Professional Documents

Culture Documents

ANo101 PFCOnSite

Uploaded by

Ricardo LopezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ANo101 PFCOnSite

Uploaded by

Ricardo LopezCopyright:

Available Formats

Application Note

PoleCap: Power Factor Correction on Site

P o w e r Q u a l i t y S o l u t i o n s

www.epcos.com/pfc

Notes Application Note

The collection of PQS Application Notes is a library with in-depth information on PFC applications, case studies and reference projects. It also serves as a helpdesk for all topics relating to PFC and PQS, is suitable for training purposes and is designed to answer frequently asked questions. Each issue will focus on a particular application topic, a specific solution or a topic of general interest. The aim is to share the extensive knowledge gained globally by EPCOS PFC experts with regional staff who deal with PFC and PQS. The authors of the PQS Application Notes have extensive experience in the field of PFC and PQS and a professional background as electrical/design engineers or product marketing managers throughout the world.

These PQS Application Notes will be issued at irregular intervals and can be downloaded from the EPCOS Internet under www.epcos.com/pfc Please contact the EPCOS PM department in Munich if you wish to receive the latest issue of the PQS Application Notes automatically by email. A list with available titles may also be obtained from the PM department in Munich.

Important Notes Some parts of this publication contain statements about the suitability of our products for certain areas of application. These statements are based on our knowledge of typical requirements that are often placed on our products for a particular customer application. It is incumbent on the customer to check and decide whether a product is suitable for use in a particular application. This Application Note may be changed from time to time without prior notice. Our products are described in detail in our data sheets. The Important Notes (www.epcos.com/ImportantNotes) and the product specific warnings and cautions must be observed. All relevant information is available through our sales offices.

EPCOS AG � ANo 101/V1 � Jan. 2007

2 of 10

Notes Application Note

PoleCap: Power Factor Correction on Site

Exposing a standard PFC capacitor to the influence of direct sunlight, weathering and rain means an enormous stress to the device. This is why outdoor PFC applications have been a very sensitive and difficult topic.

Also, PoleCap capacitors are suitable for applications under adverse conditions, for example in sawmills or cement works where one will find high dust or moisture

concentrations, or in places where the ambient temperature is very high.

With the development of the PoleCap series, EPCOS has introduced a PFC-capacitor for outdoor usage. It is designed for direct mounting on the masts of overhead power lines in rural areas or regions with commercial or industrial activities. The PoleCap series enable power distribution companies to stabilize the power supply, while simultaneously reducing power consumption and voltage drops. This Application Note gives some technical information on the PoleCap. Also, it contains an in-depth case study for the first outdoor application in India with approximately 14,000 PoleCap units installed on poles.

The Author Rajneesh Shukla, Engineer in Electricals & Electronics and MBA with 10 years of engineering experience and 7 years in marketing of PFC within EPCOS. He is responsible for business development in the Delhi region.

EPCOS AG � ANo 101/V1 � Jan. 2007

3 of 10

Notes Application Note

PoleCap: Power Factor Correction on Site

Contents PoleCap: Power Factor Correction on Site ............................................................................................5 1. Capacitors for outdoor use ........................................................................................................5 2. Requirements for outdoor capacitors ......................................................................................5 � � � � � � � � � � � � � � � � � � Mandatory properties.....................................................................................................................5

3. Adverse conditions .....................................................................................................................5 Impermeability ...............................................................................................................................5 Compact design and low weight....................................................................................................5

4. Safety features .............................................................................................................................6 Protected against shock hazard ....................................................................................................6 Overpressure disconnector ...........................................................................................................6 Self healing....................................................................................................................................6 Dry technology...............................................................................................................................6 Discharge module..........................................................................................................................6

5. Visible fault control .....................................................................................................................6 Monitoring from the ground ...........................................................................................................6

6. Superior thermal respond ..........................................................................................................6 Self-heating ...................................................................................................................................6 Single-can design ..........................................................................................................................6 Testing in Malaysia........................................................................................................................6 Hot-spot temperature.....................................................................................................................7

7. Case Study ...................................................................................................................................7 Pilot project Jaipur City, India........................................................................................................7

8. Jaipur power grid ........................................................................................................................7 Transformer capacity.....................................................................................................................7 Analysis of power factor ................................................................................................................8

9. Methodology adopted for selection of kvar ..............................................................................8 Selection of capacitors ..................................................................................................................8 Example.........................................................................................................................................8

