Artificial IntelligenceNo ratings yet

- Computer SkillsDocument5 pagesComputer SkillsHalar NawazNo ratings yet

- CH 31Document7 pagesCH 31onlydlonly67% (3)

- Ucet Vbu ,: HazaribaghDocument10 pagesUcet Vbu ,: HazaribaghAnkit SinghNo ratings yet

- Technical Description of A Computer MouseDocument4 pagesTechnical Description of A Computer MouseHawaiiChongNo ratings yet

- Expno 19Document3 pagesExpno 19sujal patadeNo ratings yet

- Choosing the Right Gaming MouseDocument3 pagesChoosing the Right Gaming MouseAhsanul HaqueNo ratings yet

- N14MICEDocument4 pagesN14MICEAhsanul HaqueNo ratings yet

- The different types of computer mice and how they workDocument1 pageThe different types of computer mice and how they workJohnPaulLlenticNo ratings yet

- Shree Swaminarayn College of Computer Science: M.Sc. (IT) Sem 1Document21 pagesShree Swaminarayn College of Computer Science: M.Sc. (IT) Sem 1Bhavin P MehtaNo ratings yet

- Computer Mouse: Image From WWW - Bristol.ac - UkDocument6 pagesComputer Mouse: Image From WWW - Bristol.ac - UkMae BallestaNo ratings yet

- How Computer Mice WorkDocument8 pagesHow Computer Mice WorkPhaniraj LenkalapallyNo ratings yet

- Example of Technical DescriptionDocument10 pagesExample of Technical DescriptionMohd Najib86% (7)

- Topic - Optical Mouse: To The Computer So That It Can Respond AppropriatelyDocument13 pagesTopic - Optical Mouse: To The Computer So That It Can Respond AppropriatelyEdwinson EdwardNo ratings yet

- Mis Ass - TasminDocument3 pagesMis Ass - Tasminaminul_sust08No ratings yet

- PDF Document 4Document28 pagesPDF Document 4JoyJoy Tabada CalunsagNo ratings yet

- How Computer Mice Work: EvolutionDocument11 pagesHow Computer Mice Work: EvolutionVishal Kumar ShawNo ratings yet

- How Computer Mouse WorksDocument8 pagesHow Computer Mouse WorksASHFORD BORJANo ratings yet

- How To Build: What Is The Cheep Spinner?Document47 pagesHow To Build: What Is The Cheep Spinner?WolfgangNo ratings yet

- Topic - Optical Mouse: To The Computer So That It Can Respond AppropriatelyDocument13 pagesTopic - Optical Mouse: To The Computer So That It Can Respond Appropriatelyapi-26172869No ratings yet

- Electronic Repair Tips: Facebook Twitter Google LinkedinDocument33 pagesElectronic Repair Tips: Facebook Twitter Google LinkedinHutanu GabrielNo ratings yet

- Optical Mouse Seminar ReportDocument13 pagesOptical Mouse Seminar Reportkarloss_kark0% (1)

- Introduction To MouseDocument2 pagesIntroduction To Mouseraghu_534No ratings yet

- Types of Mice and Their ComponentsDocument18 pagesTypes of Mice and Their ComponentsMinecraft VillagerNo ratings yet

- Space Mouse: Presented by P.Satya Siva Teja 17A51A05E9 Cse-CDocument17 pagesSpace Mouse: Presented by P.Satya Siva Teja 17A51A05E9 Cse-CNarendra kumar ChoudharyNo ratings yet

- The History and Evolution of the Computer MouseDocument3 pagesThe History and Evolution of the Computer Mousetehreem asifNo ratings yet

- Working PrinciplesDocument56 pagesWorking Principlesshyina67% (3)

- The Evolution of the Computer MouseDocument30 pagesThe Evolution of the Computer MouseSaitejaTallapelly67% (3)

- MouseDocument1 pageMouseAndrei Cosmin BuradelNo ratings yet

- MouseDocument16 pagesMousesanjay sharmaNo ratings yet

- MouseDocument20 pagesMousePaul rajNo ratings yet

- Where Do I Plug In the Mouse? (Case StudyDocument3 pagesWhere Do I Plug In the Mouse? (Case StudyVIENNA JEANZEL HERNANDEZNo ratings yet

