Professional Documents

Culture Documents

Bobtail Eqp CETP B3 Curso

Uploaded by

Antonio ArveloOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bobtail Eqp CETP B3 Curso

Uploaded by

Antonio ArveloCopyright:

Available Formats

11

MODULE 2

Module 2. Bobtail Equipment and Systems

INTRODUCTION

Bobtails deliver propane in bulk quantities to storage containers at customer locations. The U.S. Department of Transportation (DOT) regulations refer to bobtails as cargo tank motor vehicles (CTMVs) in metered delivery service. This module explains a bobtails basic equipment and systems and its functions including the cargo tank, gauges, valves, pumps, meters, delivery hoses, and emergency discharge control equipment. Understanding the bobtail and its equipment will maintain safe conditions during loading and delivery operations.

Objectives After completing this module, you will be able to:

Identify similar and different bobtail equipment and systems. Specify how the cargo tank and its connections function. Identify how the pump and associated systems operate. Indicate how the meter, delivery hose, and emergency discharge control equipment work.

12

MODULE 2. BObTAIL EQUIPmENT AND SYSTEmS

13

Lesson 1.

MODULE 2

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

MODULE 2

Cargo Tank and Connections

COMMON BObTAIL EqUIPMENT AND SYsTEMs

Regardless of their size or use, all bobtails have common equipment and systems including: Cargo tank

Data plate Gauges, valves, and connections Pump Bypass system Delivery system Emergency discharge control equipment

In this lesson, you will learn how each of these pieces of equipment and systems operate.

14

MODULE 2. BObTAIL EQUIPmENT AND SYSTEmS

LESSON 1. CARGO TANK AND CONNECTIONS

15

DIFFERENT BObTAIL EqUIPMENT AND SYsTEMs

MODULE 2

Bobtails are specialized bulk delivery vehicles and are custom built by DOT registered manufacturers. Built in a variety of sizes, bobtails may contain different equipment and systems depending on when they were built and how they will be used. Some examples of different bobtail features and equipment include, but are not limited to:

CARGO TANK

MODULE 2

Cargo tanks are the most common type of tank used to transport propane and are installed on both bobtails and transports. Bobtail cargo tanks can have a water capacity as small as 350 gallons, but 1,800-3,500 gallons is more typical. Cargo tanks are manufactured according to the American Society of Mechanical Engineers (ASME) and DOT MC 331 specications. Some older cargo tanks were built to MC 330 specications, or were non-specication ASME tanks approved for intrastate service only. These older tanks may not show a DOT specication on the data plate. Some states allow these tanks to remain in operation. NOTE: Check your companys policy on whether you can operate bobtails with older cargo tanks.

Chassis and cargo tank size Valves and their operations Gauges and their operations Location of connections Emergency discharge control equipment Liquid meter

Your bobtail may also contain other features or equipment. Because bobtails vary, it is important for you to understand their differences and be prepared to use different operating procedures for each vehicle.

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

16

MODULE 2. BObTAIL EQUIPmENT AND SYSTEmS

LESSON 1. CARGO TANK AND CONNECTIONS

17

DATA PLATE

MODULE 2

Cargo tanks used to transport and transfer propane must have a data plate attached to either its driver or passenger side. Listed below is some of the more important information to look for on a data plate. This list, however, is not comprehensive.

GAUGEs, VALVEs, AND CONNECTIONs

MODULE 2

Bobtails contain liquid level gauges which indicate the amount of liquid propane in the cargo tank. These gauges are used in the loading process and may include: Fixed maximum liquid level gauge

DOT design code or specication number Tank manufacturers name and serial number Vessel material specication number Design working pressure of the tank Water capacity in pounds and gallons Original test date The cargo tanks inspection code, retest dates, and quenched and tempered or non-quenched and tempered (QT or NQT) markings are displayed near the data plate.

Float gauge Rotary gauge

Other gauges, valves, and connections on a bobtail include: Temperature gauge

Pressure gauge Pressure relief valve Liquid ll connection Vapor equalizing connection Vapor internal valve Liquid internal valve

The month and year of the last required annual

cargo tank inspection and the ve-year cargo tank inspection date may be shown near the data plate.

Lets look at each of these gauges and valves in more detail.

NOTE: Bobtails built after October 1, 2004, are required to provide much more detailed information about the vehicle and the cargo tank itself. This information may appear on a data plate attached to the left side of the cargo tank near its front, or on a specication plate attached to the chassis of the cargo tank motor vehicle, or on plates in both locations.

Example of a specication plate attached to the chassis of the cargo tank.

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

18

MODULE 2. BObTAIL EQUIPmENT AND SYSTEmS

LESSON 1. CARGO TANK AND CONNECTIONS

19

FIXED MAXIMUM LIqUID LEVEL GAUGE

MODULE 2

PurposeIndicates when the cargo tank is lled to its maximum permitted lling level. DesignConstructed of a body with a hole and plug, and is connected to a dip tube welded inside the tank. The opening of the dip tube extends to the tanks maximum ll level.

