Professional Documents

Culture Documents

ED-2002-017 8 Channel RTD Input Module (4311) PDF

Uploaded by

Raj ChavanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ED-2002-017 8 Channel RTD Input Module (4311) PDF

Uploaded by

Raj ChavanCopyright:

Available Formats

NEXGEN PLC

8 Channels, RTD Input Module (Ordering Code 4311)

User Manual

Document No.:ED-2002-017

Version: 1.0

MESSUNG SYSTEMS EL-2, J- Block MIDC Bhosari, Pune 411026.(INDIA) Tel: (+91)-020-7120807, 7122807. Email : marketing@ms.messung.com WEB: www.messung.com

8 Ch. RTD Input Module (4311)

Messung Systems

Revision

Version 1.0 Date 16 July 2002 Description 8 Channels, RTD Input Module(Ordering Code 4311) User Manual

Published July 2002 Page 2 of 47

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Messung Systems

8 Ch. RTD Input Module (4311)

INDEX

1. Module Overview ........................................................................................................5

1.1 1.2 1.3

2.

RTD Input Module Overview ..............................................................................5 LED Indications ..................................................................................................7 General Specifications .......................................................................................8

Module Operation .......................................................................................................9

2.1 2.2 2.3 2.4

Block Diagram....................................................................................................9 RTD types and range of temperatures.............................................................10 Lead Compensation .........................................................................................11 On-Board Processor Operations......................................................................13 2.4.1 Power On Operations ..................................................................................13 2.4.2 Analog to Digital Conversion .......................................................................13 2.4.3 Excitation Current Drift Compensation ........................................................14 2.4.4 Scaling .........................................................................................................15 2.4.5 Linearization ................................................................................................15 2.4.6 Averaging.....................................................................................................15 2.5 Module Information ..........................................................................................15 2.5.1 Input Output Image Mapping .......................................................................16 2.5.2 Memory Mapping .........................................................................................17 2.5.3 Commands ..................................................................................................18 2.5.4 Module Status Bits.......................................................................................19 3. Installations and Wiring.............................................................................................20

3.1 3.2 3.3

4.

Module Installation ...........................................................................................20 Connection Details ...........................................................................................21 Precautions to be taken ...................................................................................22

Configuration and Programming...............................................................................23 Slot Configuration.............................................................................................23 Channel Configuration .....................................................................................24 4.2.1 Static Configuration .....................................................................................24 4.2.2 Dynamic Configuration ................................................................................26 4.3 Channel Information.........................................................................................27 4.3.1 Channel Data...............................................................................................27 4.3.2 Channel Status ............................................................................................27 4.4 Programming with Nexgen 4000 CPU .............................................................29 4.5 Programming with Nexgen 5000 CPU

4.1 4.2

5.

Troubleshooting ........................................................................................................40

5.1 5.2

6.

LED Indications for Diagnostics .......................................................................40 Fault Diagnostic ...............................................................................................40

Appendix 1................................................................................................................44

INDEX OF FIGURES

Figure 1 :Front View of RTD Input Module..........................................................................6 Figure 2 :Block diagram of RTD Input module ....................................................................9 Figure 3 :Schematic of input circuit ...................................................................................11 Figure 4 :ADC Conversion Cycle ......................................................................................14 Figure 5 :Input Output Image Mapping of RTD Input Module ...........................................16 Figure 6 :Memory Mapping of RTD Input Module .............................................................17

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017 Published July 2002 Page 3 of 47

8 Ch. RTD Input Module (4311)

Messung Systems

Figure 7 :Connection diagram of RTD input Module ........................................................ 21

Guidelines for the Safety of the user and protection of the IO Module This manual provides information for the use of the PLC Products. The manual has been written to be used by trained and competent personnel. The definition of such a person or persons is as follows: a) Any engineer who is responsible for the planning, design and construction of automatic equipment using the product associated with this manual should be of a competent nature, trained and qualified to the local and national standards required to fulfill that role. These engineers should be fully aware of all aspects of safety with regards to automated equipment. b) Any commissioning or service engineer must be of a competent nature, trained and qualified to the local and national standards required to fulfill that job. These engineers should also be trained In the use and maintenance of the completed product. This Includes being completely familiar with all associated documentation for the said product. All maintenance should be carried out in accordance with established safety practices. c) All operators of the completed equipment should be trained to use that product in a safe and coordinated manner in compliance to established safety practices. The operators should also be familiar with documentation, which is connected with the actual operation of the completed equipment. Note: The term-completed equipment refers to a third party constructed device, which contains or uses the product associated with this manual. Note on the Symbol used in this Manual At various times through out this manual certain symbols will be used to highlight points of Information, which are Intended to ensure the users personal safety and protect the integrity of equipment. Whenever any of the following symbols are encountered its associated. Note must be read and understood. Each of the symbols used is listed below; with a brief description of its meaning.

Hardware Warnings

1) Indicates that the identified danger WILL cause Physical and Property damage. 2) Indicates that the identified danger could POSSIBLY cause physical and property damage. 3) Indicates a point of further interest or further explanation.

Software Warning

4) Indicates special care must be taken when using this element of software.

5) Indicates a special point, which the user of the associate software element should be aware of.

6) Indicates a point of interest of further explanation.

Warning

This product can only function correctly and safely if it is transported, stored, setup, and installed correctly, and operated and maintained as recommended.

Published July 2002 Page 4 of 47

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Messung Systems

8 Ch. RTD Input Module (4311)

1. Module Overview

This chapter describes the following RTD Input Module Overview LED Indications General Specifications

1.1 RTD Input Module Overview

This RTD input module converts RTD input resistance values into the equivalent temperature values of 0.1C resolution with lead compensation. This is sigma-delta type A/D conversion. It provides 8 non-isolated channels and 16-bit resolution ADC. The individual channel can be configured for specific type of RTD input. In current version, 3 wires PT100 input is supported. RTD Type PT100 (385) C Temperature range -200.0 C to +850.0 C

The parameters and commands those are transferred to the module for advanced processing are RTD input type (in current version 3 wires PT100 (385) input is supported) Return value in case of sensor fault Averaging Channel enable/disable Maximumminimum set points Static configuration write

The module provides diagnostic information for each channel. It includes Maximum/minimum set points exceeded Invalid configuration Out of range Sensor fault detection This is an intelligent module with on-board processor and memory. The data transfer between CPU module and RTD input module takes place by 'READ_W' and 'WRITE_W' functions in the application program. The module status is available in input image and commands can be issued through output image. The figure 1 shows the front view of RTD input module

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Published July 2002 Page 5 of 47

8 Ch. RTD Input Module (4311)

Messung Systems

4311

Terminal Block Fixing Screw

ANALOG INTPUT 8 CH RTD

01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 RTD0 + RTD1 + RTD0 RTD1 RTD0 C RTD1 C RTD2 + RTD3 + RTD2 RTD3 RTD2 C RTD3 C RTD4 + RTD5 + RTD4 RTD5 RTD4 C RTD5 C RTD6 + RTD7 + RTD6 RTD7 RTD6 C RTD7 C

NO 24 V SUPPLY CPU FAULT

Module Status LEDs

CH0 CH1 CH2 CH3 CH4 CH5 CH6 CH7

Front Shield Plate

Channel Status LEDs

38 Pin Removable Terminal Block

18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38

IO Label

+ 24 V GND EARTH

Terminal Block Fixing Screw

LED Indications

Connection Details Label

Front Door

Figure 1 : Front View of RTD Input Module The module provides LED indications on the front. Brief information about channel can be written on the front door. Behind front door, 38-pin removable terminal block is provided for interfacing. The wiring details are shown on backside of front door. The RTD input module can be configured in any IO slot of the PLC. The number of RTD input modules is limited by back panel current capacity.

Published July 2002 Page 6 of 47

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Messung Systems

8 Ch. RTD Input Module (4311)

In general a channel has following information Dynamic configuration information Static configuration information Data and Status information In all, 37 words information per module is available.

1.2 LED Indications

The following table explains significance of 10 numbers of LEDs provided on the module.

No. 1 2 LED NO 24 V SUPPLY CPU FAULT Color Orange Orange Status OFF ON Description 24 VDC supply to module healthy 24 VDC supply to module absent 24 VDC circuit on-board glass fuse blown OFF Module hardware healthy and module is ready ON Module in self test CPU watchdog faulty Module busy OFF Channel not enabled ON Channel enabled and healthy Flashing Parameter mismatch with 10 Hz Invalid configuration frequency Over range Under range Sensor open circuit Sensor short circuit Lead compensation wire open circuit

Channel Status (Eight for eight channels)

Green

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Published July 2002 Page 7 of 47

8 Ch. RTD Input Module (4311)

Messung Systems

1.3 General Specifications

General specifications of 8 channels RTD input module are as given below.

