Professional Documents

Culture Documents

Sti - Is - 3589

Uploaded by

hhr2412Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sti - Is - 3589

Uploaded by

hhr2412Copyright:

Available Formats

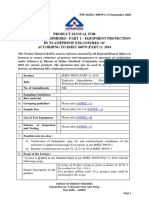

DOC : STI/3589/7

May 2006

SCHEME OF TESTING AND INSPECTION

FOR CERTIFICATION OF

STEEL PIPES FOR WATER

AND SEWAGE (168.3 to 2032 mm outside diameter)

ACCORDING TO IS 3589:2001

(Incorporating Amendment No.1 to 3)

1.0 LABORATORY- A laboratory shall be maintained which shall be suitably equipped and

staffed, where different tests given in the specification shall be carried out in accordance with the

methods given in the specification.

1.1 All testing apparatus shall be periodically checked and calibrated records of such

checks/calibration shall be maintained.

2.0 TEST RECORDS- All records of tests and inspection shall be kept in suitable forms

approved by the Bureau.

2.1 Copies of any records and other connected papers that may be required by the Bureau shall be

made available at any time on request.

3.0 QUALITY CONTROL- It is recommended that, as far as possible, statistical Quality control

(SQC) methods may be used for controlling the quality of the products during production as

envisaged in this scheme (see IS 397 (part 1): 2003 IS 397 (part 2): 2003and IS 397 (part 3): 2003).

3.1 In addition, effort should be made to gradually to introduce Quality Management system in

accordance with IS/ISO 9001:2000

4.0 STANDARD MARK The Standard Mark, as given in column (1) of the first schedule of the

Licence, shall be applied at a suitable place on the outside surface of the pipe provided always that

pipes so marked conform to all the requirements of the specification.

4.1 MARKING- In addition, following information shall be marked indelibly on the pipe:

a) Manufacturers name or trade mark;

b) Pipe designation;

c) Outside diameter and specified wall thickness,

d) Identification mark in code or otherwise to enable the date and lot of manufacture to be

traced back to works records, and

e) Licence number (CM/L..)

5.0 LEVELS OF CONTROL The tests, as indicated in Table 1 attached and at the levels of

control specified therein, shall be carried out on the whole production of the factory which is

covered by this scheme and appropriate records and charts maintained in accordance with

paragraph 2.0 above. All the production, which conforms to the Indian Standards and covered by

the Licence, shall be marked with BIS certification mark.

5.1 5.1 In respect of all other clauses of the specification and at all stages of manufacture the factory

shall maintain appropriate controls and checks to ensure that their product conforms to the various

requirements of the specification.

DOC : STI/3589/7

May 2006

6.0 REJECTIONS- A separate record shall be maintained giving information relating to the

rejection of the production not conforming to the requirements of the specification and the method

of its disposal. Such material shall in no circumstances be stored together with those conforming to

the specification.

7.0 SAMPLES The licensee shall supply, free of charge, the samples required in accordance

with the Bureau of Indian Standards (Certification) Regulations, 1988, as subsequently amended,

from the factory or godowns. The Bureau shall pay for the samples taken by it from the open

market.

8.0 REPLACEMENT Whenever a complaint is received soon after the goods with Standard

marks have been purchased and used, and if there is adequate evidence that the goods have not

been misused, defective goods are replaced free of cost by the licensee in case the complaint is

proved to be genuine and the warranty period (where applicable) has not expired. The final

authority to judge the conformity of the product to the Indian Standard shall be with the Bureau.

The firm shall have own complaint investigation system as per IS 15400.

8.1 In the event of any damages caused by the goods bearing the standard Mark or claim being

filed by the consumer against BIS Standard mark and not conforming to the relevant Indian

Standard, entire liability arising out of such non conforming product shall be of licensee and BIS

shall not in any way be responsible in such cases

9.0 STOP MARKING The marking of the product shall be stopped under intimation to the

Bureau if, any time, there is some difficulty in maintaining the conformity of their product to the

specification, or the testing equipment goes out of order. The marking may be resumed as soon

as the defects are removed under intimation to Bureau.

9.1 The marking of the product shall be stopped immediately if directed to do so by Bureau for

any reason. The marking may than be resumed only after permission by the Bureau. The

information regarding resumption of marking shall also be sent to the Bureau.