FLOAT GAUGE

MODULE 2

PurposeContinuously indicates the liquid level of propane in the cargo tank by a oat in the container that moves up and down. DesignMost are constructed of a sealed dial, a oat assembly, a mounting adaptor, and two magnets. OperationThe oat assembly rests on the surface of the liquid propane in the tank. As the liquid level in the tank changes, the oat assembly moves and the pointer magnet follows the movement. As a result, the dial pointer continuously indicates the level of the liquid in the container. Due to its simple operation, the oat gauge is relatively dependable and very easy to use. See Resources for information on checking the accuracy of a oat gauge.

The body is a hollow tting. The plug is a solid tting with a neoprene seal at its interior tip and is threaded into the body. The hollow dip tube is attached to the inlet of the body. The length of the tube depends on the size of the cargo tank. Normally, the taller the tank, the longer the tube.

OperationWhen the level of liquid propane reaches the dip tube opening, propane squirts out the partially opened vent valve, signaling you to stop lling. NOTE: Before lling, use no more than a turn to partially open the vent valve on the xed maximum liquid level gauge to be sure it is not clogged. If the vent valve is clogged, notify your supervisor unless you are authorized to remove the obstruction.

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

20

MODULE 2. BObTAIL EQUIPmENT AND SYSTEmS

LESSON 1. CARGO TANK AND CONNECTIONS

21

ROTARY GAUGE

MODULE 2

PurposeDetermines the amount of propane in the cargo tank. DesignHas an indicator arm attached to a bleeder valve; a curved, hollow dip tube that extends into the container; and a gauge face. OperationTo use this gauge, use the following steps:

TEMPERATURE AND PREssURE GAUGEs

MODULE 2

Temperature and pressure gauges are used to check the load of gas in the cargo tank.

Swing the indicator arm to the twelve oclock position. Open the bleeder to clear any liquid from the dip tube. Slowly rotate the swing arm clockwise until liquid appears from the bleeder. Make a mental note of the percentage reading. Repeat the process for the left side of the gauge face. Add the readings together and divide by 2. This is the correct percentage reading for the container.

Temperature Gauge The temperature gauge indicates the temperature of the propane and is located in the liquid space of the cargo tank. This gauge contains a tube or well that is lled with a non-corrosive liquid with a relatively low freezing point such as glycerin, oil, kerosene, or automobile antifreeze.

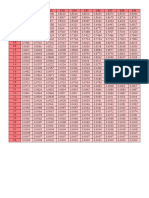

If you plan to ll the cargo tank beyond the xed maximum liquid level gauge, you must know the specic gravity and temperature of the product. Use the chart that is included on the rotary gauge dial to determine the amount of liquid propane. NOTE: The rotary gauge swing indicator arm should ALWAYS be left in the twelve oclock position. If the accuracy of the rotary or oat gauge cannot be determined, use only the xed maximum liquid level gauge. See Resources for information on checking the accuracy of the rotary gauge.

Pressure Gauge A pressure gauge helps ensure that pressures in the cargo tank are not exceeded during loading operations. This gauge has a dial face with ranges from 0 to 400 psig, a pointer, and a gas inlet.

See Resources for more information on temperature and pressure gauges.

Temperature and pressure gauges are located on the back of the bobtail.

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

22

MODULE 2. BObTAIL EQUIPmENT AND SYSTEmS

LESSON 1. CARGO TANK AND CONNECTIONS

23

ThE IMPORTANCE OF UNDERsTANDING CARGO TANK GAUGEs

MODULE 2

When lling your bobtail or your customers container, it is critical that you understand each individual gauges function and how they work together to ensure a safe product transfer. Your ability to read, monitor, and understand how gauges indicate the level of the liquid in the container is a key skill that bobtail drivers must master. Understanding exactly how the gauges are supposed to function will also help you respond appropriately if a gauge malfunctions or its reading is in conict with another gauge.

PREssURE RELIEF VALVEs

MODULE 2

Every bobtail is tted with pressure relief valves. These internal spring valves are designed so that the spring resides on the inside of the container. They protect the cargo tank from being over-pressurized. When the tank pressure exceeds 250 psig, the relief valves open and release vapor or liquid pressure into the atmosphere, reducing the tanks pressure. Pressure relief valves are designed to automatically close when the tank pressure returns to a level below 250 psig. Always ensure that pressure relief valves have weather caps and covers to protect them from ice, snow, rain, and mud.

Here are a few issues to consider as you learn more about gauges and their importance in an overall successful product transfer: Bobtail gauges help measure maximum-permitted lling capacity.

