Professional Documents

Culture Documents

Barfield 2471F Megohmmeter Manual

Uploaded by

David Santiago GiraldoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Barfield 2471F Megohmmeter Manual

Uploaded by

David Santiago GiraldoCopyright:

Available Formats

2471F

MEGOHMMETER

USER INSTRUCTION MANUAL BARFIELD M/N 2471F

56-101-00220-B September 23, 2008 ________________________________________ BARFIELD, INC.

Corporate Headquarters 4101 Northwest 29th Street Miami, Florida 33142 www.barfieldinc.com Email: gsesales@barfieldinc.com

2471F INSTRUCTION MANUAL

This page intentionally left blank.

56-101-00220-B 09 / 23 / 08

Blank Page ii

2471F INSTRUCTION MANUAL

This page intentionally left blank.

56-101-00220-B 09 / 23 / 08

Blank Page iii

2471F INSTRUCTION MANUAL

CONTACT INFORMATION

Users are requested to notify the manufacturer of any discrepancy, omission, or error found in this manual. Inquiries should include specific questions and reference the publication title, number, chapter, page, figure, paragraph, and effective date. Please send comments to: TECHNICAL CUSTOMER SUPPORT - GSTE BARFIELD, INC. P.O. BOX 025367 MIAMI, FL 33102-5367 USA

Telephone Fax Email

(305) 894-5400 (800) 321-1039 (305) 894-5401 gsesales@barfieldinc.com

56-101-00220-B 09 / 23 / 08

Contact Page iv

2471F INSTRUCTION MANUAL

This page intentionally left blank.

56-101-00220-B 09 / 23 / 08

Blank Page v

2471F INSTRUCTION MANUAL

ATTENTION

Although every effort has been made to provide the end user of this equipment with the most current and accurate information, it may be necessary to revise this manual in the future. Please be sure to complete and return a Revision Request Form to Barfield revision services and visit the company website, http://barfieldinc.com/, for publication updates. Additionally, Barfield MUST have your name and address on file as a registered user of this equipment to ensure validation of the warranty. Please complete the OWNER WARRANTY REGISTRATION card promptly. This card ensures validation of the warranty. Please send to: Barfield, Inc. P.O. Box 025367 Miami, FL 33102-5367 USA

56-101-00220-B 09 / 23 / 08

Attention Page vi

2471F INSTRUCTION MANUAL

This page intentionally left blank.

56-101-00220-B 09 / 23 / 08

Blank Page vii

2471F INSTRUCTION MANUAL

REVISION RECORD

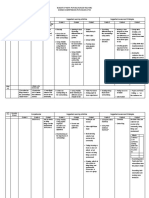

REV. A B ECO # N/A 260-00729 REV. DATE June 1986 Sep / 23 / 2008 DESCRIPTION OF CHANGE Initial Release. Company logo and contact information was updated. Chapters were reorganized.

56-101-00220-B 09 / 23 / 08

Rev. Page viii

2471F INSTRUCTION MANUAL

This page intentionally left blank.

56-101-00220-B 09 / 23 / 08

Blank Page ix

2471F INSTRUCTION MANUAL

LIST OF APPROVED REPAIR FACILITIES

The manufacturer of this equipment does not recommend the user to attempt any maintenance or repair. In case of malfunction, contact the manufacturer, to obtain the list of approved repair facilities worldwide, ensuring that this equipment will be serviced using proper procedures and certified instruments. A Return Maintenance Authorization (RMA) number will be assigned during this call, to keep track of the shipment and the service. BARFIELD PRODUCT SUPPORT DIVISION Telephone Fax (305) 894-5400 (800) 321-1039 (305) 894-5401

Shipping Address: Barfield, Inc. 4101 NW 29th Street Miami, Florida 33142 USA Mailing Address: Barfield, Inc. P.O. Box 025367 Miami, FL 33102-5367 USA

56-101-00220-B 09 / 23 / 08

Maint. Page x

2471F INSTRUCTION MANUAL

This page intentionally left blank.