10. Analysis of loss reductions ........................................................................................................9 11. Conclusions .................................................................................................................................9 12. Standards ................................................................................................................................... 10

EPCOS AG � ANo 101/V1 � Jan. 2007

4 of 10

Notes Application Note

PoleCap: Power Factor Correction on Site

Power Factor Correction

PoleCap: Power Factor Correction on Site

Recent years have repeatedly seen spectacular power outages that paralyzed major cities and even entire regions. Grid overload can be prevented by using power factor correction (PFC) equipment in the immediate vicinity of loads. Power quality improves at the same time. PoleCaps are the right tool for this purpose. The number of great blackouts is increasing all over the world, leaving large areas without electricity for hours or even for days effecting millions of people and causing billions of dollars of damage. Such incidents with serious consequences lead to ever louder demands on power companies: consumers insist on stable grids with a reliable supply of energy and high power quality. For this purpose, power capacitors have been used for many years for power factor correction in industrial power distribution, in UPS systems, in wind parks and drive systems. PFC equipment of appropriate design reduces the share of reactive current in the entire grid, simultaneously reducing power consumption and voltage drops, and stabilizing the power supply. Lower energy costs are a further benefit. 1. Capacitors for outdoor use To obtain the same effect in rural areas with mainly domestic or agricultural loads or in regions with little commercial or industrial activity, considerable capital expenditure would be needed to expand the distribution network. An alternative is to install PFC capacitors close to the source of reactive current in this case by mounting them right on the masts of the overhead power lines. 2. Requirements for outdoor capacitors Because of their exposed position, power capacitors used for this purpose must satisfy several requirements.

Several properties are mandatory for the design of capacitors for outdoor usage. They must be � � � � � � � watertight dustproof impact-resistant resistant to weathering and UV light of high dielectric strength resistant to high temperatures caused by sunlight capable of remote operational monitoring.

With the PFC-capacitors series PoleCap EPCOS satisfies these requirements. Based on proven metalized plastic film technology, PoleCaps are a logical development of the PhiCap and PhaseCap series.

Fig. 1: Cross section of a PoleCap

3. Suitable for adverse conditions However, it would be wrong to use the PoleCap outdoors only. Thanks to their high impermeability, they are also suitable wherever high levels of dust or moisture can impair operation of conventional capacitors such as in cement works and sawmills. Here PoleCap capacitors can be used either inside or outside a switch cabinet. Further advantages are their compact design and low weight. The PoleCap can be directly mounted outdoors on a power mast. They are supplied with connecting cables already fitted, leading to considerable savings in time and thus cost. In addition, the M12 threaded stud permits fast and simple mounting.

EPCOS AG � ANo 101/V1 � Jan. 2007

5 of 10

Notes Application Note

PoleCap: Power Factor Correction on Site

4. Safety features The PoleCap series also offers a host of safety features. � � � � � � All live parts are protected; cable connections are protected against shock hazards to IP 54 Integrated overpressure disconnector Self-healing design Dry technology thanks to gas impregnation Pre-mounted discharge module on ceramic basis

6. Superior thermal response What makes PoleCaps unique is their thermal response. The conventional solution for capacitors designed for outdoor use or mast mounting is to fit an additional protective casing. Capacitor losses lead to self-heating that heats up the space between inner can and outer casing. This accumulated heat then surrounds the capacitor, which is heated up already, like an electric blanket. Insufficient cooling then makes premature aging of the capacitor inevitable. The PoleCap, on the other hand, is designed to prevent this extra heat reservoir from forming. Tests have shown that PoleCaps with their single-can design operate at a significantly lower temperature than conventional capacitors with additional steel casings. The PoleCap uses convection alone for inner cooling. This property gives it a longer operating life and higher reliability. In order to accurately compare the thermal behavior of two capacitors with and without additional protective casings, tests were carried out in Malaysia under extremely harsh climatic conditions. A voltage of 440 V was applied to both capacitors, which were exposed to direct sunlight. Evaluation of the temperatures measured with thermistors shows that the can and core temperatures of the capacitor with the extra casing are significantly higher than for the PoleCap.

