Professional Documents

Culture Documents

Asynchronous Motor Operating Manual

Uploaded by

Dinesh Kumar MehraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asynchronous Motor Operating Manual

Uploaded by

Dinesh Kumar MehraCopyright:

Available Formats

Asynchronous motor Operating manual

Introduction: The Induction motor is a three phase AC motor and is the most widely used machine. Its characteristic features areo o o o

Simple and rugged construction Low cost and minimum maintenance High reliability and sufficiently high efficiency Needs no extra starting motor and need not be synchronized

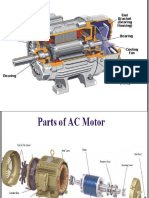

An Induction motor has basically two parts Stator and Rotor The Stator is made up of a number of stampings with slots to carry three phase windings. It is wound for a definite number of poles. The windings are geometrically spaced 120 degrees apart. Two types of rotors are used in Induction motors - Squirrel-cage rotor and Wound rotor. STATOR CONSTRUCTION: The stator and the rotor are electrical circuits that perform as electromagnets. The stator is the stationary electrical part of the motor. The stator core of a motor is made up of several hundred thin laminations. STATOR WINDINGS; Stator laminations are stacked together forming a hollow cylinder. Coils of insulated wire are inserted into slots of the stator core.

Each grouping of coils, together with the steel core it surrounds, form an electromagnet. Electromagnetism is the principle behind motor operation. The stator windings are connected directly to the power source.

ROTOR CONSTRUCTION: The rotor is the rotating part of the electromagnetic circuit. The most common type of rotor is the "squirrel cage" rotor. Other types of rotor construction will be mentioned later in the course. The construction of the squirrel cage rotor is reminiscent of rotating exercise wheels found in cages of pet rodents

The rotor consists of a stack of steel laminations with evenly spaced conductor bars around the circumference. The laminations are stacked together to form a rotor core. Aluminum is die cast in the slots of the rotor core to form a series of conductors around the perimeter of the rotor. Current flow through the conductors form the electromagnet. The conductor bars are mechanically and electrically connected with end rings. The rotor core mounts on a steel shaft to form a rotor assembly.

ENCLOSURE:

The enclosure consists of a frame (or yoke) and two end brackets (or bearing housings). The stator is mounted inside the frame. The rotor fits inside the stator with a slight air gap separating it from the stator. There is no direct physical connection between the rotor and the stator. The enclosure also protects the electrical and operating parts of the motor from harmful effects of the environment in which the motor operates. Bearings, mounted on the shaft, support the rotor and allow it to turn. A fan, also mounted on the shaft, is used on the motor shown below for cooling. ELECTROMAGNETISM: When current flows through a conductor a magnetic field is produced around the conductor. The magnetic field is made up of lines of flux, just like a natural magnet. The size and strength of the magnetic field will increase and decrease as the current flow strength increases and decreases. LEFT HAND RULE FOR CONDUCTORS: A definite relationship exists between the direction of current flow and the direction of the magnetic field. The left-hand rule for conductors demonstrates this relationship. If a currentcarrying conductor is grasped with the left hand with the thumb pointing in the direction of electron flow, the fingers will point in the direction of the magnetic lines of flux.

ASYNCHRONOUS MOTOR 440/220

ASYNCHRONOUS MOTOR

3 PH MCB A1

B1

C1

Connect 3 phase mains supply

Procedure:

Connect the mains supply 3 phase 440V with correct phase R, Y, B to the Electrical panel as indicated in the figure above. Make the connections of motor as indicated in the figure . Connections made should be tight in all respect. Loose connections may cause some hazardous problems. Switch on the power , motor will run at its speed .