56-101-00220-B 09 / 23 / 08

Blank Page xi

2471F INSTRUCTION MANUAL

TABLE OF CONTENTS

Contact Information Attention Page Revision Record Page List of Approved Repair Facilities Table of Contents List of Figures and Tables

CHAPTER

............................................................................................PAGE INTRODUCTION 1. PUBLICATION BREAKDOWN .....................................................................1 2. INFORMATION PROVIDED WITH THE UNIT .............................................1 3. RECERTIFICATION .....................................................................................3

PRODUCT DESCRIPTION 1. GENERAL ....................................................................................................5 2. THEORY.......................................................................................................6 3. SPECIFICATIONS........................................................................................6 OPERATING INSTRUCTIONS 1. GENERAL ....................................................................................................9 2. APPLICATION NOTES ...............................................................................10 3. CARE AND MAINTENANCE.......................................................................11 RECEIVING, SHIPPING, AND STORAGE 1. RECEIVING.................................................................................................13 2. SHIPPING ...................................................................................................13 3. STORAGE ...................................................................................................13

LIST OF FIGURES AND TABLES

Page Figure 1: Identification Label...............................................................................................................1 Figure 2: Owner Warranty Registration Card......................................................................................2 Figure 3: Limited Warranty Statement Card .......................................................................................2 Figure 4: General View of the Megohmmeter 2471F..........................................................................5 Table 1: Current Consumption during Resistance Measurement ......................................................6 Table 2: Resistance Reading Parameters .........................................................................................6 56-101-00220-B 09 / 23 / 08 TOC Page xii

2471F INSTRUCTION MANUAL

This page intentionally left blank.

56-101-00220-B 09 / 23 / 08

Blank Page xiii

2471F INSTRUCTION MANUAL

INTRODUCTION

1. PUBLICATION BREAKDOWN

This user instruction manual establishes the standards of operation for Barfields 2471F Megohmmeter. Its purpose is to provide sufficient information for the personnel unfamiliar with this unit to understand it, identify its parts, and operate it in accordance with proper procedures, operating techniques, precautions and limitations.

2. INFORMATION PROVIDED WITH THE UNIT

Besides this User Instruction Manual, the instrument is provided with the four items described below. A. The identification label, similar to Figure 1, is located on the back of the instrument and provides the following information: Manufacturer Name Designation of Equipment Equipment Part Number Equipment Model Number Equipment Modification (if applicable) Equipment Serial Number Equipment Options (if applicable)

459-00043 rev. B

a Sabena technics company

MEGOHMMETER TEST SET

P/N M/N

101-00220

S/N

MADE IN THE USA

2471F

M A B C D E F G H J K O D L M N O P Q R S T U

O A B C D E F P T G H J K L M

Figure 1: IDENTIFICATION LABEL

56-101-00220-B 09 / 23 / 08

Intro Page 1 of 13

2471F INSTRUCTION MANUAL B. The Owner's Warranty Registration card (Figure 2) is to be completed by the owner and returned to Barfield, Inc. within ten (10) days of purchase to ensure automatic update of printed matter and validation of warranty.

Figure 2: OWNER WARRANTY REGISTRATION CARD

C. The Limited Warranty Statement Card (Figure 3) lists the manufacturer's obligation to the original purchaser.

Figure 3: LIMITED WARRANTY STATEMENT CARD

56-101-00220-B 09 / 23 / 08

Intro Page 2 of 13

2471F INSTRUCTION MANUAL D. The Certificate of Calibration: Each new unit and re-certified unit, is delivered with a Certificate of Calibration that shows the date of the last calibration and when the next calibration is due. It certifies the accuracy of the unit and lists the part number and serial number to which it applies.

3. RECERTIFICATION

This instrument has a one-year recertification requirement. Qualified technicians in a shop equipped with the necessary tooling and facilities must perform the maintenance required by this unit.

56-101-00220-B 09 / 23 / 08

Intro Page 3 of 13

2471F INSTRUCTION MANUAL

This page intentionally left blank.