10.0 PRODUCTION DATA The licensee shall send to BIS as per the enclosed proforma- 1 to

be authenticated by a chartered accountant a statement of quantity produced, marked and

exported by him and trade value thereof at the end of each operative year of the licence.

Table 1...

DOC: STI 3589/7

MAY 2006

IS 3589:2001

STEEL PIPES FOR WATER

AND SEWAGE (168.3 TO 2032 mm outside diameter)

TABLE 1 LEVELS OF CONTROL

(Para5 of the STI)

TEST DETAILS LEVELS OF CONTROL

Test Method Clause Requirement

Clause Reference

No. of

Samples

Lot Size Frequency

REMARKS

8 Chemical composition The relevant clauses

of the relevant parts

of IS 228 and Table

2of IS 3589:2001

One One heat Every heat in

the

consignment

No chemical analysis is

required for identified

material received with test

certificate and covered

under BIS certification

scheme.

12 Tolerances

a) Length

b) Diameter

c) Thickness

d) Straight-ness

e) Ovality

f) Mass

12.4

12.3.1

12.3.2

12.5

12.3.3

12.1

IS 3589:2001

One

One hour production

of pipes of one

particular size and

steel grade

Every one

hour

In case the sample fails,

that hours production shall

not be marked unless

defective pipes are sorted

out.

10. Hydraulic pressure test 10 -do- Each pipe Those found not

conforming shall not be

marked. NDT test may be

carried out in place of

hydraulic pressure test.

Method for NDT and the

acceptance level shall be as

agreed to between the

manufacturer and the

purchaser.

9.1 Tensile Strength 9.1 &

table 4

IS:3589:2001 One Each consignment of same thickness of

skelp/plate, and size of pipes and day of

production

Incase the sample fails, two

more such samples from

different pipes shall be

drawn and tested. In the

event of any further failure

the entire days production

shall not be marked.

DOC: STI 3589/7

MAY 2006

IS 3589:2001

SEAMLESS OR ELECTRICALLY WELDED STEEL PIPES FOR WATER

AND SEWAGE (168.3 TO 2032 mm outside diameter)

TABLE 1 LEVELS OF CONTROL

(Para 5 of the STI)

TEST DETAILS LEVELS OF CONTROL

Test Method Clause Requirement

Clause Reference

No. of

Samples

Lot Size Frequency

REMARKS

9.2 Flattening test or bend

test

9.2.1 Flattening test for ERW

pipes

9.2.1 IS3589:2001 One a)Four hour production

of one particular size &

steel grade for pipes upto

& including 350 mm OD

b) 12 hrs production of

one particular size &

steel grade for pipes

above 350mm OD upto

& including 900 mm OD

c) 24 hours production

of one particular size &

steel grade for pipes

above 900 mm OD

Every four

hours

Every 12

hours

Every 24

hours

In case of failure of the

samples, the whole lot of

pipes represented by these

samples shall be tested for

test on weld and those

found failing shall be

rejected.

-do-

-do-

9.2.3 Flattening Test for

seamless pipes

9.2.3 -do- One -do- -do- -do-

9.3 Guided Bend Test (for

SAW Pipes)

9.3 -do- One -do- -do- -do-

DOC: STI 3589/7

MAY 2006

IS 3589:2001

SEAMLESS OR ELECTRICALLY WELDED STEEL PIPES FOR WATER

AND SEWAGE (168.3 TO 2032 mm outside diameter)

TABLE 1 LEVELS OF CONTROL

(Para5 of the STI)

TEST DETAILS LEVELS OF CONTROL

Test Method Clause Requirement

Clause Reference

No. of

Samples

Lot Size Frequency

REMARKS

16 Guideline of coating

16.1 Protective coating if

required

16.1

Annex

A to D

-do-

One

Four hour production

of one particular Size

& steel grade.

Every four

hour

In case the sample fails, the

tubes represented by the

sample shall not marked.

16.2 Galvanizing, if

required

16.2 -do-

IS 4736

One -do- -do- -do-

17

J oints & ends 17 IS 3589:2001 One One hour production

of one particular size

& steel grade

Every one

hour

Incase the sample fails that

hours production shall not

be marked.

