Professional Documents

Culture Documents

Investigation of Water Hammer Effect Through Pipeline Sy

Uploaded by

EmnOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Investigation of Water Hammer Effect Through Pipeline Sy

Uploaded by

EmnCopyright:

Available Formats

Vol. 2 (2012) No.

3

ISSN: 2088-5334

Investigation of Water Hammer Effect Through Pipeline System

Tan Wee Choon

1

, Lim Kheng Aik

1

, Lim Eng Aik

2

, Teoh Thean Hin

3

1

School of Mechatronic Engineering, Universiti Malaysia Perlis, Perlis, Malaysia

E-mail: tweechoon@unimap.edu.my, luc_0294@hotmail.com

2

Engineering Mathematics Institute, Universiti Malaysia Perlis, Perlis, Malaysia

E-mail: ealim@unimap.edu.my

3

Aircraft Maintenance Department, Politeknik Sultan Salahuddin Abdul Aziz Shah, Shah Alam, Malaysia

E-mail: tth9772@yahoo.com

Abstract This paper we study the condition where the water hammer effect is occurs in pipe line. Water hammer can cause the pipe

to break if the pressure is high enough. The experiment will be set-up to investigate the water hammer effect in order to avoid the

water hammer effect happen. The prevention of water hammer effect will be propose and prove the prevention method is successfully

reduce the water hammer effect. The prevention method using is installing the bypass pipe with non-return valve. The experiment is

done by capture the vibration signal by using data acquisition device and accelerometer. The pressure signal is capture after a sudden

shutoff for the valve. The signal is than analyze and convert to wave speed. The project is differentiating and compares the water

hammer phenomenon with different pipe material, pipe length, inlet diameter of pipe, and pressure in pipeline. From the experiment,

result shown that the lower strength material pipe, smaller inlet diameter pipe, and longer pipe will deal with lager water hammer

effect. Besides, the prevention method by installing by pass pipe with non-return valve of water hammer effect is proved successfully

reduce the water hammer phenomenon by 33.33% of pressure.

Keywords Water hammer effect; Vibration; Prevention study

I. INTRODUCTION

This document is a template. Pressure surge or water

hammer, as it is known, is the formation of pressure wave as

a result of sudden change in liquid velocity in a piping

system. The water hammer phenomena usually explained by

considering by ideal reservoir pipe-valve system in which

the steady flow with velocity V

o

is stopped by an

instantaneous valve closure. In other say, it occurs when the

fluid flow start or stop quickly or is forced to make a rapid

change in direction, for example quick closing the valves

and stoppage of a pump can create water hammer [1, 2].

Hydraulic transient in close conduits have been a subject

of both theoretical study and intense practical interest for

more than one hundred years [1]. Unsteady fluid flows have

been studied since man first bent water to his will. The

ancient Chinese, the Mayan Indians of Central America, the

Mesopotamian civilization bordering the Nile, Tigris, and

Euphrates river systems, and many other societies

throughout history have developed extensive systems for

conveying water, primarily for purpose of irrigations, but

also for domestic water supplies. With the arrival of the

scientific age and the mathematical developments embodied

in Newtons principia, the understanding of fluid flow took a

quantum leap in terms of its theoretical abstraction. The

advent of high-speed digital computers constituted another

discrete transformation in the study and application of fluids

engineering principles [1].

The first to successfully investigate the water hammer

problem was the Italian engineer Lorenzo Allievi which

water hammer can be analysed by two different approaches,

rigid column theory which ignores compressibility of the

fluid and elasticity of the walls of the pipe, of by full

analysis including elasticity [3].

Water hammer effect is normally happening in daily life

and only that people not realize it. A common example of a

water hammer occurs in most homes everyday: Simply

tuning off a shower quickly will send a loud thud through

the house. Water hammer can cause pipeline to break if the

pressure is high enough. Besides, when a valve in a pipe is

closed, the water downstream of the valve will attempt to

continue flowing, creating a vacuum that may cause the pipe

to collapse or implode [4]. The effect of water hammer must

be taken by analyse the situation where water hammer effect

occur and propose a prevention of water hammer effect.