56-101-00220-B 09 / 23 / 08

Blank Page 4 of 13

2471F INSTRUCTION MANUAL

CHAPTER 1: PRODUCT DESCRIPTION

1. GENERAL

(1) The 2471F (Fig. 4) is a self-contained, battery operated, high potential megohmmeter. Test potentials of 100, 200, and 500 volts DC are selectable by a panel switch. Current limiting circuitry provides safe, ABSOLUTELY SHOCK-PROOF operation. A single four inch meter scale, increasing from zero at the left to infinity at the right, is incremented from .5 to 1,000 megohms. A pushbutton on the high potential test probe provides for conveniently activating the instrument. Flashlight type batteries are used, and a self-contained battery test is incorporated. Solid-state circuitry provides the means for size reduction, high sensitivity, and dependability. The meter is a ruggedized taut-band suspension type, which eliminates the need for pivots and jewels. The high potential probe is shield-guarded so that stray leakage through lead insulation will not affect the measurement accuracy. The output current of the 2471F is limited to a maximum of 30 microamperes even at the 500 volt test potential. This current is well below human sensibility, so that there is no sensation of current if the bare probes are touched with the tester activated. This current limiting prevents damage to any circuitry or components that can withstand the applied voltage, and prevents additional damage to a circuit that exhibits any insulation deterioration. The 2471F is also protected from damage due to inadvertently connecting the probes across an energized circuit. AC or DC voltages up to 300 volts can be safely applied.

(2)

(3)

(4)

Figure 4: General View of the Megohmmeter 2471F 56-101-00220-B 09 / 23 / 08 CH. 1 Page 5 of 13

2471F INSTRUCTION MANUAL

2. THEORY

A transistor converter increases the battery supply to the 100, 200, and 500 volt test potentials selected by the panel switch. A high performance operational amplifier increases the impedance and sensitivity of the panel meter to measure the voltage drop across the test probes in terms of resistance. A panel control adjusts the calibration for infinity with the probes removed from the circuit under test. The batteries are connected to the megohmmeter circuit through transistor switches activated by a subminiature pushbutton on the high potential probe. A single receptacle provides connection to all the test lead cable circuits, and a shieldguard isolates the high potential lead from stray leakage resistance. A panel switch connects the meter for testing of either of the battery circuits or for megohmmeter indication.

3. SPECIFICATIONS

(1) The electrical specifications of the instrument are indicated in Tables 1 and 2. Table 1: Current Consumption during Resistance Measurement Test Potential (V) 100 10% 200 10% 500 10% Max. Draw (A) 6 12 30

Table 2: Resistance Reading Parameters Resistance Reading Range (M) Reading Accuracy Megohm Increments Low Midscale High 0.5 17 1000 0 to 10 %

(2)

The physical specifications of the instrument are as follows.

Weight: 3.8 lbs., approx. (with carrying case) Size: 8" x 6" x 4.75" approx. (with carrying case)

56-101-00220-B 09 / 23 / 08

CH. 1 Page 6 of 13

2471F INSTRUCTION MANUAL (3) Accessories supplied with the instrument are as follows.

(4)

Portable vinyl overall carrying case, Eveready type, with test cable compartment. Plug-in test cable leads. Separable probe clip.

Batteries required for instrument operation are as follows.

3 each of 1.5 volt C cells (Eveready E93, or equivalent) 3 each of 1.5 volt AA cells (Eveready E91, or equivalent)

56-101-00220-B 09 / 23 / 08

CH. 1 Page 7 of 13

2471F INSTRUCTION MANUAL

This page intentionally left blank.

56-101-00220-B 09 / 23 / 08

CH. 1 Page 8 of 13

2471F INSTRUCTION MANUAL

CHAPTER 2: OPERATING INSTRUCTIONS

CAUTION: DO NOT APPLY HIGH VOLTAGE TESTS TO CIRCUITRY NOT DESIGNED FOR HIGH VOLTAGE APPLICATION. MOST SOLID CIRCUITRY IS SUBJECT TO DAMAGE FROM EVEN MOMENTARY APPLICATION OF HIGH VOLTAGE. MAKE CERTAIN DEVICE UNDER TEST IS CLEAN. DIRT, MOISTURE, AND MOST DEPOSITS EXHIBIT RATHER LOW LEAKAGE RESISTANCE.

