Professional Documents

Culture Documents

AbrasiFRAC Stimulation Service (Schlumberger) PDF

Uploaded by

4s0m0z4Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AbrasiFRAC Stimulation Service (Schlumberger) PDF

Uploaded by

4s0m0z4Copyright:

Available Formats

AbrasiFRAC Stimulation Service

Perforate and stimulate in a single field operation

Cutting Perforations

Pumping Fracture Treatment Down the Annulus

Cutting Next Set of Perforations After Placing Sand Plug for Isolation

Reversing Out Sand After Fracturing Treatment

The AbrasiFRAC* service allows perforating and stimulation in a single field operation.

STIMULATION

The AbrasiFRAC stimulation service is part of a portfolio of services to maximize reservoir contact. An economic, efficient solution, the AbrasiFRAC service perforates and stimulates multiple well intervals in a single field operation, offering access in cased and openhole completions in less time. The technique enables accurate placement of fracturing treatments down the casing or the CT-casing annulus, and reduces near-wellbore pressure drop from the wellbore to the reservoir, which reduces the frequency of near-wellbore screenouts. Slurry containing abrasive solids is pumped at high differential pressures through a specially designed ABRASIJET* hydraulic pipe-cutting and perforating service gun conveyed on a CT workstring. The resulting high-velocity fluid stream perforates tubulars and any surrounding cement sheath. Abrasive fluid cutting is widely used in tubing or casing cutting applications. This tool can also be used reliably in openhole applications. The abrasive material is typically 20/40 or 100 mesh fracturing sand, which is compatible with the specially engineered jet guns. Even in harsh environments, the jet guns will perform efficiently for several hours under downhole conditions.

For multiple-stage treatments, sand plugs or bridge plugs can be used for zonal isolation between the fracturing treatment stages. The jet guns, which are available in various sizing and phasing configurations, also can be used with a retrievable or millable bridge plug.

ADDITIONAL SYSTEM FEATURES

Additional options can be used to enhance the performance of the AbrasiFRAC service. AbrasiFRAC service can be combined with downhole tools that use fiber-optic technology developed by Schlumberger to provide accurate real-time depth, bottomhole pressure, and bottomhole temperature measurements via nonobstructive fiber-optic cables. These measurements are useful in various ways; for example, distributed temperature survey measurements offer a qualitative guide to fluid migration and monitoring of the interval flow profile before and just after the stimulation treatment. A reverse check valve allows sand to be removed from the wellbore by reverse circulation between fracturing treatment stages to dress off the top of the sand plug placed for isolation.

AbrasiFRAC Stimulation Service

APPLICATIONS

I

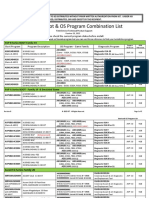

Specifications Casing size, mm [in] ABRASIJET tool OD, mm [in] Typical BHA length, m [ft] Optimum nozzle design differential pressure, MPa [psi] Max. temperature, degC [degF] Coiled tubing size 114.3 [412] 76.2 [3] 1.43 [4.7] 139.7 [512] 101.6 [4] 1.43 [4.7] 177.8 [7] 101.6 [4] 1.43 [4.7] 17.3 [2,500] 177 [350]

Perforation cutting through casing and cement sheath to provide access for stimulation treatments

BENEFITS

I

Reduces cycle time by perforating and stimulating multiple intervals in a single field operation Improves well productivity through accurate placement of stimulation treatments Minimizes frequency of nearwellbore screenout Saves costs because of reduced equipment requirements owing to reduced fracture initiation pressure

17.3 [2,500] 17.3 [2,500] 177 [350] 177 [350] (any, but based on required flow rate)

ABOUT THE CONTACT FAMILY

AbrasiFRAC technology is part of the intervention category of the Contact* four-category portfolio of staged fracturing and completion services. These technologies maximize reservoir contact by offering the most efficient and effective services for each well. The Contact intervention category enables multiple stages to be perforated/jetted, fractured, and isolated in one intervention. Contact services can be enhanced with real-time measurement options.

