Professional Documents

Culture Documents

Report - Abstract & ToC

Uploaded by

SiranGVCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Report - Abstract & ToC

Uploaded by

SiranGVCopyright:

Available Formats

ABSTRACT

Diesel engines are widely used in major sectors of any country because of its higher thermal efficiency and durability than petrol engine. Even though diesel engines produce more power, the pollutants emitted by them causes adverse effect on the environment, and also earth is running short of fossil fuel. Out of various pollutants smoke and NOx emission is significant. If measures are taken to reduce one parameter other parameter tends to increase. And also no obvious modifications to the engine design remain to further reduce particulates and NOx emissions, the industry is forced to resort to expensive after treatment methods. In order to reduce dependence on after treatment methods, additives like oxygenates are added. In the present investigation, three oxygenated additives were chosen namely dimethyl carbonate (DMC), diglyme (DGM), diethyl ether (DEE). They were mixed with standard diesel in proportions of 10%, 15% and 20% respectively. Investigations were carried out to reduce the smoke emissions of stationary diesel engine with the above blends with minimum decrease in NO x emissions and minimum decrease in brake thermal efficiency. Design of experiments (DOE) method was employed to identify the experiments to be conducted on the engine. Three factors namely fuel additive, % volume of blend and injection timing was selected as influencing factors for the investigation. To critically examine the effect of influencing factors on the chosen objective, three levels were chosen for each factor. Taguchis L9 orthogonal array (OA) was used to reduce the number of experiments to be conducted. Through multi response optimisation technique, optimum combination of fuel additive, percentage volume of blend and fuel injection timing were determined to reduce the smoke emissions and NOx emissions without much decrease in brake thermal efficiency.

i

TABLE OF CONTENTS

CHAPTER NO.

TITLE

PAGE NO.

ABSTRACT LIST OF TABLES LIST OF FIGURES LIST OF SYMBOLS AND ABBREVIATIONS

i vi vii viii

INTRODUCTION 1.1 ENERGY SCENARIO 1.2 ENERGY CONSUMPTION IN TRANSPORTATION SECTOR 1.3 THE INTERNAL COMBUSTION ENGINE 1.4 POLLUTANTS FROM DIESEL ENGINES 1.5 OXYGENATES FOR DIESEL FUELS 1.6 OXIDES OF NITROGEN EMISSION 1.7 PRESENT WORK 1.7.1 Organisation of the Report

1 1

3 4 6 7 8 8 9

LITERATURE SURVEY 2.1 GENERAL 2.2 OXYGENATED ADDITIVES-THE NEED 2.3 OXYGENATE SELECTION 2.4 DIMETHYL CARBONATE 2.5 DIGLYME 2.6 DIETHYL ETHER 2.7 NOX REDUCTION 2.8 SUMMARY

ii

10 10 11 13 14 15 16 18 19

CHAPTER NO.

TITLE

PAGE NO.

2.9 OBJECTIVES OF THE PRESENT WORK

20

SELECTION OF ADDITIVES AND ITS PROPERTIES 3.1 GENERAL 3.2 SELECTION OF OXYGENATED ADDITIVES 3.3 ADDITIVE PROPERTIES 21 21 21 23

METHODOLOGY FOR OPTIMISATION OF ENGINE PARAMETERS 4.1 OPTIMISATION OF ENGINE PARAMETERS 4.1.1 INTRODUCTION 4.1.2 TAGUCHI DESIGN 4.1.3 SELECTION OF FACTORS 4.1.4 SELECTION OF LEVELS OF FACTORS 4.1.5 SECTION OF ORTHOGONAL ARRAY (OA) 4.1.6 ASSIGNMENT OF FACTORS TO COLUMNS 4.1.7 ENGINE TESTING 4.1.7.1 EXPERIMENTAL SETUP 4.1.7.2 EMISSION MEASUREMENT 4.1.7.3 TEST PROCEDURE FOR STATIONARY ENGINES 4.1.8 ANALYSIS OF RESULT 4.1.8.1 LOSS FUNCTION 34 35 35 32 32 32 34 31 27 27 27 28 29 30

iii

CHAPTER NO.

TITLE

PAGE NO.