Fixed maximum liquid level gauges and rotary gauges are designed to emit product when the cargo tank reaches 80 to 85% of its maximum-permitted lling capacity. If a liquid level gauge shows an increase in product, then the cargo tanks pressure gauge should show an increase in pressure at the same time.

Hydrostatic Relief Valves In addition to pressure relief valves, cargo tank piping systems contain hydrostatic relief valves to protect equipment and lines from over pressurization due to the effects of liquid expansion. Hydrostatic relief valves are placed in the system where liquid propane can be trapped between two positive shutoff valves, including back check valves.

Pressure relief valves are located on the top of the bobtail.

HYDROsTATIC RELIEF VALVE

When the tank pressure exceeds 250 psig, the relief valves open and release vapor or liquid pressure into the atmosphere.

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

24

MODULE 2. BObTAIL EQUIPmENT AND SYSTEmS

LESSON 1. CARGO TANK AND CONNECTIONS

25

LIqUID FILL CONNECTION

MODULE 2

The liquid ll connection, typically located on the back head of the cargo tank, is where liquid propane ows into the tank during loading operations at the bulk plant. This connection often contains a vertical tube used to spray ll the tank during loading. The liquid ll connection typically contains a 3" ACME connector that is equipped with a cap to prevent dust and debris from entering the valve. Every opening to the cargo tank is required to be permanently labeled with the space it opens into. Therefore, the liquid ll connection must be labeled either LIQUID, or SPRAY-FILL.

VAPOR EqUALIZING CONNECTION

MODULE 2

Typically located on the back head of the cargo tank, the vapor equalizing connection is where vapor moves in and out of the cargo tank during loading operations to equalize pressure between tanks. This connection must be permanently labeled VAPOR on the back of the cargo tank. The vapor equalizing connection contains a vertical tube which extends into the vapor space at the top of the tank and typically contains a 1" ACME connector equipped with dust covers to prevent dust and debris from entering the valve. NOTE: In some jurisdictions, vapor equalizing connections are illegal to use when lling a customers container because they remove product from the customers tank during delivery operations.

Back Check Valve The liquid ll connection always has a back check valve, which is opened or closed by the force of the product or pressure.

When the bobtail is being loaded at the bulk plant, the propane being pushed from the bulk plant tank by the plant pump opens the back check valve allowing product to ow into the cargo tank. As soon as the plant hose-end valve is closed, the pressure in the cargo tank causes the back check valve to close, thus stopping the product from owing back into the plant piping.

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

26

MODULE 2. BObTAIL EQUIPmENT AND SYSTEmS

LESSON 1. CARGO TANK AND CONNECTIONS

27

INTERNAL VALVEs

MODULE 2

The bobtail cargo tank has two main internal valves: Liquid internal valveLocated at the liquid withdrawal connection near the bottom or belly of the cargo tank.

MANUAL INTERNAL VALVEs

MODULE 2

Always open manual internal valves before starting the bobtail pump during transfer operations. You must physically open these valves with levers or pneumatic operators, which operate using compressed air. Although manual internal valves may be constructed differently, they basically operate in the same way. For further information regarding the valves used on your vehicle, see the manufacturers web sites or catalog sections.

Vapor internal valveLocated at the vapor equalizing connection.

Both of these internal valves provide: Automatic excess ow protection if piping breaks away during transfer operations.

Primary shutoff protection if the emergency discharge control equipment is activated in the event of an emergency.

MANUAL INTERNAL VALVE OPERATION

Liquid internal valves may be either manual or pressure differential. Both types are equipped with a strainer assembly to prevent debris from entering the pump on the cargo tank.

1. When the operating lever is in the closed position, tank pressure holds the main and pilot valves in the closed position.

2. When the operating lever is moved to the open position, the cam moves the valve stem upward, opening the pilot valve orice. Tank pressure bleeds through the pilot orice and begins to build up downstream pressure.

Liquid internal valves are located near the bottom of the cargo tank.

3. As downstream pressure equalizes with tank pressure, the excess ow spring opens the main valve. The system is ready for transfer operations with the main valve acting as an excess ow valve. Releasing the operating lever to the closed position instantly closes both the main valve and the pilot valve.

4. If the ow of liquid propane exceeds the allowable ow rate during product transfer, this internal valve will close the main valve disc and stop product transfer.

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

28

MODULE 2. BObTAIL EQUIPmENT AND SYSTEmS

LESSON 1. CARGO TANK AND CONNECTIONS

29

PREssURE DIFFERENTIAL INTERNAL VALVEs

Pressure differential internal valves, also called Flowmatic valves, are mounted directly between the cargo tank and the pump. When the bobtail pump is turned on, the difference in pressure causes these valves to open automatically. They then close automatically when the pump is turned off and the pressure drops back down. Pressure differential internal valves also incorporate a thermal link designed to close the main valve in the event of re. If the valve fails to shut when the pump is turned off, you can manually close it using the three-way valve or the cable that is attached to the primary shutdown controls. These controls are normally located at the front of the cargo tank, just behind the drivers door. NOTE: Only qualied personnel who have specic training and experience should perform internal valve repairs.