48

Water hammer also happens in industry field. The

industrial that commonly had use steam and water would

found water hammer cases. Company like Shell is the

company had used the steam as the power. Thus, engineer

need to solve the effect of water hammer that happens in the

steam pipe. It is very dangerous if the steam pipe is break.

II. WATER HAMMER EFFECT

A. General Defination

The earliest application of the one-dimensional wave

equation to explain observed water hammer effects was

made by Joukowsky in 1898 [4 - 8]. Joukowsky correctly

predicted the maximum line pressures and disturbance

propagation times in a water distribution system in which

sudden valve closures occurred. Joukowskys equation is

expressed as:

P = aV (1)

P is the pressure rise due to the water hammer (N/m

2

), a

is the velocity of impulse waves (m/s), V is the velocity

change of liquid in the pipeline (m/s), and is the density of

liquid (kg/m

3

). The relation can also be written as

H = aV / g (2)

where H is the pressure increase due to the water hammer

in terms of column of water in meters and g is the

gravitational acceleration in m/s

2

. In deriving the above

equations the following assumptions were made: the friction

losses are much smaller than the static pressure in the pipe,

flow is single phase and there are no dissolved gases in the

liquid, the liquid velocity change occurs in a time less than

the critical time.

The speed of the pressure waves, a, is a function of the

following parameters such as specific weight and elasticity

module of the liquid, pipe diameter, wall thickness, and the

distance between the support points, and The elasticity

module of the pipe material.

The derived relation for calculating the pressure wave

speed is as follows [4, 8]:

1

1

a

DC

k Ee

=

| |

+

|

\ .

(3)

Where D is the pipe diameter, e is the pipe wall thickness, E

is the elasticity modulus of the pipe material, K is the

elasticity module of the liquid, and C

1

is a constant that can

be assumed to be equal to one.

B. Parameters Affecting Water Hammer Effect

Pressure waves in pipelines are generated due to different

normal operations in the system such as opening and closing

the valves, start up or shutting down the pumps, or any

sudden change in the pump rotational speed [8, 9].

Generally, the sources that may affect the water hammer

attenuation, shape and timing would be the pressure in pipe,

velocity flow in pipe, and sudden change of velocity flow.

However there is other sources that may affect the waveform

predicted by classical water hammer theory include

viscoelastic behavior of the pipe-wall material, blockage and

leakage in addition to the unsteady friction, cavitations and

fluid structure interaction. These discrepancies are based on

the derivation of the water hammer equations for the liquid

unsteady pipe flow [10].

C. Prevention of Water Hammer Effect

There are some methods can prevent water hammer effect.

First, design the discharge pipe based on lower liquid

velocities [6, 8, 9]. By decreasing the flow velocity, the

effect of the water hammer will be minimized.

Besides, increasing the moment of inertia of the pump [8]

can reduce the water hammer effect. Adding a flywheel on

the rotating axis of the driving motor would prevent the

rotational speed to reduce sharply and therefore restrain the

excess pressure decrease or increase.

One of the simpler methods to prevent the damaging

effects of the water hammer is to install a by-pass pipe with

a non-return valve [8, 11]. Under normal conditions, the

non-return valve will close. However, after the shutdown of

the pump, pressure will be decreased in the discharge pipe

and once it becomes less than the suction pressure, the non-

return valve will open and the liquid would enter to the

discharge pipe thereby preventing more pressure reduction.

To prevent water hammer effect, it also can install surge

tanks in piping system [6, 8, 12]. These tanks act as a

reservoir to suppress the pressure waves and are installed on

the discharge pipe. When the pressure in the pipe increases,

liquid enters the tank and is stored there. During periods of

subnormal pressure in the pipe, then, the liquid would flow

back to the pipe, preventing rapid velocity changes.

One of the methods to control the water hammer is install

air chambers [6, 8, 13]. Air chambers are basically a type of

high pressure surge tanks which can be built in smaller sizes.

In these tanks, the pressurized air locates on the top of liquid.

The size of the chamber must be large enough to compensate

the liquid in the subnormal pressure periods.