1. GENERAL

(1) (2) (3) (4) Consult component manufacturer's testing specifications for test voltage to be applied. Isolate the device under test from external power or circuitry. Insert test cable plug fully into receptacle at the top of the test set. Make certain meter pointer is resting at zero. (Adjust meter pointer zero adjust screw on meter cover bezel, if necessary). Select FUNCTION switch to B1 and then to B2 to read battery condition. (a) A reading above BATT. OK radial on the meter dial is satisfactory. NOTE: Always return the FUNCTION switch to the MEGOHMS position after a battery test to avoid small amount of battery drain. (5) (6) Place FUNCTION switch on MEGOHMS for megohmmeter operation. With RED test probe free from contact with external circuits or black probe, press probe pushbutton, and then turn FULL SCALE ADJUST as required to produce full scale deflection of meter pointer. CAUTION: THIS ADJUSTMENT MUST BE RECHECKED WHENEVER A DIFFERENT VOLTAGE SELECTION IS MADE. (7) Connect BLACK probe to low, common, or ground side of circuit to be tested. (If both sides of circuit to be tested are high, either point may be contacted with black probe). Insert accessory clip on black probe, if more convenient. Connect RED probe to other test point, and with pushbutton depressed, read insulation resistance in megohms on meter scale. (a) Consult component manufacturer's specifications for acceptable insulation resistance.

(8)

CAUTION: WAIT FOR METER TO COME TO FULL REST BEFORE READING. THERE MAY BE A MOMENTARY DELAY AFTER BUTTON IS PRESSED FOR HIGH VOLTAGE CONVERTER TO COME UP TO FULL POTENTIAL, AND CAPACITANCE IN THE CIRCUIT UNDER TEST MAY REQUIRE CHARGING TIME. (9) Consult the Application Notes (Next Section) for further details on specific application of the 2471F to insulation testing. CH. 2 Page 9 of 13

56-101-00220-B 09 / 23 / 08

2471F INSTRUCTION MANUAL

2. APPLICATION NOTES

(1) Insulation sometimes will exhibit different leakage resistance with different test potentials applied. A reduced resistance reading with an increased setting of the VOLTS switch is a normal condition in such cases. If the probes are connected across an appreciable value of capacitance, the meter will respond very slowly as a reaction to the charging time of the capacitor (approximately 5 seconds are required for 0.1 F and 1 minute for 1 F). If higher capacitance values are to be tested, the capacitor should first be charged to the test voltage before applying the megohmmeter. Be certain to connect the RED probe to the positively charged capacitance terminal, and wait for the voltage across the capacitance to equalize to the megohmmeter test potential as indicated by an on-scale steady reading on the meter. Even the slightest amount of electrical continuity to the bare red probe from a circuit not part of that being measured will introduce erroneous readings. Exercise care not to touch the bare end of the red probe or any circuitry not connected to the black probe while testing. Make certain that no part of the device under test is inadvertently grounded other than that which is normal ground. When testing devices that have been exposed to moisture or dirt, low insulation resistance will often be indicated. Complete cleaning and dry baking at a temperature about 50F above ambient will generally remove this source of leakage. In hot wet climates, even superior insulations may have conductive paths through fungus growths. Cleaning and drying may remove most of such growths, but if the spores are not killed, the growth may return in a few days. A fungus killing and growth inhibitor is recommended in such cases. A DC megohmmeter is not a substitute for an AC high-voltage break down tester. Alternating voltage strains an insulation in first one direction and then another. The behavior of the insulation under such strain is quite different from the application of a low current DC test. In many applications, both types of test are required. If the device to be tested is not subject to high voltages or high temperatures under normal operation, high-voltage DC megohmmeter tests should suffice. If a very low insulation resistance is indicated, a conventional ohmmeter should be used for fault isolation. The lower operating voltage and low resistance readability of a conventional ohmmeter is more satisfactory for finding direct or low resistance short circuits The normal deterioration of insulation results in a lowering of resistance with time. Therefore, an insulation reading just slightly above a specified minimum, generally indicates an impending failure. Corrective measures should be taken to prevent further deterioration. By recording periodic insulation measurements, deterioration trends will be indicated so that preventative maintenance can be established. Insulation minimums are generally specified (or implied) for dry atmospheric conditions. If the unit under test cannot be brought into a dry environment, or baked, reduced insulation resistance can be anticipated and allowances made accordingly. CH. 2 Page 10 of 13

(2)

(3)

(4)

(5)

(6)

(7)

(8)

56-101-00220-B 09 / 23 / 08

2471F INSTRUCTION MANUAL (9) Sometimes insulation tests are required in polarized circuits that will exhibit low resistance when subjected to an opposite polarity. Consult the test specifications for polarity. The RED probe is always positive polarity from the megohmmeter. If in doubt, make a test with probes connected in one manner and then reversed for a second test. A substantial difference in reading will indicate a polarized circuit.