EXCEss FLOw VALVEs

MODULE 2

Every bobtail is tted with another safety feature, an excess ow valve, which is located between the outlet of the liquid meter and the liquid delivery hose. It protects the system from ow surge, over-pressurization, and accidental propane discharge. During bobtail transfer operations, this valve is normally open, allowing product to ow through the piping system. It will automatically close if it senses a break in the piping or a change in ow pressure during an unloading operation.

MODULE 2

The excess ow valve is located between the outlet of the liquid meter and the liquid delivery hose.

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

30

MODULE 2. BObTAIL EQUIPmENT AND SYSTEmS

31

ChECK FOR UNDERsTANDING

MODULE 2

Lets take a moment to check how well you understand the information presented in this lesson by selecting the appropriate response to this question. Check your work on page 193.

Lesson 2.

BObTAIL PUMP

MODULE 2

Pumps and Associated Systems

The back check valves main purpose is to:

Close the liquid ll connection

A bobtail pump moves propane liquid from the cargo tank to the customers container during the unloading process. Liquid propane enters at the top of the pump and then is pushed to the pump outlet. Moving parts inside the pump are lubricated and cooled by the liquid propane that ows through them, protecting the pump from premature wear and tear.

Open the liquid ll connection

Stop product from owing back into the cargo tank

Stop product from owing back into the plant piping

Monitor the cargo tanks liquid level during unloading and never let a bobtails pump run dry because it can cause damage to the pump. Remember, if the rear axle is lower than the front axle when positioning the bobtail, the pump is more likely to run dry as the liquid level in the tank is lowered.

See Resources for more information on bobtail pumps.

Always monitor the cargo tank liquid level during unloading and never let the bobtail pump run dry.

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

32

MODULE 2. BObTAIL EQUIPmENT AND SYSTEmS

LESSON 2. PUmPS AND ASSOCIATED SYSTEmS

33

POwER TAKE-OFF (PTO) AssEMbLY

MODULE 2

Pumps on bobtails are typically operated by a power take-off (PTO) assembly which transfers power from the engine to the pump.

ENGINE PUMPING SPEEDs

MODULE 2

Engine pumping speed is controlled by manual, pneumatic, or electric devices typically located on the deck of the bobtail. The pump PTO speed ratio varies from one manufacturer to the next, so always follow the manufacturer recommendations and your company policy. Low RPMs (revolutions per minute) can result in a low ow rate, and excessive RPMs can cause pump cavitation and severe damage to the pumping system. Cavitation, if extreme, can destroy the bobtail pump, so never over speed a pump.

The PTO assembly is normally operated by one of the following:

Lever or switchGenerally located inside the cab of the truck; allows you to quickly turn the PTO and pump on and off by moving the position of the lever or switch.

Remote stationUsually located on the rear deck of the cargo tank; in case of an emergency, allows you to quickly turn the PTO and pump on and off and close the liquid internal valve; may also have an engine kill switch that immediately shuts down the engine and pump.

Pump cavitation is the turbulent ow of LP-gas and bubbles through a pump. As the pump spins and moves the liquid propane out of the cargo tank, vapor bubbles are produced. As these vapor bubbles continue to form and collapse, the pump is subjected to pressure changes which cause a hammering effect on internal pump parts and the rotor bearings.

To maintain pump efciency and optimal performance, always check the ow rate and bypass valve operation periodically, per manufacturers recommendations.

Hand held remoteCarried by the driver at all times during the unloading process; allows the driver to turn the PTO off (and sometimes on), close the internal valves, and stop the engine during an emergency.

Hydraulic Systems Pumps on some bobtails are powered by a hydraulic system instead of a PTO. With a hydraulic system, the truck engine powers a hydraulic pump which moves hydraulic uid to a device. This device then causes the propane pump to push product from the bobtail to another container. Hydraulic systems, like traditional PTO systems, require occasional maintenance. Hoses and components must be checked periodically for wear and leaks.

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

34

MODULE 2. BObTAIL EQUIPmENT AND SYSTEmS

LESSON 2. PUmPS AND ASSOCIATED SYSTEmS

35

PUMP BYPAss SYsTEM

MODULE 2

Bobtail pumps are protected by at least one bypass system with a spring-loaded automatic differential bypass valve. This valve, which is normally closed, opens to re-route propane back to the cargo tank when the pressure exceeds the manufacturers recommended differential pressure setting.

ChECK FOR UNDERsTANDING

MODULE 2

Lets take a moment to check how well you understand the information presented in this lesson by selecting the appropriate response to this question. Check your work on page 193.