4.1.8.2 NORMALIZING OF LOSS FUNCTION 4.1.8.3 ASSIGNING WEIGHTING FACTOR 4.1.8.4 MULTI-RESPONSE SIGNAL TO NOISE RATIO 4.1.8.5 OPTIMUM COMBINATION OF FACTOR LEVELS 4.1.8.6 ANOVA (ANALYSIS OF VARIANCE) 4.2 CONFIRMATION EXPERIMENT 38 40 38 38 36 36

RESULTS AND DISCUSSION 5.1 GENERAL 5.2 FACTOR INFLUENCE 5.2.1 INFLUENCING FACTOR FOR SMOKE 5.2.2 INFLUENCING FACTOR FOR NOX 5.2.3 INFLUENCING FACTOR FOR BTE 5.3 COMBINATION OF FACTOR LEVELS 5.4 MULTI RESPONSE SIGNAL TO NOISE RATIO 5.5 TAGUCHI PARAMETRIC DESIGN 5.6 PERCENTAGE INFLUENCE OF FACTOR ON CHOSEN OBJECTIVE AT DIFFERENT LOADS 5.7 EFFECT OF WEIGHT FACTOR 5.8 CONFIRMATION EXPERIMENT

41 41 41 41 42 42 43 45 45

48 50 51

iv

CHAPTER NO.

TITLE

PAGE NO.

CONCLUSION 6.1 SCOPE FOR FUTURE WORK

53 53

APPENDIX: MODEL CALCULATION FOR MRSN RATIO AND ITS VARIANCE REFERENCES 55 64

LIST OF TABLES

TABLE NO.

CONTENT

PAGE NO.

2.1 3.1 3.2

LIST OF NON-METALLIC OXYGENATES PROPERTIES OF THE ADDITIVES PROPERTIES OF THE OXYGENATED FUEL BLENDS

12 24

26 31 32 33 34

4.1 4.2 4.3 4.4 5.1

FACTORS WITH THEIR LEVELS L9 ORTHAGONAL ARRAY SPECIFICATION OF STATIONARY ENGINE SPECIFICATION OF EXHAUST GAS ANALYSER OPTIMUM COMBINATIONS OF FACTOR LEVELS AT DIFFERENT LOAD CONDITIONS

44 46 46 47

5.2 5.3 5.4 5.5

MRSN TABLE FOR NO LOAD MRSN TABLE FOR PART LOAD MRSN TABLE FOR FULL LOAD FACTOR EFFECT ON MRSN RATIO FOR TESTED FUELS AT DIFFERENT LOADS

47 51 52

5.6 5.7 5.8

EFFECT OF WEIGHTING FACTOR OPTIMUM COMBINATIONS RESPONSE VARIABLES AT OPTIMIZED CONDITION LEVELS

52

vi

LIST OF FIGURES

FIGURE NO.

CONTENT

PAGE NO.

1.1

PRODUCTION AND CONSUMPTION OF PETROLEUM PRODUCTS 2

4.1

FLOWCHART OF THE EXPERIMENTATION PROCEDURE 28 29 33 41 42 43

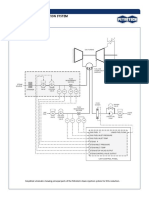

4.2 4.3 5.1 5.2 5.3 5.4

COMPONENTS OF EXPERIMENTAL DESIGN LAYOUT OF EXPERIMENTAL SETUP INFLUENCING FACTOR FOR SMOKE INFLUENCING FACTOR FOR NOX INFLUENCING FACTOR FOR BTE PERCENTAGE INFLUENCE OF FACTOR ON OBJECTIVE AT NO LOAD, PART LOAD AND FULL LOAD CONDITIONS

48

vii

LIST OF SYMBOLS AND ABBREVIATIONS

Symbols %

Percentage

Brake thermal efficiency Joules Kelvin Loss function of ith response variable in the experiment Percentage contribution of each influencing factor Normalized loss function of ith for the response variable in jth experiment

J K Lij P Sij SSe SSf SSt TL Wi Yi Yijk

Sum of squares of errors Sum of squares of each influencing factor Total sum of squares Total loss function of each experiment weighing factor for the ith response variable Response variable of the ith experiment Experimental value of the ith response variable in the jth experiment at the kth test. (k=2)

Abbreviations ASTM AVL CAD CI CO CO2 DEE DGM American Society for Testing and Materials Manufactures Name Crank Angle in Degree Compression Ignition Carbon Monoxide Carbon Di-Oxide Di-Ethyl Ether Diglyme (Di-Ethylene Glycol di-Methyl ether)

viii

DMC kJ/kg mm MRSN NOx O2 OA ppm

Di-Methyl Carbonate kilo Joule per Kilogram millimeter Multi Response Signal to Noise Oxides of Nitrogen Oxygen Orthogonal Array parts per million

ix

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Environmental Pollution IssusesDocument23 pagesEnvironmental Pollution IssusesALI RAZANo ratings yet