Besides that, by install a non-return valve also can control

the water hammer effect [6, 8]. The discharge pipes of the

pumps are normally equipped with non-return valves. The

main application of these valves is to prevent the flow

running toward the pump when it stops, thereby reducing the

adverse effects. During normal working conditions of the

pump, the supply flow would keep the non-return valve open.

Upon sudden stop of the pump, the flow rate would reduce

rapidly until it reaches zero and would then flow back to the

pump.

In addition, adding the pressure control valves would be

one of good methods to reduce water hammer effect [6, 8].

These valves are designed to open at very high pressures and

are installed at the critical points of the piping system.

During the pressure rise period, the valve would release

liquid to the outside. This would reduce the pressure in the

line and prevents any possible damages.

In other hand, it can also install the vacuum valves to the

piping system [8]. These valves are installed on those points

of the piping system in which there is a possibility of liquid

evaporation due to subnormal pressures. When the pressure

reduces beyond certain level in the pipe, these valves close

and let the atmospheric air to enter the system.

49

III. METHODOLOGY

In order to investigate the water hammer effect occurs in

pipeline, below instrumentation and procedure being used.

A. Instrumentation

To investigate the water hammer effect, lab equipment

tool that using is the LMS DAQ (use to read the vibration

signal). The sensor using is accelerometer with sensitivity of

10.2mV. Other apparatus are given in Table I.

TABLE I

APPARATUS OF EXPERIMENT

Apparatus Specifications

Pump with Inverter

40 head meter,

3 phase pump,

240-415V,

0.64k watt power,

0.5 HP

Piping system

inch pipe,

inch pipe,

1 inch pipe

Fitting

inch connector,

inch connector,

1 inch connector

Surge tank 1m cube tank

Valve

inch Ball valve,

inch Ball valve

Pressure gauge

Measure range: 0-15psi,

accuracy +1.6%,

B. Experimental Set Up

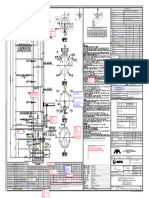

An experiment is set up as Figure 1 to analysis the

parameter that affects the water hammer effect. The

parameter tested would be the area of pipe, material of pipe

and the length of the pipe. The pipe with difference

parameter would be installing at the tested area. Sensor of

the LMS would put at the tested area and data would be

collect by DAQ system. The FFT signal would be taking and

the signal is calculated in the wave speed. The graph would

be plot by the LMS DAQ system and by calculation of wave

speed, the graph of wave speed versus the frequency also

would be plot.

Fig. 1 Experiment set up for water hammer investigation

First, Set-up the experiment work bench base on the

design. Before start experiment, the tested pipe is to be

ensuring in the horizontal position by balancing fluid. The

pump will be run for one period. During the pump running,

make sure that there is no bubble effect in the pipe. After

that, LMS data acquisition device is set-up. The

accelerometer will be put at the tested area by wax. The

result will be taken after a sudden close of the valve. The

LMS data logger will read the vibration signal of pipe. The

result of data will be taking for 3 times and the most suitable

result will be chosen. Choose the signal that when water

hammer effect is happen from data. Finally, analysis will be

done after taking the signal.

The experiment step will be repeating for other parameter

of experiment. Data of experiment will be save in the excel

form. After finish the experiment, make sure that the electric

supply of pump is turn off.

C. Experimental Set Up for Prevention of Water Hammer

Effect

For the prevention method, the pipe is design to bypass

valve with a non return valve [8] is installing to the pipe as

shown in Figure 3.3. Install a by-pass pipe with a non-return

valve is the one of the simpler methods to prevent the

damaging effects of the water hammer. Under normal

conditions, the pressure supplied by the pump would keep

the non-return valve closed. However, after the shutdown of

the pump, pressure will be decreased in the discharge pipe

and once it becomes less than the suction pressure, the non-

return valve will open and the liquid would enter from the

suction pipe to the discharge pipe thereby preventing more

pressure reduction.

