Professional Documents

Culture Documents

About Paper Coated

Uploaded by

bobokorCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

About Paper Coated

Uploaded by

bobokorCopyright:

Available Formats

About Paper

Coated products

About Paper

Coated products

www.torraspapel.com

1

Table of contents

1. Definition of coated products

2. Coated paper

2.1. Art paper

2.2. Triple-layer paper

2.3. Double-layer paper

2.4. 1/s coated paper

3. Cast coated products

3.1. Types of cast coated products

4. Carbonless products

4.1. Types of carbonless coated products

4.2. Uses of carbonless paper

A. Self-separating glue

B. De-sensitizing ink

C. Revealing sprays or felt-tipped markers

5. Thermal paper

5.1. Types of thermal paper

6. Metallized paper

6.1. Types of metallized paper

7. Solid bleached board (SBB)

7.1. Types of solid bleached board

8. Folding boxboard

9. Boxboard

10. Self-adhesive products

10.1.Types of self-adhesive products

A. Types of face material

B. Types of release liner

C. Types of adhesive

Summary

2

2

3

4

6

7

10

11

14

16

17

17

18

18

19

20

21

22

24

25

27

29

31

33

33

34

34

36

About Paper

Coated products

www.torraspapel.com

2

1. Definition of coated products

A coated product is one that has a covering consisting of a mix (or layer of coating) of

mineral and organic components, which is sometimes produced in its basic form, and

sometimes with added plastic or aluminium elements. The main aim of the coating is to

make the product more suitable for being printed on.

Coated products can have different numbers of layers of coating depending on the

quality required, and also different structural characteristics according to whether they

are going to be printed on in the form of sheets or reel.

Coated products are essentially intended for the publishing and advertising

sectors, although if we look at the market for cardboard and folding

boxboard varieties, we are entering into the heart of the packaging

products sector.

Below is a list of the different types of coated products which we will talk about during

the course of this unit.

Coated paper

Cast coated paper

Carbonless paper.

Thermal paper.

Metallized paper

Solid Bleached Board

Folding boxboard

Boxboard

Self-adhesive products

2. Varieties of coated paper

The varieties of coated paper which we produce can basically be differentiated in terms

of the concepts listed below:

The number of layers of coating applied to the paper (determining whether the

paper will be art paper, triple-layer paper, etc.).

The printing system to be used with the paper (rotogravure, offset, etc).

About Paper

Coated products

www.torraspapel.com

3

The type of machine used for printing (for sheets or for reels).

In terms of the concepts mentioned above, the four varieties of coated paper described

below will be produced:

Art paper.

Triple-layer paper.

Double-layer paper.

1/s coated paper.

2.1. Art paper

Art paper is defined as paper having three layers of coating on both sides of the

sheet. The amount of coating is usually quite large, coming to as much as 40 g/m

2

on

each side of the sheet in the case of substances higher than 200 g/m

2

.

It should be borne in mind that the amount of coating to be applied to paper can vary

according to its substance, since the layers of coating reduce the stiffness of the paper,

which for its part always requires a minimum amount of fibre.

Given its high level of coating, this type of paper gives a very high quality of printing, so

that it is important that it should be used for catalogues of products that demand a high

level of accuracy in the reproduction of the colours of the original product (catalogues

for furniture, catalogues for the sale of prestige products, etc.). These varieties usually

have a gloss, semi-matt or embossed finish and are printed on exclusively with the

sheet offset system.

The basic uses of art paper varieties are to be found almost exclusively in

the advertising sector. They can also, exceptionally, be used for publishing,

but the books concerned need to be of a very high quality, and their use for

this purpose is not very common.

In Figure no.1 can be seen an example of work completed on art coated paper.

About Paper

Coated products

www.torraspapel.com

4

Fig. 1: Printing on art coated paper.

2.2. Triple-layer paper

Triple-layer paper is similar to art paper, but with a thinner layer of coating, which

makes its quality of printing slightly inferior. This is the variety which currently has the

highest sales within the coated paper range.

The layer substance for this type of paper can vary between 25 and 30 g/m

2

on each

side of the sheet. It is found with a gloss, semi-matt or embossed finish, and is mainly

printed in sheet offset, although it can occasionally be printed using the rotogravure

system (normally for low substances) or using flexography (when used as part of self-

adhesive product face material).