Number of Input channels Conversion Method RTD input types and output range PT100 (385) Temperature resolution Accuracy Input filter frequency Conversion time RTD linearization Lead Compensation Excitation current Isolation Channel to internal circuit Channel to channel External supply requirement External supply protection Indications 8 Non-isolated Sigma delta with digital filter -2000 to +8500 0.1 C 0.5 % of full scale 50 Hz 60 ms per channel In steps of 10 C 50 ohms per lead wire 1 mA 1.5 kV optical Nil 24 V DC, 100 mA (18 30 VDV including ripple) 315 mA miniature glass fuse on module Reverse polarity protection No 24 V Supply CPU fault Channel status (8) 300 mA 8 input bits and 8 output bits Removable 38 pin terminal block 4311

Back-plane current (5 V consumption) IO points consumed Termination / Connection Ordering code

Published July 2002 Page 8 of 47

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Messung Systems

8 Ch. RTD Input Module (4311)

2. Module Operation

This chapter helps in getting started with the RTD input module. It describes the basic operation of the module. This chapter explains operational details of Block Diagram RTD Types and Range of Temperatures Lead Compensation On-Board Processor Operations Module Information

At the time of the application program development, the module can be configured using the programming software DOXMINI+ so that the special features can be used. Refer chapter 4 for configuration and programming details.

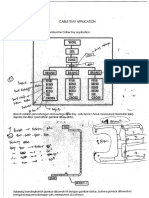

2.1 Block Diagram

Block diagram of RTD input module is shown below.

1 mA Excitation Current Source

Watch Dog

+5V

On board Processor

O P T I C A L I S O L A T I O N

Excitation Current Multiplexer / Analog to Digital Converter Reference Channel

Memory for Configuration, Data, Status Information

Instrumentation Amplifier

Channel 0 Input Circuit

RTD0+ RTD0RTD0C

CPU Module

+5V GND Module Interface Circuit

Channel Multiplexer

Channel 7 Input Circuit Miniature Glass Fuse

RTD7+ RTD7RTD7C + 24 VDC

No 24 V Supply Signal +15 V Supply for ADC Circuit -15 V +5 V GND

DC-to-DC Converter

24 V GND Earth

Figure 2 :Block diagram of RTD Input module

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Published July 2002 Page 9 of 47

8 Ch. RTD Input Module (4311)

Messung Systems

The module provides eight analog to digital channels for RTD input. CPU bus is optically isolated from ADC circuit. The analog to digital converter operates on serial data from the channels. RTD input sensor signal measurement is basically a resistance measurement which varies with temperature. For the same, module provides 1 mA excitation current to sensor. The dual matched current source is multiplexed for eight channel inputs. The enabled channel input signals are multiplexed and then instrumentation amplifier carries out amplification. Input electronic circuit provides the lead compensation. For more details, refer chapter 2.3. Amplified lead compensated input signal is provided to ADC. Sigma-delta (/ ) ADC converts only enabled analog channels to digital value one by one. On-board processor manipulates the converted count for each channel. It has following functions. Scaling Linearization Averaging Thus lead compensated, scaled and linearized temperature reading is transferred to module memory, which holds channel data information. If averaging is required, depending on the averaging count, on-board processor performs averaging of those many previous readings and updates channel data information. The channels can be independently enabled or disabled. On-board processor detects signals, which are out of range of selected input type. It also detects sensor faults. All this information is available to main CPU. The module provides auto-calibration facility to compensate for changes in excitation current due to ambient temperature. The dynamic configuration, static configuration, data, status information is available in dual port RAM on the module. The configuration of all channels is transferred to the module memory using WRITE_W function in the application program. Similarly data and status of all channels can be read by READ_W function in the application program. The module requires external 24 V for ADC circuit operation. Internally DC-to-DC converter generates 15 VDC and + 5 VDC as required by each channel. If 24 VDC is absent or on-board glass fuse is blown, module generates 'No 24 V Supply' signal for main CPU. The fuse protection for external 24 VDC supply is provided on module.

2.2 RTD types and range of temperatures

This section describes the RTD types and data range of temperatures supported by module. In current version, PT100 (385) is supported.

Type PT 100 (385) Resistance values 18.49 to 390.26 C temperature range -200.0 C to +850.0 C

Published July 2002 Page 10 of 47

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Messung Systems

8 Ch. RTD Input Module (4311)

2.3 Lead Compensation

RTD input measurement is basically sensor resistance measurement which changes with temperature. The sensor resistance is low and lead wires can add to the actual resistance of the sensor. This causes noticeable offset in actual reading. This offset varies depending upon change in lead wire resistance due to length, temperature, aging, etc. So it is necessary to eliminate effect of lead wire resistance in measurement. In RTD input module, lead compensation is provided by using 3 wire PT 100 sensor input with proper electronic circuit. The bridge is formed by dual matched current source and 3 wires PT100 sensor. The schematic of input circuit is shown below.

PT100 Sensor Excitation Current Multiplexer RL I I Channel Multiplexer V1 Instrumentation Amplifier To ADC RL RL V2

Figure 3 :Schematic of input circuit RL Lead resistance R - Sensor resistance As dual matched current sources are used, both follow each other keeping current equal. It is also assumed that lead wire resistance for three wires is equal. V1 = I (2RL+R) V2 = I (2RL) V = (V1V2) =IR =R (as I =1 mA )

From above equations, it can be observed that effect of lead wire resistance (RL) is eliminated and the voltage V is direct indication of sensor resistance (R).As explained in chapter 2.1, excitation current source is multiplexed for all the eight channels and eight sensor input signals are multiplexed to a ADC. The voltage V which is direct indication of sensor resistance is amplified by instrumentation amplifier and inputed to ADC for conversion.

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017 Published July 2002 Page 11 of 47

8 Ch. RTD Input Module (4311)

Messung Systems

Published July 2002 Page 12 of 47

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Messung Systems

8 Ch. RTD Input Module (4311)

2.4 On-Board Processor Operations

The RTD input module is an intelligent module with on-board processor. The functions of on-board processor are explained in below sections.

2.4.1 Power On Operations

After power ON, if 24 V supply to module is absent or on-board fuse is blown then on-board processor sets Ix.0 bit of input image. After power ON, this processor checks the hardware called as self test. During selftest and if hardware error is detected, Ix.0 bit of input image is set. Also CPU fault LED on front panel is put ON indicating that module is not accessible. During module operation, if module hardware is found faulty or watchdog error is detected, Ix.0 bit is set. If the module hardware is OK, Ix.0 bit is cleared. Module waits for static and dynamic configuration from the CPU module. After reception of valid configuration of RTD input channels, the module starts sampling and digital conversion cycle of enabled channels. For more details of IO image of module, refer chapter 2.9. The module continues sampling, converting the channels and updating module memory even after the PLC is put in STOP mode. But In this case, CPU module does not read the channel data and status.

2.4.2 Analog to Digital Conversion

The module samples a RTD input channel and converts lead compensated input to its digital value one by one. After power ON, first reference channel signal is sampled and conversion is started. For reference channel, on-board highly precise and stable resistor of 100 ohms is used as input. After that only enabled channels are converted as shown in the figure 4. If any error like invalid configuration is detected, channel is not converted. The disabled channels or channels with error detected are bypassed retaining earlier values. After one channel conversion, module initiates next channel conversion. During this conversion period, module processes converted data of previous channel. This process includes scaling, linearization and averaging. Thus the processed data for previous channel is made available during this period. After converting all healthy channels, processed data and status information of all the channels is transferred to respective memory area on the module. This cycle continues. Thus when the processor module performs READ_W operation, it reads either old or new information i.e. data and status of channels

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Published July 2002 Page 13 of 47

8 Ch. RTD Input Module (4311)

Messung Systems

Channel 0 disabled / error detection Reference Channel Conversion Channel 0 Conversion

Channel 1 disabled / error detection Channel 1 Conversion

Channel 2 disabled / error detection Channel 2 Conversion

Channel 3 disabled / error detection Channel 3 Conversion

Update all channel data and status

Channel 7 Conversion Channel 7 disabled / error detection

Channel 6 Conversion Channel 6 disabled / error detection

Channel 5 Conversion Channel 5 disabled / error detection

Channel 4 Conversion Channel 3 disabled / error detection

Figure 4 :ADC Conversion Cycle The module takes certain time to sample all enabled channels and convert into digital value. The required time is the module update time. The factors affecting module update time is number of channels enabled. The module update time is minimum when only one channel is enabled. Likewise the module update time is maximum when all channels are enabled. The module incorporates a digital low pass filter to reject noise on the input signal. For RTD inputs, it is fixed to 50 Hz. It provides better noise rejection for low filter frequencies.