14

Visual inspection,

Appearance and

workmanship

14.1 to

14.5

-do- Each

pipe

Those found conforming

shall be marked

You might also like

- Testing and inspection scheme for steel tubesDocument6 pagesTesting and inspection scheme for steel tubesPunam RabhaNo ratings yet

- 8887Document7 pages8887Aditya HundekarNo ratings yet

- Is: 1592Document4 pagesIs: 1592Daks ParkerNo ratings yet

- Sti 2062Document6 pagesSti 2062patrik710No ratings yet

- Scheme of Testing and Inspection For IS 613:2000Document6 pagesScheme of Testing and Inspection For IS 613:2000srj88eeeNo ratings yet

- Sti 2062Document7 pagesSti 2062fyzmfaNo ratings yet

- 1363 Scheme of Testing of Hexagonal Bolts & NutsDocument7 pages1363 Scheme of Testing of Hexagonal Bolts & Nutsjra9090No ratings yet

- Sti4923 8 PDFDocument7 pagesSti4923 8 PDFkprasad_56900No ratings yet

- Three-Phase Induction Motor Testing SchemeDocument6 pagesThree-Phase Induction Motor Testing SchemesutanuprojectsNo ratings yet

- StiDocument5 pagesStiderabeasNo ratings yet

- STI/14846/1 Dec.2000Document8 pagesSTI/14846/1 Dec.2000Tanmoy DuttaNo ratings yet

- Testing and inspection of static watthour metersDocument5 pagesTesting and inspection of static watthour metersBijuNo ratings yet

- Scheme for Testing and Certifying Portland Slag CementDocument9 pagesScheme for Testing and Certifying Portland Slag CementPooja UdupaNo ratings yet

- Quality Inspection and Testing of Household Sewing Machines HeadDocument19 pagesQuality Inspection and Testing of Household Sewing Machines HeadHarshaDesuNo ratings yet

- LPG Regulator Certification SchemeDocument10 pagesLPG Regulator Certification SchemejoysinhaNo ratings yet

- PVC Pipe Testing Scheme RevisionDocument9 pagesPVC Pipe Testing Scheme RevisionSunil Devdutt ThakoreNo ratings yet

- Central Marks Department-Iii Our Ref: CMD-III/16:15490 30 Oct 2006 Subject: Sulphide Stress Cracking Resistance Test On CNG Cylinders As Per Is 15490:2004Document9 pagesCentral Marks Department-Iii Our Ref: CMD-III/16:15490 30 Oct 2006 Subject: Sulphide Stress Cracking Resistance Test On CNG Cylinders As Per Is 15490:2004ravisharma1973No ratings yet

- Implementation of Amendment No 1 to IS 814Document11 pagesImplementation of Amendment No 1 to IS 814Brijesh SharmaNo ratings yet

- Sti 14220Document5 pagesSti 14220Dgk RajuNo ratings yet

- 3832 - 4-Chain Pulley BlockDocument8 pages3832 - 4-Chain Pulley BlockAshish PattanaikNo ratings yet

- Is 13849. 1993Document6 pagesIs 13849. 1993poornachandraknNo ratings yet

- Testing irrigation emittersDocument4 pagesTesting irrigation emittersVikas PhopaleNo ratings yet

- Bureau of Indian Standards: Central Marks Department - IiiDocument6 pagesBureau of Indian Standards: Central Marks Department - IiiVaiby CoolNo ratings yet

- PDFDocument6 pagesPDFAshutosh JoshiNo ratings yet

- gs102 1Document9 pagesgs102 1medodedo201050% (2)

- LT XLPE Power Cable SpecificationDocument9 pagesLT XLPE Power Cable SpecificationRakesh ShinganeNo ratings yet

- Prelaminated Particle Board Testing SchemeDocument4 pagesPrelaminated Particle Board Testing Schemeraviteja036No ratings yet

- 2347Document5 pages2347Abhijeet MisraNo ratings yet

- Proposed Changes to IRS-T-29-2000 CMS Crossing Manufacturing StandardsDocument11 pagesProposed Changes to IRS-T-29-2000 CMS Crossing Manufacturing StandardsShipra MishraNo ratings yet