You might also like

- Types of AlternatorsDocument12 pagesTypes of AlternatorsHamoudRazaMazherNo ratings yet

- Brushless Alternators: © 2000 Graig PearenDocument3 pagesBrushless Alternators: © 2000 Graig PearenAboalfotoh Mahmoud100% (2)

- Small Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsFrom EverandSmall Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsNo ratings yet

- CRX205 (Lot No - 9659)Document100 pagesCRX205 (Lot No - 9659)Max K.No ratings yet

- Alternator: Parts and Functions of An AlternatorDocument11 pagesAlternator: Parts and Functions of An AlternatorRomari MirandaNo ratings yet

- Induction MotorDocument46 pagesInduction MotorSyed Muhammad Munavvar Hussain100% (5)

- What Is An AlternatorDocument16 pagesWhat Is An AlternatorSanrasni100% (1)

- Workshop II ManualDocument76 pagesWorkshop II Manualzelalem walie100% (1)

- Power Supply Trainer Using Lm723 IcDocument8 pagesPower Supply Trainer Using Lm723 IcDinesh Kumar MehraNo ratings yet

- Home-made Toy Motors: A practical handbook giving detailed instructions for building simple but operative electric motorsFrom EverandHome-made Toy Motors: A practical handbook giving detailed instructions for building simple but operative electric motorsNo ratings yet

- DC Motor Are of 3 Types They Are .Document12 pagesDC Motor Are of 3 Types They Are .Krishna100% (1)

- What Is An Alternator 06-04-2011Document5 pagesWhat Is An Alternator 06-04-2011Ryan ArañaNo ratings yet

- Power Electronics 2 Eletrical DrivesDocument123 pagesPower Electronics 2 Eletrical DrivesNaga Ananth100% (1)

- PLL 565Document6 pagesPLL 565Dinesh Kumar MehraNo ratings yet

- Parts RANGER 305D Code 11457Document26 pagesParts RANGER 305D Code 11457jorge trespalacios100% (1)

- TechportDocument6 pagesTechportMaureen TatadNo ratings yet

- Basics of AC Electric Motors and PartsDocument3 pagesBasics of AC Electric Motors and PartsPankaj Kumar SinghNo ratings yet

- MachinesDocument10 pagesMachinessanjeevani rawatNo ratings yet

- Mechatronics Ktu Module 6Document36 pagesMechatronics Ktu Module 6Adarsh s nairNo ratings yet

- Direct Current MotorDocument5 pagesDirect Current Motorjamesbergano18No ratings yet

- How Generators Work: A Guide to Electrical Energy ProductionDocument33 pagesHow Generators Work: A Guide to Electrical Energy ProductionAlvinNo ratings yet

- Assignment Ac DCDocument10 pagesAssignment Ac DCKamil KhairiNo ratings yet

- Synchronous MachineDocument9 pagesSynchronous MachineAnonymous rUufA9BUNo ratings yet

- Group 2 Ac Motors Technical ReportDocument12 pagesGroup 2 Ac Motors Technical Reporttristan jeff bautistaNo ratings yet

- HTTPSWWW - Sathyabama.ac - Insitesdefaultfilescourse Material2020 10UNIT II 4 PDFDocument29 pagesHTTPSWWW - Sathyabama.ac - Insitesdefaultfilescourse Material2020 10UNIT II 4 PDFVigneshwaran J vNo ratings yet

- DC Generator ProjectDocument10 pagesDC Generator ProjectMuhammad Asif Iqbal43% (7)

- Module IiDocument14 pagesModule Iisarath.mNo ratings yet

- Unit-3 EeeDocument9 pagesUnit-3 EeeShubham KhandelwalNo ratings yet

- Beee Unit 2 MeterialDocument18 pagesBeee Unit 2 MeterialnaveenNo ratings yet

- Electrical Assignment 15-12-2018Document15 pagesElectrical Assignment 15-12-2018Mudasir SahoNo ratings yet

- Skip To ContentDocument17 pagesSkip To Contentkidanemariam teseraNo ratings yet

- Chapter 1 - Introduction To AC MotorDocument13 pagesChapter 1 - Introduction To AC MotorJiachyi YeohNo ratings yet

- Components of A GeneratorDocument2 pagesComponents of A GeneratorKhairul Alam TaifurNo ratings yet

- UNIT -IVDocument24 pagesUNIT -IVdurairajgeetha318No ratings yet

- Dot 1Document5 pagesDot 1Thomas Nathaniel AngNo ratings yet

- Brake Load Test of Squirel Cage Induction Motor 3 PhaseDocument7 pagesBrake Load Test of Squirel Cage Induction Motor 3 Phasejassisc100% (1)

- Squirrel-Cage Rotor and Stator Parts ExplainedDocument3 pagesSquirrel-Cage Rotor and Stator Parts ExplainedVivek BhatnagarNo ratings yet