2.4.3 Excitation Current Drift Compensation

As explained in chapter 2.3, excitation current has major effect on measurement. Drift in excitation current (1 mA) may occur due to change in ambient temperature, component aging, etc. This will create significant offset in measurement. So it is necessary to compensate effect of drift in excitation current. In 8 channels RTD input module, excitation current drift compensation is achieved by flexible software method. As explained in chapter 2.4.2, module always samples a default reference channel. On-board highly precise and stable resistor (100 ohms) input is provided as a channel input. In case of any drift in excitation current, proportional change in input signal to ADC is observed for this channel. This change in input signal is direct indication of change in excitation current. This offset is noted and then compensated for RTD input channels by software during analog to digital conversion cycle. This compensated count is then scaled, linearized further.

Published July 2002 Page 14 of 47

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Messung Systems

8 Ch. RTD Input Module (4311)

2.4.4 Scaling

The resistance signal from RTD sensors is scaled for equivalent temperature as per reference tables provided by standards. For the same, refer appendix 1.

2.4.5 Linearization

RTD signals are not linear e.g. 10 percent change in a RTD voltage does not correspond to a 10 percent change in its temperature. Therefore linearization of RTD signal is necessary to get equivalent temperature. Also, each RTD input type requires different linearization. In RTD input module linearization is performed by flexible software methods. This is done with look up table in steps of 10 C for each RTD input type. ADC count is mapped within its 10 C temperature range and equivalent temperature is calculated using linear interpolation method.

2.4.6 Averaging

The module provides user selectable averaging facility so that stable value is available for processing and necessary control action. The module samples and converts enabled channels one by one. The module keeps digital value into different memory locations. Depending on the averaging count, the module performs averaging of those many previous readings and updates channel data information. Thus if the averaging counts of channel 0, 1 and 2 are 1, 4 and 8 respectively, then initially data of channel 0, 1 and 2 are updated after 1, 4 and 8 conversion cycles respectively. After that, it gets updated in every cycle. One conversion cycle means sampling and converting all enabled channels as explained in chapter 2.3.2. Thus combination of filter frequency and averaging count can be selected to get optimum channel update time and stable temperature reading.

2.5 Module Information

This section explains the entire information required and available with RTD input module. The following points are discussed Input Output Image Mapping Memory Mapping Commands Module Status Bits

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Published July 2002 Page 15 of 47

8 Ch. RTD Input Module (4311)

Messung Systems

2.5.1 Input Output Image Mapping

Input output image mapping related to RTD input module is shown below. CPU module

Module Not OK Invalid Configuration Set Points Exceeded Out of Range Sensor Fault

RTD Input module

Ix.0 Ix.1 Ix.2 Ix.3 Ix.4 Input Scan Channel 0

Input Image 1.1.1.1.1

Logic Scan EN IMM_IN ENO

Channel 1

Channel 2

SLOT Channel 3 Qx.0 Output Scan

Output Image

Static Configuration Write

Logic Scan IMM_OUT ENO EN SLOT

Module Interface circuit

Channel 4

Channel 5

Channel 6

Channel 7

Figure 5 :Input Output Image Mapping of RTD Input Module The module consumes 8 input bits (1 byte) of input image and 8 output bits (1 byte) of output image in the CPU module. CPU reads the status of module in input scan. CPU writes user commands to module in output scan. For immediate updation of input and output image, IMM_IN and IMM_OUT functions can be used in application program whenever required. For the details refer chapter 2.4.3 and 2.4.4.

Published July 2002 Page 16 of 47

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Messung Systems

8 Ch. RTD Input Module (4311)

2.5.2 Memory Mapping

The memory mapping related to RTD input module is shown in figure below. CPU module

17 words hold channel dynamic Information of 8 channels Channel Enable Word MW66 Channel 0 High Set Point MW68 Channel 0 Low Set Point MW70

RTD Input module

17 words hold channel dynamic information of 8 channels Channel Enable Word MMW00 Channel 0 High Set Point MMW02 Channel 0 Low Set Point MMW04

Logic Scan

WRITE_W Channel 7 High Set Point Channel 7 Low Set Point MW96 MW98 EN SLOT DATA LEN ADDR ENO Channel 7 High Set Point Channel 7 Low Set Point MMW30 MMW32

8 words hold channel static information of 8 channels Channel 0 Static Configuration MW50 Channel 7 Static Configuration MW64

8 words hold channel static information of 8 channels Channel 0 Static Configuration MMW96 Channel 7 Static Configuration MMW110

8 words hold data for 8 channels Channel 0 Data MW100 Channel 7 Data MW114

Logic Scan

8 words hold data for 8 channels Channel 0 Data MMW128 Channel 7 Data MMW142

4 words hold status of 8 channels Channel Set Point Status MW120 Channel Configuration Status MW122 Channel Input Range Status MW124 Channel Sensor Fault Status MW126

READ_W ENO EN SLOT DATA LEN ADDR

4 words hold status of 8 channels Channel Set Point Status MMW146 Channel Configuration Status MMW148 Channel Input Range Status MMW150 Channel Sensor Fault Status MMW152

Figure 6 :Memory Mapping of RTD Input Module The configuration (grouped as static and dynamic) from PLC variable area e.g. memory or page is transferred to module memory when WRITE_W function gets executed in application program i.e. in logic scan. The module takes action on static configuration information only when static configuration write command is issued. This can be issued by setting Qx.0 bit of output image. In case of dynamic configuration information, the module detects any change in configuration and if any valid change is detected, it takes appropriate action. After power ON, module starts its channel conversion operation only after receiving valid configuration. If channel configuration is modified or channel is enabled / disabled, it takes effect only in the subsequent conversion cycle. The channel configuration can be modified using WRITE_W function. Similarly channel can be enabled or disabled during normal operation for optimum results. The channel temperature readings and status information can be read from the module using READ_W function.

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017 Published July 2002 Page 17 of 47

8 Ch. RTD Input Module (4311)

Messung Systems

2.5.3 Commands

As discussed in chapter 2.4.1, output image bits are used as user commands to module. User can issue various commands to module through application program. CPU writes commands in output image area of module in output scan. The module reads output image area cyclically and takes appropriate action. If 'IMM_OUT' function is executed in logic scan for a particular slot, it stops current logic scan, executes output scan for defined slot and resumes logic scan again. This is useful when ever immediate updation of output image is needed. The functions of output image bits are given below

No Bit Address Command Write static configuration OFF Status ON 1 Qxx.0 Description It gives command to the module to accept static configuration or change static configuration as per contents of module memory words MMW #96 to MMW#110. Write static command is OFF.

Note xx is slot number in which module is fixed. Qxx.1 to Qxx.7 are reserved and should not be used.

Published July 2002 Page 18 of 47

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Messung Systems

8 Ch. RTD Input Module (4311)

2.5.4 Module Status Bits

As discussed in chapter 2.4.1, input image bits are used as module status indications. User can check the module status through application program. The module writes status in its input image area cyclically. The CPU reads this input image area in input scan. If 'IMM_IN' function is executed in logic scan for a particular slot, it stops current logic scan, executes input scan for defined slot and resumes logic scan again. This is useful when ever immediate updation of input image is needed. The functions of input image bits are given below

No 1 Bit Address Ixx.0 Module Status Module Not Ready Status ON Description 24 VDC supply to module absent 24 VDC circuit fuse blown. Module CPU watch dog fault. Module not ready. 24 VDC Supply to module healthy Module healthy and ready Invalid static configuration Parameter mismatch Valid static configuration Valid parameters Any channel temperature reading above high set point Any channel temperature reading below low set point All channel temperature readings within high and low set points Over range for any enabled channels/s. Under range for any enabled channels/s. All enabled channel inputs are within specified range Sensor open circuit for any enabled channels/s. Sensor short circuit for any enabled channels/s. Lead compensation wire open circuit for any enabled channels/s. All enabled channel inputs are connected properly. MMW for storing the details Not Applicable

OFF 2 Ixx.1 Invalid Configuration Set point exceeded ON OFF 3 Ixx.2 ON

#148

#146

OFF 4 Ixx.3 Out of Range ON

#150

OFF 5 Ixx.4 Sensor Fault ON

#152

OFF

Note xx is slot number in which module is fixed. Ixx.5 to Ixx.7 are reserved and should not be used.