FEATURES

I

Accurately places stimulation treatments Eliminates need for wireline perforation

www.slb.com/reservoircontact

*Mark of Schlumberger Copyright 2007 Schlumberger. All rights reserved. 07-CT-002

You might also like

- Facsrite Sand Screen: ApplicationsDocument2 pagesFacsrite Sand Screen: ApplicationssouthliNo ratings yet

- Siebtechnik Decanter CentrifugesDocument14 pagesSiebtechnik Decanter CentrifugesDedi Mulyadi50% (2)

- Expandable SolutionsDocument2 pagesExpandable SolutionsHunterNo ratings yet

- Discover How Slant Drilling Techniques Revolutionized Heavy Oil RecoveryDocument184 pagesDiscover How Slant Drilling Techniques Revolutionized Heavy Oil RecoveryWeatherford75267% (3)

- Top performing sand control meets groundbreaking inflow control technologyDocument2 pagesTop performing sand control meets groundbreaking inflow control technologyBinay ChetriNo ratings yet

- BC Towbrosec BR Au 0915 LRDocument8 pagesBC Towbrosec BR Au 0915 LRnermeen ahmedNo ratings yet

- Drip Irrigation and Installation: Efficiently Pulling It All TogetherDocument8 pagesDrip Irrigation and Installation: Efficiently Pulling It All Togetherrommel duranNo ratings yet

- Pumpguard PsDocument2 pagesPumpguard PsBehnamNo ratings yet

- DripNet PC 16125-16150-16250-ENG-2003-12-29Document2 pagesDripNet PC 16125-16150-16250-ENG-2003-12-29BarkhamnNo ratings yet

- D-GASSERS Orizontal + Vertical PDFDocument2 pagesD-GASSERS Orizontal + Vertical PDFciucalata880% (1)

- EDI FlexAir-Magnum-spec Sheet PDFDocument2 pagesEDI FlexAir-Magnum-spec Sheet PDFomega AlfaNo ratings yet

- p57 Quantum One Trip Seal LatchDocument1 pagep57 Quantum One Trip Seal LatchPak RioNo ratings yet

- Powerdrive x6Document7 pagesPowerdrive x6ice_PLNo ratings yet

- EDI FlexAir Magnum Spec SheetDocument2 pagesEDI FlexAir Magnum Spec SheetMurukan PadmanabhanNo ratings yet

- DB DISA FLEX LowresDocument8 pagesDB DISA FLEX LowresdfeltrinpNo ratings yet

- 650 0090eu UksafDocument4 pages650 0090eu Uksafrokojeg956No ratings yet

- Powerdrive X6: Rotary Steerable System For High-Performance Drilling and Accurate Wellbore PlacementDocument6 pagesPowerdrive X6: Rotary Steerable System For High-Performance Drilling and Accurate Wellbore PlacementClOudyo VirgílioNo ratings yet

- High Efficiency Phase Separation Internals BrochureDocument8 pagesHigh Efficiency Phase Separation Internals BrochurePoncho RmzNo ratings yet

- Ubbink Air Excellent BrochureDocument24 pagesUbbink Air Excellent BrochureRazvan AlexandrescuNo ratings yet

- SmartROC T35 T40Document8 pagesSmartROC T35 T40Giulio BelmondoNo ratings yet

- DX Brochure 2013Document16 pagesDX Brochure 2013Gerko Berrios García100% (1)

- Exp IDocument16 pagesExp IJefferson LlanosNo ratings yet

- Trays of Columns PDFDocument16 pagesTrays of Columns PDFamirejazminhassNo ratings yet

- Eurox Cross Flow ScrubberDocument8 pagesEurox Cross Flow Scrubbergiuseppe tropianoNo ratings yet

- High-Performance Downflow Dust CollectorDocument8 pagesHigh-Performance Downflow Dust CollectorDanny DiazNo ratings yet

- H07127 ThreePhaseHorzSepDocument2 pagesH07127 ThreePhaseHorzSepGuillermo Manuel SchödlNo ratings yet

- MAPfrac Frac Sleeve SpecificationDocument8 pagesMAPfrac Frac Sleeve Specificationhitesh kumarNo ratings yet

- Coiled Tubing Workover ApplicationsDocument60 pagesCoiled Tubing Workover Applicationsak_adamNo ratings yet

- Broadband Sequence Williston Cs PDFDocument2 pagesBroadband Sequence Williston Cs PDFKevin MusterNo ratings yet

- A12370 PerformanceDocument2 pagesA12370 PerformanceClef GonadanNo ratings yet

- SPT High Efficiency Phase Separation Internals BrochureDocument8 pagesSPT High Efficiency Phase Separation Internals BrochurefunctionlakeNo ratings yet

- Fisa Sisteme FiltrareDocument7 pagesFisa Sisteme FiltrareDragos MafteiNo ratings yet