Fig. 2 Experiment set up for water hammer prevention investigation

IV. DATA AND RESULTS

From the experiment conducted, the results are given as

follow:

A. Effect of Pipe Length

For this study parameter, two different pipe lengths which

are 1.5 meter and 1 meter length inch PVC pipe being

used as the specimens. The working pressure of the system

is 2.5 psi. The results for amplitude pressure and wave speed

are given in Figure 3 till Figure 6 respectively.

B. Effect of Pipe Material

For this study parameter, two different pipe material

which are steel and PVC pipe of 1 meter length inch in

diameter being considered. The working pressure of the

system is 2.5 psi. The results for amplitude pressure and

wave speed are given in Figure 7 till Figure 10 respectively.

C. Effect of Working Pressure

For this study parameter, two different ranges of working

pressure which are 2.5 psi and 2.2 psi being consider. While

the specimen is 1 meter length inch PVC pipe being

considered. The results for amplitude pressure and wave

speed are given in Figure 9 and Figure 12 respectively.

50

D. Prevention of Water Hammer Effect

For this study, a non return valve is installing within the

system. The specimen to be tested under this condition is the

1 meter length inch PVC pipe with working pressure of

2.5 psi being considered. The results for amplitude pressure

and wave speed are given in Figure 13 and Figure 14

respectively.

0.000

0.005

0.010

0.015

0.020

0.025

0.030

0.035

0 1000 2000 3000 4000 5000 6000

P

r

e

s

s

u

r

e

(

P

a

)

Frequency (Hz)

Fig. 3 Amplitude pressure of specimen 1.5 meter length inch PVC pipe

for working pressure of 2.5 psi.

1414.2440

1414.2441

1414.2442

1414.2443

1414.2444

1414.2445

1414.2446

0 1000 2000 3000 4000 5000 6000

W

a

v

e

s

p

e

e

d

(

m

/

s

)

Frequency (Hz)

Fig. 4 Wave speed of specimen 1.5 meter length inch PVC pipe for

working pressure of 2.5 psi.

0.000

0.005

0.010

0.015

0.020

0.025

0 1000 2000 3000 4000 5000 6000

P

r

e

s

s

u

r

e

(

P

a

)

Frequency (Hz)

Fig. 5 Amplitude pressure of specimen 1 meter length inch PVC pipe for

working pressure of 2.5 psi.

942.8293

942.8294

942.8295

942.8296

942.8297

0 1000 2000 3000 4000 5000 6000

W

a

v

e

s

p

e

e

d

(

m

/

s

)

Frequency (Hz)

Fig. 6 Wave speed of specimen 1 meter length inch PVC pipe for

working pressure of 2.5 psi.

0.000

0.005

0.010

0.015

0.020

0.025

0 1000 2000 3000 4000 5000 6000

P

r

e

s

s

u

r

e

(

P

a

)

Frequency (Hz)

Fig. 7 Amplitude pressure of specimen 1 meter length inch Steel pipe for

working pressure of 2.5 psi.

365.8874

365.8875

365.8876

365.8877

365.8878

0 1000 2000 3000 4000 5000 6000

W

a

v

e

s

p

e

e

d

(

m

/

s

)

Frequency (Hz)

Fig. 8 Wave speed of specimen 1 meter length inch Steel pipe for

working pressure of 2.5 psi.

0.000

0.005

0.010

0.015

0.020

0.025

0.030

0.035

0 1000 2000 3000 4000 5000 6000

P

r

e

s

s

u

r

e

(

P

a

)

Frequency (Hz)

Fig. 9 Amplitude pressure of specimen 1 meter length inch PVC pipe for

working pressure of 2.5 psi.

365.8874

365.8875

365.8876

365.8877

365.8878

365.8879

0 1000 2000 3000 4000 5000 6000

W

a

v

e

s

p

e

e

d

(

m

/

s

)

Frequency (Hz)

Fig. 10 Wave speed of specimen 1 meter length inch PVC pipe for

working pressure of 2.5 psi.

0.000

0.005

0.010

0.015

0.020

0 1000 2000 3000 4000 5000 6000

P

r

e

s

s

u

r

e

(

P

a

)

Frequency (Hz)

Fig. 11 Amplitude pressure of specimen 1 meter length inch PVC pipe

for working pressure of 2.2 psi.