Whenever accessing the module, user must check the module status bit Ix.0. If any error condition is detected in input image, check corresponding module memory word to get more details to locate exact problem.

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Published July 2002 Page 19 of 47

8 Ch. RTD Input Module (4311)

Messung Systems

3. Installations and Wiring

This chapter provides the following information Module Installation Connection Details Precautions to be taken

3.1 Module Installation

The installation procedure for RTD input module is same as any other discrete I/O module. Put the module in to the desired slot of the PLC. 1. Tighten the screw provided at the top of the module. 2. Connect the terminal block at the front of the module and tighten it.

Published July 2002 Page 20 of 47

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Messung Systems

8 Ch. RTD Input Module (4311)

3.2 Connection Details

The figure shows the connection diagram of RTD input module

01 02 03 04 05

RTD 1

06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 RTD0+ RTD1+ RTD0RTD1RTD0C RTD1C RTD2+ RTD3+ RTD2RTD3RTD2C RTD3C RTD4+ RTD5+ RTD4RTD5RTD4C RTD5C RTD6+ RTD7+ RTD6RTD7RTD6C RTD7C

RTD 8

+ 24 VDC GND EARTH

33 34 35 36 37 38

+ 24 V 0V EARTH

Figure 7 :Connection diagram of RTD input Module In figure, RTDs are connected to channel 0 and 7. For interfacing RTDs, 38-pin terminal block is provided. RTD input is connected to RTDn+, RTDn- and RTDnC terminals, where n is a channel number. For healthy working, ensure correct polarity of RTD element. It is ensured that all the three connections of a RTD element come in line on terminal block for easy connectivity. RTD 0 is connected to terminal cumbers 10, 12 and 14. RTD 1 is to be connected to terminal numbers 11, 13 and 15. RTD 7 is to be connected to terminal numbers 29, 31, and 33.

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017 Published July 2002 Page 21 of 47

8 Ch. RTD Input Module (4311)

Messung Systems

For functioning of RTD input module, external 24 VDC supply is required. Connect 24 VDC supply between terminals 36 (+ 24 V) and 37 (0 V). Connect terminal 38 to earth busbar in control panel.

3.3 Precautions to be taken

All the normal precautions concerning the wiring and protection of an electronic equipment in an industrial environment should be observed. To guard against coupling noise from one conductor to another, follow the guidelines given below. Inside control panel Following guidelines to be observed inside control panel. All power circuit wiring e.g. connected to Power Supply Module, power contactors, etc i.e. high voltage wiring should be kept separate and apart from RTD signals. Digital Input wiring and Digital Output wiring (especially, relay output and AC output) should be separately bundled and kept as apart as possible from RTD signals. RTD signals should be carried through shielded cables.

Outside control panel Following guidelines to be observed outside control panel. Depending upon the type of modules used in PLC, separate ducts should be provided for Power circuit wiring and power cables. Input cables Output cables All cables carrying low level signals for analog IO modules, thermocouple/ RTD input modules and for communication.

Wherever possible, it is recommended to Avoid parallel routing of cables carrying analog signals and power cables, etc over long distances Ensure that cables carrying analog signals cross at right angles to power cables so that minimum length of cable will be in close vicinity of power cables. Run cables on metallic surfaces Avoid number of joints Keep cable lengths as short as possible.

Published July 2002 Page 22 of 47

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Messung Systems

8 Ch. RTD Input Module (4311)

4. Configuration and Programming

This chapter explains configuration of RTD input module and transferring information with RTD input module. This information is useful for application program development. The module configuration consists of Slot configuration and Channel configuration

4.1 Slot Configuration

The RTD input module provides eight RTD input channels, which can be independently operated. Configuring the slot for RTD input module is just like any other discrete IO module only. The programming and documentation software DOXMINI+ is used for configuration and programming. The module consumes 1 byte of input image and 1 byte of output image. The input image is used for reading status of module. The output image is used for writing user commands to module. For more details, refer chapter 2.4.3 and 2.4.4. The IO byte consumption along with configuration of Nexgen PLC is shown below.

Power Supply Module Nexgen 4000 CPU Module Slot 0 32 DC Input Module I0.0 to I0.7 I1.0 to I1.7 I2.0 to I2.7 I3.0 to I3.7 Slot 1 32 DC Output Module Q4.0 toQI4.7 Q5.0 to Q5.7 Q6.0 to Q6.7 Q7.0 to Q7.7 Slot 2 RTD Input Module I8.0 to I8.7 Q8.0 to Q8.7 Slot 3 16 DC Output Module Q9.0 to Q9.7 Q10.0 to Q10.7

Input module in first slot 0 consumes IB0 to IB3 of input image. Output module in slot 1 consumes QB4 to QB7 of output image. RTD input module consumes IB8 of input image and QB8 of output image.16 DC Output module in slot 3 consumes QB9 and QB10 of output image. The IO byte consumption along with configuration of Nexgen5000 PLC is shown below.

Power Supply Module

Nexgen5000 CPU Module

Slot 0 32 DC Input Module (4632) %IX0.0 - %IX0.7 %IX1.0 - %IX1.7 %IX2.0 - %IX2.7 %IX3.0 - %IX3.7

Slot 1 32 DC Output Module (4732)

Slot 2 RTD Input Module (4311)

Slot 3 16 DC Output Module (4716)

%QX0.0 - %QX0.7 %IX4.0 - %IX4.7 %QX5.0 - %QX5.7 %QX1.0 - %QX1.7 %QX4.0 - %QX4.7 %QX6.0 - %QX6.7 %QX2.0 - %QX2.7 %QX3.0 - %QX3.7

Input module in first slot 0 consumes IB0 to IB3 of input image. Output module in slot 1 consumes QB0 to QB3 of output image. The analog input module consumes IB4 of input image and QB4 of output image.16 DC Output module in slot 3 consumes QB5 and QB6 of output image.

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Published July 2002 Page 23 of 47

8 Ch. RTD Input Module (4311)

Messung Systems

4.2 Channel Configuration

The RTD input module can be configured in any slot of PLC. It provides eight non-isolated channels. These channels can be independently configured for different types of RTD inputs. The channel configuration is grouped in two types Static configuration This information decides basic functioning of a channel. Normally, this information is not altered in run time e.g. type of RTD. Dynamic configuration This information does not affect basic functioning of channel. This information is changed during run time e.g. high and low set points for temperature reading.

4.2.1 Static Configuration

After power ON, the configuration of one or more channels can be transferred to the module using WRITE_W function. The global variables, memory or page can be used to hold channel configuration. The channel static configuration information includes RTD input type Filter frequency (fixed to 50 Hz for RTD inputs) Return value on sensor fault and Averaging This information is transferred to module memory by using 'WRITE_W function. The module takes action on this information when static configuration write command is issued (on rising edge of Qx.0 bit). After that only static configuration or change in static configuration is effective. This static configuration information is to be stored in bit form in one word for each channel. The following table gives information to be stored. The valid combination of bits must be set. Module memory words MMW #96 to MMW #110 are module memory words for static configuration. MMW #96 - Channel 0 Static Configuration Word

Item Input type Description PT100 (385) Invalid Invalid 50 Hz Invalid Invalid Zero Upper Scale Lower Scale Invalid 16 8 4

0 0 1 1 0 0 1 0 1 0 0 1 0 1 15 14 13 12 11 10 9 8 7 6 5 4 0 0 1 0 0 1 0 0 1 0 1 1 3 0 0 1 2 0 0 1 1 0 0 1 0 0 1 1

Filter Return value on sensor fault Avg. Samples

Published July 2002 Page 24 of 47

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Messung Systems

8 Ch. RTD Input Module (4311)

Item Res. 1 --

Description

15 0

14 0

13 0

12 0

11 1

10 1

MMW #98 to MMW #110 Channel 1 to 7 static configuration words.

MMW #98 MMW #110 Channel 1 static configuration word Channel 7 static configuration word

Input type The RTD input module supports different types of inputs. The inputs include 3 wires PT100 (385) Bit 0 to bit 4 hold input type information. Filter frequency Next three Bits, Bit 5 to bit 7 defines the low-pass filter frequency. For RTD input module, 50 Hz filter is fixed by default. User has no selection choice.

Bit 7 0 Bit 6 0 Bit 5 0 Filter Frequency Update time for a Channel 50 Hz 60 ms

This is in built function of ADC. The filter frequency affects noise rejection on incoming RTD signal. Also it affects channel update time. Return value on sensor fault circuit Next two bits, bit 8 and bit 9 define the value of the channel temperature reading when sensor fault is detected for that channel. Here sensor fault means sensor open circuit, sensor short circuit and lead compensation wires open circuit.

