Professional Documents

Culture Documents

Factors Affecting Dielectric Withstanding Voltage in Space Environments

Uploaded by

zakariiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Factors Affecting Dielectric Withstanding Voltage in Space Environments

Uploaded by

zakariiCopyright:

Available Formats

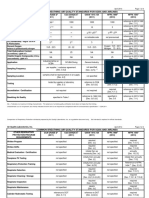

PRODUCT TECHNICAL BULLETIN #35 Dielectric Withstanding Voltage (DWV) in a Space Environment

Dielectric breakdown in a connector can occur as a result of at least three distinct failure modes: breakdown of the connector housing material, arcing over the surface of the housing, and breakdown of the air between closely spaced contacts. Because there are several different potential modes of failure, the Dielectric Withstanding Voltage (DWV) of a connector is influenced by a number of factors, some of which are more important than others depending on the application conditions. The most obvious factor effecting DWV is the spacing between the contacts in the connector. Closer spacing between contacts results in lower DWV, all other things being equal. Next, the plastic from which the connector housing is made has a very significant effect on the DWV of the connector. Some plastics have much better insulation properties than others, and use of a plastic with a high dielectric strength will reduce the likelihood that dielectric failure will occur through the plastic itself. Less obvious, but equally important, are the characteristics of the surface of the housing (specifically moisture and contamination) and density of the air (or other gas) in the environment surrounding the connector. Moisture and contamination on the surface of the connector housing can produce a partially conductive path between contacts which can become the weak link allowing breakdown as the voltage between the contacts increases. Air is not a perfect insulator and breakdown through air will occur if the electric field strength (which is a function of the voltage, and the spacing between opposite polarity contacts) is too high. The high electric field ionizes the gas molecules in the air space between the contacts. These ionized molecules are conductive and their presence initiates an avalanche of current between the contacts. As the density of the air increases, the electric field strength required to cause ionization and breakdown increases. In other words, air (and most other gasses) is a better insulator when its density is high than when the density is low. Since lowering the pressure of a gas decreases its density, breakdown of a gas generally occurs at lower and lower voltages as the pressure is reduced. Similarly, since air pressure is lower at higher altitudes, the dielectric strength of a connector will be lower at a high altitude than it is at sea level. This is the reason that all connectors have lower DWV ratings at high altitude (typically 70,000 ft.) than at sea level. For AirBorns W-Series, and R-Series connectors for example, the DWV rating at sea level (1 atm.) is 1000 volts, but the rating at 70,000 ft. is only 300 volts. The 700 volt difference has nothing directly to do with the design of the connector, it is solely the result of the reduction in the density (and thus the dielectric strength) of the air surrounding the connector at high altitude. The trend of reducing DWV as altitude increases applies only up to a point however. Beyond this point, as the pressure is reduced still further the DWV of the connector may actually rise (assuming that the failure mode is breakdown of

PTB35, ~

Page 1

the air, and not housing insulation or over surface breakdown). The reason for this that at very low pressure (in the vacuum of space well above the earths atmosphere) the density of the air is so low that there are very few air molecules present in the gap between the connector contacts. Under these conditions, breakdown can no longer occur as a result of ionizing the gas molecules since there are simply not enough gas molecules present to support the "avalanche" of ionization and current that constitutes breakdown. So, at some point, dependent on the gas pressure and the spacing between the pins, further reduction of the pressure will actually result in an increase in the DWV of the connector. Thus, the voltage at which breakdown occurs in a good vacuum is no longer a function of breakdown of the air, but of other variables such as the dielectric strength of the insulator material (which is typically very high) and the cleanliness of the surface of the insulator in between adjacent pins. In general, breakdown in a hard vacuum situation would be expected to occur as a result of "over surface" breakdown, not breakdown "through" the insulator material itself. Based on all the above, it is generally expected that the DWV of a connector in a hard vacuum environment is probably similar to what it would be at sea level, assuming that the connector is clean. However, if the connector must operate continuously (for example during launch of a space vehicle) from sea level, through the upper atmosphere, and finally in space, the DWV capability at high altitude will still be the limiting factor. If, on the other hand, the connector doesn't get powered until the equipment (a satellite for example) is already in space, then the high altitude DWV may not be a limitation. It is also important to understand that the DWV rating of a connector is not a working voltage rating, but merely an indication of the magnitude of the voltage that the connector can withstand without immediate, catastrophic failure of its insulation.