51

315.6160

315.6161

315.6162

315.6163

315.6164

0 1000 2000 3000 4000 5000 6000

W

a

v

e

s

p

e

e

d

(

m

/

s

)

Frequency (Hz)

Fig. 12 Wave speed of specimen 1 meter length inch PVC pipe for

working pressure of 2.2 psi.

0.000

0.005

0.010

0.015

0 1000 2000 3000 4000 5000 6000

P

r

e

s

s

u

r

e

(

P

a

)

Frequency (Hz)

Fig. 13 Amplitude pressure of prevention study for specimen 1 meter length

inch PVC pipe for working pressure of 2.5 psi.

942.8293

942.8294

942.8295

942.8296

0 1000 2000 3000 4000 5000 6000

W

a

v

e

s

p

e

e

d

(

m

/

s

)

Frequency (Hz)

Fig. 14 Wave speed of prevention study for specimen 1 meter length inch

PVC pipe for working pressure of 2.5 psi.

V. WAVE SPEED

In this paper, there are 6 specimens that are considered for

investigation of water hammer effect. These specimens are

including 1 meter length inch of PVC pipe, 1 meter length

inch of steel pipe, 1 meter length inch of PVC pipe, and

1.5 meter length inch of PVC pipe. For 1 meter length

inch PVC pipe, the data are taken in two different pressures.

This is to compare the different pressure of water hammer

effect. For 1 meter length inch of PVC pipe, the by-pass

pipe with non-return valve is installed to reduce the water

hammer effect.

For comparison of different diameter pipe for

investigation of water hammer effect, the PVC pipe of

inch and inch is installed for experiment work. Both

experiments use the same level of pressure to conduct the

experiment. From the experiment data result, 1 meter length

inch PVC pipe have higher pressure compare to the 1

meter length inch PVC pipe. inch of PVC pipe has the

maximum pressure of 0.031 Pa and inch of PVC pipe has

the maximum pressure of 0.020 Pa. The inch pipe deal

with higher pressure compare to inch pipe when the valve

is shut off suddenly. As a conclusion, the bigger diameter

pipe occur more water hammer effect compare to smaller

diameter pipe.

There are two types of pipe material that household using,

there are steel pipe and PVC pipe. Hence, comparison

between steel pipe and PVC pipe is done in this experiment.

Both pipe using the same level of pressure and same

diameter. From the experiment data, the PVC pipe deal with

more water hammer effect compare to steel pipe. The

maximum pressure of PVC pipe is 0.031 Pa and is higher

than pressure of steel pipe which has pressure of 0.021 Pa.

This is due to the mechanical properties of the material pipe

where steel has higher strength compare to PVC. As a

summary, the steel pipe occur smaller water hammer effect

compare to PVC pipe.

An experiment also compares the water hammer effect

between the long pipe and shorter pipe. Both experiments

are conduct under same diameter of pipe, same level of

pressure and same material of pipe. The long pipe using is

1.5 meter and shorter pipe is 1 meter length. From the

experiment, 1.5 meter length pipe deal with larger pressure

compare with 1 meter length pipe. From the data, the 1.5

meter length pipe has the maximum pressure of 0.030 Pa and

1 meter length pipe has the maximum pressure of 0.020 Pa.

Therefore, it can be conclude that longer pipe occur more

water hammer effect.

For comparison of different pressure, the experiment is

done by using same pipe but different pressure setting by

pump with inverter. As predicted, the higher pressure supply

will due with larger water hammer effect in pipe. From

experiment, the pipe with supply pressure of 2.5 psi has the

maximum pressure signal of 0.031 Pa and the pressure

supply of 2.2 psi has the maximum pressure signal of 0.018

Pa. As a conclusion, higher pressure supply in pipe will

create a greater water hammer effect compare with the

smaller pressure supply in pipe.