Bit9 0 0 1 1 Bit8 0 1 0 1 Sensor Fault value Zero Upper scale Lower scale Invalid

In such sensor fault condition, the channel value can be set to any one of above options considering safety in control action. Averaging Next two Bits, Bit10 and Bit 10 define the selection of sampling value for averaging.

Bit10 0 0 1 1 Bit11 0 1 0 1 Averaging Samples 16 8 4 1 Published July 2002 Page 25 of 47

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

8 Ch. RTD Input Module (4311)

Messung Systems

If the averaging counts of channel 0, 1 and 2 are 1, 4 and 8 respectively, then initially data of channel 0, 1 and 2 are updated after 1, 4 and 8 conversion cycles respectively. After that, it gets updated in every cycle. One conversion cycle means sampling and converting all enabled channels as explained in chapter 2.3.2. Module memory words MMW #0 to MMW #32 are module memory words for dynamic configuration. MMW #0 is a channel enable / disable word. MMW #2 to MMW #32 provides high and low set points for individual channels.

4.2.2 Dynamic Configuration

The channel dynamic configuration information includes Channel enable/ disable Channel high and low set points This information is transferred to module memory by using 'WRITE_W function. The module detects change in dynamic configuration information in its own scan. If valid change is detected, appropriate action is initiated and dynamic configuration or change in dynamic configuration is effective in consecutive scan. Channel Enable The eight bits in module memory word MMW #0 defines the enable status of the all the channels. If it is 0 channel is disabled and if it is 1 channel is enable. The module samples only enabled channels and converts into digital value. The channel data for disabled channels is forced to zero. Thus enabling only used channels can minimize the module update time. If a particular channel is important at particular instance, all other channels can be disabled temporarily and only one channel conversion can be carried out to get fast response. MMW #0 Channel enable / disable word

Item Ch 1 Description Disable Enable Disable Enable 0 0 0 0 0 0 0 0 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 0 1

Ch 8 Res

0 1

Bit 0 of MMW #0 is enable / disable bit for channel 0.Bit 7 of MMW #0 is enable / disable bit for channel 7. Bits 8 to 15 are reserved and should not be used. Channel High and Low set points User can define high and low set points for individual channel temperature readings available in 0.1 C resolution. If channel temperature is above high set point, corresponding high bit in MMW #146

Published July 2002 Page 26 of 47 8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Messung Systems

8 Ch. RTD Input Module (4311)

is set. If channel temperature is below low set point, corresponding bit in MMW # 146 is set. MMW #2 to MMW #32 - Channel High and Low set points

MMW #2 MMW #4 MMW #30 MMW #32 Channel 0 high set point (in 0.1 C resolution) Channel 0 low set point (in 0.1 C resolution) Channel 7 high set point (in 0.1 C resolution) Channel 7 low set point (in 0.1 C resolution)

Valid range for high and low set points is 200.0 C to 800.0 C for PT 100 input type. If settings are not within range of that input type, Ixx.1 bit is set indicating invalid configuration. Refer MMW #148 to point out faulty channel configuration. If high set point for a channel is less than that of low set point and vice versa, Ixx.1 bit is made ON indicating parameter mismatch. Refer MMW #148 to point out faulty channel configuration. MMW #34 to MMW #94 are reserved and should not be used.

4.3 Channel Information

For the configured channels, necessary information is available as channel data and status bits. This is explained in details below.

4.3.1 Channel Data

Module memory words MMW #128 to MMW #142 are module memory words for channel temperature readings. This is nothing but ambient temperature. The temperature reading resolution is 0.1 C. For enabled channels, this information is updated cyclically in module. The data is read and stored using READ_W function in application program.

RTD Type PT 100 (385) C Temperature range -200.0 C to 850.0 C

4.3.2 Channel Status

Channel status information is available in MMW #146 to MMW #152 in bit form as follows. Channel high and low set point status MMW #146 stores high and low limit status of individual channels.

Item Ch 1 Description < Max. limit > Max. limit > Min. limit < Min. limit < Max. limit > Max. limit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 1 0 1 Published July 2002 Page 27 of 47 0 0 1

Ch 8

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

8 Ch. RTD Input Module (4311)

Messung Systems

Item

Description > Min. limit < Min. limit

15 14 13 12 11 10 0 1

First two bits bit 0 and bit 1 holds high and low point status of channel 0 comparing high and low set points in MMW #2 and MMW #4 respectively. Channel 0 high bit, bit 0 becomes ON when temerature reading is above high set point. It becomes OFF when temprature reading is below high set point. Low bit becomes ON when temerature reading is below low set point. It becomes OFF when temprature reading is above low set point. Similarly next two bits gives high and low point status of cahnnel 2 and so on. Channel configuration status Module memory word MMW #148 holds status of validity of configuration and parameters for all the channels. MMW #148 Channel configuration and parameter mismatch status

Item Description 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Ch 1

Config. valid Config. Invalid

Config. valid Config. Invalid 0 1 0 0 0 0 0 0 0 0

0 1

Ch 8 Res

Bit 0 of MMW #148 gives channel 0 configuration status and bit 7 of MMW #148 gives channel 7 configuration status. Configuration bit is ON when In dynamic configuration if high set point is not within specified input range if low set point is not within specified input range if high set point < low set point In all these cases, Ixx.1 bit becomes ON. Corresponding green channel LED starts flashing. Channel out of range status MMW #150 stores over range and under range status of individual channels.

Item Ch 1 Description < Over range Over range > Under range Under range < Over range Over range > Under range Under range 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 1 0 1 0 1 0 0 1

Ch 8

Published July 2002 Page 28 of 47

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Messung Systems

8 Ch. RTD Input Module (4311)

First two bits bit 0 and bit 1 gives over range and under range status of channel 0 depending on input type selected. Next two bits give over range and under range status of channel 1 and so on. Over range bit becomes ON when RTD input is above specified input signal. Under range bit becomes ON when RTD input is below specified input signal. In all these cases, corresponding green channel LED starts flashing. Sensor Fault Error MMW #152 stores sensor fault status of individual channels.

Item Ch 1 Description Input connected Sensor fault Input connected Sensor fault 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 0 1

Ch 8 Res

0 1 0 0 0 0 0 0 0 0

Bit 0 of MMW #152 holds status of channel 0. It becomes ON if channel 0 is configured and input signal is not connected. Bit 1 of MMW #154 holds status of channel 1. In ADC conversion cycle, first sensor fault status for configured channel is checked. If sensor fault is detected, channel is bypassed and returns value in case of open circuit is stored as channel temperature reading. Bit 9 and bit 8 of static configuration word of a channel decides return value as zero, upper scale or lower scale considering safety in control action. If open circuit error bit is set for a channel, corresponding channel LED (green color) on module starts flashing.

4.4 Programming with Nexgen 4000 CPU

The data in PLC variables is transferred to the RTD input module when 'WRITE_W' function is executed. The data in the PLC variables can be updated using functions like 'MOV_W', arithmetic or any other functions. The data from RTD input module memory can be transferred to PLC variables when 'READ_W' function is executed. The WRITE_W function below shows data transfer from the CPU module's memory to RTD input module memory. The details of transfer are RTD input module is configured in slot 2 of PLC Start address of memory on the CPU module is MW50 Length of data area to be transferred is 8 words Address on the RTD input module in slot 2 is #96

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Published July 2002 Page 29 of 47

8 Ch. RTD Input Module (4311)

Messung Systems

M0.0 ----- WRITE_W ---M0.1 +---| |---+--------- |EN ENO|-+---------+---( )--| | #2 -|SLOT | | | MW50 -|DATA | | | #8 -|LEN | | | #96 -|ADDR | | | ------------------'WRITE_W' function gets executed when condition for enable 'EN' is ON. 'ENO' output becomes ON, when EN is ON and function is executed successfully. ENO is OFF if Parameters of function are invalid or not within specified range. RTD input module is not accessible to CPU module So 8 words (MW50 to MW64) information from CPU memory is transferred to the memory at address #96 onwards of RTD input module fitted in slot 2. The 'READ_W' function below shows data transfer from the RTD input module memory to CPU memory. The details of transfer are RTD input module is configured in slot 2 of PLC Address on the RTD input module in slot 2 is #128 Start address of memory on the CPU module is MW100 Length of data area to be transferred is 8 words M0.2 ------ READ_W ----M0.3 +---| |---+--------- |EN ENO|-+---------+---( )--| | #2 -|SLOT | | | #128 -|ADDR | | | #8 -|LEN | | | MW100-|DATA | | |

--------------READ_W' function gets executed when condition for enable 'EN' is ON. 'ENO' output becomes ON, when EN is ON and function is executed successfully. ENO is OFF if parameters of function are invalid or not within specified range. RTD input module is not accessible to CPU module. So 8 words (MMW128 to MMW142) information on RTD input module fitted in slot #2 are transferred to the CPU memory words (MW100 to MW114). Example of basic application program is given below. For the same, refer Nexgen PLC configuration shown in chapter 4.1. In the configuration, following points are to be noted.