(10) If the megohmmeter indicates either an upward or downward scale reading with the probes connected, but with the pushbutton released, the circuit under test is energized. (Small potentials may not produce a reading without button pressed but will introduce erroneous readings). Make certain that all power to the device has been removed and that all capacitances have been discharged. Some devices will retain residual voltages long after the power has been removed. (11) Some tests require that jumpers be placed between two or more points on the device under test while making insulation tests. This is generally done to prevent possible damage to portions of the circuit that are not designed for high voltage application, or to make an overall insulation test for a number of circuits simultaneously. Be certain to follow the test specification procedures when jumpers are indicated.

3. CARE AND MAINTENANCE

The 2471F megohmmeter is designed to give lasting accurate performance provided reasonable care is exercised in operating and handling. (1) Keep test set in its carrying case at all times to reduce the danger of damage from vibration, shock, and moisture. Exercise reasonable care to avoid dropping or excessive shock. Protect from rain and exposure. Store in cool, clean, dry place to reduce contamination and battery deterioration. REMOVE BATTERIES IF TEST SET IS TO BE STORED FOR PROLONGED PERIODS. Do not subject megohmmeter to electrically energized circuit. The 2471F is safe from damage from externally applied AC or DC voltages up to 300 volts, but high voltages may be dangerous to the operator and will produce erroneous readings. Two sets of batteries are used. The three smaller AA cells (Eveready E91, or equivalent) provide the positive 4.5 volts for the operational amplifier and triggering of the battery transistor switches. The three larger C cells (Eveready E93, or equivalent) provide the negative 4.5 volts for the operational amplifier and high voltage converter. The 2471F is designed for operation with alkaline type cells, but conventional zinc carbon cells may be used as temporary replacements. The B1 position of the FUNCTION switch connects the meter for testing the condition of the C cells, and the B2 position for the AA cells. A reading below the BATT. OK radial on the meter scale is an indication of unsatisfactory battery condition. A more significant test may be made by observing the meter on the B1 and B2 positions with the probe pushbutton depressed. The pointer will drop slightly on the B1 position, but should remain above the BATT. OK radial. There should be no more than a barely perceptible drop on B2 with the button depressed.

(2) (3)

(4)

(5)

56-101-00220-B 09 / 23 / 08

CH. 2 Page 11 of 13

2471F INSTRUCTION MANUAL (6) To gain access to the batteries, release the strap across the top of the meter and remove tester from its carrying case. Place the test set in a clean area. (A clean cloth or paper pad placed to the right of the test set to receive the inverted panel it desirable). Remove the four corner panel screws. Withdraw the panel and rest it inverted to the right of its case. Push one of the battery holding clips aside while withdrawing the batteries. When replacing cells, make certain they are all inserted in the retainer tube in the same direction. The small terminal + (plus) end should connect to the RED terminal end of the respective battery holder.

(7)

56-101-00220-B 09 / 23 / 08

CH. 2 Page 12 of 13

2471F INSTRUCTION MANUAL

CHAPTER 3: RECEIVING, SHIPPING, AND STORAGE

1. RECEIVING

No special unpacking procedures are necessary. It is recommended that the factory shipping container and packing materials be retained should it become necessary for any reason to reship the instrument. It is also recommended to inspect carefully the instrument for damage. If damaged, do not use it and immediately notify the carrier and the manufacturer.

2.

SHIPPING

Use standard delicate electronic equipment packaging procedures, when packing the instrument for reshipment.

3.

STORAGE

Place a four-ounce bag of desiccant inside the carrying case (optional). Store in a dry place with a temperature range of -10 C to +50 C.

56-101-00220-B 09 / 23 / 08

CH. 3 Page 13 of 13

You might also like

- Pitot-Static Test Set: User Instruction ManualDocument64 pagesPitot-Static Test Set: User Instruction ManualPeter McKevitzNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Barfield Sight Compass 56 101 01200 DDocument34 pagesBarfield Sight Compass 56 101 01200 DPhilip Madekufamba IINo ratings yet

- Scelleuse de Tube - Sang - Manual - Cr4aa - Cr6aa - Cr6psaa - Eng - 04Document36 pagesScelleuse de Tube - Sang - Manual - Cr4aa - Cr6aa - Cr6psaa - Eng - 04Med KerroumNo ratings yet

