Professional Documents

Culture Documents

Design and Characteristic Analysis of Supersonic Nozzles For High Gas Pressure Laser Cutting

Uploaded by

Gonçalo Nuno RodriguesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Characteristic Analysis of Supersonic Nozzles For High Gas Pressure Laser Cutting

Uploaded by

Gonçalo Nuno RodriguesCopyright:

Available Formats

ELSEVIER Journal ofMaterials Processing Technology 63 (1997) 217-222

Journal of

Materials

Processing

Technology

Design and Characteristic Analysis of Supersonic Nozzles for High Gas Pressure Laser Cutting

H. C. Man*, 1. Duan, T. M. Vue

Department ofManufacturing Engineering, The Hong Kong Polytechnic University, Kowloon, Hong Kong

Abstract

A new method for the design of a supersonic nozzle tip for high gas pressure laser cutting is presented. The design is based on the

theory of gas dynamics in that the potential energy of high stagnation pressure is converted totally into effective velocity energy so that a

high momentum of the exit jet can be obtained for improving the capability of removing molten debris quickly and minimizing the heat-

affected zone of the cut edges. Another purpose is to increase the cutting speed and minimize gas consumption under high pressure

cutting conditions. The behavior of the exit jet under the condition of stagnation gas pressure ranging from 4 - 16 bar are investigated by

means of a computer simulation test. The results of theoretical analysis and of the simulation test show that for a supersonic jet, each

sectional diameter and curve contour of the supersonic nozzle must be designed strictly according to the theory of gas dynamics. An exit

jet with high momentum, good uniform and a tidy boundary can be obtained and the tolerance of the working distance between the

nozzle tip and the workpiece can be increased.

Keywords: high gas pressure, laser cutting, supersonic nozzle

Introduction

Amongst the many process parameters in laser cutting, the

cut-assist gas pressure and gas flow pattern are of prime

importance to the cut edge quality. In the conventional oxygen-

assisted laser cutting process in which oxygen is used for the

generation of exothermal energy during the oxidation process,

the oxygen pressure normally ranges from 0.5 to 4 bar with a

nozzle diameter of 0.8 - 1.5 mm. Oxygen-assisted laser cutting is

used mainly for ferrous alloys because ferrous oxides are of low

viscosity and can be easily blown away from the cut kerf. The cut

edges of laser cut ferrous alloys normally consist of a thin layer

of ferrous oxide but this, together with the edge quality, is

normally acceptable in most applications. However, amongst the

ferrous alloys, laser cut edges of stainless steels are normally

inferior to those of other carbon steels. This is because the

chromium content in the stainless steels forms molten chromium

oxides during the laser cutting process and these oxides have a

high viscosity and tend to cling to the cut edge as dross if the

cut-assist gas pressure is not sufficiently high to blow it away.

Similar problems arise in the laser cutting of aluminium and

titanium alloys because the molten oxides of these alloys are also

of high viscosity. Thus high cut-assist gas pressure is normally

required to obtain a better cut edge quality. Indeed, using

conventional low pressure oxygen-assisted laser cutting, alloys of

C

r

, AI, T

j

are classified as difficult materials to cut.

Recent development in high pressure inert gas laser cutting

[1 - 5] has helped to alleviate the above-mentioned problems to

To whom correspondence should be addressed

0924-0136197/$15.00 @ 1997 Elsevier Science SA All rights reserved

PII S0924-0136(96)02627-1

some extent. By using inert gas pressure ranging from 8 to 25

bar, the molten metal in the cut kerf is blown away by the sheer

force of the gas stream. Because of the absence of oxygen in the

gas stream, no viscous oxide is formed inside the cut kerf and, as

pure molten metals are normally of relative low viscosity at

temperature above the melting point, they can be blown away

relatively easily. However, there are several problems

accompanying current high pressure inert gas laser cutting, which

hinder the wide application of this process, the latter having the

capability of producing shiny and oxide-free cut edges with a

minimum heat-affected zone. The main problems are: (i) too high

a gas consumption rate; and (ii) too low a tolerance of the

working distance between the nozzle tip and the workpiece.

The main cause of these problems is the poor design of the

cutting nozzle tip. When the high pressure inert gas process was

developed, the main research efforts were directed onto the

integrity of the lens system and the whole nozzle assembly under

the high pressure regime. However, the design of the nozzle tip

was still the same as those used for low pressure oxygen-assist

laser cutting technology. To date, no literature on the design of a

nozzle tip used for high inert gas pressure can be found. This

paper attempts to discuss our a new design of nozzle tip for high

inert gas pressure laser cutting.