Published July 2002 Page 30 of 47

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Messung Systems

8 Ch. RTD Input Module (4311)

I 8.0 is a module status bit as 'Module Not OK' bit. I8.0 is set if 24 VDC supply to module is not healthy and / or hardware fault, watchdog fault is observed on module. I 8.1 is a configuration status bit as 'Invalid Configuration' bit. I 8.1 is set if for one or more channels, configuration is invalid. I 8.2 is a maximum minimum set point status bit as 'Set point Exceeded' bit. I 8.2 is set if for one or more configured channels, input signal is below or above limits set. I 8.3 is a RTD input range status bit as 'Out of Range' bit. I 8.3 is set if for one or more configured channels, input signal is below or above specified range. I 8.4 is a open circuit status bit as 'Sensor Fault ' bit. I 8.4 is set if for one or more configured channels, input is not connected. Q 8.0 is a command for 'Static Configuration Write'. When this bit is set by user, RTD input module accepts static configuration available in module memory words MMW#96 to MMW#110 and configures the module accordingly. S 4.2 is a 'Module Error' bit for the module fitted in slot 2. While developing the application program, first check whether the module is healthy. For the same, check 'Module Error' bit S 4.2 and 'Module Not Ok' bit I8.0. If any bit is set, declare respective fault. In this case, module is not accessible. If both are OFF, then only enable 'WRITE_W' and 'READ_W' functions for RTD input module. The static configuration information consists of basic attributes like return value in case of sensor fault of input signal (zero, upper scale, lower scale) and no. of averaging samples ( 0, 4, 8, 16 ). This configuration is to be transferred to module memory MMW#96 to MMW#110, if all the 8 channels are used. In this example, channels are configured for PT 100 50 Hz filter Return value is of upper scale in case of sensor fault No. of averaging samples is 4 For this configuration, the value $0900 should be written to respective module memory word.

Static Configuration Word

$0902

15 14 13 12 11 10 0 0 0 0 1 0 Reserved

9 0

8 1

7 0

6 0 50 Hz Filter

5 0

4 0

3 0

2 0

1 0

0 0

Avg. of Return 4 value of Samples upper scale

RTD input

So MW50 to MW 64 should contain $0900, for the configuration required. This information is transferred to RTD module memory MMW#96 to MMW#110, when 'WRITE_W' function is executed.

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Published July 2002 Page 31 of 47

8 Ch. RTD Input Module (4311)

Messung Systems

When 'WRITE_W' function is executed successfully, ENO output becomes ON, When ENO is ON, set 'Static Configuration Write' command bit informing the module to accept the static configuration or change in configuration. Once this information is transferred to module, it is valid as long as PLC power is present. It is recommended to enable 'WRITE_W function when Warm start is observed i.e. System bit S0.6 is ON Cold start is observed i.e. System bit S0.7 is ON Module Error bit becomes OFF i.e. System bit S4.2 is ON Module Not OK bit becomes OFF i.e. Input bit I8.0 is ON and Any other condition as per requirement of application program e.g. memory bit M2.0 is ON. S0.6 ------ WRITE_W ---Q8.0 +---| |---+---------+---------|EN ENO|-+---( )--| | | S0.7 | | | +---| |---+---------| #2 -|SLOT | | | | S4.2 M0.4 | | | +---| |---+---|N|---| MW50 -|DATA | | | | I8.0 M0.5 | | | +---| |---+---|N|---+ #8 -|LEN | | | | M2.0 M2.1 | | | +---| |---+---|P|---+ #96 -|ADDR | | | ------------------If 'WRITE_W' function is executed successfully, Q8.0 bit becomes ON for one scan duration. If this bit is not ON even if function enable conditions are ON, declare fault and take appropriate action. Once, static configuration is written, channels are enabled as per requirement. To enable all the channels, memory word MW166 should contain $00FF value. Enable 'WRITE_W' function with any condition M0.6 with interlocks of Module Error bit S4.2 and 'Module Not Ok' bit I8.0.

Published July 2002 Page 32 of 47

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Messung Systems

8 Ch. RTD Input Module (4311)

When 'WRITE_W' function is executed, the data $00FF is transferred to module memory MMW#00. The maximum and minimum set points for each channel is transferred to module memory words MMW#02 to MMW#32 if 'WRITE_W' function is executed successfully, M0.7 bit becomes ON. If this bit is not ON even if function enable conditions are ON, declare fault and take appropriate action. M0.6 S4.2 I8.0 ------ WRITE_W ---M0.7 +---| |---+---|/|---+---|/|---|EN ENO|-+---( )--| | | | #2 -|SLOT | | | | | MW166 -|DATA | | | | | #17 -|LEN | | | | | #0 -|ADDR | | | ------------------After transferring static and dynamic configuration information to RTD module memory, module starts functioning. Enable 'READ_W' function with any condition M1.0 with interlocks of Module Error bit S4.2 and 'Module Not Ok' bit I8.0. When 'READ_W' function is executed, the temperature readings (0.1 C resolution) stored in module memory MMW#128 to MMW#142 are transferred to CPU memory MW100 to MW#114 respectivelIf 'READ_W' function is executed successfully, M1.1 bit becomes ON. If this bit is not ON even if function enable conditions are ON, declare fault and take appropriate action. M1.0 S4.2 I8.0 ------ READ_W ----M1.1 +---| |---+---|/|---+---|/|---|EN ENO|-+---( )--| | | | #2 -|SLOT | | | | | #128 -|ADDR | | | | | #8 -|LEN | | | | | MW100 -|DATA | | | -------------------

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Published July 2002 Page 33 of 47

8 Ch. RTD Input Module (4311)

Messung Systems

To read the status of temperature readings for maximum and minimum set points, it is necessary to read MMW#146 when I8.2 bit 'Set point Exceeded' in ON. I8.2 S4.2 I8.0 ------ READ_W ----M1.5 +---| |---+---|/|---+---|/|---|EN ENO|-+---( )--| | | | #2 -|SLOT | | | | | #146 -|ADDR | | | | | #1 -|LEN | | | | | MW126 -|DATA | | | ------------------Here M126.0 is over range bit for channel 0 and M126.1 is for under range for channel 0. Similarly, M127.6 is over range bit for channel 7 and M127.7 is for under range for channel 7. With this status, appropriate action can be taken for temperature control. To read the status of each channel, read the status information when ever corresponding input image bit is ON. This is depicted below. 'Invalid Configuration bit I8.1 becomes ON, if one or more channel configuration data is invalid. To find out exact faulty channel/s, read MMW#148 from module. I8.1 S4.2 I8.0 ------ READ_W ----M1.2 +---| |---+---|/|---+---|/|---|EN ENO|-+---( )--| | | | #2 -|SLOT | | | | | #148 -|ADDR | | | | | #1 -|LEN | | | | | MW118 -|DATA | | | ------------------When this 'READ_W' function is executed successfully, check CPU memory bits M118.0 to M118.7. M118.0 bit is ON if channel 0 configuration is invalid, M118.1 bit is ON if channel 1 configuration is invalid and so on. In this correct the configuration of faulty channel. In case of invalid configuration for particular channel, channel temperature reading becomes #0.