- 4 Motors: D.C. Motors Principles of D.C. MotorsDocument10 pages4 Motors: D.C. Motors Principles of D.C. MotorsmanjunathagNo ratings yet

- CNC Drive ClassificationDocument20 pagesCNC Drive Classificationamit kumarNo ratings yet

- DcmachineDocument54 pagesDcmachineRoyal Ritesh SharmaNo ratings yet

- BET PosterDocument4 pagesBET PosterSiddharth MohantyNo ratings yet

- Application of DC Shunt Motor: Lovely Professional University Amit Raj ROLL NO-RB4802A28 Reg. No-10803543 B.Tech - MEDocument5 pagesApplication of DC Shunt Motor: Lovely Professional University Amit Raj ROLL NO-RB4802A28 Reg. No-10803543 B.Tech - MEshailesh singhNo ratings yet

- Construction of DC Machines: By, Francisco L. Bacud Jr. BSEE-3 (STEM) Submitted To, Engr. Mark Anjo Luyun (Professor)Document6 pagesConstruction of DC Machines: By, Francisco L. Bacud Jr. BSEE-3 (STEM) Submitted To, Engr. Mark Anjo Luyun (Professor)FLVC Mark Anjo LuyunNo ratings yet

- The Copperbelt University: School of TechnologyDocument40 pagesThe Copperbelt University: School of TechnologyMU Len GANo ratings yet

- ELE290 Induction Motor GuideDocument21 pagesELE290 Induction Motor GuideHarizx SaufixNo ratings yet

- ELE290 Chapter 6Document21 pagesELE290 Chapter 6imfendiNo ratings yet

- Ac MotorDocument17 pagesAc Motorthebeast.suazoNo ratings yet

- Construction of A DC GeneratorDocument6 pagesConstruction of A DC GeneratorHammad khanNo ratings yet

- DC MotorDocument21 pagesDC MotorSameera MadhushankaNo ratings yet

- ALTERNATOR TITLEDocument23 pagesALTERNATOR TITLEpremameNo ratings yet

- AC MotorDocument8 pagesAC MotorSmai HondoNo ratings yet

- Altena TorDocument8 pagesAltena TorJb EnarioNo ratings yet

- DC MachineDocument53 pagesDC MachineBikash ParhNo ratings yet

- AlternatorDocument3 pagesAlternatorshekharpremsureNo ratings yet

- Electrical Motors 2013Document28 pagesElectrical Motors 2013Stephen StewartNo ratings yet

- Unit 2Document85 pagesUnit 2Naitik NavyNo ratings yet

- University of Palestine College of Applied Science and Urban Planning Electrical Machine & Control Systems Lecture #13 Electrical Machines Fundamentals DC MachinesDocument24 pagesUniversity of Palestine College of Applied Science and Urban Planning Electrical Machine & Control Systems Lecture #13 Electrical Machines Fundamentals DC MachinesHatem DheerNo ratings yet

- AC Motor GuideDocument24 pagesAC Motor GuideNikhil JangidNo ratings yet

- Assignment Synchronous Generator and Induction MotorDocument20 pagesAssignment Synchronous Generator and Induction MotorSyahril Abdullah100% (1)

- Induction Motor Operation Explained in 40 CharactersDocument3 pagesInduction Motor Operation Explained in 40 CharactersAnil KumarNo ratings yet

- Electrical Machine 5 Compiled by Course Lecturer EngrDocument66 pagesElectrical Machine 5 Compiled by Course Lecturer EngrJames JohnNo ratings yet

- Notes For Power System 5th SemDocument28 pagesNotes For Power System 5th SemSidhant SharmaNo ratings yet

- Unit VDocument7 pagesUnit VMonte CarloNo ratings yet

- Experiment # 7 Load Test of A Three Phase Induction MotorDocument22 pagesExperiment # 7 Load Test of A Three Phase Induction MotorKumar shantanu BasakNo ratings yet

- Introduction To Turbo GeneratorDocument42 pagesIntroduction To Turbo GeneratorTirumalesh ReddyNo ratings yet

- The Clapp Oscillator: ObjectiveDocument4 pagesThe Clapp Oscillator: ObjectiveDinesh Kumar MehraNo ratings yet