1. Defects of the Traditional Laser Cutting Nozzle used for

high gas pressure

Most commonly used cutting nozzles for the laser cutting

process are of parallel, conical and convergent types, as shown

in Fig. I, in which the gas passages belong to the subsonic and

218 H.e. Man et al.!Journal of Materials Processing Technology 63 (1997) 217-222

Fig. 3 Jet coming from subsonic and transonic

nozzles under conditions of high pressure

normal shock

disk

jet boundary

nozzl

oblique

shock

surface of

workpiece

Fig.! Commonly used cutting nozzles: (a) parallel;

(b) convergent; (c) conical

transonic type[6 - 8]. From the requirement of high cutting speed

and good cutting quality under circumstances of high gas

pressure, there exist serious defects in these kinds of nozzles.

When the gas pressure Po <1.89kg/cm

2

(0.185MP

a

) (absolute

pressure ), velocity V and flow Q increase with the increasing of

inlet pressure Po, but when Po reaches 1.89 kg / cm

2

(0.185MP

a

)

, V attains a maximum value ( i.e. the local sonic velocity, Mach

number M = I). A further increase in Po also increases the flow

Q, but the gas velocity will remain constant, as illustrated in Fig.

2. At the same time, when the exit pressure PI is greater than

the ambient pressure Ph (back pressure), the speed of the exit jet

flow Q

velocity V

sonic

velocity

!.89 2 3 4

inlet pressure Po , kg/cm

2

(absolute pressure)

Fig. 2 Relationship between velocity, flow and pressure

at of the exit ofa transonic nozzle (after [10])

may reach supersonic speed, which causes the transversal

expansion of the jet in an explosive fashion. The exit gas

particles are accelerated radially and displaced from their

equilibrium positions, thereby creating a pressure reduction in the

core of the jet that causes the particles to reverse their direction

of motion. As a result, periodic intermittent shock waves are

formed which makes the jet thinner in some sections and thicker

in others. JfPoexceeds 5 - 6 kg/cm

2

(0.49 - 0.588MP

a

), there

will be some strong oblique shocks and even normal shock

waves, which result in loss in energy ( some energy is changed

into heat) and turbulent flow of the jet, as illustrated in Fig. 3.

The above phenomenon may interfere seriously in the

focusing of the laser beam because non-uniform jet flow

produces gradients of gas density that result in a change of the

refractive index in the gas field, which leads to secondary

focusing or diverging of the laser beam, as illustrated in Fig. 4.

The result of interference can affect obviously the melting

efficiency and change the mode of the laser beam ,which causes

poor cutting quality and low cutting speed. On the other hand,

the decrease in the energy of the jet caused by the normal shock

can reduce the momentum of the jet so that the capability of

removing molten debris quickly is degraded. This will also

result in an increase of the HAZ and in the roughness of the cut

edges. Finally, the range of distance between the nozzle tip and

workpiece is too sensitive to be tolerable in some laser cutting

processes.

Fig. 4 interference of the gradient ofthe gas

density with the laser beam focusing

Therefore, it can be seen that only increasing the inlet

pressure Po (in order to obtain a high jet energy) would cause a

deterioration of the cutting characteristics in these kinds of

subsonic and transonic nozzles.

When a supersonic nozzle is used as a laser cutting nozzle,

the condition of the exit jet can be greatly improved because this

nozzle has good gas dynamic characteristics. Especially under

the conditions of a correct design, the potential energy of Po can

be changed totally into the effective speed energy, so that the

velocity of the jet used in laser cutting will surpass the sonic

speed and increase with the increase of inlet pressure Po. A

higher momentum of the jet can be obtained to improve the

capability of removing the molten debris. This factor will lead to

a great increase of laser cutting speed and a reduction of the heat-

affected zone. On the other hand, the jet boundary exiting from

the supersonic nozzle is long and sharp-pointed, which is

suitable for precise cutting and for the cutting of thick plate.

2. Operating Theory of Supersonic Nozzle

A theory of one-dimensional steady gas dynamics can be

applied to the flow in a short duct of small divergence and

curvature on the basis of the assumption that the gas is a perfect

gas, without viscous stress, and that the transversal gradients of

pressure ( P ), velocity of flow ( V ), temperature ( T ) and gas

density ( p ) are negligible. The physical parameters of a perfect

gas are constant and uniform on each cross-sectional area ( A )

and the flow of perfect gas is an isentropic and adiabatic process,

without energy loss and heat exchange [6].

The laser cutting supersonic nozzle is generally of small

divergence and non-curvature as well as having a short duct. The

gas velocity in the duct is so fast that heat exchange has no time

to occur and therefore the motion of gas in the duct is an

adiabatic process. On the other hand, the development of

boundary layers will have little influence on the flow because no

matter how much the velocities in the boundary layer have been

H.e. Man et al. / Journal of Materials Processing Technology 63 (1997) 217-222 219

sectional area A remains constant, i.e. dA = O. Also, dv = 0 , dp

= 0, dp = 0 and M=1 can be obtained from Eqns. (1)-(3). The

evaluation above shows that the cross-sectional area A will reach

a minimum value, known as the throat sectional area A

e

(critical

value ), and the velocity V in the throat section will achieve sonic

speed, Le. V = a (critical velocity).

