Professional Documents

Culture Documents

DIN 2391-2 Cijevi Specijalne

Uploaded by

Miran VidovićCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DIN 2391-2 Cijevi Specijalne

Uploaded by

Miran VidovićCopyright:

Available Formats

Global Marketing for Tube & Pipe www.TubeSolution.

com

DI N 2391-81 Part I I SEAMLESS PRECI SI ON STEEL TUBES

1.Field of application

This Standard defines the technical delivery conditions for seamless precision steel tubes according to DIN 2391 Part 1 which are made fromthe steel grades listed in section 5.

Tubes according to this Standard are mainly used where accuracy to dimension and, possibly, small wall thicknesses and good surface condition are required.

Chemical composition (%)

!

"

Grade Mfg. Process

C Si Mn P S Ni Cr Mo Others

#

!

"

St30Si S 0.10Max 0.30Max 0.55Max 0.040Max 0.040Max - - - -

#

!

"

St30A1 S 0.10Max 0.05Max 0.55Max 0.040Max 0.040Max - - - Al deoxydized

#

!

"

St35 S 0.17Max 0.35Max 0.40Max 0.050Max 0.050Max - - - -

#

!

"

St45 S 0.21Max 0.35Max 0.40Max 0.050Max 0.050Max - - - -

#

St52 S 0.22Max 0.55Max 1.60Max 0.050Max 0.050Max - - - -

Global Marketing for Tube & Pipe www.TubeSolution.com

!

"

#

Cold -finished/hard Cold ! -finished/soft Annealed Normalized " #

Tensile Test MPa or N/mm

2

Grade Material number

Min Yield point Tensile Strength

Remarks (Similar to J I S)

- 400Min

- 355Min

- 285Min

St30Si 1.0211

215 295~420

(STKM11)

- 400Min

- 355Min

- 285Min

St30Al 1.0212

215 295~420

(STKM11)

- 440Min

- 370Min

- 315Min

St35 1.0308

235 340~470

(STC38)

- 540Min

- 470Min

- 390Min

St45 1.0408

255 440~570

(STKM13)

- 590Min

- 540Min

- 490Min

St52 1.0580

350 490~630

(STKM19)

Global Marketing for Tube & Pipe www.TubeSolution.com

Welded Steel Tubing and Pipe-Corresponding to DIN 2391-1

Nominal dimension 0.5 0.8 1 1.2 1.5 1.8 2 2.2 2.5 2.8 3 4.5 5 5.5 6 7 8 9 10 12 14 16 18 20 22 25 Wall thickness

s

Permissible deviation

Outside diameter da

Nominal

dimension

Permissible deviation

4

5

6

7

8

9

10

0.1

12

14

15

16

18

20

22

25

26

28

0.08

Global Marketing for Tube & Pipe www.TubeSolution.com

30

32

35

38

40

0.15

42

45

48

50

0.20

55

60

0.25

65

70

0.30

75

80

0.35

85

90

0.40

95

100

0.45

110

120

0.50

130

140

0.70

150 0.80

Global Marketing for Tube & Pipe www.TubeSolution.com

160

170

180

0.90

190

200

1.0

220

240

1.20

260 1.30

1) For outside diameters of nominal dimensions 4 and 5 mm, the permissible deviation fromthe nominal dimension

s of the wall thickness is 20 % For outside diameters of nominal dimensions 6 to 8 mm, the permissible deviation

fromthe nominal dimension s of the wall thickness is 15%.

s/D

=1/60

s/D

=1/40

s/D

=1/20

3. Quality grade

The tubes are supplied in the following quality grades:

Table 1. Steel grades

Steel grade

Quality grade

Code number Material number

A and B

St 30 Si

St 30 Al

St 35

St 45

St 52

1.0211

1.0212

1.0308

1.0408

1.0580

A precision steel tubes intended primarily for mechanical stressing, without any particular quality requirement and without acceptance test certificate

B precision steel tubes intended primarily for mechanical stressing, with special requirement and exclusively with acceptance test certificate

C

precision steel tubes with special requirement according to section 12. Theses requirements and corresponding tests must be agreed, with the customer having to specify his requirements at the

time of enquiry and on ordering

Global Marketing for Tube & Pipe www.TubeSolution.com

All steel grades according to quality grade A and B, as well as other steels, e.g. according to

C

DI N 1651

DI N 17 100

DI N 17 200

DIN 17 210

DIN 17 211

DIN 17 212

6. Chemical composition

6.1. Table 2 contains data on the chemical composition of the steels. Small departures from these data which apply to the ladle analysis, are permissible if they do not impair the

properties of the steel when in use.