- D-Sander SwacoDocument5 pagesD-Sander SwacoJuan Sebastian Diaz CuadrosNo ratings yet

- Ote Fp-S Filter Press Eng Web PDFDocument8 pagesOte Fp-S Filter Press Eng Web PDFRegina Choque HuallpaNo ratings yet

- Decanter SiebtechnikDocument16 pagesDecanter SiebtechnikzamburittiNo ratings yet

- IADC Directional DrillingDocument10 pagesIADC Directional DrillingomnoyNo ratings yet

- BM34003 0910 WebDocument12 pagesBM34003 0910 WebRujisak MuangsongNo ratings yet

- Expro DST CatalogueDocument12 pagesExpro DST CatalogueSudish BhatNo ratings yet

- vVIBRAX - SIEBTECHNIK GMBH PDFDocument32 pagesvVIBRAX - SIEBTECHNIK GMBH PDFzamburittiNo ratings yet

- Superfrac Koch PDFDocument16 pagesSuperfrac Koch PDFMPilarAlfonsoGonzálezNo ratings yet

- DELTAFLUID Leaflet Restriction Orifices A4Document4 pagesDELTAFLUID Leaflet Restriction Orifices A4TONNo ratings yet

- Cavitrol® IV TrimDocument2 pagesCavitrol® IV TrimAhmed KhairyNo ratings yet

- Bubble Cap Tray Design and ManufacturingDocument4 pagesBubble Cap Tray Design and ManufacturingPujo PurwantoNo ratings yet

- TERRATEC RBM Brochure PDFDocument5 pagesTERRATEC RBM Brochure PDFGustavo BenitesNo ratings yet

- Separators: For Steam, Air and Gas SystemsDocument16 pagesSeparators: For Steam, Air and Gas SystemsmrazamudinishakNo ratings yet

- HRS AS 4 Series Datasheet 2018Document1 pageHRS AS 4 Series Datasheet 2018Muneeb AkhtarNo ratings yet

- Rotaria SK-L BrochureDocument4 pagesRotaria SK-L BrochureWashington Huallpa100% (1)

- Sepax SeperatorDocument6 pagesSepax Seperatoradanis01100% (1)

- Gas Liquid Separation Technology SulzerDocument24 pagesGas Liquid Separation Technology SulzerCH1253100% (1)

- Gas Liquid Separation TechnologyDocument24 pagesGas Liquid Separation TechnologyCuong TranHungNo ratings yet

- NETZSCH ImpactMill Condux General CatalogDocument12 pagesNETZSCH ImpactMill Condux General CatalogProjetos GeigerNo ratings yet

- Technip Drilling BrochureDocument12 pagesTechnip Drilling Brochurenedumaran.sNo ratings yet

- Zarandas MongooseDocument12 pagesZarandas MongooseLuis Alfredo Gregorio RivasNo ratings yet

- Mongoose Pro Shaker BrochureDocument12 pagesMongoose Pro Shaker BrochureOscar Rodrigo Andrade SilvaNo ratings yet

- Mülheim an der Ruhr company profiles decanter centrifugesDocument14 pagesMülheim an der Ruhr company profiles decanter centrifugeszeppilli23No ratings yet

- Sliding SleeveDocument13 pagesSliding SleeveSuriya BaluNo ratings yet

- Aquatrax PCDocument4 pagesAquatrax PCMiguel Angel Pimentel TamayoNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- English WorkbookDocument99 pagesEnglish WorkbookTrà MinhNo ratings yet

- (SPE 3474) Analysis & Prediction of Gas Well PerformanceDocument10 pages(SPE 3474) Analysis & Prediction of Gas Well Performance4s0m0z4No ratings yet

- AbrasiFRAC Stimulation Service (Schlumberger) PDFDocument2 pagesAbrasiFRAC Stimulation Service (Schlumberger) PDF4s0m0z4No ratings yet

- Barrenas Triconicas PDFDocument4 pagesBarrenas Triconicas PDF4s0m0z4No ratings yet

- A Rod Pumping System For California Lift RequirementsDocument8 pagesA Rod Pumping System For California Lift Requirements4s0m0z4No ratings yet

- Igt - Boot Os List Rev B 10-28-2015Document5 pagesIgt - Boot Os List Rev B 10-28-2015Hector VillarrealNo ratings yet