- Certification of Plywood For Concrete Shuttering WorkDocument10 pagesCertification of Plywood For Concrete Shuttering WorkJGD123No ratings yet

- Sti 2062 PDFDocument7 pagesSti 2062 PDFNarendra VermaNo ratings yet

- Scheme of Testing and Inspection For Certification of Carbon Steel Cast Billet Ingots Billets Blooms and Slabs For Re Rolling Into Seel For General Structural Purpose PDFDocument6 pagesScheme of Testing and Inspection For Certification of Carbon Steel Cast Billet Ingots Billets Blooms and Slabs For Re Rolling Into Seel For General Structural Purpose PDFbipinagarwalNo ratings yet

- AnnexureDocument3 pagesAnnexureqamarNo ratings yet

- Nepal Standards Certification Scheme for Testing and Inspection of Deformed Steel BarsDocument13 pagesNepal Standards Certification Scheme for Testing and Inspection of Deformed Steel BarsLakshman KhanalNo ratings yet

- Astm B517-09Document3 pagesAstm B517-09Srinivasan KrishnamoorthyNo ratings yet

- Group Structured Wall Piping STI GuidelinesDocument8 pagesGroup Structured Wall Piping STI GuidelinesMarketing Dept APEL 1100% (1)

- INSTA SBC EN 13589-2 Sep 2009Document17 pagesINSTA SBC EN 13589-2 Sep 2009Kipodim100% (1)

- General Specification For Welding and Weld Inspection (EIL)Document19 pagesGeneral Specification For Welding and Weld Inspection (EIL)Mitchel Fernandes100% (6)

- Sulphur Removal UnitDocument73 pagesSulphur Removal UnitClaudio AmoreseNo ratings yet

- 07 - CP 11-14-7 - Reinforcing Steel PDFDocument6 pages07 - CP 11-14-7 - Reinforcing Steel PDFRyan100% (1)

- Product Manual For Explosive Atmospheres - Part 1 - Equipment Protection by Flameproof Enlcosures "D" ACCORDING TO IS/IEC 60079 (PART 1) : 2014Document7 pagesProduct Manual For Explosive Atmospheres - Part 1 - Equipment Protection by Flameproof Enlcosures "D" ACCORDING TO IS/IEC 60079 (PART 1) : 2014ranjith_007No ratings yet

- Engineering ProceduresDocument23 pagesEngineering ProceduresadammzjinNo ratings yet

- Self - Evaluation-Cum-Verification Report)Document13 pagesSelf - Evaluation-Cum-Verification Report)Rakesh PandeyNo ratings yet

- Nyse125 - Nickel Aluminium Bronze Castings For Water Service PDFDocument5 pagesNyse125 - Nickel Aluminium Bronze Castings For Water Service PDF이선엽0% (1)

- DFD8803 3lpeDocument33 pagesDFD8803 3lpeshoaib1985No ratings yet

- SS Material Tech ReqtDocument13 pagesSS Material Tech ReqtDinesh ShahNo ratings yet

- Quality Control Manual for Pressure Vessel FabricationDocument13 pagesQuality Control Manual for Pressure Vessel FabricationHoque AnamulNo ratings yet

- Monitoring & MeasurementsDocument158 pagesMonitoring & MeasurementsaszlizaNo ratings yet

- 3LPE Coating SpecsDocument36 pages3LPE Coating SpecsRudra Pandit100% (1)

- General Technical Specifications For CS & SS Pipes and Pipe FittingsDocument10 pagesGeneral Technical Specifications For CS & SS Pipes and Pipe FittingsrajaNo ratings yet

- RDSO specification bipolar corrosion inhibitorDocument13 pagesRDSO specification bipolar corrosion inhibitorRegina Miller100% (1)

- Inspection and Test ProcedureDocument8 pagesInspection and Test Proceduregaehdd1100% (1)

- Fabricated BogieDocument16 pagesFabricated BogiemailbkraoNo ratings yet

- Self Evaluation Verification ReportDocument13 pagesSelf Evaluation Verification Reportpandasukanta100% (1)

- Part K MATERIALS 430 - Erstl - K - Egstl - K-CV - 2013Document209 pagesPart K MATERIALS 430 - Erstl - K - Egstl - K-CV - 2013Dave DumontNo ratings yet

