Professional Documents

Culture Documents

HP Access Fitting Assemblies PDF

Uploaded by

Nicholas MaldonadoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HP Access Fitting Assemblies PDF

Uploaded by

Nicholas MaldonadoCopyright:

Available Formats

HP Access Fitting Assemblies

Datasheet COR 13 004

High Pressure Access Systems are specialized piping arrangements that permit internal access to production plant vessels and pipework operating under full process conditions. The corrosion monitoring industry standard for such access systems is based on a 2-inch nominal bore design. The HP System is the generic design and is widely used throughout the world. This system is compatible and interchangeable with access fitting equipment produced by other major manufacturers. When operated with a Retrieval Tool and Service Valve, high pressure access systems allow the installation and retrieval of: coupon holders probes chemical injection and sampling probes, quills, and nozzles These devices can be installed or retrieved safely and without plant shutdown, at working pressures up to 3,600 psi. High pressure access systems are used most frequently (although not exclusively) in oil and gas production operations. This is typical of high pressure operations in which users are not prepared to shut down and depressurize process systems in order to remove or install corrosion monitoring devices. High pressure access systems consist of five basic components: an Access Fitting Body a Plug Assembly a Cover a Service Valve a Retrieval Tool The access fitting body is the specialized pipe fitting which is permanently attached to the process plant vessel or pipework. Access fitting bodies can be welded or flange-mounted. The plug assembly is the carrier for the installed device and, depending on the type of device being used, a solid plug assembly or a hollow plug assembly is selected. The plug assembly screws into the access fitting body and seals the bore of the fitting to contain line pressure. The access fitting body together with its plug assembly, and cover (designed to protect the external thread) is known as an access fitting assembly. The retrieval tool and service valve are the components which are required to perform the online installation and retrieval of the plug assembly. With the plug assembly removed during the retrieval procedure, the service valve is used to contain line pressure. One service valve and one retrieval tool may be used to maintain a number of access fitting assemblies.

___________________________________________

Anode Engineering Pty Ltd www.anodeengineering.com Toll Free: 1800 446 400 sales@anodeengineering.com COR 13 004 Rev 00 Page 1 of 4

The following equipment can typically be installed into process lines using standard access fitting assemblies: Corrosion Coupons Electrical Resistance Probes Linear Polarization Probes Biological Probes Erosion Probes

By using access fitting bodies which incorporate a side-tee, the following functions can be additionally undertaken: Chemical Injection Process Sampling Sand Monitoring

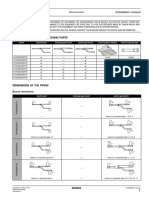

Standard HP models

Model HP1000 Flareweld HP2000 Buttweld HP3000 Socketweld HP4000 NPT Flanged RF (HP6000), RTJ (HP5000) or API (HP7000) Size: 150# 300# 4/600# 9/1500# 2500# Temperature Rating: -20 F (28.9 C) to +350 F (176.6 C) Pressure Rating: 6000 PSI or as flange rating. Plug Assemblies The Plug Assembly is the retrievable carrier which holds corrosion monitoring, chemical injection, or various other devices which may be installed through the access fitting. There are two distinct types of plug assemblies - the Solid Plug and the Hollow Plug. The plug assembly screws into the bore of the access fitting body and is designed to seal the fitting against line pressure. When tee type access fittings are being used, a pipe plug or nipple and shut-off valve is additionally required to seal the fitting. The standard material of construction for the plug assembly is 316 Stainless Steel. It should be noted that when stainless steel or duplex materials are specified for the access fitting body, the plug assembly should be specified to be Nitronic 60 to prevent thread galling. All plug assemblies are individually pressure tested at the factory and are rated for operation at 6000 psi. The operating temperature range for standard plug assemblies is -50F (-45C) to 350F (176C), but this range can be extended by use of alternative sealing materials. Height (in) 5.25 5.25 6.25 6.25 Height (in) 5.25 5.25 6.25 6.25 6.25 Weight K g 2.5 ((5. 2.0 5 5 2.0 5 2.0 5 Weight Kg 4.8 5.3 7.0 14.0 18.2

___________________________________________

Anode Engineering Pty Ltd www.anodeengineering.com Toll Free: 1800 446 400 sales@anodeengineering.com COR 13 004 Rev 00 Page 2 of 4