In the experiment, there is installation of bypass pipe with

non return valve for the prevention method. This method not

100 % prevents the water hammer effect but it can reduce

the water hammer effect. There are no ideal cases where

there is no water hammer effect when sudden shut off the

valve. From the experiment, the pressure in the pipe is

reduce after apply the prevention method. Before install the

bypass pipe with non-return valve, the maximum pressure

signal is 0.020 Pa. However, after applied the prevention

method to the experiment system, the maximum pressure

signal is 0.012 Pa. The mean pressure is reducing about

33.33% where from 0.030 Pa reduces to 0.020 Pa. This

proves that the prevention method that suggested is success

to reduce the water hammer effect.

VI. CONCLUSIONS

The study of water hammer effect phenomena in the

pipeline is very important for household usage and industry

especially for industry which related to pipeline such as gas

and oil industry and pipe manufacturing industry. The model

experiment of water hammer effect is build in order to

investigate the water hammer effect. From the study, it can

be conclude that there are some parameters influencing

water hammer phenomena. The obvious parameters are

material of pipe and the pressure in the pipe.

The pipe material gives account into friction factor. The

friction factor is most likely the parameter to determine the

water hammer effect. From the result of the experiment, get

52

that the water hammer effect in the PVC pipe is greater than

the water hammer effect in steel pipe. Another important

parameter that will affect the water hammer effect is the

pressure in the pipe. The pressure in pipeline is directly

influence by the initial velocity. From the experiment result,

the high pressure pipeline occur more water hammer effect.

This is due to the inverter pump is setting more initial

velocity of fluid. Beside these 2 parameters, there are

parameters like inlet diameter and length of the pipe also

influence the water hammer effect.

The prevention method of water hammer effect which

install the bypass pipe with non return valve had prove that

the method is successfully to reduce the water hammer effect

in the pipeline. From the experiment, the pressure in the pipe

with prevention method is lower compare to the pipe that

without prevention method. The mean pressure is reducing

about 33.33% after installing the prevention method. This

method is most useful in the household usage as the non-

return valve is not an expensive item.

NOMENCLATURE

a velocity of impulse waves ms

-1

C

1

constant

D pipe diameter m

e pipe wall thickness m

E elasticity modulus of the pipe material Nm

-2

g gravitational acceleration ms

-2

H pressure head rise m

K elasticity module of the liquid Nm

-2

P pressure rise due to the water hammer Nm

-2

V velocity ms

-1

Greek letters

density of liquid kgm

-3

Subscripts

o instantaneous valve closure

ACKNOWLEDGMENT

Authors are grateful for the financial support from

Universiti Malaysia Perlis (UniMAP) to conduct this

research work.

REFERENCES

[1] C. K. Su, and C. Camara, Cavitation luminescence in a water

hammer: Upscaling sonoluminescence, Journal of Physics of Fluids,

vol. 15, pp. 1457- 1461, 2003.

[2] D. J. Wood, Water Hammer Analysis Essential and Easy,

Journal of Environment Engineering, vol. 131, pp. 1123- 1131, 2005.

[3] Data Evaluation Report on PPP water hammer tests, Institut fr

Umwelt, UK.

[4] (2004) The LMNO Engineering Software Ltd. website. [Online].

Available: http:// www.lmnoeng.com /

[5] A. Bergant, A.R. Simpson, and A.S. Tijsseling, Water Hammer with

colum separation: His torical Review, Journal of Fluid and

Structure, vol. 22, pp. 135- 171, 2005.

[6] Water Hammer- Consultant Experience, Gugich & Associates Pty

Ltd, UK.

[7] M. Zhao, A. Mclnnis, and H. Axworthy, A Review of the Water

Hammer Theory and Practice, Journal of Applied Mechanic Review,

vol. 58, pp. 49- 76, 2005.

[8] S. Nourbakhsh, B. Jaumotte, C. Hirsch and H. Parizi, Turbopumps &

Pumping systems: Part 2, Springer Berlin Heidelberg, UK, 2007.

[9] J. Fennel, Practical Solutions to Water Hammer, Revised Edition.

Copper Development Centre Australia limited, Australia, 2000.