5. Visible fault control Capacitors mounted on masts must permit operational monitoring from the ground. The PoleCap series are equipped with a red strip that becomes visible as soon as the overpressure disconnector has triggered in response to a malfunction. Fig. 2: PoleCap in operation

Fig. 3: Red strip visible after triggering of overpressure disconnector

Fig. 4: Conventional PFC capacitor with external casing

EPCOS AG � ANo 101/V1 � Jan. 2007

6 of 10

Notes Application Note

PoleCap: Power Factor Correction on Site

8. Jaipur power grid Jaipur city has an installed capacity of 4600 transformers of 11 KV / 0.433 KV of various ratings: � � � � � � � 25 kVA 40 kVA 63 kVA 100 kVA 250 kVA 315 kVA 500 kVA

These transformers are dedicated to feed the distribution network. Total capacity of installed transformers is approx. 1000 MVA. An analysis was performed and showed an average power factor of LT lines of 0.85 (Fig. 6).

Fig. 5: New PoleCap design with excellent cooling features

The PoleCap without extra casing attains a hotspot temperature 7 C lower than in conventional solutions. This is a significant advantage, as experience shows that a temperature reduction of this size roughly doubles the operating life of the capacitor. 7. Case Study The city of Jaipur in Rajasthan, India, was one of the pioneers for PFC on site with the objective targets � � � Reduction of kvar consumption Reduction of line losses Improvement and stabilization of power quality

Apart from these objectives, the utility board of Jaipur Vidyut Vitran Nigam Ltd. has required some features for the design of the PFC capacitor: � � � � Protection degree IP 54 Protection against influence of water, sun and dust High degree of temperature resistance Fault identification from the ground

Fig. 6: Analysis of average power factor Average loading on each transformer is 50 %. Summer Season Demand: 430 MW (506 MVA) Winter season demand: 300 MW (353 MVA) Total losses of Jaipur City: 17%

Company Jaipur Vidyut Vitran Nigam Ltd. has received the official order to evaluate a tailormade solution to fulfill all requirements. The necessary evaluation was performed together with PFC-specialists from EPCOS India.

EPCOS AG � ANo 101/V1 � Jan. 2007

7 of 10

Notes Application Note

PoleCap: Power Factor Correction on Site

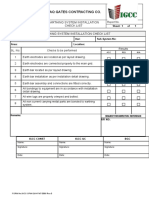

9. Methodology adopted for selection of kvar Minimum loading on transformers (average 20% of kVA rating) Power Factor: 0.85 Capacitor selected: for 100 kVA transformer: 20 x 0.85 x M.F.*) = 20 x 0.85 x 0.619 = 10.5 kvar So selection of capacitors has been done on basis of 10% of kVA rating of the transformers (in multiples of 5 kvar). Example: For 100 kVA transformer: 10 kvar (= 2 x 5 kvar capacitors) and these two capacitors installed at the tail end or place where the higher concentration of load exists, of distribution lines and on poles. Selection of kvar steps, rated voltage 440 V: 13,000 PoleCap of 5 kvar 250 PoleCap of 10 kvar 125 PoleCap of 20 kvar 13,375 PoleCap capacitors After installation of PoleCap, further readings of grid parameter taken at various places (Fig. 6). Now the analysis shows an improvement of power factor correction from 0.85 to 0.95.

10. Analysis on loss reductions Installed capacity of transformers: 1000 MVA Power factor at peak demand: 0.85 During summer: 430 MW or 506 MVA During winters: 300MW or 353 MVA After installation of 70,000 kvar, Power Factor improves to 0.91 Result for peak demands : During summer: During winter: 472 MVA 330 MVA

Reduction in Resistive Transmission Losses (MVA12 x MVA22) x 100 % MVA12 = 13 % saving in terms of line losses

Fig. 7: Analysis after installation of PoleCap

*) M.F. = weighting factor, see PFC Product Profile, current version, page 71

EPCOS AG � ANo 101/V1 � Jan. 2007

8 of 10

Notes Application Note

PoleCap: Power Factor Correction on Site

11. Conclusion Jaipur city is the first city in India that invested in power quality. This pilot project and the analysis performed imposingly documented the achievements of power factor correction by PoleCap: Reduction of losses � Improvement of power factor � Stabilization of power supply With its unique design and optimized thermal behavior, the PoleCap is not only the perfect capacitor for outdoor applications, but also under tight surrounding conditions: wherever one has to consider the presence of dust, water or UV-impact, the PoleCap will allow power factor correction at site. Datasheets for the particular types are available in the EPCOS Internet, www.epcos.com/pfc or contact your local sales office.

