Professional Documents

Culture Documents

RL101

Uploaded by

docrafiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RL101

Uploaded by

docrafiCopyright:

Available Formats

Field Automation Systems

Specification Sheet 4:RL101 January 2000

ROCLINK Configuration Software

The RL101 ROCLINK Configuration Software (Version 2.2) is used to configure and monitor FloBoss 500 Flow Managers, FloBoss 407 Flow Managers, and ROC300Series Remote Operation Controllers (ROCs) with a FlashPAC or ROCPAC, including all Canadian custody transfer versions. Some of the many functions provided are: configuring I/O points, AGA flow calculations, and the history database; calibrating meter inputs (using up to five calibration points); and retrieving log data. The software requires at least 450 Kbytes of RAM and runs on a personal computer (minimum of a 486DX processor) using DOS 5.0 or higher. It can also run as a DOS application with Microsoft Windows 3.1, 95, 98, or NT. The computer needs a high-density 3.5-inch floppy drive, 640 Kbytes of base RAM, and 10 Mbytes of free hard drive space. The ROCLINK software is designed for ease of use. Pulldown menus simplify accessing the functions provided by the software, and dialog boxes help to direct selections and data entry. Actions can be performed either by using the keyboard or by using a pointing device such as a mouse. When you select an item from a menu, a screen appears that provides the requested information in an easy-to-read format and lets you enter the applicable configuration data. The menu structure lists choices from which you can select the desired function. Some items, when selected, bring up another menu, which lists additional functions. Once a function is selected, the associated screen or dialog box displays. Help screens can be accessed either from the Help menu or in a context-sensitive fashion from within the menus and screens. This feature makes it easy to obtain on-line information for any ROCLINK topic. A typical screen (see Figure 1) displays parameters and their associated values or selected options. Values are contained in data fields, many of which can be edited. Some parameters have options listed below them, with the selected option marked. Pushbuttons bring up dialog boxes for further configuration details, or perform a desired action, such as the Save pushbutton shown in Figure 1. The pushbuttons can be activated either by clicking with a mouse or by pressing a key (such as the Enter key or a function key). A status line at the bottom of the screen contains pertinent information about the option or parameter currently highlighted. Dialog boxes are areas that pop up on the screen, allowing further selections to be made or values to be entered. They can also display to provide messages and more detailed information.

TM

The User Interface

The ROCLINK software employs a character-based graphical user interface, similar in many ways to the Windows operating system. Upon logging on to the ROCLINK software, you see the available functions presented in drop-down menus (see Figure 1).

Menu Bar Menu Data Field

Pushbutton Status Line Figure 1. Sample Configuration Screen

ROCLINK, FloBoss, Fisher, Fisher-Rosemount, and Managing The Process Better are marks owned by the Fisher-Rosemount group of companies. All other marks are the property of their respective owners. Fisher Controls International, Inc. 1996-2000. All Rights Reserved.

Field Automation Systems

File

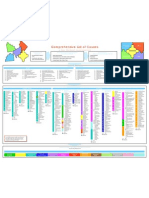

Direct Connect ROC Directory Upgrade to FlashPAC3 Quick Setup3 New FB503/553 Configuration FB504 Configuration Open.. Event File Alarm File Audit Log File Minute History File Hourly History File Daily History File ROCPAC Config. File FLASH Config. File Collect ROC Data...2 All EFM Report History Events/Alarms Download...2 ROC Config. to Disk Disk Config. to ROC User Programs3 Update Firmware3 Update Hardware3 Configure ROCLINK Convert... Minute History File Hourly History File Daily History File ROCLINK Security1 Print Configuration2 EFM Reports1 Macros1 Record Macro Play Macro Stop Recording Exit

Specification Sheet 4:RL101 Page 2 History

Setup Min/Max Minute Hour Day Events Alarms Audit Log3

Meter

Plate Change Calibration Setup Gas Quality History3 EFM Reports Select Meter Type3

I/O

MVS Sensor3 Analog Inputs Analog Outputs3 Discrete Inputs3 Discrete Outputs3 Pulse Inputs3

Utilities

User Programs3 Security... ROCLINK Operator FB500 Logon Op3 ROC400 LCD Op3 ROC300 LCD Op3 Macros... Record Macro Play Macro Stop Recording ROC Memory AI Calibration3 MVS Calibration3 Calibration Values3

Data

PID Control3 FST... Register Editor Soft Points Tank Monitoring3 Radio Control3 Opcode Setup Modbus3 Modbus Config3 Modbus Registers3 User List Setup LCD Setup3 User Data3