If A was continuously reduced in order to attain supersonic

speed there would be M = via>1. This conclusion is impossible

from Eqn. (I) which requires dA > 0 when M>I, so that V

keeps at sonic speed, called the shock phenomena.

In order to make the jet exceed sonic speed after passing the

throat section, the cross-sectional area of the nozzle must increase

continuously and the P and p decrease correspondingly to keep

Eqns. (1) - (3) established. Therefore, the supersonic nozzle

must be a kind of converging--diverging nozzle which consists

of three sections: convergent (subsonic zone), throat (critical

zone) and divergent (supersonic zone).

(2)

(1)

dA

A

reduced by friction forces, the retarded layers have no difficulty

in following the favourable pressure gradients of the expansion,

so that the affect of friction can be approximately neglected.

Under these conditions, the motion of the gas in a laser cutting

nozzle can be considered as a barotropic and isentropic process,

and the equations of one-dimensional steady gas dynamics can be

applied in the design of the supersonic nozzle.

The differential relationships between the change of speed

and pressure and the change of cross-sectional area and density

are easily established by one-dimensional gas dynamics

equations [6 - 8], these relationships being:

dA 2 dv

-=(M -1)-

A V

V

d p 2 dv

-=M

p

(3) 3. Design Theory of a Supersonic Nozzle

Fig. 5 Conceptual diagram of a supersonic nozzle

In order to produce an exit jet with high momentum, good

uniform and a tidy boundary, as well as with low turbulence and

energy loss, the dimensions of each section in supersonic nozzle

need to be designed correctly and calculated precisely on the

basis of gas dynamics. The methods of design are as follows.

3.1 Stable section

Just as pointed out above, the supersonic nozzle should

consist of three sections: convergent, throat and divergent.

However, in the real supersonic nozzle, there is a stable section

before the convergent section in order to make the flow uniform

and non-turbulent. Thus, the nozzle should consist of four

sections: stable, convergent, throat and divergent, as shown in

Fig. 5.

L

2

divergent

section

throat

section

L o ~ L l

stable convergent

section section

The function of the stable section is to make the incoming

flow from a tank more uniform and non-turbulent and its

velocities at every point of the stable section nearly parallel with

the axis without transverse velocity components. The diameter

Do of the stable section depends on the diameter De of the throat

section. In theory, the greater is Do the better, but in reality, Do is

limited by the nozzle structure and manufacturing method as well

as by the focal length and diameter of the laser beam.

The length L

o

of the stable section should be sufficiently

long to ensure the incoming flow is stable. For this reason, it is

usually about 10 times as great as the throat diameter De.

However, in practice, L

o

is often limited by the focal length and

diameter of the laser beam. Therefore, L

o

is determined according

to real conditions.

p VA = const (4)

where A is cross-sectional area; V is the velocity of the gas; P is

pressure; M is Mach number (M = via ); k is the ratio of specific

heats; a is the speed of sound; and p is the density of the gas.

From these equations, bearing the name of Hugoniot, it is

possible to draw the following important conclusions.

(i) If M < I, the sign of dv is opposite to the sign of dA and the

sign of dp is identical to the sign of dA, Le. in the subsonic

motion of a gas, the speed of flow decreases with increasing

cross-sectional area and pressure of the stream, which is the

condition of a subsonic diffuser, and conversely, the speed

increase with decreasing cross-sectional area and pressure, which

is the condition of a subsonic nozzle.

(ii) If M > I, the sign of dv is identical with the sign of dA but

opposite to the sign of dp, Le. in the supersonic motion of gas in

a convergent duct the flow is retarded, which is the condition of a

supersonic diffuser, whilst in a divergent duct, the flow is

accelerated which is the condition of a supersonic nozzle.

(iii) If M = 1, then dA = 0; the corresponding section of the duct

will be critical. The condition dA =0 is identical with the

necessary condition for the area to have a stationary value. It is

easy to see that this stationary value must be a minimum, for if

the critical section of the duct had maximum area, a subsonic

stream would slow down and a supersonic stream would

accelerate, which could not, either way, lead to sonic flow at the

critical section: thus when M = 1, the velocity of flow reaches

sonic speed and the cross-section of the duct must be minimum,

called the critical area or throat section (A

e

).

By applying these characteristics, a supersonic nozzle can be

made to produce a gas jet with supersonic speed. When the

stagnant gas in a nozzle starts to accelerate, the speed of flow

increases slightly, but the density of gas p can be considered as

constant, i.e. V a, M 1. From Eqn. (4), it is easy to draw

the conclusion that with the increase of V, A must be reduced in

order to keep Eqn. (4) established so that the nozzle must be first

converged. With a further increase in V, the stagnation pressure

begins to decrease significantly and causes a decrease in density

of the gas that can offset part of the increase in speed V.