EPCOS AG � ANo 101/V1 � Jan. 2007

9 of 10

Notes Application Note

PoleCap: Power Factor Correction on Site

12. Standards The recommendations and proposals stated in this Application Note are (among others) based on several international standards for PFC capacitors, LV switchgear design and electricity:

IEC60831: LV-PFC Capacitor Standard IEC61921: Power Capacitors LV-PFC-Banks DIN EN61921: Leistungskondensatoren Kondensatorbatterien zur Korrektur des Niederspannungsleistungsfaktors EN 50160: Voltage Characteristics of Electricity supplied by Public Distribution Systems Engineering Recommendation G5/4: Planning levels for harmonic voltage distortion and the connection of non-linear equipment to transmission systems and distribution networks in the United Kingdom IEEE Std. 519-1992: IEEE Recommended practices and requirements for harmonic control in electrical power systems IEC60439-1/2/3: Low voltage switchgear and control gear assemblies

The specifications in the standards and manufacturers datasheets should be obeyed in any case.

Published by EPCOS AG Product Marketing PFC P. O. Box 80 17 09 D-81617 Munich/Germany

EPCOS AG � ANo 101/V1 � Jan. 2007

10 of 10

You might also like

- Cda-S220 PDocument10 pagesCda-S220 PRicardo LopezNo ratings yet

- Cda-S178 PDocument8 pagesCda-S178 PRicardo LopezNo ratings yet

- Bentley UtilitiesDocument1 pageBentley UtilitiesRicardo LopezNo ratings yet

- Chapter 24 - DC Short-Circuit AnalysisDocument24 pagesChapter 24 - DC Short-Circuit AnalysisRicardo LopezNo ratings yet

- TB 04300002 eDocument19 pagesTB 04300002 eRicardo LopezNo ratings yet

- 43944Document2 pages43944Ricardo LopezNo ratings yet

- CT SDocument2 pagesCT SRicardo LopezNo ratings yet

- Chapter 20 - User-Defined Dynamic ModelsDocument25 pagesChapter 20 - User-Defined Dynamic ModelssiekhaiNo ratings yet

- Opmu 0CDocument4 pagesOpmu 0CRicardo LopezNo ratings yet

- Chapter 00 - Table of ContentsDocument12 pagesChapter 00 - Table of ContentssiekhaiNo ratings yet

- Chapter 04 - User Access ManagementDocument17 pagesChapter 04 - User Access ManagementRicardo LopezNo ratings yet

- ETAP Generator Start-UpDocument11 pagesETAP Generator Start-UpSeanChan100% (1)

- ANo109 ControllingThePowerDocument10 pagesANo109 ControllingThePowerRicardo LopezNo ratings yet

- ANo116 Design Rules For PFC Systems - 090205Document11 pagesANo116 Design Rules For PFC Systems - 090205Ricardo LopezNo ratings yet

- TB 01400002 eDocument23 pagesTB 01400002 eRicardo LopezNo ratings yet

- EPCOS PFC Product Brief 2010Document8 pagesEPCOS PFC Product Brief 2010Ricardo LopezNo ratings yet

- ANo110 MKV RuggedTypesDocument9 pagesANo110 MKV RuggedTypesRicardo LopezNo ratings yet

- PDF InstallationAndMaintenanceDocument13 pagesPDF InstallationAndMaintenanceRicardo LopezNo ratings yet

- ANo103 SpinningPFCDocument8 pagesANo103 SpinningPFCRicardo LopezNo ratings yet

- PFC in The Plastics Industry: Application NotesDocument8 pagesPFC in The Plastics Industry: Application NotesRicardo LopezNo ratings yet

- PFC and HarmonicsDocument13 pagesPFC and HarmonicsArturo Fidel NeiraNo ratings yet

- ANo106 MorePowerWithPhaseCapDocument10 pagesANo106 MorePowerWithPhaseCapRicardo LopezNo ratings yet

- ANo112 Economical FriendlyDocument8 pagesANo112 Economical FriendlyRicardo LopezNo ratings yet

- PFC 10 CommandmentsDocument6 pagesPFC 10 CommandmentsRicardo LopezNo ratings yet

- ANo100 OptimizedDesignofPFCDocument10 pagesANo100 OptimizedDesignofPFCRicardo LopezNo ratings yet

- PhiCap CapacitorsDocument16 pagesPhiCap CapacitorsJuan MoralesNo ratings yet

- ANo102 HomeCapDocument9 pagesANo102 HomeCapRicardo LopezNo ratings yet

- PhiCap CapacitorsDocument16 pagesPhiCap CapacitorsJuan MoralesNo ratings yet

- PhiCap CapacitorsDocument16 pagesPhiCap CapacitorsJuan MoralesNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Response Coordination of Distributed Generation and Tap Changers For Voltage SupportDocument7 pagesResponse Coordination of Distributed Generation and Tap Changers For Voltage SupportraghudtsNo ratings yet