6.2. In carrying out subsequent testing on the finished tube, the maximum permissible contents in terms of carbon, phosphorus and sulfur as defined by the ladle analysis of table

2 may be increased:

of the particular maximum content.

Table 2. Steel grades and chemical composition of the steels (ladle analysis)

Steel grade Chemical composition, %

Symbol Material number

C

max

Si

max

Mn P

max

S

max

St 30 Si 1.0211 0.10 0.30 ! 0.55 0.040 0.040

St 30 Al 9) 1.0212 0.20 0.05 ! 0.55 0.040 0.040

St 35 1.0308 0.17 0.35 " 0.40 0.050 0.050

St 45 1.0408 0.21 2) 0.35 " 0.40 0.050 0.050

St 52 1.0580 0.22 0.55 ! 1.60 0.050 0.050

1) This steel is deoxidized using aluminum.

2) In subsequent testing on the individual tube, the C-content must not exceed 0.25%.

- in the case of deviations due to sampling and method of analysis by + 5 %

- in the case of deviations due to segregation:

for rimming steels by + 20%

for killed steels by + 5 %

Global Marketing for Tube & Pipe www.TubeSolution.com

7. Condition on delivery

The tubes are supplied in one of the conditions listed in table 3. Other conditions on delivery are specified in table 9 (quality grade C).

Table 3. Conditions on delivery

Term Symbol Explanation

Cold-finished/hard

(cold-finished as-drawn)

BK No heat treatment after the last cold-forming process. The tubes therefore have only low deformability.

Cold-finished/soft

(lightly cold-worked)

BKW

After the last heat treatment there is a light finishing pass (cold drawing) With proper subsequent processing,

the tube can be cold-formed (e.g. bent, expanded) within certain limits.

Annealed GBK After the final cold-forming process the tubes are annealed in a controlled atmosphere or under vacuum.

Normalized NBK The tubes are annealed above the upper transformation point in a controlled atmosphere or under vacuum.

8. Mechanical and technological properties

8.1. The mechanical properties depend on the condition on delivery as defined in table 3.

8.2. In technological testing (drift expanding test and flattening test) the samples must comply with the requirements of sections 11.2.3.2. and 11.2.3.3.

8.3. In the case of other steel grades and/or other conditions on delivery then those specified in tables 2, 3 and 8, the mechanical and technological properties must be mutually

agreed. In these cases, the tubes are supplied according to quality grade C.

8.4. The steels listed in table 2 are deemed to be suitable for welding because of their chemical composition and metal lurgical treatment.

In the BK or BKW conditions on delivery, the mechanical properties are modified in the zone which has been subjected to heating. This should be taken into account (see DIN 8528

Part 1) in assessing the weldability of a component.

Table 4. Mechanical properties of the tubes at room temperature

Condition on delivery

Steel grade

Cold-finished/hard

(BK) 3)

Cold-finished/soft

(BKW) 3)

Annealed

(GBK) 3)

Normalized

(NBK)

Code

number

Material

number

Tensile

strength

Rm

N/

Elongation at

repture

A5

%

Tensile

strength

Rm

N/

Elongation at

repture

A5

%

Tensile

strength

Rm

N/

Elongation at

repture

A5

%

Tensile

strength

Rm

N/

Upper

yield point

ReH

N/

Elongation at

repture

A5

%

Global Marketing for Tube & Pipe www.TubeSolution.com

min min min min min min min min

St 30 Si 1.0211 400 8 330 12 280 30 290 to 420 215 30

St 30 Al 1.0212 400 8 330 12 280 30 290 to 420 215 30

St 35 1.0308 440 6 370 10 315 25 340 to 470 235 25

St 45 1.0408 540 5 470 8 390 21 440 to 570 255 21

St 52

1.0580 590 4 540 7 490 22 490 to 630 355 22

3) The yield point for the annealed (GBK)condition on delivery is at least 50% of the (ultimate) tensile strength. Depending upon the degree of deformation in the drawing

operation, the yield point of tubes delivered in the cold-finished/hard (BK)and cold-finished/soft(BKW) conditions, may be increased to a level close to the tensile strength.

I n calculating the yield point, the following values are recommended: cold-finished/hard condition on delivery " 80% of the tensile strength, cold-finished/soft condition on

delivery " 70% of the tensile strength.