The main uses of triple-layer paper are especially in the advertising

sector, although this type of paper can also be found in the high-quality

publishing sector.

In Figure no.2 are shown some products printed using this type of paper:

About Paper

Coated products

www.torraspapel.com

5

Fig. 2: Printing on triple-layer paper.

In the following table is a list of the basic uses both of art paper and of triple-layer

coated paper:

MAIN USES OF ART AND

TRIPLE-LAYER COATED PAPER

Luxury

publishing

Prestige

advertising

Catalogues

and

brochures

Memoirs

Calendars

Book covers

Post-cards

Posters

Files

About Paper

Coated products

www.torraspapel.com

6

2.3. Double-layer paper

A characteristic of double-layer paper is that the substance of the layer of coating is

about 20 g/m

2

on both sides of the sheet. This type of paper can have a gloss, semi-

matt, matt and even thick matt finish. The difference between the last two types of finish

is in the release liner, which in the case of the thick matt finish will have a lower level of

mineral composition (or load) so as to try to achieve a higher caliper.

Double-layer paper, also known as " industrial or modern coated paper" , is

used in the publishing sector, for colour supplements, magazines,

catalogues, etc.

In the following illustration can be seen some examples of printing on double-layer

paper:

Fig. 3: Printing on double-layer paper.

Double-layer paper can be printed on in sheets, but printing on reels is also quite

frequent. In the case of our paper varieties, printing both in sheets and in reels is

essentially carried out using the offset system. When printing on sheets, the action of

this variety in the paper machine is similar to that of the previous varieties (art and

triple-layer paper), although the profile of the print is less marked due to its thinner layer

of coating. In the case of printing on reels, the paper passes through the rotary drying

device known as the heat set, in which the temperature of the paper web can rise as

high as about 130

C.

One particularity of the "heat set" printing system is that both sides of the sheet are

printed simultaneously, and the drying process is carried out at the end. Due to the high

temperature attained by the paper, any water it contains evaporates, making it come off

the surface. This evaporation of the water may cause a problem of blistering, given that

About Paper

Coated products

www.torraspapel.com

7

the paper contains ink on both sides and usually in large quantities. Obviously, the

problem will be less important if the quantities of ink concerned are small, and by the

same token will be more critical in the case of gloss paper varieties, because they are

more calendered and thus more closed in and less porous.

In order to avoid the problem of blistering, the release liner paper will be produced with

a lower level of coating (so that it is more porous and will allow the water to emerge

more easily). In such cases, the level of substance of the paper is not usually higher

than 150 g/m

2

, due to the fact that when the substance increases, the porousness of

the paper diminishes and the chances of blistering occurring increase. Paper on reels is

also produced with a lower degree of humidity, so as to avoid problems both of

blistering and of register.

In the case of double-layer paper, there is currently a variety with a quality of 80 g/m

2

which is used as wrapping paper for cigarette packets and which replaces the old

wrapping paper for cartons of ten packets. This type of product is printed using the

rotogravure system.

In the following table the main uses of double-layer coated paper are listed:

MAIN USES OF DOUBLE-LAYER/

THICK COATED PAPER

School books

Direct Marketing

Diccionaries

Correspondence

Encyclopaedias

Magazines

Catalogues and

brochures

Advertising

Memoirs

2.4. 1/s Coated Paper

1/s coated paper (with the coating on one side only) represents a speciality product

within the range of double-layer coated paper varieties. It nearly always has a gloss

finish, although it sometimes also has an embossed finish.

This type of paper always has a special treatment on the reverse side so as to avoid

curling up of the edges, which is a very complicated problem that appears during

printing, and is more frequent in this type of paper than in those with coatings on both

sides due precisely to the fact of having a difference between the two sides of the

sheet.

About Paper

Coated products

www.torraspapel.com

8

The market for 1/s coated paper is basically centred on labels, although the

product also has a significant share in other markets, such as cigarettes (in

terms of the soft packet sector), chocolate wrappers, book covers, etc.