- Loss Estimation: A Load Factor MethodDocument7 pagesLoss Estimation: A Load Factor MethodIDESNo ratings yet

- Qatar Electricity & Water Corporation Mission StatementDocument82 pagesQatar Electricity & Water Corporation Mission StatementFahad Amjad100% (2)

- Basic Line ProtectionDocument30 pagesBasic Line ProtectionMaduike Obinna HenryNo ratings yet

- Substation LightingDocument13 pagesSubstation LightingHikmat AyerNo ratings yet

- Iraq Gates Earthing System Installation ReportDocument1 pageIraq Gates Earthing System Installation ReportAhmedNo ratings yet

- Unit Auxiliary Transformer (UAT) Generator Sisi A Dan Sisi BDocument1 pageUnit Auxiliary Transformer (UAT) Generator Sisi A Dan Sisi BRizaldi Lukman ImaniNo ratings yet

- Power Distribution Systems and Its Characteristics IDocument16 pagesPower Distribution Systems and Its Characteristics IMohammedSaadaniHassani100% (1)

- Electrical WiringDocument11 pagesElectrical WiringRasydan AliNo ratings yet

- High-Efficiency AC Power Distribution For Data Centers: White Paper 128Document19 pagesHigh-Efficiency AC Power Distribution For Data Centers: White Paper 128aaaaNo ratings yet

- 150 KV Tower Equipment and Accesories For Suspension Type With 2 Circuit LineDocument39 pages150 KV Tower Equipment and Accesories For Suspension Type With 2 Circuit LineCiel Panthomhive100% (2)

- Ee6801 Eeguc Notes PDFDocument187 pagesEe6801 Eeguc Notes PDFVairaperumal KNo ratings yet

- Program: Bachelor of Science in Industrial Technology (Bsit)Document7 pagesProgram: Bachelor of Science in Industrial Technology (Bsit)Industrial TechnologyNo ratings yet

- ABB Hard To Find Information On Distribution Systems Part IIDocument27 pagesABB Hard To Find Information On Distribution Systems Part IIRafat ThongNo ratings yet

- Distribution TransformerDocument2 pagesDistribution Transformeranon_765971No ratings yet

- Wiring Diagram - Defender Td5 (1999)Document55 pagesWiring Diagram - Defender Td5 (1999)Nick Short100% (1)

- ADMS Guide - 2 11.2015 PDFDocument33 pagesADMS Guide - 2 11.2015 PDFBharat RajNo ratings yet

- 1 P 006Document16 pages1 P 006salman GtrNo ratings yet

- Sub Station Training ReportDocument26 pagesSub Station Training Reportprem080990% (10)

- Product Datasheet: Circuit Breaker Compact NSX250F - TMD - 250 A - 3 Poles 3dDocument2 pagesProduct Datasheet: Circuit Breaker Compact NSX250F - TMD - 250 A - 3 Poles 3dJOSE RODRIGUEZNo ratings yet

- Voltage Ratings of Surge ArrestersDocument1 pageVoltage Ratings of Surge ArrestersmiguelpaltinoNo ratings yet

- Accenture Achieving High Performance With Theft Analytics PDFDocument20 pagesAccenture Achieving High Performance With Theft Analytics PDFAna MedanNo ratings yet

- Electronics 07 00062Document19 pagesElectronics 07 00062sanafayaz12No ratings yet

- Dse-0075.2 Cpi-500 enDocument3 pagesDse-0075.2 Cpi-500 enIeħor BissNo ratings yet

- V1 BHAAAS2020 Final Dautbasic Konjic OstaliDocument20 pagesV1 BHAAAS2020 Final Dautbasic Konjic OstaliNedisDautbasicNo ratings yet

- Technical Specifications - EnglishDocument126 pagesTechnical Specifications - EnglishAmitendu PatnaikNo ratings yet

- PSPCL Tariff Order FY 2021 22 Annex 2Document21 pagesPSPCL Tariff Order FY 2021 22 Annex 2Himanshu SundanNo ratings yet

- Supply Code RajasthanDocument39 pagesSupply Code RajasthanManojNo ratings yet

- A Presentation On The Pre-Feasibility Study of MicroDocument19 pagesA Presentation On The Pre-Feasibility Study of MicroPitamber BhusalNo ratings yet