System

Clock Information Flags Comm Ports

Help

Getting Started Keys Help Contents About

Display

New Display Display 13 Display 23 Display on Disk Monitor... Flow Discrete Input3 Discrete Output3 Analog Input Analog Output3 Pulse Input3 PID Loop3

KEY: 1 Initial menu only 2 Not included on initial menu 3 Device Dependent

Figure 2. Menu Tree for the ROCLINK Software

Figure 2 shows the overall menu structure for the functions that can be performed using the ROCLINK software. Note that some functions may not be available, depending on the users access level and the way that the FloBoss or ROC is equipped. ROCLINK can record custom sequences called macros, which can play back dozens of keystrokes at a time.

Security

The software provides multiple levels of security for controlling access to ROCLINK functions as well as the FloBoss/ROC database. Making changes to passwords or to the access level for personnel is accomplished through the Security menu, which is available only to an authorized person.

Customizing Features

You can build custom displays for the FloBoss or ROC that combine both graphic and dynamic data elements. Using ROCLINK, the displays can then be used to monitor the operation of a FloBoss or ROC in its application either locally or remotely.

The contents of this publication are presented for informational purposes only. While every effort has been made to ensure informational accuracy, they are not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. Fisher Controls reserves the right to modify or improve the designs or specifications of such products at any time without notice.

For information, contact Fisher Controls: Marshalltown, Iowa 50158 USA Singapore 128461 Cernay 68700 France Sao Paulo 05424 Brazil

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- AGA Calculations 1985 VS 1992 StandardsDocument26 pagesAGA Calculations 1985 VS 1992 StandardsGeorge KasepNo ratings yet

- The Calibration of Flow Meters PDFDocument35 pagesThe Calibration of Flow Meters PDFRené Mora-CasalNo ratings yet

- The Forrester Wave™ - Enterprise BI Platforms (Vendor-Managed), Q3 2019Document21 pagesThe Forrester Wave™ - Enterprise BI Platforms (Vendor-Managed), Q3 2019julius gamboaNo ratings yet

- SAS - ChecklistDocument27 pagesSAS - ChecklistmfilipelopesNo ratings yet

- C++ Programming ExercisesDocument6 pagesC++ Programming Exercisesragunath32527117No ratings yet

- CommissioningDocument12 pagesCommissioningchowhk100% (4)

- Danload 6000 - Worksheets and SpecificationsDocument16 pagesDanload 6000 - Worksheets and Specificationseschulz78No ratings yet

- Mms PaperDocument14 pagesMms Papernom3formoiNo ratings yet

- Rvreaaaa GGREDocument1 pageRvreaaaa GGREdocrafiNo ratings yet

- TypicallyDocument1 pageTypicallydocrafiNo ratings yet

- Biugluglgp 7Document1 pageBiugluglgp 7docrafiNo ratings yet

- Word XpresssDocument1 pageWord XpresssdocrafiNo ratings yet

- HTC 10 - HTC 10 User GuideDocument172 pagesHTC 10 - HTC 10 User GuidedocrafiNo ratings yet

- DownloadlllDocument1 pageDownloadllldocrafiNo ratings yet

- RandomlyDocument1 pageRandomlydocrafiNo ratings yet

- Dyna CimDocument1 pageDyna CimdocrafiNo ratings yet

- BFBNDFNDG SRGSH hreHeHDocument1 pageBFBNDFNDG SRGSH hreHeHdocrafiNo ratings yet

- MonalyDocument1 pageMonalydocrafiNo ratings yet

- MonalyDocument1 pageMonalydocrafiNo ratings yet

- CLXDocument1 pageCLXdocrafiNo ratings yet

- DoccccDocument5 pagesDoccccdocrafiNo ratings yet

- Comprehensive List of CausesDocument1 pageComprehensive List of CausesAndy DolmanNo ratings yet

- DoccccDocument5 pagesDoccccdocrafiNo ratings yet

- HART Interface Card: Specification SheetDocument2 pagesHART Interface Card: Specification SheetdocrafiNo ratings yet

- Comprehensive List of CausesDocument1 pageComprehensive List of CausesAndy DolmanNo ratings yet