4) In the case of tubes of outside diameter ! 30 mm, the wall thickness of which is ! 3mm, the minimum value of the yield point is 10 N / lower.

J I S ASTM BS DIN NF ISO

Standard

Number

Grade Type

Standard

Number

Grade Type

Standard

Number

Grade Type

Standard

Number

Grade Type

Standard

Number

Grade Type

Standard

Number

Grade Type

I ndex

Number

G3445 STKM11A C A512 MT1010 C 1717 ERWC1 C 2391 St30Si C 3304 R28 C C017

A513 MT1010 C St30A1 C 3305 " C

2393 St28 C 3306 " C

RSt28 C

2394 St28 C

USt28 C

RSt28 C

STKM12A C A512 MT1015 C 1717 ERWC2 C 2391 St37-2 3304 R33 C

A513 MT1015 C 6323 HFS3 C RSt37-2 3305 " "

STKM12B C A512 MT1015 C 2394 St37-2 3306 " "

A513 MT1015 C Ust38-2

Global Marketing for Tube & Pipe www.TubeSolution.com

A519 MT1015 C RSt-2

STKM12C C 1717 CEWC2 C A49-322 TU37b C

" CFSC3 C A49-327 TU37b C

6323 CFS3 C

" CFS3A C

STKM13A C A312 MT1020 C 1717 ERWC3 C 2391 St45 C A49-324 TU37b C 2937 TS4 C

A513 MT1020 C 2393 St44-2 C A49-330 TU37b C 3304 R37 "

2394 St44-2 C A49-343 TU38b C 3305 " "

STKM13B C A513 MT1020 C 3306 " "

STKM13C C 1717 CEWC3 C

" CFSC4 C

6323 CFS4 C

STKM14A C A513 MT1020 C 6323 HFS4 C 2937 TS9 C

3304 R42 "

STKM14B C 6323 HFS5 C 3305 R42 C

STMK14C C 3306 " "

STKM15A C A513 1030 C

A519 1030 C

STKM15C

STKM16A C A519 1040 C A49-311 TUXC35 C

A49-312 TUXC35 C

STKM16C C

STKM17A C A519 1050 C 6323 HFS8 C

STKM17C C 6323 CFS8 C

Global Marketing for Tube & Pipe www.TubeSolution.com

STKM18A C A519 1518 C 1717 ERWC5 C A49-310 TU52b C

A49-311 TU52b C

A49-312 TU52b C

STKM18B C A49-321 TU52b C

A49-323 TU52b C

A49-326 TU52b C

STKM18C C A49-330 TU52b C

A49-341 TS42a C

" TS47a C

A49-343 TS18M5 C

STKM19A C A519 1524 C 2391 ST52 C 2937 TS18 C

2393 ST52-3 C 2938 Gr.1 C

2394 ST52-3 C 3304 R50 C

3305 R50 C

3306 R50 C

STKM20A C

You might also like

- PAK Transformer Study 15Nov2019NREL v2Document33 pagesPAK Transformer Study 15Nov2019NREL v2Asim RiazNo ratings yet

- Effect of CalciteDocument27 pagesEffect of CalciteprasadNo ratings yet

- La Guia MetAs 10 06 Densidad AguaDocument19 pagesLa Guia MetAs 10 06 Densidad AguaMayreneDavilaNo ratings yet

- Aeroduct Insulatedanduninsulatedflexibleducts Uae 22sep22Document10 pagesAeroduct Insulatedanduninsulatedflexibleducts Uae 22sep22marrukhjNo ratings yet

- Pipe Ramming HDD Assist Equipment Selection Charts 08-2011Document1 pagePipe Ramming HDD Assist Equipment Selection Charts 08-2011Alex P CartyNo ratings yet

- LEM-2X2 Motor OverviewDocument2 pagesLEM-2X2 Motor OverviewmohiNo ratings yet

- Filtro Parker 932630QDocument5 pagesFiltro Parker 932630QJuan Alejandro Cañas ColoradoNo ratings yet

- Sieve Analysis of Granular Sub Base: As Per MORT&H TABLE 400-1Document1 pageSieve Analysis of Granular Sub Base: As Per MORT&H TABLE 400-1Amjad PathanNo ratings yet

- Pump CurveDocument8 pagesPump CurveClark HonradoNo ratings yet

- Week 1 practice sheet solutionsDocument1 pageWeek 1 practice sheet solutionsjnanendraNo ratings yet