- To Measure Power Factor in A SingleDocument5 pagesTo Measure Power Factor in A SingleDinesh Kumar MehraNo ratings yet

- Analog To Digital Conversion Trainer: Instructions Manual ForDocument5 pagesAnalog To Digital Conversion Trainer: Instructions Manual ForDinesh Kumar MehraNo ratings yet

- Leakagge MethodDocument4 pagesLeakagge MethodDinesh Kumar MehraNo ratings yet

- Capaliiry Flow MethodDocument3 pagesCapaliiry Flow MethodDinesh Kumar MehraNo ratings yet

- Full Adder Using MultiplexerDocument3 pagesFull Adder Using MultiplexerDinesh Kumar Mehra0% (1)

- Oscillator Circuit Using GatesDocument8 pagesOscillator Circuit Using GatesDinesh Kumar MehraNo ratings yet

- Analog To Digital Conversion, ADC0804Document3 pagesAnalog To Digital Conversion, ADC0804Dinesh Kumar MehraNo ratings yet

- Series RL CircuitDocument3 pagesSeries RL CircuitDinesh Kumar MehraNo ratings yet

- Capacitor in Series and ParallelDocument3 pagesCapacitor in Series and ParallelDinesh Kumar MehraNo ratings yet

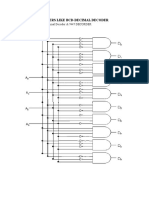

- Design of Decoders Like Bcd-Decimal Decoder Aim: Circuit DiagramDocument3 pagesDesign of Decoders Like Bcd-Decimal Decoder Aim: Circuit DiagramDinesh Kumar MehraNo ratings yet

- Full Adder Using MultiplexerDocument3 pagesFull Adder Using MultiplexerDinesh Kumar MehraNo ratings yet

- RC Phase Shift OscillatorDocument2 pagesRC Phase Shift Oscillatordinesh189100% (1)

- AC Single Phase Induction Motor Instruction Manual GuideDocument5 pagesAC Single Phase Induction Motor Instruction Manual GuideDinesh Kumar MehraNo ratings yet

- Instruction Manual of Diac CharcteristicsDocument4 pagesInstruction Manual of Diac CharcteristicsDinesh Kumar MehraNo ratings yet

- CLASSa Power AmpDocument1 pageCLASSa Power AmpDinesh Kumar MehraNo ratings yet

- Design Temperature SensorDocument2 pagesDesign Temperature SensorDinesh Kumar MehraNo ratings yet

- Arithmetic Logic UnitDocument7 pagesArithmetic Logic UnitDinesh Kumar MehraNo ratings yet

- Capacitor StartingDocument3 pagesCapacitor StartingDinesh Kumar MehraNo ratings yet

- Colpitts OscillatorDocument3 pagesColpitts OscillatorDinesh Kumar MehraNo ratings yet

- AC Single Phase Induction Motor Instruction Manual GuideDocument5 pagesAC Single Phase Induction Motor Instruction Manual GuideDinesh Kumar MehraNo ratings yet

- Astable Multivibrator Using TransistorsDocument2 pagesAstable Multivibrator Using Transistorsdinesh189No ratings yet

- To Convert The Given Analog Input Into Its Equivalent Digital OutputDocument2 pagesTo Convert The Given Analog Input Into Its Equivalent Digital OutputDinesh Kumar MehraNo ratings yet

- LOGIC GATE TRAINER MANUALDocument5 pagesLOGIC GATE TRAINER MANUALDinesh Kumar MehraNo ratings yet

- Colpitts OscillatorDocument3 pagesColpitts OscillatorDinesh Kumar MehraNo ratings yet

- TriacDocument7 pagesTriacDinesh Kumar MehraNo ratings yet

- D/A Converter: Digital to Analog ConversionDocument3 pagesD/A Converter: Digital to Analog ConversionDinesh Kumar MehraNo ratings yet

- Engine Electrical System OverviewDocument51 pagesEngine Electrical System OverviewnahomNo ratings yet

- Full Height Turnstile User Manual - ARMA KONTROLDocument21 pagesFull Height Turnstile User Manual - ARMA KONTROLdinilmadhuNo ratings yet

- The Electric Motor IIDocument6 pagesThe Electric Motor IIGray Fox GarcíaNo ratings yet