Solid Plugs Solid plugs carry coupon holders, injection/sampling systems, sand probes, and bioprobes With HP solid plugs, the solid plug nut is unscrewed from the base of the plug and replaced by the device being installed. A left-hand thread is used to ensure that installed devices do not become loose during the retrieval procedure. Hollow Plugs Hollow plugs are used with electrical resistance (E/R) probes, linear polarization resistance (LPR) probes, and hydrogen probes. To connect these devices with HP hollow plugs, the hollow plug seal nut is removed and the monitoring device is screwed into the female thread in the base of the hollow plug. A left-hand thread is used. Access is allowed through the top of the hollow plug for electrical connections to be made directly to probes for the purpose of taking readings. Protective Covers Protective covers are designed with internal threads which mate with the access fitting body and are recommended to prevent damage to the fittings exterior thread. In addition, they protect the surfaces against which the service valve seals during retrieval operations. Heavy Duty Pressure Rated Covers Heavy duty pressure rated covers are manufactured as standard in AISI 1018 and are supplied with a paint coat finish suitable for the most aggressive environments. Covers are individually pressure tested for a pressure rating of 4000 psi and are available with an optional bleed valve and/or pressure gauge. Covers are available with or without a centre hole. Centre holes are required when an external sensor connection is required to be permanently installed. Covers with a 1/2" NPT centre hole are required where continuous monitoring of electrical probes is required. Connection of an electrical probe to a permanent monitoring instrument requires the use of a probe adapter that extends through the 1/2" hole in the cover. The probe adaptor must be ordered separately.

___________________________________________

Anode Engineering Pty Ltd www.anodeengineering.com Toll Free: 1800 446 400 sales@anodeengineering.com COR 13 004 Rev 00 Page 3 of 4

Mounting Options

Body Styles

Pipeline Size/Flange Type Flareweld ANSI Flange API Flange

Body Material

1 - Flare Weld 2 - Butt Weld 3 - Socket Weld 4 - NPT 5 - 2" ANSI Flange RJ 6 - 2" ANSI Flange RF 7 - 2" API Flange RJ

0 - Non-Tee 1 - 1/4" Tee 2 - 1/2" Tee 3 - 3/4" Tee 4 - 1" Tee 5 - 1/2" 150# RF 6 - 1/2" 300# RF 7 - 1/2" 4/600# RF 8 - 1/2" 9/1500# RF 9 - 1/2" 2500# RF A - 1/2" 150# RJ B - 1/2" 300# RJ C - 1/2" 4/600# RJ D - 1/2" 9/1500# RJ E - 1/2" 2500# RJ F - 1" 9/1500# RJ G - 1" 2500# RJ H - 3/4" 9/1500# RJ J - 1" 150# RF Y - Tee 1/2" & 3/4" (for blank) Z - Misc.

1 - 2" 2 - 3" 3 - 4" 4 - 6" 5 - 8" - 10" 6 - 12" - 18" 7 - 20" - 36" 8 - Flat 9 - 38" - 48"

0 - N/A 1 - 150# 2 - 300# 3 - 4/600# 4 - 9/1500# 5 - 2500#

0 - N/A 1 - 2000# 2 - 3/5000# 3 - 10,000#

1 - AISI 1018 Carbon Steel 2 - ASTM A105 Carbon Steel 3 - ASTM A350 LF2 Carbon Steel 4 - AISI 316SS / 316 L 5 - Duplex SS 6 - ASTM A694 7 - 321 SS 8 - C276

HP

0 Not Reqd 1 - Solid 2 Hollow

X

0 Not Reqd 1 - 316 2 3i6L 3 C276 4 Nit 60 5- CS

X -

0 Not Required 1 Viton Ring TeflonPrimary Packing 2- Ethylene Propylene O Ring Vespel Primary Packing 3. Kalrez O Ring Vespel Primary Packing No O Ring NIT60 Packing 5 - Hydrin O-Ring Teon 6 - Nitrile O-Ring Teon

0 Not Required 1- Heavy Prot Cover w/o hole (non pressure rated) 2- Heavy Prot Cover with hole (non pressure rated) 3- Polycarbonate Cover w/o hole 4 - Polycarbonate Cover w/Hole 5 - 4000 PSI Rated Cover w/Bleed Valve 6 - 4000 PSI Rated Cover w/Bleed Valve &Pressure Gauge 7 - 4000 PSI Rated Cover w/ 1/2 NPT Hole, Bleed Valve & Pressure Gauge 8 - 4000 PSI Rated Cover w/o Hole 9 - 4000 PSI Rated Cover w/ 1/2 NPT Hole A - 4000 PSI Rated Cover w/Pressure Gauge B - C.S. MH Cover - Fire Safe C - 4000 PSI Rated Cover w/ 1/2 NPT Hole & Pressure Gauge D - 4000 PSI Rated Cover w/ 1/2 NPT Hole & Bleed Valve