- iK60N iC60N-iC60H-iC60L C120Document11 pagesiK60N iC60N-iC60H-iC60L C120Long Nguyễn Đặng ThànhNo ratings yet

- Week-1 Practice: 21K61A0117 Sai DeepikaDocument1 pageWeek-1 Practice: 21K61A0117 Sai DeepikajnanendraNo ratings yet

- Crane Operator's Cab 4Document26 pagesCrane Operator's Cab 4Arslan AhmedNo ratings yet

- A M 01 - SpecifikacijeDocument7 pagesA M 01 - SpecifikacijeAlija KolakovicNo ratings yet

- Technical Specification: ConfigurationDocument34 pagesTechnical Specification: ConfigurationAhmed IbrahimNo ratings yet

- Provil CV ME 2018Document12 pagesProvil CV ME 2018Anov HerdiyantoNo ratings yet

- Grafik Perbandingan Sudut Terhadap PengujianDocument1 pageGrafik Perbandingan Sudut Terhadap Pengujianfaidathun nifahmiNo ratings yet

- Metric-to-AWG Conversion Chart - Technical Resources - Lapp TannehillDocument3 pagesMetric-to-AWG Conversion Chart - Technical Resources - Lapp TannehillEngChengLengNo ratings yet

- Copia de Catalogo Transmision de PropelDocument2 pagesCopia de Catalogo Transmision de PropelFrancisco Javier González LópezNo ratings yet

- Mercedes: Actros Mp2 Actros Mp3 Actros Mp4 G330 - 16 SpeedsDocument73 pagesMercedes: Actros Mp2 Actros Mp3 Actros Mp4 G330 - 16 SpeedsJonathan TDS ZFNo ratings yet

- Oil Pan and Suction TubeDocument2 pagesOil Pan and Suction TubeCalon KayaNo ratings yet

- MIL-111443-Brochure DiversionDocument8 pagesMIL-111443-Brochure DiversionCésar David Pedroza DíazNo ratings yet

- Gross Profit Margin Histogram for 25 Shadow StocksDocument5 pagesGross Profit Margin Histogram for 25 Shadow StocksDevilish LuciferNo ratings yet

- MITSUBISHI INSULATED GATE BIPOLAR TRANSISTOR SPECIFICATIONSDocument4 pagesMITSUBISHI INSULATED GATE BIPOLAR TRANSISTOR SPECIFICATIONSGer CLNo ratings yet

- Cilindro Dirección WA1200Document2 pagesCilindro Dirección WA1200Eduardo SanchezNo ratings yet

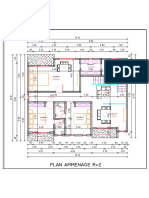

- Plan Ammenage R+2: BalconDocument1 pagePlan Ammenage R+2: BalconKONAN KOFFI DESIRENo ratings yet

- Name of The Work: Reconstruction of Bridge at CH: 22.100 KM of Anaveri Branch Canal Near Arisinaghatta Village, Honnali Tq. Davanagere DistrictDocument1 pageName of The Work: Reconstruction of Bridge at CH: 22.100 KM of Anaveri Branch Canal Near Arisinaghatta Village, Honnali Tq. Davanagere DistrictEr Bharath Yadav MNo ratings yet

- Teams performance analysisDocument4 pagesTeams performance analysisramaiahgantaNo ratings yet

- DCP - San Juan - Vinces - Macuno 23+000Document1 pageDCP - San Juan - Vinces - Macuno 23+000gonzalo velascoNo ratings yet

- Monthly Cases of Dengue Fever Admitted in Tubigon Community Hospital: Tubigon ResidentsDocument2 pagesMonthly Cases of Dengue Fever Admitted in Tubigon Community Hospital: Tubigon ResidentsGina BoligaoNo ratings yet

- Rotron Transportation CatalogDocument54 pagesRotron Transportation CatalogSolikin PatiNo ratings yet

- Assignment 11Document1 pageAssignment 11acer nitroNo ratings yet

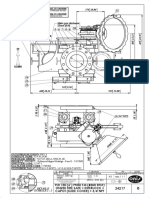

- 1 24217 Rev3Document2 pages1 24217 Rev3Javier GarcíaNo ratings yet

- Document summary of door lock component specificationsDocument1 pageDocument summary of door lock component specificationsYayak Surya CandraNo ratings yet

- Glo Sikarapid TechnologyDocument4 pagesGlo Sikarapid TechnologyKing MKNo ratings yet