The bobtail pump is powered by:

Burning a portion of the vapor for energy

The pump differential bypass valve will automatically open when the pump builds pressure to the set point, usually about 80 psig, or 80 pounds over tank pressure.

Be sure to follow company procedures and the manufacturers suggestions for adjusting the automatic bypass valve.

Hook-up to an electrical circuit

The pressure of the liquid propane on the bottom of the tank

Some bobtails may have a manual bypass system running parallel to the automatic bypass system. Manual bypass systems must be closed unless self-loading. In cases where the a bulk plant loses power or if a plant pump is out of service, you may need to self-load by using your bobtail pump, which would require you to open the automatic bypass system, if applicable. NOTE: Pump bypass systems are custom designed for each bobtail and container.

The power take-off (PTO) assembly

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

Discovery: Connections, Valves, and Gauges

37

LEARNING ACTIVITY

Lesson 3. Meters, Hoses, and Emergency

Discharge Control Equipment

LIqUID METERs

Most bobtails are equipped with a liquid meter installed in the pump discharge line. Liquid meters use either a volumetric or a mass ow method (sound resonance) to accurately measure liquid propane, ensure that vapor does not pass through the measuring chamber, and report the amount of liquid propane passing through it.

MODULE 2

Most liquid meters include:

A vapor eliminator with a built-in strainer to eliminate vapor from the stream of liquid prior to the liquid entering the measuring chamber. A register with a ticket printer or an electronic meter to measure in gallons the amount of liquid delivered and print a delivery ticket. A measuring chamber (volumetric method) that measures the amount of liquid passing through the meter and provides a mechanical link that operates the register. Flow tubes (mass ow method) if so equipped (not shown) that uses sound recognition to measure the amount of liquid passing through the meter and provides a signal of the measured quantity to the register. NOTE: A liquid meter will have either a measuring chamber or a ow tube, but not both. A differential valve (volumetric method) installed at the outlet of a liquid meter, designed to hold 1015 psi of back pressure on the liquid propane in the meter, and prevent vapor from forming inside the meter. A temperature compensator (volumetric method) to adjust the register/measuring chamber gear ratio to supply a reading of the product ow as if it had a temperature of 60 F. This process ensures uniformity of measurement regardless of the product temperature from summer to winter.

Tampering with the meter in any way, by anyone other than weights and measures ofcials or registered meter repair personnel, or even removing the seal attached by weights and measures ofcials, can be a violation of state law.

38

MODULE 2. BObTAIL EQUIPmENT AND SYSTEmS

LESSON 3. METERS, HOSES, AND EmERGENCY DISChARGE CONTROL EQUIPmENT

39

LIqUID DELIVERY HOsEs

MODULE 2

Bobtails are equipped with a liquid delivery hose which transfers propane from the cargo tank to the customers container. Although most hoses are 1" diameter and up to 150 ft long, the actual size and length of the hose will vary. DOT requires bobtails to limit the delivery hose to a nominal inside diameter of 1" or less. In most cases, the delivery hose is connected to and stored on a hose reel. Most hose reels are equipped with either an electric or air-operated rewind motor. Quite often, a hose will lie on a crushed rock driveway or rest against a structural member on the truck. Severe pulsation and vibration can cause damage to the hose cover at the point of contact. This abrasion is the most common cause of premature delivery hose failure, so care should be taken when placing the hose for delivery.

EMERGENCY DIsChARGE CONTROL EqUIPMENT

MODULE 2

All bobtails must be equipped with emergency discharge control equipment to help prevent the unintended release of propane during loading and unloading operations.

There are two types of emergency discharge control systems used on bobtails:

Manually Activated SystemsOperated by the driver at a remote shutdown station usually located at the front of the cargo tank on the drivers side or at the rear deck of the vehicle.

Off-Truck Remotely Activated Systems (RF controls)Allow the driver to stop the ow of propane in an emergency by using a hand-held radio frequency transmitter. There are two types of hand-held radio frequency transmitters: query and non-query. Query devices have a timing feature that requires the driver or operator to respond to a system query signal to continue the product transfer before a pre-set pumping time has elapsed. Non-query devices can stop the ow of product and shut off the vehicle engine when the driver activates the system in the event of a complete delivery hose separation.

See Resources for information on safety air brake system interlocks.

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

40

MODULE 2. BObTAIL EQUIPmENT AND SYSTEmS

LESSON 3. METERS, HOSES, AND EmERGENCY DISChARGE CONTROL EQUIPmENT

41

ChECK FOR UNDERsTANDING

MODULE 2

Lets take a moment to check how well you understand the information presented in this lesson by selecting the appropriate response to this question. Check your work on page 193.