- Product Manual PM-1239-pt1-cmd2 PDFDocument12 pagesProduct Manual PM-1239-pt1-cmd2 PDFMohd Masoom AliNo ratings yet

- STI59864Document6 pagesSTI59864Paviter SinghNo ratings yet

- DIN en 1090 EnglishDocument2 pagesDIN en 1090 EnglishLiliana GeorgianaNo ratings yet

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- Reaffirmed 1996Document13 pagesReaffirmed 1996Ritesh kumarNo ratings yet

- Splitting Tensile Strength of Concrete - Method of TestDocument11 pagesSplitting Tensile Strength of Concrete - Method of Testhhr2412No ratings yet

- IS 9295-1983 With Amd3Document15 pagesIS 9295-1983 With Amd3hhr2412No ratings yet

- Weld Imperfections and Preventive MeasuresDocument25 pagesWeld Imperfections and Preventive Measuresecaph244100% (1)

- Is 6398 - 1983 PDFDocument12 pagesIs 6398 - 1983 PDFhhr2412No ratings yet

- IS-460-Part-3-1985 - 1997Document10 pagesIS-460-Part-3-1985 - 1997hhr2412No ratings yet

- Is 6394 - 2006Document6 pagesIs 6394 - 2006hhr2412No ratings yet

- Indian Standard (Second Revision) : Method For Bend TestDocument12 pagesIndian Standard (Second Revision) : Method For Bend Testhhr2412No ratings yet

- Is 2062 (2011) - Hot Rolled Medium and High Tensile Structural SteelDocument14 pagesIs 2062 (2011) - Hot Rolled Medium and High Tensile Structural Steelsridar_2004No ratings yet

- Is 6752 - 2014 PDFDocument7 pagesIs 6752 - 2014 PDFhhr2412No ratings yet

- Welding Inspection Multiple Choice QuestionsDocument4 pagesWelding Inspection Multiple Choice QuestionsSurendra KamalNo ratings yet

- Under FillDocument1 pageUnder Fillhhr2412No ratings yet

- 460 (Part-3)Document10 pages460 (Part-3)rambinod100% (1)

- Weld Imperfections and Preventive MeasuresDocument25 pagesWeld Imperfections and Preventive Measuresecaph244100% (1)

- Is 2041Document8 pagesIs 2041hhr2412No ratings yet

- Is - 2002 - 2007Document11 pagesIs - 2002 - 2007hhr2412No ratings yet

- 19a. IS 3601-2006 - BilanguageDocument30 pages19a. IS 3601-2006 - Bilanguagehhr2412No ratings yet

- Is-1566-1982 (2000)Document15 pagesIs-1566-1982 (2000)hhr2412100% (1)

- 3r. IS 10842 - 1984Document13 pages3r. IS 10842 - 1984hhr2412No ratings yet

- 1732 Steel BarsDocument6 pages1732 Steel Barsvarchasv_g0% (1)

- Is 228 Part 9Document5 pagesIs 228 Part 9np27031990100% (1)

- 1732 Steel BarsDocument6 pages1732 Steel Barsvarchasv_g0% (1)

- 1a6. IS 228 - Part - 06 - 1987Document11 pages1a6. IS 228 - Part - 06 - 1987hhr2412No ratings yet

- 1a11. IS 228 - Part - 11 - 1990Document6 pages1a11. IS 228 - Part - 11 - 1990hhr2412No ratings yet

- Is228 8Document5 pagesIs228 8Six RameshNo ratings yet

- 1a6. IS 228 - Part - 06 - 1987Document11 pages1a6. IS 228 - Part - 06 - 1987hhr2412No ratings yet

- 1a10. IS 228 - Part - 10 - 1989Document6 pages1a10. IS 228 - Part - 10 - 1989hhr2412No ratings yet

- 228 7Document5 pages228 7kumarvizayinNo ratings yet

- 1a6. IS 228 - Part - 06 - 1987Document11 pages1a6. IS 228 - Part - 06 - 1987hhr2412No ratings yet

- Sti - Is - 3589Document5 pagesSti - Is - 3589hhr2412No ratings yet