- Instructions Manual Skatey 150/250/400/600Document19 pagesInstructions Manual Skatey 150/250/400/600Denys GavrylovNo ratings yet

- Small Clone ChorusDocument2 pagesSmall Clone ChorusamndsnaNo ratings yet

- Interpretation 1Document17 pagesInterpretation 1ysunnyNo ratings yet

- Apple Led Cinema Display 24inchDocument84 pagesApple Led Cinema Display 24inchSantos MichelNo ratings yet

- SOLUTIONS : Midterm Exam For Simulation (CAP 4800)Document14 pagesSOLUTIONS : Midterm Exam For Simulation (CAP 4800)Amit DostNo ratings yet

- LL Baby Carrier Corner Drool Pads TutorialDocument9 pagesLL Baby Carrier Corner Drool Pads TutorialBryan DerryNo ratings yet

- 11 EngineDocument556 pages11 Enginerumen80100% (3)

- Oyo Summer Internship ReportDocument31 pagesOyo Summer Internship ReportJayasree S RNo ratings yet

- Importance and Behavior of Capital Project Benefits Factors in Practice: Early EvidenceDocument13 pagesImportance and Behavior of Capital Project Benefits Factors in Practice: Early EvidencevimalnandiNo ratings yet

- Priceliost Ecatalog 2021 Div. DiagnosticDocument2 pagesPriceliost Ecatalog 2021 Div. Diagnosticwawan1010No ratings yet

- Managerial Accounting and Cost ConceptsDocument67 pagesManagerial Accounting and Cost ConceptsTristan AdrianNo ratings yet

- Less Than a Decade to Avoid Catastrophic Climate ChangeDocument1 pageLess Than a Decade to Avoid Catastrophic Climate ChangeXie YuJiaNo ratings yet

- Nippon Metal Primer Red Oxide TDSDocument2 pagesNippon Metal Primer Red Oxide TDSPraveen KumarNo ratings yet

- Philippine Supreme Court Acquits Man of Estafa Due to Lack of KnowledgeDocument2 pagesPhilippine Supreme Court Acquits Man of Estafa Due to Lack of KnowledgeUrsulaine Grace FelicianoNo ratings yet

- Manage Hospital Records with HMSDocument16 pagesManage Hospital Records with HMSDev SoniNo ratings yet

- CLS1Document3 pagesCLS1Shaina Kaye De GuzmanNo ratings yet

- Resume DaniellaAmatoDocument2 pagesResume DaniellaAmatoDaniellaNo ratings yet

- Marcel Breuer: Hungarian-American Designer, Architect and Bauhaus PioneerDocument8 pagesMarcel Breuer: Hungarian-American Designer, Architect and Bauhaus PioneerYosaphat Kiko Paramore DiggoryNo ratings yet

- Energy Efficiency Existing Ship Index (Eexi) : Regulatory DebriefDocument8 pagesEnergy Efficiency Existing Ship Index (Eexi) : Regulatory DebriefSalomonlcNo ratings yet

- ROUTERDocument26 pagesROUTERIsraelNo ratings yet

- EG3000 ManualDocument7 pagesEG3000 ManualJose Armando Perez AcostaNo ratings yet

- 136 ADMU V Capulong (Roxas)Document2 pages136 ADMU V Capulong (Roxas)Trisha Dela RosaNo ratings yet

- Integrated Building Management Platform for Security, Maintenance and Energy EfficiencyDocument8 pagesIntegrated Building Management Platform for Security, Maintenance and Energy EfficiencyRajesh RajendranNo ratings yet

- Solar Winds OrionAPM DatasheetDocument4 pagesSolar Winds OrionAPM DatasheetArun J D'SouzaNo ratings yet

- Holmes 1993Document8 pagesHolmes 1993Rumaisa KrubaNo ratings yet

- Cost Analysis Format-Exhaust DyeingDocument1 pageCost Analysis Format-Exhaust DyeingRezaul Karim TutulNo ratings yet

- Kim Lighting WTC Wide Throw Cutoff Brochure 1976Document24 pagesKim Lighting WTC Wide Throw Cutoff Brochure 1976Alan MastersNo ratings yet

- ADVOCACY AND LOBBYING NDocument7 pagesADVOCACY AND LOBBYING NMwanza MaliiNo ratings yet

- In Gov cbse-SSCER-191298202020 PDFDocument1 pageIn Gov cbse-SSCER-191298202020 PDFrishichauhan25No ratings yet