[10] A. Bergant, A. Tijsseling, and J. Vtkovsk, Further investigation of

Parameters affecting Water hammer wave attenuation, shape and

timing Part 1: Mathematical Tools, Eindhoven University of

Technology, Netherlands, 2001.

[11] A National Drinking Water Clearing House Fact Sheet, Tech Brief

National Drinking Water Clearinghouse at West Virginia University,

US.

[12] Boyle, Fluid Kinetics Water Hammer Solution, Fluid Kinetic surge

arrestor article, Fluid Kinetic Corporation, Ventura, Carlifornia, 1996.

[13] A. Dudlik, H. M. Prasser, and S. Schlter, Prevention of Water

Hammer behind fast acting shut off, Fraunhofer UMSICHT,

Oberhausen, 2005.

53

You might also like

- Cabeq 2006 1 3Document16 pagesCabeq 2006 1 3altealodNo ratings yet

- Mechanical Agitator Power Requirements for Liquid BatchesDocument24 pagesMechanical Agitator Power Requirements for Liquid BatchesAixa BerchiNo ratings yet

- AMS02200605Document17 pagesAMS02200605singh271983No ratings yet

- Mechanical Integrity Management of Bulk Storage TanksDocument84 pagesMechanical Integrity Management of Bulk Storage Tanksjimmytry100% (1)

- Mechanical Agitator Power Requirements for Liquid BatchesDocument24 pagesMechanical Agitator Power Requirements for Liquid BatchesAixa BerchiNo ratings yet

- Agitator FailureDocument7 pagesAgitator FailureMark G CaragayNo ratings yet

- Demir Cevheri Ile Ilgili DokumanDocument12 pagesDemir Cevheri Ile Ilgili DokumanEmnNo ratings yet

- ARI-Strainer technical specificationsDocument6 pagesARI-Strainer technical specificationsEmnNo ratings yet

- Bursi PipingSystemDocument38 pagesBursi PipingSystemEmnNo ratings yet

- Bstgfinalreport PDFDocument118 pagesBstgfinalreport PDFDragos AndreiNo ratings yet

- Depliant Mav Eng WebDocument12 pagesDepliant Mav Eng WebEmnNo ratings yet

- Wind Load and Roof Load CalculationDocument20 pagesWind Load and Roof Load CalculationleodegarioporralNo ratings yet

- 1 - Leser 310Document26 pages1 - Leser 310EmnNo ratings yet

- 8.criteria For The Optimum Design of Drive & Brake Units in Belt ConveyorsDocument15 pages8.criteria For The Optimum Design of Drive & Brake Units in Belt ConveyorsEmnNo ratings yet

- 09 034Document68 pages09 034EmnNo ratings yet

- H2S - GeorgiaPacificInvestigationReportDocument52 pagesH2S - GeorgiaPacificInvestigationReportSubkiAmatNo ratings yet

- Wilco Bulk Plant DSDocument4 pagesWilco Bulk Plant DSEmnNo ratings yet

- Orion Double AdjustmentDocument2 pagesOrion Double AdjustmentEmnNo ratings yet

- Sulfuric Acid PumpsDocument4 pagesSulfuric Acid PumpsEmnNo ratings yet

- Cam and GrooveDocument4 pagesCam and GrooveEmnNo ratings yet

- Chapter 1 - Manual & Mechanical Control Techniques: A. Weed PullingDocument7 pagesChapter 1 - Manual & Mechanical Control Techniques: A. Weed PullingEmnNo ratings yet

- RotterDocument19 pagesRotterEmnNo ratings yet

- 8.criteria For The Optimum Design of Drive & Brake Units in Belt ConveyorsDocument15 pages8.criteria For The Optimum Design of Drive & Brake Units in Belt ConveyorsEmnNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Production Forecasting & Performance AnalysisDocument43 pagesProduction Forecasting & Performance AnalysisAtul KhatriNo ratings yet

- Unconventional Flare Gas Recovery Systems (FGRS)Document4 pagesUnconventional Flare Gas Recovery Systems (FGRS)Alvaro Andres Blanco Gomez100% (1)

- New SANDVIK Basic HydraulicDocument106 pagesNew SANDVIK Basic HydraulicSamuel Ernesto Matsinhe100% (1)