- Cross Reference AWG To MM2 - Multi - Cable CorporationDocument1 pageCross Reference AWG To MM2 - Multi - Cable CorporationSANTIAGO FABRICIO TORRES VACACELANo ratings yet

- Environmentalists Take NoteDocument2 pagesEnvironmentalists Take NoteFrancoise JohnstonNo ratings yet

- Anchor YS.Document2 pagesAnchor YS.RizkiNo ratings yet

- Proceq GPR Live - Grid Paper - 5cmDocument1 pageProceq GPR Live - Grid Paper - 5cmmohammad loai sabbaghNo ratings yet

- Ronda 5130.d PDFDocument1 pageRonda 5130.d PDFce4rwsNo ratings yet

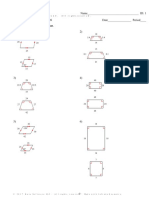

- Similar PolygonsDocument3 pagesSimilar PolygonskarinNo ratings yet

- Statistical analysis report for Bright Star Rubber CorporationDocument1 pageStatistical analysis report for Bright Star Rubber CorporationSandeep BhutadaNo ratings yet

- Virtual LabsDocument1 pageVirtual LabsAnumuskan KashyapNo ratings yet

- Inox Ve Sinh Nhà A.vinh ChotDocument5 pagesInox Ve Sinh Nhà A.vinh ChotLý Văn ThọNo ratings yet

- Relate Tables, Graphs, and Equations: BatchesDocument2 pagesRelate Tables, Graphs, and Equations: Batchesahmeeeeeeeeee.expmdNo ratings yet

- Master links and assemblies product specificationsDocument1 pageMaster links and assemblies product specificationsTrịnh Đức HạnhNo ratings yet

- National Metric Coding SystemDocument1 pageNational Metric Coding SystemMohammad Afzal AhmadiNo ratings yet

- Ryobi 50Cc Chain Saw ITEM NO. RY5020 MFG. NO. 090840005 Repair SheetDocument7 pagesRyobi 50Cc Chain Saw ITEM NO. RY5020 MFG. NO. 090840005 Repair SheetAvila MatthNo ratings yet

- NP 3153 MT 3 430: Technical SpecificationDocument7 pagesNP 3153 MT 3 430: Technical SpecificationCassie SmithNo ratings yet

- Bitfury Clarke B1549493-010 Datasheet: 1 October 2018 Revision: 0.5Document20 pagesBitfury Clarke B1549493-010 Datasheet: 1 October 2018 Revision: 0.5victor silvaNo ratings yet

- PC750-7 S/N 20001-UP (Overseas Version)Document2 pagesPC750-7 S/N 20001-UP (Overseas Version)АлександрNo ratings yet

- Classeur 2Document2 pagesClasseur 2Twin KileNo ratings yet

- Practice Problems For Engineering Drawing Ii: August 2019Document24 pagesPractice Problems For Engineering Drawing Ii: August 2019Fatma MalikiNo ratings yet

- Komatsu pc200-9c Y1620-41A1A PageDocument2 pagesKomatsu pc200-9c Y1620-41A1A Pageluis delgadoNo ratings yet

- Horus h59 Reticle Technical SpecsDocument5 pagesHorus h59 Reticle Technical SpecsThomas MpourtzalasNo ratings yet

- 2020 Data Warehouse Benchmark Compares Speed and Cost of Redshift, Snowflake, Presto and BigQueryDocument10 pages2020 Data Warehouse Benchmark Compares Speed and Cost of Redshift, Snowflake, Presto and BigQuerynickhug2000No ratings yet

- S40148C 3Document81 pagesS40148C 3Claudio AlmiciNo ratings yet

- Laborator 1Document1 pageLaborator 1Last HeroNo ratings yet

- STRUCTURAL Design-8Document1 pageSTRUCTURAL Design-8Swathi OnelineNo ratings yet

- The Fusion Marketing Bible: Fuse Traditional Media, Social Media, & Digital Media to Maximize MarketingFrom EverandThe Fusion Marketing Bible: Fuse Traditional Media, Social Media, & Digital Media to Maximize MarketingRating: 5 out of 5 stars5/5 (2)

- Din 71412 MazaliceDocument1 pageDin 71412 MazaliceMiran VidovićNo ratings yet

- General Tolerances DIN ISO 2768Document2 pagesGeneral Tolerances DIN ISO 2768Vasil Gospodinov83% (23)