- Ict Microproject by DurvaDocument13 pagesIct Microproject by DurvaDurva YerunkarNo ratings yet

- Computer Engineering Seminar Topic | Space MouseDocument26 pagesComputer Engineering Seminar Topic | Space MousekavneetrekhiNo ratings yet

- Ucet Vbu, Hazaribag: Technical DescriptionDocument4 pagesUcet Vbu, Hazaribag: Technical DescriptionAnkit SinghNo ratings yet

- Project Repor1Document19 pagesProject Repor1Anupama VijayanNo ratings yet

- Mice and TrackballsDocument18 pagesMice and TrackballsDrift GeeNo ratings yet

- Space MouseDocument22 pagesSpace MouseSamir PandaNo ratings yet

- The 4 Types of Computer Mice ExplainedDocument2 pagesThe 4 Types of Computer Mice ExplainedMandela HouseNo ratings yet

- 3D CONTROLLER SPACE MOUSE REVOLUTIONIZES GRAPHICS MANIPULATIONDocument37 pages3D CONTROLLER SPACE MOUSE REVOLUTIONIZES GRAPHICS MANIPULATIONNikhil DixitNo ratings yet

- Computer ReportDocument12 pagesComputer ReportKingNo ratings yet

- Space Mouse: An Intuitive 3D Controller for Computer GraphicsDocument26 pagesSpace Mouse: An Intuitive 3D Controller for Computer GraphicseballNo ratings yet

- Space MouseDocument6 pagesSpace Mouseanubha goyalNo ratings yet

- E-Ball Research PaperDocument4 pagesE-Ball Research PaperNarasimha LeViNo ratings yet

- How Computer Mouse Work: EvolutionDocument8 pagesHow Computer Mouse Work: EvolutionAmir M. VillasNo ratings yet

- Mouse Devices: Mechanical Mice Have Become Increasingly Scarce Since The Introduction of The Optical MouseDocument7 pagesMouse Devices: Mechanical Mice Have Become Increasingly Scarce Since The Introduction of The Optical Mouseing. Diosiris CamachoNo ratings yet

- The Evolution of the Electronic MouseDocument2 pagesThe Evolution of the Electronic MousejoniecaelijunNo ratings yet

- Mouse and Its WorkingDocument13 pagesMouse and Its Workingniki2009shrmaNo ratings yet

- Technical DescriptionDocument4 pagesTechnical Descriptionapi-407460266No ratings yet

- Rubber Dome Membrane Metal Contact Foam Element: KeyboardsDocument15 pagesRubber Dome Membrane Metal Contact Foam Element: KeyboardsshahirmonNo ratings yet

- Mouse PDFDocument5 pagesMouse PDFjadhavbhavesh1131No ratings yet

- Seminar Report on Space MouseDocument30 pagesSeminar Report on Space MouseWaitingforu MyGrlNo ratings yet

- Pointing Devices Explained: Mice, Trackballs, Touchpads & MoreDocument6 pagesPointing Devices Explained: Mice, Trackballs, Touchpads & MoreAhmed EmadNo ratings yet

- Control 3D Objects with the Space MouseDocument25 pagesControl 3D Objects with the Space MousepiyushasetNo ratings yet

- OS Concepts and Mouse HistoryDocument5 pagesOS Concepts and Mouse HistoryAbigail de LeonNo ratings yet

- First Semester English ExamDocument4 pagesFirst Semester English Examyexid34No ratings yet

- Ncarpenterames-Slc Org 20140317 114841Document2 pagesNcarpenterames-Slc Org 20140317 114841api-249141434No ratings yet

- Resume As of 15 Mar 2014Document2 pagesResume As of 15 Mar 2014api-249141434No ratings yet

- Byu Scholarship EssaysDocument3 pagesByu Scholarship Essaysapi-249141434No ratings yet

- StudenttranscriptDocument2 pagesStudenttranscriptapi-249141434No ratings yet

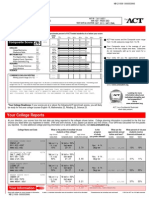

- Act Score ReportDocument2 pagesAct Score Reportapi-249141434No ratings yet

- I Searchessaywriting1010Document8 pagesI Searchessaywriting1010api-249141434No ratings yet