- Abrasive Blasting Check ListDocument3 pagesAbrasive Blasting Check ListSreejith SureshNo ratings yet

- Pneumatically Actuating Rammer-1596 PDFDocument4 pagesPneumatically Actuating Rammer-1596 PDFM L PrabhuNo ratings yet

- Direct Fired Vaporizer UpgradesDocument5 pagesDirect Fired Vaporizer UpgradesYogi MaulanaNo ratings yet

- Steam Turbine Fundamentals and DesignDocument20 pagesSteam Turbine Fundamentals and DesignAhmed HashimNo ratings yet

- Crosby Series BP Omni-TrimDocument16 pagesCrosby Series BP Omni-TrimSilvio CalviNo ratings yet

- Thermodynamic exercises solved step-by-stepDocument5 pagesThermodynamic exercises solved step-by-stepToMemNo ratings yet

- R & AC Important Questions: Iv Me, I SemDocument17 pagesR & AC Important Questions: Iv Me, I Semapi-362935264100% (1)

- Module 03: Setting Up Physics: Introduction To ANSYS FluentDocument53 pagesModule 03: Setting Up Physics: Introduction To ANSYS FluentLuis Alejandro Amante SantanaNo ratings yet

- Flowirl 8700Document77 pagesFlowirl 8700srinivasan0198150% (6)

- Filter Regulator LFR-1/2-D-7-O-MIDI: Data SheetDocument1 pageFilter Regulator LFR-1/2-D-7-O-MIDI: Data SheetRichard Rodriguez GarciaNo ratings yet

- 4274-CD-VD-LG201000019D1004001 - US CommentedDocument1 page4274-CD-VD-LG201000019D1004001 - US CommentedUnmesh ShuklaNo ratings yet

- ScheduleDocument2 pagesSchedulecbcyouthygnNo ratings yet

- LNG Hazards and SafetyDocument60 pagesLNG Hazards and SafetyAhmad Imran50% (2)

- Bachelor of Technology (Civil) - Level 05 Cex 5231 - Mechanics of Fluids - Year 2015/2016 Assignment 06 - Suggested AnswersDocument10 pagesBachelor of Technology (Civil) - Level 05 Cex 5231 - Mechanics of Fluids - Year 2015/2016 Assignment 06 - Suggested AnswersMufeesNo ratings yet

- ME2134 Review SlidesDocument60 pagesME2134 Review SlidesowenwongsohyikNo ratings yet

- AQT MSV 1 Suavizador Manual UnlockedDocument8 pagesAQT MSV 1 Suavizador Manual UnlockedEdgar CastroNo ratings yet

- Etd 2mark With AnswerDocument16 pagesEtd 2mark With AnswerERKATHIR100% (1)

- Compressor PDFDocument46 pagesCompressor PDFJohn QueliopeNo ratings yet

- D2060-M - Medical Vacuum and Gas SystemsDocument7 pagesD2060-M - Medical Vacuum and Gas Systemspaintbrush793053No ratings yet

- ABSA 4th Class B HelpDocument53 pagesABSA 4th Class B HelpAnonymous eMaZdX9100% (1)

- Pump Operating RangeDocument2 pagesPump Operating RangeNikesh100% (1)

- Pressure Test Flushing Pickling PassivationDocument12 pagesPressure Test Flushing Pickling PassivationVidal Choque N.100% (1)

- Fixed Displacement Vane Pumps DatasheetDocument6 pagesFixed Displacement Vane Pumps DatasheetPatrick Sucre MumoNo ratings yet

- Steam Stop ValveDocument15 pagesSteam Stop Valveankur raiNo ratings yet

- E1 - Gas Properties - Methane vs. EthaneDocument11 pagesE1 - Gas Properties - Methane vs. EthaneHeli SolankiNo ratings yet

- IGCSE Chemistry Chapter 1Document7 pagesIGCSE Chemistry Chapter 1Spike ChingyenNo ratings yet

- 160 75-O1 PDFDocument40 pages160 75-O1 PDFSanthoshkumar RajendranNo ratings yet