PTB35, ~

Page 2

You might also like

- Sharif University Internal Combustion Engines Course OutlineDocument2 pagesSharif University Internal Combustion Engines Course OutlinealikajbafNo ratings yet

- Flightdeck CAAC ATPL Study Material Meteorology Part II 2019 PDFDocument50 pagesFlightdeck CAAC ATPL Study Material Meteorology Part II 2019 PDFosamaNo ratings yet

- FUNDAMENTALS AND APPLICATIONS OF DIELECTRIC-BARRIER DISCHARGES (U. Kogelschatz)Document7 pagesFUNDAMENTALS AND APPLICATIONS OF DIELECTRIC-BARRIER DISCHARGES (U. Kogelschatz)THE NIKOLA TESLA INSTITUTENo ratings yet

- Cable Testing Rev 0Document8 pagesCable Testing Rev 0johnyquest_007No ratings yet

- Chapter 3 Breakdown of SolidDocument48 pagesChapter 3 Breakdown of SolidVon JinNo ratings yet

- PRE-LAb HVDocument4 pagesPRE-LAb HVRizqy M Mreww33% (3)

- Engineers Newsletter Air Distribution Cold Air Makes Good SenseDocument6 pagesEngineers Newsletter Air Distribution Cold Air Makes Good SensesamersibaniNo ratings yet

- Corona: Electrical Power Transmission and Distribution Eee/Git/GitamuniversityDocument10 pagesCorona: Electrical Power Transmission and Distribution Eee/Git/GitamuniversityRohanNo ratings yet

- Comparing Respiratory Protection StandardsDocument4 pagesComparing Respiratory Protection StandardsDaniel RodasNo ratings yet

- Vibration Damper in Transmission LineDocument4 pagesVibration Damper in Transmission LineSuleman BaigNo ratings yet

- Workmate 2000 ManualDocument12 pagesWorkmate 2000 Manualzakarii100% (1)

- IceboundDocument248 pagesIceboundMichael100% (1)

- Electrical QuestionnaireDocument113 pagesElectrical QuestionnaireSneha Mittal0% (1)

- Corona LossDocument10 pagesCorona LossGaurav Organ100% (1)

- Electrical Discharges - How The Spark, Glow and Arc WorkDocument17 pagesElectrical Discharges - How The Spark, Glow and Arc WorkzakariiNo ratings yet

- Technical Handbook Air CurtainsDocument13 pagesTechnical Handbook Air Curtainsaca111111No ratings yet

- A Report On Urban Heat Island EffectDocument26 pagesA Report On Urban Heat Island EffectDimitrijević Jovanović DraganaNo ratings yet

- MT CE Inerting in The Chemical Industry UK A5 RZ VIEW17 180614Document56 pagesMT CE Inerting in The Chemical Industry UK A5 RZ VIEW17 180614lhphong021191No ratings yet

- Department of Education: Velcar Elementary School Macabaklay, Gapan City - Ooo-First Periodical Test in Science VDocument4 pagesDepartment of Education: Velcar Elementary School Macabaklay, Gapan City - Ooo-First Periodical Test in Science VMary Ann ManalastasNo ratings yet

- Breakdown VoltageDocument4 pagesBreakdown VoltagesvirkomartinkoNo ratings yet

- Failure Mechanisms in High Voltage PCBsDocument6 pagesFailure Mechanisms in High Voltage PCBsrudi tuaNo ratings yet

- Fundamentals of Electrical ContactsDocument4 pagesFundamentals of Electrical ContactsAshisNo ratings yet

- InsulatorDocument16 pagesInsulatorMohammedNo ratings yet

- U /U U Is The Power Frequency Voltage Between Phase and Earth (V RMS)Document3 pagesU /U U Is The Power Frequency Voltage Between Phase and Earth (V RMS)shashidhargoudNo ratings yet

- Breakdown in LiquidsDocument11 pagesBreakdown in Liquidsvinayuv880% (1)

- Treeing and Tracking in Solid DielectricsDocument4 pagesTreeing and Tracking in Solid Dielectricssana majidNo ratings yet