SUMMARY

MODULE 2

Some important points to remember from this module are:

Bobtails can be different sizes and have different equipment. However, all bobtails have a cargo tank and connections, a pump and associated systems, liquid meter, hoses, and emergency discharge control equipment. The typical bobtail has a cargo tank that ranges between 1,800 and 3,500 gallons water capacity. Bobtails contain liquid level gauges used in the loading process to indicate the amount of liquid propane in the cargo tank. DOT requires that all bobtails have internal valves to prevent a massive release of product in an emergency. Most bobtails are equipped with a liquid meter installed in the pump discharge line to calculate the correct number of gallons delivered. All bobtails must be equipped with emergency discharge control equipment to help prevent the unintended release of propane during unloading operations.

One reliable way to ensure that the liquid delivery hose does not become damaged is to _____.

Purchase hose that has a nominal inside diameter of 2" or more

Ensure that the hose does not rest against items that may cause wear during the loading operation

Load your bobtail when the weather conditions are favorable

Cover the hose during loading operations

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

2007 CERTIFIED EMPLOYEE TRAINING PROGRAM

You might also like

- Report On Turbo Cooling SystemDocument33 pagesReport On Turbo Cooling SystemDeepakKumarNo ratings yet

- 2016 Jayco Jay Feather Owners Manual PDFDocument152 pages2016 Jayco Jay Feather Owners Manual PDFChad BallNo ratings yet

- Studyguide BobtailDocument23 pagesStudyguide BobtailVitor GS100% (1)

- ETRTO's 50+ Years of Standardizing TiresDocument18 pagesETRTO's 50+ Years of Standardizing TiresGammaNo ratings yet

- OGRA LPG Rules 2001Document17 pagesOGRA LPG Rules 2001محمد نعمان بٹNo ratings yet

- Chapter 11 ThermodynamicsDocument217 pagesChapter 11 Thermodynamicsnt100% (1)

- Heat Load Resistance of Cryogenic Storage TanksDocument70 pagesHeat Load Resistance of Cryogenic Storage Tanksakur3003No ratings yet

- TBV Cryogenic Ball Valves CAMERONDocument20 pagesTBV Cryogenic Ball Valves CAMERONboudissaNo ratings yet

- Oil & Gas SeperationDocument34 pagesOil & Gas Seperationassatpute100% (2)

- Impact of Cargo Loading On Bulk CarriersDocument12 pagesImpact of Cargo Loading On Bulk CarriersSunil Kumar P GNo ratings yet

- Saddle Wear Plate DesignDocument2 pagesSaddle Wear Plate DesignsterlingNo ratings yet

- Agiba HSE compliance and safety metrics for drilling rigsDocument3 pagesAgiba HSE compliance and safety metrics for drilling rigskhaledNo ratings yet

- LPG Vertical Compressor Sales BrochureDocument12 pagesLPG Vertical Compressor Sales Brochurekeyonltd100% (2)

- Rudder and Manoeuvring ArrangementDocument15 pagesRudder and Manoeuvring ArrangementLeonidas MauricioNo ratings yet

- LPG Design Guiudliines DubaiDocument15 pagesLPG Design Guiudliines Dubairiyas100% (3)

- Bulk Receiving ProceduresDocument21 pagesBulk Receiving Proceduresemongclooney11100% (1)

- Bunkers sampling guidelines summaryDocument2 pagesBunkers sampling guidelines summarygamronNo ratings yet

- Sei NotesDocument19 pagesSei NotesJAGJIT SINGHNo ratings yet

- Normam04 r1 enDocument73 pagesNormam04 r1 enVladimir PintoNo ratings yet

- Natural Gas Dehydration Using TEG - With Gas Condition Plots in HYSYSDocument11 pagesNatural Gas Dehydration Using TEG - With Gas Condition Plots in HYSYSMuhammad ImranNo ratings yet

- Cargo Ship Safety Construction and Load Lines Survey ReportDocument14 pagesCargo Ship Safety Construction and Load Lines Survey ReporttacoriandNo ratings yet

- 2739 2009Document68 pages2739 2009Tim Wilson100% (1)

- Smith Meter Lact UnitDocument8 pagesSmith Meter Lact UnitDiana Lucía PadillaNo ratings yet

- Petroleum Products Measurement and Quality AssuranceDocument16 pagesPetroleum Products Measurement and Quality Assuranceابوالحروف العربي ابوالحروفNo ratings yet

- GUNVOR Independent Inspection Requirements Rev - 6Document34 pagesGUNVOR Independent Inspection Requirements Rev - 6Bhagoo HatheyNo ratings yet

- SGS-OI-Safe Talk-Heat Stress and Ramadan-A4-EN-004Document4 pagesSGS-OI-Safe Talk-Heat Stress and Ramadan-A4-EN-004Faraz AliNo ratings yet

- PTRT 2470: Gas Processing FacilitiesDocument95 pagesPTRT 2470: Gas Processing FacilitiesNapoleon Berrios100% (1)