Plug Type

Plug Material

Plug Seal Materials

1. To order an access tting body only, use the rst four characters on the chart. Example: if a 1/4" Tee 4/600# ANSI Flange RJ tting made of Duplex SS is required, order part # HP5135. 2. To order a body with a plug assembly, use the rst seven characters on the chart. Example: If a 3/4 Tee 4 Flareweld made of ASTM A105 Carbon Steel is required with a solid CS hydrin O-ring Teon packing plug, order part # HP1332155. 3. To order a body with a plug assembly and a cover, use all eight characters on the chart. Example: If a Non-Tee 9/1500# ANSI Flange RF tting made of AISI 316 SS with a hollow no O-ring NIT60 packing 316 plug and polycarbonate cover with no hole is required, order part # HP60442143.

Cover Options

___________________________________________

Anode Engineering Pty Ltd www.anodeengineering.com Toll Free: 1800 446 400 sales@anodeengineering.com COR 13 004 Rev 00 Page 4 of 4

You might also like

- 63 Cosasco Two-Inch System Injection and Sampling AssembliesDocument4 pages63 Cosasco Two-Inch System Injection and Sampling Assembliesalamandy66100% (1)

- Model"Dc": Dual Chamber Orifice FittingDocument13 pagesModel"Dc": Dual Chamber Orifice FittingFrankNo ratings yet

- As 1301 en F Series Manifolds and Multi Way CocksDocument20 pagesAs 1301 en F Series Manifolds and Multi Way CocksTache MihaiNo ratings yet

- Distribution Manifolds FINALDocument8 pagesDistribution Manifolds FINALSrta IncognitaNo ratings yet

- Manifold PDFDocument32 pagesManifold PDFvivek_enggNo ratings yet

- Instrument Manifold Valves - Series 5000Document16 pagesInstrument Manifold Valves - Series 5000Maria MantillaNo ratings yet

- Alco Hi Tek Mono FlangeDocument7 pagesAlco Hi Tek Mono FlangelimresNo ratings yet

- Mini Hermet Pressure SwitchesDocument24 pagesMini Hermet Pressure SwitchesMilosglNo ratings yet

- Piping Inspector Questions 1Document6 pagesPiping Inspector Questions 1Badiuzzama786100% (1)

- IOM Ball Valve Top EntryDocument8 pagesIOM Ball Valve Top Entrytoader56No ratings yet

- Medical Gas Pipeline RequirementsDocument20 pagesMedical Gas Pipeline RequirementsJoe_AverageNo ratings yet

- Catálogo FarrisDocument20 pagesCatálogo FarrissueNo ratings yet

- ElectroFusion Installation Manual (European Version)Document44 pagesElectroFusion Installation Manual (European Version)Jorge BaronNo ratings yet

- Transducer AccessoriesDocument6 pagesTransducer AccessoriesMohan ArumugavallalNo ratings yet

- As 0201 Gauge Valves and Pressure Gauge Accessories enDocument36 pagesAs 0201 Gauge Valves and Pressure Gauge Accessories enTomas PinheiroNo ratings yet

- s05nmdl2sm PDFDocument22 pagess05nmdl2sm PDFmn_aminNo ratings yet

- Aluminum Crust BreakerDocument8 pagesAluminum Crust BreakersenamotoNo ratings yet

- Hose Fittings Catalogue PDFDocument20 pagesHose Fittings Catalogue PDFSuresh HaldipurNo ratings yet

- Socket Welded ParkerDocument28 pagesSocket Welded ParkermansoorkasmiNo ratings yet

- What Is A Flushing RingDocument6 pagesWhat Is A Flushing RingFarooqNo ratings yet

- A1-Cam Groove CouplingsDocument40 pagesA1-Cam Groove CouplingsedwinramonNo ratings yet

- FARRIS PSV MODEL 2700 New Cat PDFDocument20 pagesFARRIS PSV MODEL 2700 New Cat PDFPeter James Castelo0% (1)

- Instrumentation Tube Fittings GuideDocument60 pagesInstrumentation Tube Fittings GuideHermanNo ratings yet