According to Eqn. (4), the convergence of the cross-sectional

area A becomes slow, i.e. the value of dA is low. When the

increase in V is just offset by the reduction in p, the cross-

220 H.e. Man et al./Journal of Materials Processing Technology 63 (1997) 217-222

3.3 Throat Section

(8)

(9)

[(

I+

Al Me 2

= M

I

( k-I 2)

I+--M

2 e

where A, is the exit area; A

e

is the throat area; Po is the pressure

in the tank expressed as inlet pressure (absolute pressure); P, is

the pressure at exit (absolute pressure); Me is the Mach number

in the throat section; M, is the Mach number at exit.

The curvature of the divergent section must be designed

rigorously by calculation on the basis of gas dynamic theory,

which has features that enable not only the exit supersonic speed

of the jet to be uniform and parallel, but also the jet boundary to

be tidy and limpid, so that the energy loss reaches the lowest

value.

X

Fig. 7 Three-dimensionally symmetricall-diverging

In the calculation of the three-dimensional dynamic curve

section, there is a simpler and more practical method, which is

Foelsch's analytical calculation [9]. Fig. 7 shows a conceptual

diagram of a design on the divergent section using Foelsch's

method. The throat section consists of a circular arc of radius R.

In the divergent section, the expansion curve contour consists of

a circular arc CD extended from the throat section and a straight

B

D/2

R.: C

I

In gas dynamics, the value of the throat diameter is

determined by the need of the cutting flow according to the range

of cutting thickness, and then, by the equation of computing flow

. If the gas absolute temperature To = 273K at the inlet section,

under the consideration of a choking effect at the throat section

and selecting the flow coefficient f.1 = 0.93, a computing equation

can be obtained as follows:

D, V (=) (7)

Po + I

where V is the cutting gas volumetric flow under standard

conditions (m

3

I h); and Po is the gas pressure at the inlet

(kg I mm\

3.4 Divergent Section

The function of the divergent section is to further accelerate

the flow, which latter has achieved sonic speed at the throat

section, by means of expansion, until the exit jet reaches an

expected Mach number. This section is the most important

section in the supersonic nozzle. The dimensions of the exit area

can be calculated by means of Eqn. (8) according to the given

inlet pressure Po , which latter can be calculated using Eqn. (9)

and the exit velocity of flow [8]:

(6)

(5)

I+-----L, I

Fig. 6 Curve contour in the convergent seeton

x

a = - (Shown in Fig. 6 )

L,

where R is the radius of an arbitrary convergent cross-sectional

area; R

e

is the radius of the throat sectional area; Ra is the radius

of the stable sectional area; L

j

is the length of the convergent

section; and x is the length of an arbitrary convergent section.

This type of converging curvature has an advantage that the

velocity of flow entering the throat section is quite uniform.

The design of the throat section is relatively important

because it is a transitional cross-sectional area which transfers

the subsonic speed into the supersonic speed. Just as mentioned

above, the cross-sectional area closer to the throat section can

not be varied quickly, so that a circular arc with quite a large

radius is provided over the region of transition in gas dynamics.

where k is the ratio of specific heats (for air, N

2

, k = 1.4; for Ar,

k = 1.658 )

There are numerous theories about the design of a

converging curvature. However, most of them are quite

complicated. In this paper, a simpler but more practical equation

[10] is applied in the design of the convergent section, which is

derived from the conclusion of an ideal axial incompressible

symmetry flow:

3.2 Convergent Section

The function of the convergent section is to accelerate gas

flow, but at the same time, to keep the flow uniform and parallel.

The characteristics of the convergent section are mainly

determined by two factors, one being the converging ratio, Le.

A

o

IA

e

( A

o

is the convergent inlet area, A

e

is the throat area )

which accelerates the gas flow and ensures the speed of flow to

reach sonic speed, whilst the second is the convergent curve

which maintains the velocity of flow uniform.

From theory of one-dimensional steady gas dynamics [6 - 8],

the equation of A

o

I A

e

can be attained as follows:

k+1

A M((I + 2(k-l)

o e 2

----

A M k-I 2

e 0 (l + --Me)

2

H.e. Man et 01. / Journal of Materials Processing Technology 63 (1997) 217-222

(a)

e'

b' c' d'

(b)

(c)

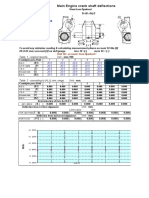

Fig. 8 Configuration of the exit jet for Dc/D, =1.3 M, =2 and k=l ..II. for different

pressure ratios: (a) Ft/P,=l; (b) P

b

/P,=O.8; (c) Ft/P,=O.5

221

line DA with length equal to R, the arc AB being the

compression curve contour. The normal distance from A to X

axis is the radius of exit cross-sectional area of the nozzle.

Finally, a modification of the coanda layer effect should be

considered.