- Propane Gas and Liquefied GasDocument10 pagesPropane Gas and Liquefied GasJ.SIVIRANo ratings yet

- Gaseous Fuels Combustion CalculationsDocument16 pagesGaseous Fuels Combustion CalculationsLos Bastardos100% (2)

- Standard Equipment GuideDocument4 pagesStandard Equipment GuideSyed Mujtaba Ali BukhariNo ratings yet

- AmSpec CertifikatDocument2 pagesAmSpec CertifikatDejvid VasNo ratings yet

- New NGL Recovery ProcessDocument9 pagesNew NGL Recovery ProcessEbby Onyekwe100% (1)

- PTS 20162Document53 pagesPTS 20162ronelbarafaeldiegoNo ratings yet

- Exceeding Expectations: Did You KnowDocument2 pagesExceeding Expectations: Did You KnownarutorazNo ratings yet

- Ullage Report For DeliveryDocument72 pagesUllage Report For DeliveryAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Z-values vs time curveDocument1 pageZ-values vs time curveMichell RiveraNo ratings yet

- Hover CraftDocument54 pagesHover CraftShakti PrasadNo ratings yet

- Triton Master BrochureDocument37 pagesTriton Master BrochureenglffNo ratings yet

- Patent eDocument5 pagesPatent eDaniel OliveiraNo ratings yet

- Flight Reference Card Tarot 680 Pro: Airborne Geosciences Facility (Uoe-Ag)Document24 pagesFlight Reference Card Tarot 680 Pro: Airborne Geosciences Facility (Uoe-Ag)Manolo PhintoNo ratings yet

- Exceeding Expectations: Please Visit Us at Our Website or Contact Us at 800 286-2208Document3 pagesExceeding Expectations: Please Visit Us at Our Website or Contact Us at 800 286-2208Indra NainggolanNo ratings yet

- Specification For Carbon and Alloy Steel Forgings For Thin-Walled Pressure VesselsDocument7 pagesSpecification For Carbon and Alloy Steel Forgings For Thin-Walled Pressure VesselsAnilNo ratings yet

- FreetDocument32 pagesFreetHamed GeramiNo ratings yet

- Jis F2017 - 1982Document0 pagesJis F2017 - 1982Ronaldo AndradeNo ratings yet

- Trade Oil Offer NEW OffferDocument7 pagesTrade Oil Offer NEW Offfererick tafurNo ratings yet

- Tabel ASTMDocument19 pagesTabel ASTMAnton SujarwoNo ratings yet

- LPG Carrier Cargo Motor and Compressor Room SafetyDocument8 pagesLPG Carrier Cargo Motor and Compressor Room SafetyÁřvíňď PřášáďNo ratings yet

- Bombardier 415: Pilot Operations HandbookDocument0 pagesBombardier 415: Pilot Operations HandbookMinh TùngNo ratings yet

- Gas Hydrate Tutorial: Crystal Structures and PropertiesDocument134 pagesGas Hydrate Tutorial: Crystal Structures and PropertiesGinoNo ratings yet

- Imdg 39-18Document1 pageImdg 39-18Bogdan Nedelcu100% (1)

- NR 23 Fire ProtectionDocument8 pagesNR 23 Fire ProtectionVítor Andrade SoaresNo ratings yet

- Dokumen - Tips - 1 CNG Dealer Training 2 What Is CNG CNG Is Natural Gas Compressed To A Pressure of 200 250 KGCM G Why CNG Is Used in Vehicles Instead of NaturalDocument39 pagesDokumen - Tips - 1 CNG Dealer Training 2 What Is CNG CNG Is Natural Gas Compressed To A Pressure of 200 250 KGCM G Why CNG Is Used in Vehicles Instead of NaturalCandraNo ratings yet

- Amends To SDs 2011Document214 pagesAmends To SDs 2011duaankushNo ratings yet

- Guidance On Continuous Machinery Survey Cms eDocument15 pagesGuidance On Continuous Machinery Survey Cms eKaptan Leventcum100% (1)

- ASTM TablesDocument460 pagesASTM TablesAbhishek PandeyNo ratings yet

- Tanker LCC Operating ProceduresDocument37 pagesTanker LCC Operating ProceduresCiocio CiohodaruNo ratings yet

- J3 Gross WT IncreaseDocument18 pagesJ3 Gross WT Increaseagpilot19yahoo.comNo ratings yet

- BWM Electrolysis TypeDocument4 pagesBWM Electrolysis TypeAldo Sitorus100% (1)

- Install Exhaust ScrubbersDocument16 pagesInstall Exhaust ScrubbersClaudio SantellanesNo ratings yet

- Air-Winch Manual PDFDocument56 pagesAir-Winch Manual PDFQuyet Nguyen0% (1)