- AS 2601 EN E Series Valves and Manifolds PDFDocument56 pagesAS 2601 EN E Series Valves and Manifolds PDFTache MihaiNo ratings yet

- As 2601 en E Series Valves and ManifoldsDocument52 pagesAs 2601 en E Series Valves and ManifoldsdbmingoNo ratings yet

- Conexiones ParkerDocument215 pagesConexiones ParkerAndres LopezNo ratings yet

- TRDP - SSSVDocument23 pagesTRDP - SSSVsambhajiNo ratings yet

- Diagnostic Orifice Bleed Adapters & Specialty FittDocument14 pagesDiagnostic Orifice Bleed Adapters & Specialty FittPartsGopher.comNo ratings yet

- 63 Injection Sampling AssembliesDocument4 pages63 Injection Sampling AssembliesAbdul Hannan NazeerNo ratings yet

- ORFS fitting guideDocument7 pagesORFS fitting guidelink2u_007No ratings yet

- Schrader VentiliDocument8 pagesSchrader VentiliSLANO77No ratings yet

- PSV FarrisDocument20 pagesPSV FarrisIkhsan Arif100% (1)

- Index: Product List SR. NODocument40 pagesIndex: Product List SR. NOch_yustinusNo ratings yet

- TankerDocument60 pagesTankerlopezdestructionNo ratings yet

- ASCO Valve 8016gh Solenoid ImDocument6 pagesASCO Valve 8016gh Solenoid ImLeonardNo ratings yet

- Piping Inspector QuestionsDocument10 pagesPiping Inspector QuestionsRichard Periyanayagam100% (1)

- Ball Valve Seat Seal Injection SystemDocument28 pagesBall Valve Seat Seal Injection SystemmudrijasmNo ratings yet

- 05 Pipeline Modification Without ShutdownDocument17 pages05 Pipeline Modification Without ShutdownPradhipta86No ratings yet

- Pneumatic Fittings Push in FittingsDocument7 pagesPneumatic Fittings Push in FittingsSiddharth GuptaNo ratings yet

- ENTS 400 Rev5Document62 pagesENTS 400 Rev5Scherjeal Jangda100% (1)

- Válvula DurcoDocument12 pagesVálvula DurcoJames Henrry López EspejoNo ratings yet

- Piping and Components Inspection PDFDocument30 pagesPiping and Components Inspection PDFriysallNo ratings yet

- Electrical Resistance (ER) Probes: Features and Advantages Other EquipmentDocument4 pagesElectrical Resistance (ER) Probes: Features and Advantages Other EquipmentHạo Nam-Born To WinNo ratings yet

- Butterfly Valve-Concentric DesignDocument6 pagesButterfly Valve-Concentric Designbharadwaj037No ratings yet

- Monoflanges VariAS BlocksDocument20 pagesMonoflanges VariAS BlocksamuihNo ratings yet

- Coupons and Holders for Pipeline Corrosion MonitoringDocument4 pagesCoupons and Holders for Pipeline Corrosion MonitoringPuneet Vikram SinghNo ratings yet

- Ham-Let Astava Line of ManifoldsDocument24 pagesHam-Let Astava Line of ManifoldsjcestupinanNo ratings yet

- Electrofusion Jointing of Pe Pipe and Fittings For Pressure ApplicationsDocument31 pagesElectrofusion Jointing of Pe Pipe and Fittings For Pressure ApplicationsMohammed sabatinNo ratings yet

- Instrument Hookup DWGDocument26 pagesInstrument Hookup DWGkassimhos83% (6)

- Recoil Screw Thread InsertsDocument61 pagesRecoil Screw Thread InsertsAce Industrial SuppliesNo ratings yet

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Document3 pagesDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)RamanNegiNo ratings yet

- Api Plan 11Document6 pagesApi Plan 11johnsaballaNo ratings yet

- Burmad 400 Series-Globe Type Deluge ValveDocument8 pagesBurmad 400 Series-Globe Type Deluge Valvenastyn-1No ratings yet

- Vent and DrainDocument2 pagesVent and DrainBinodh DanielNo ratings yet

- Spirax Sarco BTM-7Document3 pagesSpirax Sarco BTM-7Bambang Agung LaxmonoNo ratings yet

- 5032-6 Fixed Inductors PDFDocument2 pages5032-6 Fixed Inductors PDFRobert NixonNo ratings yet