- U0/U U Is The Power Frequency Voltage Between Phase and Earth (V RMS)Document3 pagesU0/U U Is The Power Frequency Voltage Between Phase and Earth (V RMS)ShashidharNo ratings yet

- Electrical Engineering Dielectric Breakdown Electrical Insulation High Voltage Corona Discharge Brush DischargeDocument2 pagesElectrical Engineering Dielectric Breakdown Electrical Insulation High Voltage Corona Discharge Brush DischargemayureshNo ratings yet

- Insulator For 1500kVDocument13 pagesInsulator For 1500kVdc12dcNo ratings yet

- Breakdown of Solid DielectricsDocument17 pagesBreakdown of Solid DielectricsSumaira SaifNo ratings yet

- PPM 15-16Document69 pagesPPM 15-16right12351No ratings yet

- HVE CIA-1 AnswersDocument7 pagesHVE CIA-1 AnswersMaddy MohaNo ratings yet

- Corona EffectDocument13 pagesCorona Effectketan adhwan100% (1)

- Analysis of Corona Effect On Transmission LineDocument14 pagesAnalysis of Corona Effect On Transmission Lineyassinema1992No ratings yet

- CorrosionControl ACPowerLinesDocument8 pagesCorrosionControl ACPowerLinesbayuNo ratings yet

- Breakdown in Solid DielectricsDocument18 pagesBreakdown in Solid DielectricsRohinigp100% (1)

- Electrical BreakdownDocument4 pagesElectrical Breakdowndraganscribd12No ratings yet

- Monitoring of Leakage Current On HV Surge Arrester As Pollution Indicator of External InsulationDocument6 pagesMonitoring of Leakage Current On HV Surge Arrester As Pollution Indicator of External InsulationLucho RufoNo ratings yet

- Bushing Design Guide for Preventing Gliding DischargesDocument1 pageBushing Design Guide for Preventing Gliding DischargesHamayoun MurtazaNo ratings yet

- Do More With Less: PARTIAL DISCHARGE: PD, Common in Air-Cooled Stator Windings, Is Not Well Understood at The Plant LevelDocument4 pagesDo More With Less: PARTIAL DISCHARGE: PD, Common in Air-Cooled Stator Windings, Is Not Well Understood at The Plant LevelAnonymous 1AAjd0No ratings yet

- Solid Insulators ExplainedDocument8 pagesSolid Insulators ExplainedMehmet Efe OzbekNo ratings yet

- Influence of Humidity On Positive Impulse Flashover Along Cylindrical Insulating Surfaces Bridging A Short Rod-Plane GapDocument5 pagesInfluence of Humidity On Positive Impulse Flashover Along Cylindrical Insulating Surfaces Bridging A Short Rod-Plane GapPantelis N. MikropoulosNo ratings yet

- High Voltage Engineering Field Stress InsulationDocument8 pagesHigh Voltage Engineering Field Stress InsulationsbpathiNo ratings yet

- Effects of High Altitude and Atmospheric IcingDocument6 pagesEffects of High Altitude and Atmospheric IcingMilton CuscoNo ratings yet

- Breakdown in Composite DielectricDocument15 pagesBreakdown in Composite DielectricSumaira SaifNo ratings yet

- PDO Course 3Document27 pagesPDO Course 31MM1R HL'No ratings yet

- Coron A EffectDocument15 pagesCoron A EffectGunjan VarshneyNo ratings yet

- Introduction To Power Systems: (ECEG-3154)Document14 pagesIntroduction To Power Systems: (ECEG-3154)Tsega Solomon KidaneNo ratings yet

- Electrical Notes Vibration Damper in Transmission LineDocument3 pagesElectrical Notes Vibration Damper in Transmission Lineindranil1988No ratings yet

- EDigest-High Voltage RelaysDocument5 pagesEDigest-High Voltage RelaysMustafaTünelNo ratings yet

- Report MainDocument42 pagesReport Mainayabulela421No ratings yet

- Kogelschatz - 2002 - Filamentary, Patterned, and Diffuse Barrier Discharges PDFDocument10 pagesKogelschatz - 2002 - Filamentary, Patterned, and Diffuse Barrier Discharges PDFThiago SantosNo ratings yet

- Effects On CablesDocument5 pagesEffects On CablesKrishna OodhorahNo ratings yet