- Combination ModuleDocument252 pagesCombination ModuledocrafiNo ratings yet

- DoccccDocument5 pagesDoccccdocrafiNo ratings yet

- CPU 95 BrochureDocument6 pagesCPU 95 BrochuredocrafiNo ratings yet

- 63 PimDocument2 pages63 PimdocrafiNo ratings yet

- Combination ModuleDocument252 pagesCombination ModuledocrafiNo ratings yet

- Flame MonitorDocument44 pagesFlame MonitordocrafiNo ratings yet

- RLwin A6091Document242 pagesRLwin A6091docrafiNo ratings yet

- Surface Engineering Chapter DeGarmo's MaterialsDocument40 pagesSurface Engineering Chapter DeGarmo's MaterialsdocrafiNo ratings yet

- D 301028 X 012Document4 pagesD 301028 X 012docrafiNo ratings yet

- Architectural Challenges in Agile PracticeDocument4 pagesArchitectural Challenges in Agile PracticePranab PyneNo ratings yet

- What Is TXE - 514738 - ByTt - TXEFW - CompGuide - Rev2p0Document175 pagesWhat Is TXE - 514738 - ByTt - TXEFW - CompGuide - Rev2p0Sumit BansalNo ratings yet

- Impacts of Emerging TechnologiesDocument3 pagesImpacts of Emerging TechnologieskumNo ratings yet

- Bus Scheduling and Booking System AbstractDocument2 pagesBus Scheduling and Booking System AbstractMagesh KarthikNo ratings yet

- VNX DP Upgrading Disk FirmwareDocument5 pagesVNX DP Upgrading Disk Firmwarevijayen123No ratings yet

- Face Sketch Synthesis Via Sparse Representation-Based Greedy SearchDocument6 pagesFace Sketch Synthesis Via Sparse Representation-Based Greedy SearchshaliniNo ratings yet

- An Introduction To: Compressive SensingDocument28 pagesAn Introduction To: Compressive Sensingsomu6402No ratings yet

- Usb Cam LogDocument3 pagesUsb Cam LogKunal GaikwadNo ratings yet

- (2010) Product Reed-Solomon Codes For Implementing NAND Flash Controller On FPGA Chip 05445821Document5 pages(2010) Product Reed-Solomon Codes For Implementing NAND Flash Controller On FPGA Chip 05445821t67678No ratings yet

- Parminder Bhatia: Industrial ExperienceDocument3 pagesParminder Bhatia: Industrial ExperienceParminder BhatiaNo ratings yet

- Advanced Diploma in Cyber Defense Overview (ADCDDocument8 pagesAdvanced Diploma in Cyber Defense Overview (ADCDrahulmultivisionNo ratings yet

- Nonlinear Programming Solution TechniquesDocument9 pagesNonlinear Programming Solution Techniquesprincesslove521_4165No ratings yet

- AWS DevOps Online Training 60 DaysDocument5 pagesAWS DevOps Online Training 60 DaysSampath PolishettyNo ratings yet

- Logistic Regression Learning AnnotatedDocument77 pagesLogistic Regression Learning AnnotatedJuan Esteban Mejia VelasquezNo ratings yet

- Concept of Computer FilesDocument9 pagesConcept of Computer Filespower2014No ratings yet

- Autoit Help ManualDocument37 pagesAutoit Help ManualBotykai ZsoltNo ratings yet

- Wrong ResultsDocument18 pagesWrong ResultsConstantin CaiaNo ratings yet

- Animish Gadve ResumeDocument1 pageAnimish Gadve Resumeagadve4690No ratings yet

- AN957 - dsPIC33FJ12MC202 VersionDocument3 pagesAN957 - dsPIC33FJ12MC202 VersiontedozallennNo ratings yet

- Vyatta-QuickStart 6.5R1 v01Document55 pagesVyatta-QuickStart 6.5R1 v01Arturo M. GittensNo ratings yet

- 8086 Final ProjectDocument30 pages8086 Final ProjecttiggafputuhsNo ratings yet

- Technology Guide 3: Information Technology For Management 4 Edition Turban, Mclean, Wetherbe John Wiley & Sons, IncDocument29 pagesTechnology Guide 3: Information Technology For Management 4 Edition Turban, Mclean, Wetherbe John Wiley & Sons, Incjaydeep.panchasara7189No ratings yet

- Layer 7 SOA OverviewDocument2 pagesLayer 7 SOA OverviewLayer7TechNo ratings yet

- Driving Two Stepper Motors at The Same TimeDocument3 pagesDriving Two Stepper Motors at The Same TimeMohammed Al Hosini100% (2)

- Push Notification Setup On KamailioDocument32 pagesPush Notification Setup On KamailioAbid Ur RehmanNo ratings yet

- Complete Final Sem Report PDFDocument79 pagesComplete Final Sem Report PDFbhanu pratap mishraNo ratings yet