- Pp10 CCGT Power Station: Operation and Maintenance Manual Sootblower Seal Air FansDocument13 pagesPp10 CCGT Power Station: Operation and Maintenance Manual Sootblower Seal Air Fansanbesivam87_49857255No ratings yet

- Millennium Ii Multi-Channel Transmitter: User Manual Single or Dual ChannelDocument47 pagesMillennium Ii Multi-Channel Transmitter: User Manual Single or Dual ChanneldavidNo ratings yet

- MVH-G218BT - Manual de ServicoDocument72 pagesMVH-G218BT - Manual de ServicoFernando Aparecido BaldáviaNo ratings yet

- Fuel Quantity Test Set 2548hDocument49 pagesFuel Quantity Test Set 2548hNANDO7695No ratings yet

- Echoswitch Ii: Manual - Mn300650 09 July 08 Revision ADocument33 pagesEchoswitch Ii: Manual - Mn300650 09 July 08 Revision Aderekbrch7No ratings yet

- Component Maintenance Manual HawkerDocument60 pagesComponent Maintenance Manual HawkerEagle1968100% (1)

- Using Lock-N-Stitch Procedures For Casting Repair InsertosDocument32 pagesUsing Lock-N-Stitch Procedures For Casting Repair InsertosAlan GonzalezNo ratings yet

- CPAP M SeriesDocument171 pagesCPAP M SeriesAndrés CárdenasNo ratings yet

- FlowLine Level Switch EchoSwitch LU74 LU77 LU78 ManualDocument27 pagesFlowLine Level Switch EchoSwitch LU74 LU77 LU78 ManualPromagEnviro.comNo ratings yet

- KM-500 Autokeratometer ManualDocument54 pagesKM-500 Autokeratometer Manualbertbowden100% (2)

- 7800 Controller Manual 87-0021 - RevE - 021411Document50 pages7800 Controller Manual 87-0021 - RevE - 021411Dario Yañez CNo ratings yet

- Liquid Level Switches Asme B31.1 ConstructionDocument36 pagesLiquid Level Switches Asme B31.1 Constructionsamer8saifNo ratings yet

- HS-65L CB Test ReportDocument37 pagesHS-65L CB Test ReportVictor PerezNo ratings yet

- 3082 Conductivity Meter ManualDocument19 pages3082 Conductivity Meter ManualEquipDocNo ratings yet

- Bite 2 and Bite 2P: Battery Impedance Test EquipmentDocument144 pagesBite 2 and Bite 2P: Battery Impedance Test EquipmentMichel Ivan SalyrosasNo ratings yet

- 7180 Rudder Angle Indicator: Owner's Operation, Installation & Maintenance ManualDocument24 pages7180 Rudder Angle Indicator: Owner's Operation, Installation & Maintenance Manualabduallah muhammadNo ratings yet

- Brookfield Viscometer AnaloogDocument37 pagesBrookfield Viscometer AnaloogNataša LukićNo ratings yet

- AcuDC 240 Power Energy Meter User ManualDocument93 pagesAcuDC 240 Power Energy Meter User ManualNgẫng NgợNo ratings yet

- 40L Insufflator Repair ProcedureDocument13 pages40L Insufflator Repair ProcedureErnesto GarcíaNo ratings yet

- Manual Operación y Mantenimiento BI652203-00-EnDocument394 pagesManual Operación y Mantenimiento BI652203-00-Enjlparedesy100% (1)

- RE5VL42ADocument29 pagesRE5VL42AroozbehxoxNo ratings yet

- BXT6500 Series PDFDocument76 pagesBXT6500 Series PDFjosue jetavionicsNo ratings yet

- General Reuse and Salvage Guideline For Hydraulic Piston Pumps and MotorsDocument157 pagesGeneral Reuse and Salvage Guideline For Hydraulic Piston Pumps and MotorsIngemak UrbanoNo ratings yet

- New Procedure DLR PDFDocument68 pagesNew Procedure DLR PDFAll in OneNo ratings yet

- Стандартные методы маркировки деталей САТDocument34 pagesСтандартные методы маркировки деталей САТforgotten.planet.2023No ratings yet

- 3180 OXIMETRO 1905 v3Document25 pages3180 OXIMETRO 1905 v3Ernesto AcostaNo ratings yet

- SMARTLYTE Service ManualDocument81 pagesSMARTLYTE Service Manualقابوس الراشديNo ratings yet