- Impulse Flashover Voltages at Low PressuresDocument4 pagesImpulse Flashover Voltages at Low PressuresentropifiedNo ratings yet

- Power System PPT On CORONADocument17 pagesPower System PPT On CORONAShadab Khan78% (9)

- What Is Corona Effect or Corona LossDocument5 pagesWhat Is Corona Effect or Corona LossDjidi Egrey SougoumiNo ratings yet

- Week 3Document3 pagesWeek 3Renuka KutteNo ratings yet

- Lecture 5Document18 pagesLecture 5Muhammad AhmadNo ratings yet

- The Pollution Flashover On High Voltage InsulatorsDocument8 pagesThe Pollution Flashover On High Voltage Insulatorshalel111No ratings yet

- VCBDocument3 pagesVCBMitesh GandhiNo ratings yet

- Electrical contacts in MV & HV power circuit breakersDocument5 pagesElectrical contacts in MV & HV power circuit breakerschandraippaNo ratings yet

- 17 - Corona and Induced Current EffectsDocument6 pages17 - Corona and Induced Current EffectsFullmetal OverlordNo ratings yet

- Contact SystemDocument52 pagesContact SystemdrivetecNo ratings yet

- Detect internal defects in high voltage capacitors with partial discharge testingDocument3 pagesDetect internal defects in high voltage capacitors with partial discharge testingDeyan ZhelevNo ratings yet

- North Bengal University Power System Protection CourseDocument12 pagesNorth Bengal University Power System Protection CourseEsha Jahin0% (1)

- Insulators: Desirable Properties of InsulatorsDocument10 pagesInsulators: Desirable Properties of InsulatorsethanNo ratings yet

- Transition Fep Pmma PtfeDocument4 pagesTransition Fep Pmma PtfezakariiNo ratings yet

- Cleansky 2 WP5 ElectricDocument5 pagesCleansky 2 WP5 ElectriczakariiNo ratings yet

- The Effect of Thermooxidative Aging On The Durability of Glass Fiber Reinforced Epoxy - 2015 - 15pDocument15 pagesThe Effect of Thermooxidative Aging On The Durability of Glass Fiber Reinforced Epoxy - 2015 - 15pzakariiNo ratings yet

- A7 Gprs GSM Gps ShieldDocument25 pagesA7 Gprs GSM Gps ShieldzakariiNo ratings yet

- Time Domain Reflectometry Theory: Application NoteDocument16 pagesTime Domain Reflectometry Theory: Application NoteyadamyugandharNo ratings yet

- Analysis of Elastomer Vulcanizate Composistion by TG-DTG TechniquesDocument21 pagesAnalysis of Elastomer Vulcanizate Composistion by TG-DTG TechniqueszakariiNo ratings yet

- Permittivity Tan Delta of Epoxy Vs FrequencyDocument10 pagesPermittivity Tan Delta of Epoxy Vs FrequencyzakariiNo ratings yet

- HIFLEX TPO Resins Technical PaperDocument31 pagesHIFLEX TPO Resins Technical PaperzakariiNo ratings yet

- Ageing and Life Prediction Conference 2008 PalmenDocument42 pagesAgeing and Life Prediction Conference 2008 PalmenzakariiNo ratings yet

- On-Line Time Domain Reflectometry Diagnostics of MV XLPE Power CablesDocument83 pagesOn-Line Time Domain Reflectometry Diagnostics of MV XLPE Power CableszakariiNo ratings yet

- RF Detection of PD in Current TransformersDocument4 pagesRF Detection of PD in Current TransformerszakariiNo ratings yet

- Analysis of the α, β, And γ Relaxations in PolychlorotrifluoroethyleneDocument63 pagesAnalysis of the α, β, And γ Relaxations in PolychlorotrifluoroethylenezakariiNo ratings yet

- Crystallinity and Dielectric Properties of PEEK, Poly (Ether Ether Ketone) - 1994Document9 pagesCrystallinity and Dielectric Properties of PEEK, Poly (Ether Ether Ketone) - 1994zakariiNo ratings yet

- Agilent - Basics of Measuring The Dielectric Properties of MaterialsDocument32 pagesAgilent - Basics of Measuring The Dielectric Properties of Materialszakarii100% (1)