4. Characteristic Analysis on a Supersonic Jet

The behaviour of the exit jet coming from two-dimensional

supersonic nozzle is investigated by means of a computer

simulation test under the conditions of stagnation gas pressure Po

ranging from 4 - 16 bar, (as shown in Fig. 8). The results show

that for supersonic jet, after each of the sectional diameters and

curve contours of the supersonic nozzle have been designed

strictly based on the theory of gas dynamics, the velocity,

momentum and configuration of the exit jet depend mainly on

the given Mach number and working pressure ratio.

When the exit pressure PI (nozzle tip pressure) is slightly

greater than the back pressure Ph (i.e. Ph =: 1 bar, PI =: 1.25 bar,

Ph / P

I

= 0.8, M = 2), the shape of exit jet is as illustrated in Fig.

8(b). The exit jet forms expansion waves with its streamlines

turning outwards through an angle eat the nozzle tip a a'. There

are two families of expansion waves from exit points a and a',

which stretch out as an isentropic process until the exit pressure

decreases to the back pressure Ph' Then, these waves are reflected

by the boundary of the free jet ( bcd and b'c'd' )to form two

families of compression waves. The velocity and pressure P

z

in

region 2 keep constant ( i.e. P

z

= Ph ), the pressure P

3

in region 3

being less than Ph because of the expansion ( P

3

=: 0.25 bar), but

the velocity in this region 3 increases. Without consideration of

viscous effect, there exists a relationship of PI - Ph = Ph - P

3

Finally, these compression waves begin to move towards the

axial line of jet to the reflected points e and e' of the boundary.

In the meanwhile, the pressure of the jet gradually recovers the

value of PI ( region 4 ). If there were no loss of energy in the

process, this alternating change would continue, so that the

configuration of the exit jet would appear as an undulating

movement.

When the difference between PI and Ph is greater, i.e. Ph / PI

= 0.5, the situation of the exit jet is quite complicated, as shown

in Fig. 8(c). Some stronger oblique shock and normal shock (

Mach shock disk) emerge at the cross region of the compression

waves because when PI 2 bar, the pressure P

3

must be equal to

or less than the absolute vacuum pressure in order to keep the

relationship of PI - Ph = Ph - P

3

established. However, this is

222

H.G. Man et al. / Journal of Materials Processing Technology 63 (/997) 217-222

impossible in fact, and as a result a normal shock disk must be

produced. The normal shock disk can cause loss in energy which

reduces the momentum of the exit jet, produce turbulent flow of

the exit jet which would interfere seriously the focusing of laser

beam, and shorten the effective length of the exit jet. The shorter

this length, the more sensitive is the distance between the nozzle

tip and the workpiece.

When Pi = Pb' i.e. P

b

/ p]= 1 (the" design" pressure ratio) ,

the characteristic lines ac', ad' and a'c, a' d coincide separately

with ab' and a'b. The shape of the exit jet is illustrated in Fig.

8(a), an exit jet with high momentum, good uniformity and a tidy

boundary being obtained.

From the above analysis, an important conclusion is obtained

that for a supersonic nozzle used in high pressure laser cutting, as

soon as the ratio between the exit diameter D] and the throat

diameter Dc is determined, the exit Mach number M

i

is fixed

and the ratio between the inlet pressure Po and the exit pressure

PI is also defined, the value of Po also being defined by

equation (9) since PI = P

b

;; 1 bar. For instance, when Pi = P

b

;; 1

bar, if D] / Dc = 1.3, M= 2, Po is about 7.8 bar, and if D] / Dc =

1.62, M= 2.5, Po is about 17 bar . Any greater deviation from the

computed value of Po can result in a characteristic deterioration

of the exit jet.

5. Conclusions

1. Subsonic and transonic nozzles are not suitable for high

pressure laser cutting because a normal shock disk, turbulent

flow and a short effective length of the exit jet cause a

deterioration of the cutting characteristics under the conditions of

P

o

>5bar.

2. A supersonic nozzle has good gas dynamic characteristics so

that it is suitable for high pressure laser cutting. However, it

should consist of four sections: stable, convergent, throat and

divergent. Each of the sectional dimensions must be designed

strictly on the basis of the theory of gas dynamics.

3. In order to obtain a good exit jet, the inlet pressure Po should

be equal to the computed value, as a large deviation would result

in a poor exit jet.

References

[1] H. C. Man, Technical review of CO

2

laser cutting systems

and processes, Proc. 2nd Int. Conf. on Power Beam Tech.,

Stratford-Upon-Avon, The Welding Inst. U. K., (1990) pp.

248-257.

[2] S. E. Nielsen, Laser cutting with high pressure cutting gases

and mixed gases, Proc. 3rd Int. Conf. Lasers in

Manufacturing, IFS (Conferences) Ltd., Bedford, UK, (1986)

p.25.