Published July 2002 Page 34 of 47 8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Messung Systems

8 Ch. RTD Input Module (4311)

'Out of Range' bit I8.3 becomes ON, if one or more channel input signal/s is/are below or above specified range for selected input type. To find out exact faulty channel/s, read MMW#150 from module. I8.3 S4.2 I8.0 ------ READ_W ----M1.3 +---| |---+---|/|---+---|/|---|EN ENO|-+---( )--| | | | #2 -|SLOT | | | | | #150 -|ADDR | | | | | #1 -|LEN | | | | | MW120 -|DATA | | |

---------------When this 'READ_W' function is executed successfully, check CPU memory bits M120.0 to M121.7 for over range and over range status. M120.0 bit is ON if channel 0 input signal is above specified range, M120.1 bit is ON if channel 0 input signal is below specified range and so on. In this case, take proper action. For a particular channel, if input signal is above specified range, channel temperature reading remains at maximum value. For PT100 input, this is 850.0 C. For a particular channel, if input signal is below specified range, channel temperature reading remains at minimum value. For PT100 input, this is -250.0 C 'Sensor Fault' bit I8.4 becomes ON, if one or more channel input is disconnected. To find out exact faulty channel/s, read MMW#152 from module. I8.4 S4.2 I8.0 ------ READ_W ----M1.4 +---| |---+---|/|---+---|/|---|EN ENO|-+---( )--| | | | #2 -|SLOT | | | | | #152 -|ADDR | | | | | #1 -|LEN | | | | | MW122 -|DATA | | |

---------------When this 'READ_W' function is executed successfully, check CPU memory bits M122.0 to M122.7 for sensor fault status. M122.0 bit is ON if channel 0 sensor is faulty, M122.1 bit is ON if channel 1 sensor is faulty and so on. In this case, take proper action. For a particular channel, in case of sensor fault, channel temperature reading is forced to value

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017 Published July 2002 Page 35 of 47

8 Ch. RTD Input Module (4311)

Messung Systems

selected by user. In this case, it is upper scale value, which is 850.0 C for PT100 input type.

4.5 Programming with Nexgen 5000 CPU

The configuration data in PLC variables is transferred to the RTD input module when 'IM_Write function is executed. The data in the PLC variables can be updated using operators like 'MOVE', arithmetic or any other functions. The data from analog input module memory can be transferred to PLC variables when 'IM_Read' function is executed. The IM_Write function below shows data transfer from the CPU module's memory to Thermocouple input module memory. The details of transfer are

The RTD input module is configured in slot 2 of PLC The configuration information is stored in an 8 word array Static_Config & in 17 word array Dynamic_Config. Length of data area to be transferred is 16 bytes at MMW96 for Static_Config & 34 bytes at MMW0 for Dynamic_Config.

'IM_Write' function gets executed when BOOLean input 'Config_Dn' & Wr_Delay.Q is TRUE. BOOLean output 'Config_Dn' becomes TRUE, when function is executed successfully. It is FALSE if

Parameters of function are invalid or not within specified range. RTD input module is not accessible to CPU module .

Published July 2002 Page 36 of 47

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Messung Systems

8 Ch. RTD Input Module (4311)

So 8 words configuration information ( Static ) from CPU memory is transferred to the memory at address 96 onwards & 17 words configuration information ( Dynamic) from CPU memory is transferred to memory 0 onwars of Thermocouple input module fitted in slot 2. The 'IM_Read function shows data transfer from the Theromocouple input module memory to CPU memory. The details of transfer are -

The Thermocouple input module is configured in slot 2 of PLC Address on the Thermocouple input module in slot 2 is 128 The data to be stored in PLC variable array Thermocouple_Data & AIStatus array. Length of data area to be transferred is 16 bytes for Thermocouple_data & 8 bytes for AIstatus .

'IM_Read' function gets executed when ' Rd_Delay.Q ' is ON. 'Rd_Dn' & Stat_Rdy output becomes ON, when EN is ON and function is executed successfully. ENO is OFF if Parameters of function are invalid or not within specified range The module is not accessible to CPU module

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Published July 2002 Page 37 of 47

8 Ch. RTD Input Module (4311)

Messung Systems

Example of basic application program is given below. For the same, refer Nexgen PLC configuration shown in chapter 4.1. In the configuration, following points are to be noted. %IX4.0 is a module status bit as 'Module Not OK' bit. %IX4.0 is set if 24 VDC supply to module is not healthy and / or hardware fault, watchdog fault is observed on module. %IX4.1 is a channel status bit as. %IX4.1 is set if for one or more channels, configuration is invalid and / or any channel error like open circuit is observed. _BRACK_0_IOERR.2 is a 'Module Error' bit for the module fitted in slot 2. While developing application program, first check whether the module is healthy. For the same, check 'Module Error' bit _BRACK_0_IOERR.2 and 'Module Not Ok' bit %IX4.0. If any bit is set, declare respective fault. In this case, module is not accessible. If both are OFF, then only enable 'IM_Write' and 'IM_Read functions for RTD module. Once Thermocouple input data is read successfully, the data can be processed as the application requirement. If RTD input data read is to be displayed on HMI or SCADA, the varaible AIData should be mapped to any memory varaible while declaration like RTD_Data AT%MW100: ARRAY [0..7] OF INT;

Published July 2002 Page 38 of 47

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Messung Systems

8 Ch. RTD Input Module (4311)

Here the RTD data for the channels is stored in memory variable %MW100 to %MW116 in integer format. Channel 0 data is stored in %MW100 while channel 7 data is stored in %MW16. If input image bit %IX4.0 or %IX4.1 is TRUE, the appropriate error should be declared and further processing of analog input data read should be hold. If input image bit %IX4.1 is TRUE, the status of all the channels can be read and individual channel error and exact cause can be located with the help of an application program as shown below.

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Published July 2002 Page 39 of 47

8 Ch. RTD Input Module (4311)

Messung Systems

5. Troubleshooting

In this chapter, following points related to thermocouple input module are discussed. LED Indications for diagnostics Fault Diagnostic

5.1 LED Indications for Diagnostics

The following table explains significance of LED provided for module status and diagnostic purpose on the module.

No. 1 LED Color Status OFF ON OFF 2 CPU fault Orange ON OFF 3 CJC Fault Orange ON OFF ON 4 Channel Status (Eight for eight channels) Green Flashing with 10 Hz frequency Description 24 VDC supply to module healthy 24 VDC supply to module absent 24 VDC circuit on-board glass fuse blown Module hardware healthy and module is ready Module in self test CPU watchdog faulty Module busy CJC sensor OK. CJC sensor short CJC sensor open Channel not enabled Channel enabled and healthy Parameter mismatch Invalid configuration Over range Under range Open circuit CJC fault

No 24 V Supply Orange

5.2 Fault Diagnostic

This section explains various possibilities of faults related to thermocouple Input Module and external interface and corrective action to be taken. Faults may occur in Modules as a whole Specific channel only Application Program. In first two cases, replacement of module is required where as third case can be sorted out by on line monitoring of application program. Equipments required The following equipments are required for fault diagnosis of thermocouple input module. Screw driver Digital Multi meter with measuring facility for o mV DC voltage. o Continuity and resistance. Set up for on line monitoring of application program as follows. o PC with DOXMINI+ software o PC to Nexgen PLC Cable

Published July 2002 Page 40 of 47

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Messung Systems

8 Ch. RTD Input Module (4311)

The following diagnostic flow chart shows various possibilities of faults if thermocouple module is not in operation as per requirement and corrective action to be taken.

Module not working

ON

No 24V Supply LED status?

OFF

Confirm 24 VDC supply at terminals 36 & 37. Take proper action.

ON

No 24V Supply LED status?

OFF

Check on-board glass fuse. * If blown, replace it by same type.

YES

Module working OK?

NO

ON

No 24V Supply LED status?

OFF

Diagnosis Over ON CPU Fault LED Status? OFF

Replace Module Module Hardware faulty ON CJC Fault LED Status? OFF

Replace Module

CJC sensor short or open. All enabled channel LEDs will start flashing

Replace Module

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Published July 2002 Page 41 of 47

8 Ch. RTD Input Module (4311)

Messung Systems

Diagnostic flow chart continues.

ON

IO ERR LED Status?

OFF

ON

Module Error System bit Status ?

OFF

Fix module properly. Check expansion cable if it is in expansion rack. Check configuration of PLC. Take proper action.

ON Replace Module

Module Error System bit Status? YES

OFF

Module working OK?

NO

Diagnosis Over

Flashing

Channel LED Status?

ON

OFF Check module input image bits Ix.1 to Ix.4 Check application program. Enable channel.

Invalid configuration or parameter Mismatch. Take proper action. Temperature reading beyond Maximum - minimum set points. Take proper action. Temperature reading out of range of input type configured. Take proper action. Thermocouple element connections open circuit. Take proper action.

Ix.1 is set

OFF

Channel LED Status?

ON

Ix.2 is set

Replace Module

Ix.3 is set

Ix.4 is set

Published July 2002 Page 42 of 47

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Messung Systems

8 Ch. RTD Input Module (4311)

Diagnostic flow chart continues.

NO

Temperature reading Ok?

YES

Remove thermocouple element and short the terminals. Now module should show ambient temperature.

Diagnosis Over

NO Check application program. Check for JMP, MCR-ME interlocks if any. NO

Temperature reading Ok?