- Design Fil de LitzDocument2 pagesDesign Fil de LitzzakariiNo ratings yet

- VictrexSTFlyer12 US01Document2 pagesVictrexSTFlyer12 US01zakariiNo ratings yet

- Polyimide 2Document51 pagesPolyimide 2NitaAyuHandareniNo ratings yet

- DMA Basics Part 2 - Polymer TransitionsDocument6 pagesDMA Basics Part 2 - Polymer TransitionszakariiNo ratings yet

- Pdata Tse397Document3 pagesPdata Tse397zakariiNo ratings yet

- Step 10Document31 pagesStep 10zakariiNo ratings yet

- Wiremax Products On Connectronics Corp.Document2 pagesWiremax Products On Connectronics Corp.zakariiNo ratings yet

- Vestakeep Ar1130 E10 AdDocument2 pagesVestakeep Ar1130 E10 AdzakariiNo ratings yet

- Reactive SiliconesDocument64 pagesReactive SiliconesUmanath R PoojaryNo ratings yet

- Polyimide 2Document51 pagesPolyimide 2NitaAyuHandareniNo ratings yet

- Raychem Spec 44Document8 pagesRaychem Spec 44zakariiNo ratings yet

- Fep HandbookDocument28 pagesFep HandbookzakariiNo ratings yet

- Universities Research Journal 2011 Effectiveness of Solar DryersDocument13 pagesUniversities Research Journal 2011 Effectiveness of Solar DryersAfthirah AmiraNo ratings yet

- Smog Explained: Types, Causes and Formation of Photochemical SmogDocument23 pagesSmog Explained: Types, Causes and Formation of Photochemical SmogvinodkumarmishraNo ratings yet

- Analyzing climate statistics using climographs and precipitation graphsDocument11 pagesAnalyzing climate statistics using climographs and precipitation graphsThomas BookerNo ratings yet

- Worldwide Marine Radiofacsimile Broadcast Schedules: National Weather ServiceDocument131 pagesWorldwide Marine Radiofacsimile Broadcast Schedules: National Weather ServiceJosé CostaNo ratings yet

- Review Paper of Electric VehiclesDocument4 pagesReview Paper of Electric VehiclesEditor IJTSRDNo ratings yet

- Climate Srinagar - MeteoblueDocument6 pagesClimate Srinagar - MeteobluePrarthna RoyNo ratings yet

- Fluid Mechanics White 7th SOL Part1 Part1Document5 pagesFluid Mechanics White 7th SOL Part1 Part1Jose EscobarNo ratings yet

- C Cat Ranarex GravitometerDocument2 pagesC Cat Ranarex GravitometerFrancisco RamirezNo ratings yet

- Greenhouse Gases and Climate Change NotesDocument7 pagesGreenhouse Gases and Climate Change Notesshelter musasaNo ratings yet

- Beginners Guide To OrchidsDocument18 pagesBeginners Guide To OrchidslanamkNo ratings yet

- Land Vs Water StudentDocument4 pagesLand Vs Water Studentwackowacky 97No ratings yet

- Effective and Chemical Free Deoxygenation of WaterDocument5 pagesEffective and Chemical Free Deoxygenation of WaterAlessio DeOsimoNo ratings yet

- Membrane Dryer Flow ConceptDocument6 pagesMembrane Dryer Flow ConceptCatalin FrincuNo ratings yet

- HW3 SolutionsDocument2 pagesHW3 Solutionslaulaulenchoi89% (9)

- Pra VeenDocument71 pagesPra Veen04 G.V. YESHWANTHNo ratings yet

- 7th Social Studies NotesDocument237 pages7th Social Studies Notesahmedezaz2No ratings yet

- Exercise ExplanDocument18 pagesExercise ExplanchandraNo ratings yet

- Frontal DepressionDocument6 pagesFrontal DepressionZeroNo ratings yet

- Grade 6 q2 Health LasDocument47 pagesGrade 6 q2 Health LasZoren Jovillanos EmbatNo ratings yet

- Processing Instructions V 13.0 Refraprotect FDocument3 pagesProcessing Instructions V 13.0 Refraprotect FMohammed AbdalrhmanNo ratings yet

- Light Human Eye and The Colourful WorldDocument23 pagesLight Human Eye and The Colourful Worldfatema vyasNo ratings yet