- Bulk Storage SilosDocument5 pagesBulk Storage SilosMiran VidovićNo ratings yet

- TU Vjezbe 03Document21 pagesTU Vjezbe 03Bahro ČuturaNo ratings yet

- CAx ADocument38 pagesCAx AMiran VidovićNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 09200-1 Lath and PlasterDocument9 pagesITCC in Riyadh Residential Complex J10-13300 09200-1 Lath and PlasteruddinnadeemNo ratings yet

- OPERATION AND MAINTENANCEDocument132 pagesOPERATION AND MAINTENANCEgavallapalliNo ratings yet

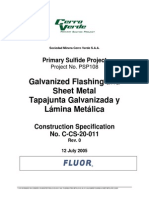

- C-CS - 20 - 011 - Galvanized Flashing & Sheet Metal Rev - 0Document12 pagesC-CS - 20 - 011 - Galvanized Flashing & Sheet Metal Rev - 0Yvan Nuñez EscobedoNo ratings yet

- Woven Fabric Defects PracticalDocument2 pagesWoven Fabric Defects PracticalAlemu HaileNo ratings yet

- 3.BOQ (Arch. & Metal Work)Document13 pages3.BOQ (Arch. & Metal Work)Andy YuliantoNo ratings yet

- Glass Ionomer CementDocument54 pagesGlass Ionomer CementNasecaNo ratings yet

- Relining For High Pressure PipeDocument14 pagesRelining For High Pressure PipeCostache AlexandruNo ratings yet

- IC DiagramDocument2 pagesIC DiagramgulammeeraNo ratings yet

- Gillfab 1367 Laminate: January 2012Document5 pagesGillfab 1367 Laminate: January 2012cbol91311No ratings yet

- MyDocument61 pagesMynvnrev0% (1)

- Chemical Properties & Compositions of Stainless Steel GradesDocument4 pagesChemical Properties & Compositions of Stainless Steel GradesPrabhakar KattulaNo ratings yet

- Gabe Suarez On Knife FightingDocument2 pagesGabe Suarez On Knife Fightingtkn111100% (4)

- Types of ResistorsDocument28 pagesTypes of Resistorsjinto0007100% (3)

- Pyrometallurgy of Ferro VanadiumDocument24 pagesPyrometallurgy of Ferro VanadiumNadyaZulfaniNo ratings yet

- Metallocene Linear Low-Density Polyethylene Properties and ApplicationsDocument15 pagesMetallocene Linear Low-Density Polyethylene Properties and ApplicationsRodriguez JohannNo ratings yet

- Pavement StandardsDocument89 pagesPavement Standardsnathychidaz100% (1)

- Silicone SoftenerDocument9 pagesSilicone SoftenerMandeep Singh100% (1)

- Rajasthan State Road Development & Construction Corporation LTDDocument59 pagesRajasthan State Road Development & Construction Corporation LTDVandhana RajasekaranNo ratings yet

- Mastic CarbowrapDocument2 pagesMastic CarbowrapGlishna Peushan WidanapathiranaNo ratings yet

- Heat Treatment: Dr. Santosh S. HosmaniDocument5 pagesHeat Treatment: Dr. Santosh S. Hosmaniprakush01975225403No ratings yet

- Application - Cast Iron RepairDocument16 pagesApplication - Cast Iron RepairAnonymous L0ChmPGNo ratings yet

- Prestress ScribdDocument4 pagesPrestress ScribdKanadeTachibanaNo ratings yet

- 5P02729B4B 10.06 WebDocument8 pages5P02729B4B 10.06 WebmutazsalihNo ratings yet

- Lysaght Roofing Walling Installation ManualJul2015Document68 pagesLysaght Roofing Walling Installation ManualJul2015Sriram VjNo ratings yet

- Dry Stack Manual & Reference Tek 14-22Document6 pagesDry Stack Manual & Reference Tek 14-22rickbmayNo ratings yet

- Effects of Cryogenic Treatment On Cutting Tool DurabilityDocument19 pagesEffects of Cryogenic Treatment On Cutting Tool DurabilityShaheen KunhikrishnanNo ratings yet

- ReferencesDocument10 pagesReferenceshassanNo ratings yet

- Shaft Seals DatabookletDocument64 pagesShaft Seals Databookletingrbarros100% (1)

- Creating Openings in Unbonded Post-Tensioned Slabs: ViewpointDocument4 pagesCreating Openings in Unbonded Post-Tensioned Slabs: ViewpointUdaya KumarNo ratings yet

- Work Section Preambles ExplainedDocument55 pagesWork Section Preambles ExplaineddophongxdNo ratings yet