- Generator-Transformer Unit Protection Instruction Manual (EN - YJBH2011.0091.1101)Document470 pagesGenerator-Transformer Unit Protection Instruction Manual (EN - YJBH2011.0091.1101)mspd2003100% (1)

- Eee52 - Electrical Machines - Ii - Fast Track 2019Document4 pagesEee52 - Electrical Machines - Ii - Fast Track 2019Preethi Sinha100% (2)

- Toyota 7fbef15 Driver Motor 1 PartsDocument2 pagesToyota 7fbef15 Driver Motor 1 PartsEverybody LiesNo ratings yet

- Manual AWA 2 & 4Document138 pagesManual AWA 2 & 4Alex Aros CNo ratings yet

- A Survey On Slip Power Recovery DrivesDocument9 pagesA Survey On Slip Power Recovery Drivesesaivanan1150% (2)

- Fail Safe Break & Break Motor: Presented byDocument16 pagesFail Safe Break & Break Motor: Presented byShubham GaikwadNo ratings yet

- EEE8155 Design and Analysis of Electrical Machines and DrivesDocument13 pagesEEE8155 Design and Analysis of Electrical Machines and DrivesstephenNo ratings yet

- Scilab Textbook Companion for Electrical Machines 3rd EditionDocument113 pagesScilab Textbook Companion for Electrical Machines 3rd Editionajai_cseNo ratings yet

- Top Small, Medium Scale Business Ideas List For Beginners, Start - Up Entrepreneurs To StartDocument50 pagesTop Small, Medium Scale Business Ideas List For Beginners, Start - Up Entrepreneurs To StartklockNo ratings yet

- Ee 2352 - Solid State Drives Unit-V Synchronous Motor Drives Mr.R.Essaki Raj, Senior LecturerDocument26 pagesEe 2352 - Solid State Drives Unit-V Synchronous Motor Drives Mr.R.Essaki Raj, Senior LecturerVenkedesh RNo ratings yet

- Multiple Choice Questions For Chapter 25: All Questions Have Only One Correct AnswerDocument3 pagesMultiple Choice Questions For Chapter 25: All Questions Have Only One Correct AnswerJoshua GyetuahNo ratings yet

- Evaluation of 2004 Toyota Prius Hybrid Electric Drive System Interim ReportDocument43 pagesEvaluation of 2004 Toyota Prius Hybrid Electric Drive System Interim Reportmkdir911No ratings yet

- Integrated Chargers For EV's and PHEV'sDocument6 pagesIntegrated Chargers For EV's and PHEV'sCR Athira100% (1)

- IPM ModelDocument66 pagesIPM Modelbobo249No ratings yet

- HT SQUIRREL CAGE INDUCTION MOTORSDocument11 pagesHT SQUIRREL CAGE INDUCTION MOTORSGopalMahantaNo ratings yet

- Electric Machine IIDocument1 pageElectric Machine IIMahmoud AbuziadNo ratings yet

- Technical Background On Linear Induction Motors in Transportation Jun 1970Document99 pagesTechnical Background On Linear Induction Motors in Transportation Jun 1970Shantanu GaikwadNo ratings yet

- Excitation Systems Ka Lun Khaa LoDocument7 pagesExcitation Systems Ka Lun Khaa Lointel345No ratings yet

- Gen Synch Conditions Write UpDocument5 pagesGen Synch Conditions Write UpanandNo ratings yet

- Dual Stator Winding Induction Machine - Problems, Progress, and Future Scope PDFDocument12 pagesDual Stator Winding Induction Machine - Problems, Progress, and Future Scope PDFTaiwoNo ratings yet

- Computation of Additional Losses Due To Rotoreccentricity in Electrical MachinesDocument8 pagesComputation of Additional Losses Due To Rotoreccentricity in Electrical Machinesafru2000No ratings yet

- EE360 - Synchronous MachinesDocument85 pagesEE360 - Synchronous MachinesAliAl-jaziriNo ratings yet

- Permanent Magnet Alternator theory sessionDocument27 pagesPermanent Magnet Alternator theory sessionseikh_aiNo ratings yet

- Ed Lab ManualDocument27 pagesEd Lab ManualBonnieNo ratings yet