- Grove G9 Wafer Gate ValveDocument9 pagesGrove G9 Wafer Gate Valvetxlucky80No ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Model 7601 Transducer Data Sheet-FlowmeterDocument2 pagesModel 7601 Transducer Data Sheet-FlowmeterJorgeSerracínNo ratings yet

- Phillips ObstiVision XGP+500Document5 pagesPhillips ObstiVision XGP+500suhasacharya117No ratings yet

- Pipe Concrete AnchorDocument6 pagesPipe Concrete AnchorRahmat RiskiNo ratings yet

- Angela Wensley Report Nueva Aldea 2010 PDFDocument144 pagesAngela Wensley Report Nueva Aldea 2010 PDFa_parratNo ratings yet

- Ce 20Document6 pagesCe 20valeNo ratings yet

- Radiamatic Detectors and Accessories Specification: FunctionDocument8 pagesRadiamatic Detectors and Accessories Specification: FunctionKatty MenaNo ratings yet

- Crude Oil Stabilization Weekly Report 13 Jan 2023Document6 pagesCrude Oil Stabilization Weekly Report 13 Jan 2023Andy ArdianNo ratings yet

- E644 1285343-1Document21 pagesE644 1285343-1jmrozo350% (2)

- Rolls-Royce RB211 Trent 700 UCPG (Full Permission) - 2Document33 pagesRolls-Royce RB211 Trent 700 UCPG (Full Permission) - 2ArabyAbdel Hamed SadekNo ratings yet

- Air System ComponentsDocument6 pagesAir System ComponentsEliasNo ratings yet

- Siphonic Roof Drainage Systems ExplainedDocument7 pagesSiphonic Roof Drainage Systems ExplainedRenzo Marquina AstoNo ratings yet

- Pump Tutorial 2Document19 pagesPump Tutorial 210teste10No ratings yet

- MAN Marine Diesel Engine - enDocument1,566 pagesMAN Marine Diesel Engine - enYacine GhanemiNo ratings yet

- Vertical Flame ArresterDocument13 pagesVertical Flame ArresterKris WilliamsNo ratings yet

- Tutorial Letter 101/0/2019: Fluid Mechanics III (Theory)Document18 pagesTutorial Letter 101/0/2019: Fluid Mechanics III (Theory)Mluleki Dean DladlaNo ratings yet

- 7.4.3 Restricted Use of Combustible MaterialsDocument4 pages7.4.3 Restricted Use of Combustible MaterialsVECTOR MARINE & OFFSHORE TECHNOLOGYNo ratings yet

- Horizontal Flame ArresterDocument5 pagesHorizontal Flame ArresterMustafa PardawalaNo ratings yet

- Alkali Boil OutDocument5 pagesAlkali Boil OutprithwichandraNo ratings yet

- HDF120-180 User ManualDocument4 pagesHDF120-180 User ManualVijay Pawar Innovative TechnologiesNo ratings yet

- Pipe Spool Fabrication Sequencing by Automated PlanningDocument10 pagesPipe Spool Fabrication Sequencing by Automated PlanningSerge BNo ratings yet

- DW Uhp UsDocument9 pagesDW Uhp UsnotengofffNo ratings yet

- HIS KIT Includes THE Following Parts: Installation ManualDocument4 pagesHIS KIT Includes THE Following Parts: Installation ManualOPER123No ratings yet

- Exchanger Book 1Document20 pagesExchanger Book 1Will SmithNo ratings yet

- G608XX FlowmeterDocument32 pagesG608XX Flowmeterahad_shiraziNo ratings yet

- Back To Basics - Guzzler Classic PDFDocument2 pagesBack To Basics - Guzzler Classic PDFEliseo Gonzalez100% (1)

- Ruidp Isor 2022Document762 pagesRuidp Isor 2022Ankit ChaudharyNo ratings yet

- Sarco Sizing SoftwareDocument4,922 pagesSarco Sizing SoftwarePetarPetrovic100% (1)

- 3 A Sanitary Standards Quick Reference GuideDocument98 pages3 A Sanitary Standards Quick Reference GuidefitiranNo ratings yet

- ABB Lummus Global B.V. Piling SpecificationDocument25 pagesABB Lummus Global B.V. Piling SpecificationRama Krishna Reddy DonthireddyNo ratings yet

- Section - 13D: Locating Field Welds: Section 13 - Pipe Fabrication Shop Issues Flowr8Document9 pagesSection - 13D: Locating Field Welds: Section 13 - Pipe Fabrication Shop Issues Flowr8Satish SonawaneNo ratings yet