- Final Physics Rocket ReportDocument10 pagesFinal Physics Rocket Reportapi-249141434No ratings yet

- CloningessayDocument2 pagesCloningessayapi-249141434No ratings yet

- Give Us A Full EducationDocument4 pagesGive Us A Full Educationapi-249141434No ratings yet

- TheeffectsofprohibitionDocument1 pageTheeffectsofprohibitionapi-249141434No ratings yet

- 1-DBS Hardware IntroductionDocument10 pages1-DBS Hardware IntroductionShahzad AhmedNo ratings yet

- Claim Form: TERABAND SMART SOLUTION SDN BHD (2021010083320) (1408631-K)Document200 pagesClaim Form: TERABAND SMART SOLUTION SDN BHD (2021010083320) (1408631-K)muhammad amirul mukmininNo ratings yet

- DB1800ADocument2 pagesDB1800AMario DeejayNo ratings yet

- 01 MS 16JB+16J9 v2.0 G EnglishDocument60 pages01 MS 16JB+16J9 v2.0 G EnglishRonnie Smith100% (1)

- Stmicro Mcu Pfe 2012xDocument15 pagesStmicro Mcu Pfe 2012xkbma2009No ratings yet

- Eprom: FeaturesDocument12 pagesEprom: FeaturesmanzellaNo ratings yet

- SA Industrial Washer Brochure PDFDocument4 pagesSA Industrial Washer Brochure PDFAl AdcockNo ratings yet

- GUID Partition Table (GPT)Document28 pagesGUID Partition Table (GPT)Tad PerzynskiNo ratings yet

- Oracle Database 10g: Real Application Clusters Duration: 5 Days DescriptionDocument3 pagesOracle Database 10g: Real Application Clusters Duration: 5 Days Descriptionbrad_pitt777No ratings yet

- Serial Port Control Through A Shell Script - Stack OverflowDocument2 pagesSerial Port Control Through A Shell Script - Stack OverflowAntonio DxNo ratings yet

- Description Features: PT6311 VFD Driver/Controller ICDocument22 pagesDescription Features: PT6311 VFD Driver/Controller ICMaciek KuśnierzNo ratings yet

- SynopsisDocument12 pagesSynopsisAnonymous aYm8hnODINo ratings yet

- Chantillon Digital Force Gauges Dfii Series Manual EnglishDocument84 pagesChantillon Digital Force Gauges Dfii Series Manual EnglishHugo AguiarNo ratings yet

- 74HC151Document11 pages74HC151jnax101No ratings yet

- Computerized Grading System for Samar State UniversityDocument2 pagesComputerized Grading System for Samar State UniversityFlorlyn Mae Sudio RemegioNo ratings yet

- Um10430 1 PDFDocument1,278 pagesUm10430 1 PDFKavyashreeMNo ratings yet

- Linear Actuator La23 Data Sheet EngDocument8 pagesLinear Actuator La23 Data Sheet EngAlfonso MedinaNo ratings yet

- Active Directory: Troubleshooting: WorkshopplusDocument2 pagesActive Directory: Troubleshooting: WorkshopplusMailbox 4allworkNo ratings yet

- Data Sheet Iridium Accessori Manuale Tecnico Sailor SC4000Document20 pagesData Sheet Iridium Accessori Manuale Tecnico Sailor SC4000Den CakraNo ratings yet

- Viper 100Document8 pagesViper 100SeanNo ratings yet

- Trunks & GSMDocument107 pagesTrunks & GSMdumera2002No ratings yet

- Cetpa Infotech Pvt. LTD: Department of Embedded SystemDocument49 pagesCetpa Infotech Pvt. LTD: Department of Embedded SystemsknagarNo ratings yet

- Compal Electronics Schematics DocumentDocument40 pagesCompal Electronics Schematics DocumentPaco ChavesNo ratings yet

- BA9x LCD Operating Manual EnglishDocument61 pagesBA9x LCD Operating Manual EnglishPaul MolinNo ratings yet

- OSS ReferenceDocument336 pagesOSS ReferenceMonish R Nath50% (2)

- GPUs by Power ConsumptionDocument3 pagesGPUs by Power Consumptionmahnuri idNo ratings yet

- Trabtech Basic LevelDocument88 pagesTrabtech Basic LevelFer NandoNo ratings yet