- 2303 KEITHLEY User ManualDocument152 pages2303 KEITHLEY User ManualHưng HuỳnhNo ratings yet

- MT-215 TTLDocument14 pagesMT-215 TTLTecnicos SlotsNo ratings yet

- Rs1483 - Genius1022-1023-Nm32la User Manual Rev 12 PN Um-0001 Rsid 1483 enDocument33 pagesRs1483 - Genius1022-1023-Nm32la User Manual Rev 12 PN Um-0001 Rsid 1483 enHieu LeNo ratings yet

- Biorad 680 ManualDocument68 pagesBiorad 680 ManualAnonymous GpSrL6rjNo ratings yet

- Instruction Manual: Model 680 Microplate ReaderDocument69 pagesInstruction Manual: Model 680 Microplate ReaderEdgar Mendoza GarcíaNo ratings yet

- Mettler Sonicare 730 Service ManualDocument28 pagesMettler Sonicare 730 Service ManualMari Olson100% (1)

- CM 21 002 RevCDocument113 pagesCM 21 002 RevCYolanda PeñaNo ratings yet

- Installation and operating instructions for Movitec V 2, 4, 6 & 90 High-Pressure In-Line pumpsDocument28 pagesInstallation and operating instructions for Movitec V 2, 4, 6 & 90 High-Pressure In-Line pumpsRenderf AlipioNo ratings yet

- 21010-BAE-70000-In-SP-0030 Tech Spec For Inst. and Controls For Packaged EquipmentDocument52 pages21010-BAE-70000-In-SP-0030 Tech Spec For Inst. and Controls For Packaged EquipmentJignesh BanavaNo ratings yet

- Emc Test Report: Tim Chen Andy ZhangDocument25 pagesEmc Test Report: Tim Chen Andy ZhangNara NocheNo ratings yet

- Boss 332 545 551 Use - Maintenance ManualDocument140 pagesBoss 332 545 551 Use - Maintenance ManualbadrezzineNo ratings yet

- HI PE PLUS Operator ManualDocument24 pagesHI PE PLUS Operator ManualVenera Segunda ManoNo ratings yet

- 411-254-0EI Hydraulic EdgeofDock InstallationOwnersManualDocument24 pages411-254-0EI Hydraulic EdgeofDock InstallationOwnersManualUttam Kumar GhoshNo ratings yet

- Safety of Household and Similar Electrical Appliances Part 2-29: Particular Requirements For Battery ChargersDocument158 pagesSafety of Household and Similar Electrical Appliances Part 2-29: Particular Requirements For Battery ChargersFemko CorporationNo ratings yet

- VC0706 Digital Video Processor DatasheetDocument0 pagesVC0706 Digital Video Processor Datasheetcopperratt7228No ratings yet

- Adapter Engine Bleed TestDocument23 pagesAdapter Engine Bleed Testabu72100% (1)

- NEHS1175-00 Caterpillar Cam Bearing R&I ToolDocument6 pagesNEHS1175-00 Caterpillar Cam Bearing R&I ToolnixcaloNo ratings yet

- Operational, Functional and Configuration Manual: Generator ControlDocument254 pagesOperational, Functional and Configuration Manual: Generator Controlsorangel_123No ratings yet

- Brookfield Manual PDFDocument36 pagesBrookfield Manual PDFAnonymous T32l1RNo ratings yet

- Inspection and Reuse of Critical Fasteners Used in All EnginesDocument30 pagesInspection and Reuse of Critical Fasteners Used in All Enginesma.powersourceNo ratings yet

- Manual 7215 RevC 2000 PDFDocument88 pagesManual 7215 RevC 2000 PDFJEFFREY DEE MAURY NORIEGANo ratings yet

- DC 146 Series Oven Manual 04-21-11Document72 pagesDC 146 Series Oven Manual 04-21-11vividor_aNo ratings yet

- Cardinal Scale 205 Weight Indicator Installation and Technical ManualDocument58 pagesCardinal Scale 205 Weight Indicator Installation and Technical ManualKennyGabrielNo ratings yet

- Part Manual Serie 40112Document316 pagesPart Manual Serie 40112gabrielperezv100% (1)

- AcuDC 240 Power Energy Meter User Manual PDFDocument93 pagesAcuDC 240 Power Energy Meter User Manual PDFFeriferi FerencNo ratings yet