[3] J. M. Weick, W. Bartel, Laser cutting without oxygen and its

benefits for cutting stainless steel, Proc. 6 the Int. Conf.

Laser in Manufacturing, by IFS (Conferences) Ltd., Bedford,

UK, (1989), p. 81 .

[4] J. Fieret, M. J. Terry and B. A. Ward, Overview of flow

dynamics in gas-assisted laser cutting. Fourth Int.

Symposium on Optical and Optoelectronic Applied Science

and Engineering, Topical meeting on high power laser, 30

March - 3 April, The Hague, The Netherlands, (1987),

p.818.

[5] B. A. Ward, Supersonic characteristics of nozzles used with

lasers for cutting, Proc. Int. Congo on application of lasers

and electro-optics, Boston, MA, USA, (Nov. 1984). p.730.

[6] Howard W. Emmons, Fundamentals of Gas Dynamics,

Princetion, New Jersey, Princetion University Press, (1958).

[7] Ascher H.Shapiro, The Dynamics and Thermodynamics oj

Compressible Fluid Flow, New York, Chichester Brisbane,

Toronto, Singapore, (1953).

[8] Maurice I. Zucrow Joe D. Hoffman, Gas Dynamics. 605

Third Avenue, New York, N. Y. 10016, USA, (1976).

[9] K.Foelsch, The Analytical Design of an Axially Symmetric

Laval Nozzle for a Parallei and Uniform Jet J. Aero. Sci. 16

(31) (1949), p. 32.

[10] I.C.Crown, Supersonic Nozzle Design, No.1651 NACA

Tech. Note (1948).

You might also like

- 5 Factors That Influence The Precision of Plasma CutsDocument2 pages5 Factors That Influence The Precision of Plasma CutsazharzebNo ratings yet

- An Analysis of The Shielding Gas Flow FRDocument12 pagesAn Analysis of The Shielding Gas Flow FRJovano BarpNo ratings yet

- Cutting Processes - Plasma Arc Cutting - Process and Equipment ConsiderationsDocument5 pagesCutting Processes - Plasma Arc Cutting - Process and Equipment ConsiderationsSairul SahariNo ratings yet

- Job Knowledge 51Document5 pagesJob Knowledge 51Mehmet SoysalNo ratings yet

- Generation of The Striations During Laser CuttingDocument17 pagesGeneration of The Striations During Laser CuttingEhsan KhanNo ratings yet

- A Brief Overview of Plasma Cutting: Figure 1 - Temperature DifferencesDocument8 pagesA Brief Overview of Plasma Cutting: Figure 1 - Temperature DifferencesAdibah BiagiNo ratings yet

- Corte Por Plasma 7Document23 pagesCorte Por Plasma 7Ronny De La CruzNo ratings yet

- Figure 3.1 Metal Cutting of 5Document10 pagesFigure 3.1 Metal Cutting of 5joneth1g.1mostaceroNo ratings yet

- Report CuttingDocument7 pagesReport CuttingTiffany JohnstonNo ratings yet

- Thermal CuttingDocument18 pagesThermal CuttingSarah100% (1)

- N9509-Welding Techniques For Tailored BlanksDocument7 pagesN9509-Welding Techniques For Tailored BlanksAgustine SetiawanNo ratings yet

- Amp ReportDocument21 pagesAmp ReportAadip KushwahaNo ratings yet

- Optimizing Gas Supply For Industrial Lasers: OEM ScopeDocument8 pagesOptimizing Gas Supply For Industrial Lasers: OEM ScopeHaryanto GunawanNo ratings yet

- Cutting Processes Application of Oxyfuel CuttingDocument5 pagesCutting Processes Application of Oxyfuel CuttingMehmet SoysalNo ratings yet

- Diala, Jour, Volume, 37, 2009: "Cutting Mild Steel by Carbon Dioxide Laser"Document14 pagesDiala, Jour, Volume, 37, 2009: "Cutting Mild Steel by Carbon Dioxide Laser"Natalie WyattNo ratings yet

- Metals: Investigation On The Inert Gas-Assisted Laser Cutting Performances and Quality Using Supersonic NozzlesDocument16 pagesMetals: Investigation On The Inert Gas-Assisted Laser Cutting Performances and Quality Using Supersonic NozzlesGonzalo MaggioniNo ratings yet

- Plasma ArcDocument5 pagesPlasma ArcTanu RdNo ratings yet

- Plasma Cutting AssignmentDocument7 pagesPlasma Cutting AssignmentMuziKhumalo0% (1)

- Effect of Parameters on Al-17Si PowderDocument14 pagesEffect of Parameters on Al-17Si PowderdaffaNo ratings yet

- GMAWDocument7 pagesGMAWmostafaNo ratings yet

- Advances in SteelmakingDocument190 pagesAdvances in Steelmakingrajkumar baskeyNo ratings yet

- Advances in SteelmakingDocument189 pagesAdvances in SteelmakingAnjaniAkula100% (1)