- REP - 11352 Good Practices Care and Custody of Propane PDFDocument38 pagesREP - 11352 Good Practices Care and Custody of Propane PDFdimasNo ratings yet

- Easicult Application Brochure - Jet FuelDocument2 pagesEasicult Application Brochure - Jet Fuelviktor_gligorovNo ratings yet

- Wiring Circuit Numbers M-Series TrucksDocument26 pagesWiring Circuit Numbers M-Series Truckskastein100% (1)

- Carter Carburetor Identify Plunger Rod Assembly by Shaft NumberDocument3 pagesCarter Carburetor Identify Plunger Rod Assembly by Shaft Numberisland14No ratings yet

- F15257 PDFDocument123 pagesF15257 PDFMarbin ClaureNo ratings yet

- Airtester HP-3-GB D3188001 03Document7 pagesAirtester HP-3-GB D3188001 03federalulNo ratings yet

- Velan Butterfly Valves PDFDocument24 pagesVelan Butterfly Valves PDFTushar Lanjekar100% (1)

- Technical Data Design Sheets - Tornado Da Fa PDFDocument14 pagesTechnical Data Design Sheets - Tornado Da Fa PDFMilena Lemus FonsecaNo ratings yet

- Contoh Soal Tes IFIA AgroDocument57 pagesContoh Soal Tes IFIA AgrolacalluNo ratings yet

- Germany Research VesselsDocument83 pagesGermany Research VesselsChakma NhikiNo ratings yet

- Experiment No. 04 PLC (Bottle Filling Machine) Date: AIMDocument3 pagesExperiment No. 04 PLC (Bottle Filling Machine) Date: AIMSahil GawadeNo ratings yet

- P A ManualDocument65 pagesP A ManualARE YOU TECH CRAZYNo ratings yet

- (TP0A016) Smith Meter® LACT UnitDocument8 pages(TP0A016) Smith Meter® LACT UnitRoberto Carlos Teixeira100% (1)

- Fundamentals of Natural Gas Liquid MeasurementsDocument9 pagesFundamentals of Natural Gas Liquid Measurementsmakasad26No ratings yet

- Hand Out Kuliah Boiler Fuels and CombustionDocument53 pagesHand Out Kuliah Boiler Fuels and CombustionlirenavirenaNo ratings yet

- Pool Heater Owners ManualDocument170 pagesPool Heater Owners ManualTrent FontenotNo ratings yet

- Natural Gas IncidentsDocument55 pagesNatural Gas IncidentsInternational CertificationNo ratings yet

- TFM. Risk Analysis of LPG Tanks at The Wildland-Urban Interf PDFDocument98 pagesTFM. Risk Analysis of LPG Tanks at The Wildland-Urban Interf PDFRod SantosNo ratings yet

- RJ Final Ta Gpp5 CogenDocument1,349 pagesRJ Final Ta Gpp5 CogenPand AemonaEonNo ratings yet

- Gas Safety AwarenessDocument5 pagesGas Safety AwarenessAyaNo ratings yet

- Retrofits Applications Worth ConsideringDocument7 pagesRetrofits Applications Worth ConsideringBharti FamilyNo ratings yet

- HirtzDocument11 pagesHirtzMahmoud MuhamedNo ratings yet

- Sergey B. Dorofeev - A Flame Speed Correlation For Unconfined Gaseous ExplosionsDocument18 pagesSergey B. Dorofeev - A Flame Speed Correlation For Unconfined Gaseous ExplosionsSodaMoussezNo ratings yet

- A Comparative Study Between Propane Dehydrogenation (PDH) Technologies and Plants in Saudi ArabiaDocument16 pagesA Comparative Study Between Propane Dehydrogenation (PDH) Technologies and Plants in Saudi ArabiaBihina HamanNo ratings yet

- TSSA Certification Exam GuideDocument9 pagesTSSA Certification Exam GuideROCCONo ratings yet

- ASSEMBLER: Leave This Manual With Consumer. CONSUMER: Keep This Manual For Future ReferenceDocument52 pagesASSEMBLER: Leave This Manual With Consumer. CONSUMER: Keep This Manual For Future ReferenceMirjana PrekovicNo ratings yet

- Gillette Generators - Operation and Installation GuideDocument32 pagesGillette Generators - Operation and Installation GuideDayo IdowuNo ratings yet

- Precooling Strategies For Efficient Natural Gas Liquefaction - Gas Processing & LNGDocument20 pagesPrecooling Strategies For Efficient Natural Gas Liquefaction - Gas Processing & LNGMuhammad ImranNo ratings yet

- Gaseous Fuels: NotesDocument45 pagesGaseous Fuels: NotesMohini SharmaNo ratings yet

- Heat of Combustion of Candle WaxDocument14 pagesHeat of Combustion of Candle Waxmarzinus0% (1)