YES

Monitor binary data value for channel with PC based Programming Software YES

Temperature reading Ok?

Probably problem is on thermocouple element side. Take proper action. Connect wires to terminal block.

YES Diagnosis Over

Temperature reading Ok?

NO Contact MESSUNG SYSTEMS

* The fuse should be replaced by same type strictly Rating - 315 mA, 250 V Sub- miniature fuse link no. 372 Make WICKMANN Note For healthy operation of module always ensure that supply to module is within specified range i.e. 18 VDC to 30 VDC including ripple. Always ensure that thermocouple elements are of isolated tip type.

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Published July 2002 Page 43 of 47

8 Ch. RTD Input Module (4311)

Messung Systems

6. Appendix 1

This section shows the reference tables for PT100 (385). The table gives resistance value of PT100 sensor and equivalent temperature.

C -200 -199 -198 -197 -196 -195 -194 -193 -192 -191 -190 -189 -188 -187 -186 -185 -184 -183 -182 -181 -180 -179 -178 -177 -176 -175 -174 -173 -172 -171 -170 -169 -168 -167 -166 -165 -164 -163 -162 -161 -160 -159 -158 -157 -156 -155 -154 -153 -152 -151 -150 -149 -148 -147 -146 -145 -144 -143 -142 -141 Ohms 18.52 18.96 19.39 19.82 20.25 20.68 21.11 21.54 21.97 22.40 22.83 23.26 23.69 24.12 24.55 24.97 25.39 25.82 26.25 26.67 27.10 27.52 27.95 28.37 28.80 29.22 29.65 30.07 30.49 30.92 31.34 31.76 32.18 32.61 33.03 33.45 33.86 34.28 34.70 35.12 35.54 35.96 36.38 36.80 37.22 37.63 38.05 38.47 38.89 39.31 39.72 40.14 40.56 40.97 41.39 41.80 42.22 42.64 43.05 43.46 C -140 -139 -138 -137 -136 -135 -134 -133 -132 -131 -130 -129 -128 -127 -126 -125 -124 -123 -122 -121 -120 -119 -118 -117 -116 -115 -114 -113 -112 -111 -110 -109 -108 -107 -106 -105 -104 -103 -102 -101 -100 -99 -98 -97 -96 -95 -94 -93 -92 -91 -90 -89 -88 -87 -86 -85 -84 -83 -82 --81 Ohms 43.88 44.29 44.71 45.12 45.53 45.95 46.35 46.76 47.18 47.59 48.00 48.41 48.82 49.23 49.64 50.06 50.47 50.88 51.29 51.70 52.11 52.52 52.92 53.33 53.74 54.15 54.56 54.97 55.38 55.78 56.19 56.60 57.00 57.41 57.82 58.22 58.63 59.04 59.44 59.85 60.26 60.67 61.07 61.48 61.87 62.29 62.69 63.10 63.50 63.91 64.30 64.70 65.11 65.51 65.91 66.31 66.72 67.12 67.52 67.92 C -80 -79 -78 -77 -76 -75 -74 -73 -72 -71 -70 -69 -68 -67 -66 -65 -64 -63 -62 -61 -60 -59 -58 -57 -56 -55 -54 -53 -52 -51 -50 -49 -48 -47 -46 -45 -44 -43 -42 -41 -40 -39 -38 -37 -36 -35 -34 -33 -32 -31 -30 -29 -28 -27 -26 -25 -24 -23 -22 --21 Ohms 68.33 68.73 69.13 69.53 69.93 70.33 70.73 71.13 71.53 71.93 72.33 72.73 73.13 73.53 73.93 74.33 74.73 75.13 75.53 75.93 76.33 76.73 77.13 77.52 77.92 78.32 78.72 79.11 79.51 79.91 80.31 80.70 81.10 81.50 81.89 82.29 82.69 83.08 83.48 83.88 84.27 84.67 85.06 85.46 85.85 86.25 86.64 87.04 87.43 87.83 88.22 88.62 89.01 89.40 89.80 90.19 90.59 90.98 91.37 91.77 C -20 -19 -18 -17 -16 -15 -14 -13 -12 -11 -10 -9 -8 -7 -6 -5 -4 -3 -2 -1 Ohms 92.16 92.55 92.95 93.34 93.73 94.12 94.52 94.91 95.30 95.69 96.09 96.48 96.87 97.26 97.65 98.04 98.44 98.83 99.22 99.61 C 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 Ohms 100.00 100.39 100.78 101.17 101.56 101.95 102.34 102.73 103.12 103.51 103.90 104.29 104.68 105.07 105.46 105.85 106.24 106.63 107.02 107.40 107.79 108.18 108.57 108.96 109.35 109.73 110.12 110.51 110.90 111.28 111.67 112.06 112.45 112.83 113.22 113.61 113.99 114.38 114.77 115.15 115.54 115.93 116.31 116.70 117.08 117.47 117.85 118.24 118.62 119.01 119.40 119.78 120.16 120.55 120.93 121.32 121.70 122.09 122.47 122.86 C +60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 Ohms 123.24 123.62 124.01 124.39 124.77 125.17 125.55 125.93 126.32 126.70 127.08 127.46 127.85 128.23 128.61 128.99 129.38 129.76 130.14 130.52 130.90 131.28 131.67 132.05 132.43 132.81 133.19 133.57 133.95 134.33 134.71 135.09 135.47 135.85 136.23 136.61 136.99 137.37 137.75 138.13 138.51 138.89 139.27 139.65 140.03 140.39 140.77 141.15 141.53 141.91 142.29 142.66 143.04 143.42 143.80 144.18 144.56 144.94 145.32 145.69

Published July 2002 Page 44 of 47

8 Ch. RTD Input Module User Manual/V1.0 Document No.: ED-2002-017

Messung Systems

8 Ch. RTD Input Module (4311)

C 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159 160 161 162 163 164 165 166 167 168 169 170 171 172 173 174 175 176 177 178 179

Ohms 146.07 146.45 146.82 147.20 147.58 147.95 148.33 148.71 149.08 149.46 149.83 150.21 150.58 150.96 151.34 151.71 152.09 152.46 152.84 153.21 153.58 153.95 154.32 154.71 155.08 155.46 155.83 156.21 156.58 156.96 157.33 157.71 158.08 158.45 158.83 159.20 159.56 159.94 160.31 160.68 161.05 161.43 161.80 162.17 162.54 162.91 163.28 163.66 164.03 164.40 164.77 165.14 165.51 165.88 166.25 166.62 167.00 167.37 167.74 168.11

C 180 181 182 183 184 185 186 187 188 189 190 191 192 193 194 195 196 197 198 199 200 201 202 203 204 205 206 207 208 209 210 211 212 213 214 215 216 217 218 219 220 221 222 223 224 225 226 227 228 229 230 231 232 233 234 235 236 237 238 239

Ohms 168.48 168.85 169.22 169.59 169.96 170.33 170.69 171.06 171.43 171.80 172.17 172.54 172.91 173.27 173.64 174.01 174.39 174.75 175.12 175.49 175.86 176.23 176.59 176.96 177.33 177.70 178.06 178.43 178.80 179.16 179.53 179.90 180.26 180.63 180.99 181.36 181.73 182.09 182.46 182.82 183.19 183.55 183.92 184.28 184.65 185.01 185.38 185.74 186.11 186.47 186.84 187.20 187.56 187.93 188.29 188.65 189.02 189.38 189.74 190.11

C 240 241 242 243 244 245 246 247 248 249 250 251 252 253 254 255 256 257 258 259 260 261 262 263 264 265 266 267 268 269 270 271 272 273 274 275 276 277 278 279 280 281 282 283 284 285 286 287 288 289 290 291 292 293 294 295 296 297 298 299

Ohms 190.47 190.83 191.20 191.56 191.92 192.28 192.66 193.02 193.38 193.74 194.10 194.47 194.83 195.19 195.55 195.90 196.26 196.62 196.98 197.35 197.71 198.07 198.43 198.79 199.15 199.51 199.87 200.23 200.59 200.95 201.31 201.67 202.03 202.38 202.74 203.10 203.46 203.82 204.18 204.54 204.90 205.25 205.61 205.97 206.33 206.70 207.05 207.41 207.77 208.13 208.48 208.84 209.20 209.55 209.91 210.27 210.62 210.98 211.34 211.69

C 300 301 302 303 304 305 306 307 308 309 310 311 312 313 314 315 316 317 318 319 320 321 322 323 324 325 326 327 328 329 330 331 332 333 334 335 336 337 338 339 340 341 342 343 344 345 346 347 348 349 350 351 352 353 354 355 356 357 358 359