- Plasma Arc CuttingDocument13 pagesPlasma Arc CuttingSarahNo ratings yet

- Laser Bending PresentationDocument109 pagesLaser Bending PresentationVivek SharmaNo ratings yet

- 19BME073 Plasma Cutting Lab ReportDocument2 pages19BME073 Plasma Cutting Lab ReportMeet LadNo ratings yet

- Tribology Issues in RollingDocument15 pagesTribology Issues in RollingProfessor HeistNo ratings yet

- Important Factors in Pipe Butt Welding of Super Duplex Stainless Steel (SDSS) UNS S32760 Using The GTAW Welding Process (FINAL)Document18 pagesImportant Factors in Pipe Butt Welding of Super Duplex Stainless Steel (SDSS) UNS S32760 Using The GTAW Welding Process (FINAL)MubeenNo ratings yet

- Laser (01 18)Document18 pagesLaser (01 18)Ayrton PabloNo ratings yet

- Applied SciencesDocument22 pagesApplied SciencesDu RoyNo ratings yet

- Plasma Cutting The History of Plasma CuttingDocument11 pagesPlasma Cutting The History of Plasma Cuttingdca abreuNo ratings yet

- Journal Pre-Proofs: Infrared Physics & TechnologyDocument21 pagesJournal Pre-Proofs: Infrared Physics & TechnologyVishwa ChethanNo ratings yet

- Assignment Advance Manufacturing Processes: by Vaibhav M. Enroll No. 171E021 May 8, 2020Document11 pagesAssignment Advance Manufacturing Processes: by Vaibhav M. Enroll No. 171E021 May 8, 2020Vaibhav MishraNo ratings yet

- Fe and Fu Planning: Preparation and Sheet Metal Cutting ShopDocument7 pagesFe and Fu Planning: Preparation and Sheet Metal Cutting ShoprampdwnNo ratings yet

- BOC 217076 Facts About Plasma Technology FA Low ResDocument32 pagesBOC 217076 Facts About Plasma Technology FA Low ResAndrei SavvaNo ratings yet

- Cswip - Section 15-Thermal Cutting ProcessesDocument10 pagesCswip - Section 15-Thermal Cutting ProcessesNsidibe Michael EtimNo ratings yet

- Chapter 2Document8 pagesChapter 2majodavis75No ratings yet

- Design of Gravity Die CastingsDocument25 pagesDesign of Gravity Die CastingsM PraveenNo ratings yet

- Plasma MachiningDocument34 pagesPlasma MachiningMonil DaveNo ratings yet

- Module-III Plasma Arc Machining (Pam) :: Modern Manufacturing Processes (Peme 5306)Document7 pagesModule-III Plasma Arc Machining (Pam) :: Modern Manufacturing Processes (Peme 5306)Anonymous dL8dsCncNo ratings yet

- Abrasive Jet Machining (Ajm) : Dept. of ME, ACEDocument8 pagesAbrasive Jet Machining (Ajm) : Dept. of ME, ACEJabir 08No ratings yet

- Beam Polarization Influence On Laser CuttingDocument15 pagesBeam Polarization Influence On Laser Cuttingxafat53862No ratings yet

- Laser Welding of Thin Sheet Steel With Surface OxidationDocument6 pagesLaser Welding of Thin Sheet Steel With Surface OxidationSerkan ApayNo ratings yet

- AGA Cutting Aluminum Facts About UKDocument16 pagesAGA Cutting Aluminum Facts About UKmekag94No ratings yet

- Optimizing Welding Parameters for Submerged Arc WeldingDocument6 pagesOptimizing Welding Parameters for Submerged Arc WeldingsettaNo ratings yet

- Laser Beam Welding Under Vacuum Achieves High Penetration DepthsDocument11 pagesLaser Beam Welding Under Vacuum Achieves High Penetration DepthsSudhakar LavuriNo ratings yet

- Plasma Arc MachiningDocument24 pagesPlasma Arc MachiningArnav SharmaNo ratings yet

- Atomization Process For Metal PowderDocument6 pagesAtomization Process For Metal PowderJavo BarrelNo ratings yet

- Mah Rle 2021Document28 pagesMah Rle 2021Vishwa ChethanNo ratings yet

- LBMDocument25 pagesLBMwisejackNo ratings yet

- Casting Process Design GuidelinesDocument8 pagesCasting Process Design GuidelinesSanjay ShahNo ratings yet

- Riveiro 2019Document31 pagesRiveiro 2019y suresh babuNo ratings yet

- Linde Group - Facts About Laser CuttingDocument20 pagesLinde Group - Facts About Laser CuttingddadaraNo ratings yet

- Advantages of Heavy-Duty MAG WeldingDocument9 pagesAdvantages of Heavy-Duty MAG WeldingNaksalitNo ratings yet