- Modular Aftertreatment System BrochureDocument4 pagesModular Aftertreatment System BrochureSalatyelNo ratings yet

- Traffic Engineering MicroprojectDocument13 pagesTraffic Engineering MicroprojectSohel Torane100% (1)

- Diesel – A Clean and Efficient Fuel Achieving BSVI Emission StandardsDocument25 pagesDiesel – A Clean and Efficient Fuel Achieving BSVI Emission StandardsPragg AggarwalNo ratings yet

- Mechanical Engineering Interview Questions and Answers Set3 - Preparation For EngineeringDocument9 pagesMechanical Engineering Interview Questions and Answers Set3 - Preparation For EngineeringRajneesh Patel100% (1)

- Freightliner BC M2 Driver Manual PDFDocument197 pagesFreightliner BC M2 Driver Manual PDFRubén GonzàlezNo ratings yet

- 0653 s16 Ms 32Document5 pages0653 s16 Ms 32yuke kristinaNo ratings yet

- Fertilizer ManufacturingDocument17 pagesFertilizer ManufacturingSambiri PisiraiNo ratings yet

- BOC TrainingDocument574 pagesBOC TrainingDanielAlejandroRamosQuero100% (2)

- Emissions Control BrochureDocument12 pagesEmissions Control BrochureAlliance Transport Technologies LtdNo ratings yet

- Lecture 5 - Air Pollution Control - WebDocument62 pagesLecture 5 - Air Pollution Control - WebChrisNo ratings yet

- Steam Injection NOx ReducDocument2 pagesSteam Injection NOx ReducEdison CheongNo ratings yet

- Me 482 ENERGY CONSERVATION AND MANAGENET Text Book Prepared by Faris KK FOR KTU S8Document103 pagesMe 482 ENERGY CONSERVATION AND MANAGENET Text Book Prepared by Faris KK FOR KTU S8vpzfaris85% (13)

- AFBC Technology Overview for Army Heating PlantsDocument101 pagesAFBC Technology Overview for Army Heating Plantsdika wahyu0% (1)

- 2.A.3 Glass Production GB2013Document27 pages2.A.3 Glass Production GB2013grcNo ratings yet

- USOO8568134B2 Coanda gas burner apparatusDocument29 pagesUSOO8568134B2 Coanda gas burner apparatusFabrizio FerrerioNo ratings yet

- Sensor Systems Broch 09 MedDocument12 pagesSensor Systems Broch 09 MedscribdkhatnNo ratings yet

- MPFIDocument22 pagesMPFIDilip PatelNo ratings yet

- Evolving Needs of Tunnel Ventilation in A Changing World PDFDocument14 pagesEvolving Needs of Tunnel Ventilation in A Changing World PDFRajesh JainNo ratings yet

- Air Pollution and Control Unitwise Solved Question Papers PDFDocument41 pagesAir Pollution and Control Unitwise Solved Question Papers PDFmd hesham uddinNo ratings yet

- Presentation On Gas Power PlantDocument82 pagesPresentation On Gas Power Plantakshay gupta100% (2)

- IELTS Reading Practice 1 (Academic) Time Allowed: 1 Hour Number of Questions: 40 Instructions All Answers Must Be Written On The Answer SheetDocument92 pagesIELTS Reading Practice 1 (Academic) Time Allowed: 1 Hour Number of Questions: 40 Instructions All Answers Must Be Written On The Answer SheetCold Reaper GamingNo ratings yet

- Staged Low Nox Combustion Systems For Coal Fired Boilers and CorrosionDocument9 pagesStaged Low Nox Combustion Systems For Coal Fired Boilers and CorrosionvyshnavkumarNo ratings yet

- Turow Power PlantDocument14 pagesTurow Power Plantdobrilog100% (1)

- CFD Applications For Performance Improvement in Power PlantsDocument36 pagesCFD Applications For Performance Improvement in Power Plantsdillipsh123No ratings yet

- Dry Gas Seals SiemensDocument11 pagesDry Gas Seals Siemensahbabar808No ratings yet

- MC 10165111 9999Document15 pagesMC 10165111 9999ZuskerNo ratings yet

- Industria1 C o M B U S T I o N Pollution and C o N T R o L PDFDocument890 pagesIndustria1 C o M B U S T I o N Pollution and C o N T R o L PDFAfzaal AshrafNo ratings yet

- Performance AnalysisDocument10 pagesPerformance AnalysisHimanshu RanjanNo ratings yet