- BIOBASE Horizontal Laminal Flow Cabinet BBS-H1100'1500' BBS-H1800 (X) User Manual 202007Document26 pagesBIOBASE Horizontal Laminal Flow Cabinet BBS-H1100'1500' BBS-H1800 (X) User Manual 202007iqbalNo ratings yet

- Pirates Past Noon Chapter SummaryDocument20 pagesPirates Past Noon Chapter SummaryGuerrilla Mystic100% (2)

- What Are Hydrometeorological HazardsDocument3 pagesWhat Are Hydrometeorological Hazardsamika sugiyamaNo ratings yet

- Pa31t OmDocument91 pagesPa31t OmPercy HornickelNo ratings yet

- Uttarakhand 10Document15 pagesUttarakhand 10Suhasi SNo ratings yet

- Aarushi Patidar Geography PPT On Weather Conditions in Different Parts of IndiaDocument14 pagesAarushi Patidar Geography PPT On Weather Conditions in Different Parts of IndiaAarushi PatidarNo ratings yet

- Jubail United Petrochemical Company (United) Job Safety Analysis - Worksheet (Attachment V)Document4 pagesJubail United Petrochemical Company (United) Job Safety Analysis - Worksheet (Attachment V)Muhammad Umar GondalNo ratings yet

- Et ZC362-L9Document31 pagesEt ZC362-L9rajpd28No ratings yet

- Texto Traducion InglesDocument6 pagesTexto Traducion InglesLeyner José Córdoba100% (1)

- 400 Golden Rules of English GrammarDocument50 pages400 Golden Rules of English GrammarTanvir Fuad75% (4)

- Aditional Words List For Spelling Bee Regional ContestDocument2 pagesAditional Words List For Spelling Bee Regional ContestElmer EscobedoNo ratings yet

- Corrosion Under InsulationDocument28 pagesCorrosion Under InsulationNurulFatimahalzahra100% (7)

- GLITTERING LYRICSDocument31 pagesGLITTERING LYRICSNurul Chiko-pyon IzraNo ratings yet

- Understanding PoetryDocument79 pagesUnderstanding PoetryDesigner61100% (2)

- Rossby and Kelvin WaveDocument18 pagesRossby and Kelvin Waveayu_28488No ratings yet

- HeliconiaDocument4 pagesHeliconiaGayathri AgNo ratings yet

- Masonry Walls Materials and ConstructionDocument8 pagesMasonry Walls Materials and ConstructionPedro SilveiraNo ratings yet

- Bulla Ice Cream-Quiz 2Document3 pagesBulla Ice Cream-Quiz 2JASPREET KAURNo ratings yet

- Science GR 345 4th Quarter MG Bow 1Document8 pagesScience GR 345 4th Quarter MG Bow 1api-359551623No ratings yet

- Moldova PlateauDocument9 pagesMoldova PlateauCojocaru EmiliaNo ratings yet

- Tongue TwistersDocument63 pagesTongue Twistersazlinazainal80No ratings yet

- Uganda's Location on East Africa MapDocument55 pagesUganda's Location on East Africa MapMonydit santinoNo ratings yet

- Waterproofing and Damp ProofingDocument5 pagesWaterproofing and Damp ProofingAnand KunkulolNo ratings yet

- Planning Principles for Residential BuildingsDocument12 pagesPlanning Principles for Residential BuildingsAbhyudayaPrakashNo ratings yet

- Evidence of Global Warming in Nigeria: Ukponmwan. H. Nosakhare and Ajibade, F. BrightDocument9 pagesEvidence of Global Warming in Nigeria: Ukponmwan. H. Nosakhare and Ajibade, F. BrightEditor IJRITCCNo ratings yet

- Lighting Comparison Chart PDFDocument2 pagesLighting Comparison Chart PDFpaul_aldNo ratings yet

- Man Overboard Rescue TurnDocument3 pagesMan Overboard Rescue TurnBorislav PetrovNo ratings yet

- PsychrometryDocument7 pagesPsychrometryVirma Anne CorpuzNo ratings yet

- Basic Science QuizesDocument50 pagesBasic Science QuizesHailey ConstantinoNo ratings yet

- Drought AnalysisDocument13 pagesDrought AnalysisSrikanth ReddyNo ratings yet

- Termite ControlDocument8 pagesTermite ControlJoshua EdokpayiNo ratings yet