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- O Repensar Da Fonoaudiologia Na Epistemologia CienDocument5 pagesO Repensar Da Fonoaudiologia Na Epistemologia CienClaudilla L.No ratings yet

- Water Chemistry PDFDocument24 pagesWater Chemistry PDFravichan_2010No ratings yet

- Beam StandardDocument44 pagesBeam StandardweldmindNo ratings yet

- Tugas Tekres TamiDocument15 pagesTugas Tekres TamiTami AndiniNo ratings yet

- Introduction To Random MatricesDocument508 pagesIntroduction To Random Matricesjorelex100% (1)

- Za Sans 5011 2005 PDFDocument18 pagesZa Sans 5011 2005 PDFJan-Louis ReyndersNo ratings yet

- Boardwork No.1 and 2Document9 pagesBoardwork No.1 and 2John Nalog100% (1)

- Structure-First YearDocument12 pagesStructure-First Yearioemk251No ratings yet

- Siesmic Protection Ufc 3 310 04Document128 pagesSiesmic Protection Ufc 3 310 04irastemhemNo ratings yet

- General Relativity: Matthias Bartelmann Institut F Ur Theoretische Astrophysik Universit at HeidelbergDocument196 pagesGeneral Relativity: Matthias Bartelmann Institut F Ur Theoretische Astrophysik Universit at HeidelbergparonimusNo ratings yet

- Programming ExercisesDocument2 pagesProgramming ExercisesDaryl Ivan Empuerto HisolaNo ratings yet

- Computer Numerical Control CNC: Ken Youssefi Mechanical Engineering DepartmentDocument43 pagesComputer Numerical Control CNC: Ken Youssefi Mechanical Engineering DepartmentSreedhar PugalendhiNo ratings yet

- The Evolution of Consciousness According to Bhagavad-GitaDocument14 pagesThe Evolution of Consciousness According to Bhagavad-Gitatrabajo mpdNo ratings yet

- Crankweb Deflections 9 Cyl ELANDocument2 pagesCrankweb Deflections 9 Cyl ELANСлавик МосинNo ratings yet

- II Assignment MMDocument3 pagesII Assignment MMshantan02No ratings yet

- Malla Curricular Ingenieria Civil UNTRMDocument1 pageMalla Curricular Ingenieria Civil UNTRMhugo maldonado mendoza50% (2)

- 01 - The Freerider Free Energy Inverter Rev 00DDocument18 pages01 - The Freerider Free Energy Inverter Rev 00Dpeterfoss791665No ratings yet

- Advances in Heat Transfer 2 (1965)Document469 pagesAdvances in Heat Transfer 2 (1965)alejandro_baro419No ratings yet

- Roxtec Product Catalogue GB FI RU SE IT 2011 2012Document252 pagesRoxtec Product Catalogue GB FI RU SE IT 2011 2012mmaleniNo ratings yet

- Quincy Qrds Series Single-Stage, Oil-Less Reciprocating Air Compressors 2-30 HPDocument8 pagesQuincy Qrds Series Single-Stage, Oil-Less Reciprocating Air Compressors 2-30 HPCoral IcmNo ratings yet

- Gamma World 1E Mutations PDFDocument23 pagesGamma World 1E Mutations PDFSean M Kelly100% (1)

- Magnetism and Electromagnetism - Electrical Multiple Choice Questions and AnswersDocument10 pagesMagnetism and Electromagnetism - Electrical Multiple Choice Questions and AnswersNagesh GillNo ratings yet

- J.F.M. Wiggenraad and D.G. Zimcik: NLR-TP-2001-064Document20 pagesJ.F.M. Wiggenraad and D.G. Zimcik: NLR-TP-2001-064rtplemat lematNo ratings yet

- Eco Brick Paper 140314 - Full Paperr2Document30 pagesEco Brick Paper 140314 - Full Paperr2zero kakumaruNo ratings yet

- Laser Flash Photolysis Purpose A Reactive Free Radical Ketyl IsDocument16 pagesLaser Flash Photolysis Purpose A Reactive Free Radical Ketyl IspathinfoNo ratings yet

- Rife Energy Medicine Cures DiseasesDocument5 pagesRife Energy Medicine Cures DiseasesOna OnićNo ratings yet

- Siniloan Integrated National High SchoolDocument4 pagesSiniloan Integrated National High SchoolKimberlyn VelascoNo ratings yet

- CE 437/537 Retaining Wall Design ExampleDocument8 pagesCE 437/537 Retaining Wall Design ExampleJefferson Nobleza67% (3)

- Navier-Stokes Simulations of Projectile Base Flow with and without BleedDocument42 pagesNavier-Stokes Simulations of Projectile Base Flow with and without BleednanocardosoNo ratings yet

- Rock Sizing For Culvert Outlets PDFDocument0 pagesRock Sizing For Culvert Outlets PDFwrobinsonf2scomNo ratings yet