1/s coated paper is considered a special paper, due not so much to the printing systems

used with it (which are normally the conventional ones) as to the multiple treatments to

which it is subsequently subjected, such as guillotining, die-cutting, or being used in

"labelling devices".

Depending on the end uses to which it is put, 1/s coated paper has numerous

specialized varieties, such as the following:

Standard 1/s coated paper. This is a product which is used for labels that do

not need any additional treatment, such as those used for wine or spirit bottles

that are non-returnable (fig. 4).

Fig. 4: Label for non-returnable bottle.

WS 1/s coated paper. This is the paper which is used for labels for products

sold in returnable bottles. Its treatment gives the paper a high level of resistance

to humidity, so that when the bottles are washed before being re-filled and re-

labelled, the old labels can be removed from the bottles without getting torn

during the "washing" process. If this were not the case, they would cause

dirtiness and make it necessary to change the washing water, which would

greatly increase costs.

The designation WS (wet strength, or resistance to humidity) is also used for

other products intended for the returnable bottle market, which we shall talk

about later.

RH 1/s coated paper. This product is suitable for rotogravure printing and is

essentially intended for yoghurt labels. This variety's main characteristic is that it

needs a high degree of smoothness and compressibility in order to be able to be

About Paper

Coated products

www.torraspapel.com

9

printed on satisfactorily, in addition to a reverse side that can accept the

attachment of heat-sealable glue so that the label can be attached to the plastic

container of the yoghurt through the effects of heat.

Fig. 5: Yoghurt labels.

Fungicidal 1/s coated paper. This variety contains a bactericidal ingredient in

order to be able to maintain suitable conditions for the product of which it forms

the packaging (usually soap or other types of detergent). As far as printing is

concerned, its characteristics are the same as those of a standard paper variety.

1/s coated paper for cigarette packets. This is normally used specifically for

so-called "soft" packets, since "hard" packets are made with coated cardboard,

which we will discuss below. Its basic characteristics are a high degree of

smoothness and compressibility, since it is printed on using the rotogravure

process. Its percentage of stress is lower than that of a standard 1/s coated

paper variety, since it requires a high degree of stiffness in order to be able to

withstand adequately its final stage of preparation, bearing in mind the high

speed at which cigarette-packing machines operate.

1/s coated paper for self-adhesive products. The basic difference between

this variety intended for self-adhesive products and other standard 1/s coated

paper varieties is that it must have a higher degree of tensile strength so as to be

able to withstand matrix stripping when the self-adhesive product is handled in

reels. The printing systems used for this product are flexography, when printing

takes place in reels, and offset, when printing is onto sheets.

In order to understand the matrix stripping process we can see the following

illustration, in which a machine for printing self-adhesive paper can be observed, with a

view of a blank reel and of a printed reel, as well as of the remaining part of the web.

The web is usually fairly thin in order to make the most of the product, and thus if it is

not strong enough it can break, and this will make it necessary to stop the machine.

About Paper

Coated products

www.torraspapel.com

10

Fig. 6: Matrix stripping in a machine for printing self-adhesive paper.

In the following table the main uses of 1/s coated paper are listed:

MAIN USES OF 1/s COATED

PAPER

Labels

Wrappings (chocolate, soaps, etc.)

Book covers

Cigarette packets (soft packets)

Various compound products

3. Cast coated products

The characteristic feature of cast-coated paper varieties is that in their case the gloss is

produced through heat rather than through friction, which to some extent conditions

both the purposes for which they are used and the printing system to be applied. This

type of paper is used basically when coated on one side only, although very

occasionally it can be coated on both sides.

The consumption of this product has evolved over time, and if it was formerly common

to find it in the high-quality packaging market, its consumption today is centred on the

market for labels, especially of the self-adhesive variety. Nevertheless, it continues to

be manufactured in high substances for packaging, files, menus, etc., although in some

About Paper

Coated products

www.torraspapel.com

11

of these markets it is being substituted by other products which we will discuss later.

The reason for its abandonment in the packaging market may be its low level of

resistance to rubbing, which makes it necessary to plasticize it in order to give it greater

resistance. Logically carrying out this operation reduces the need for the product to be

cast-coated, since the high gloss effect can be achieved through the use of the plastic.

Cast-coated paper can be white or, alternatively have coloured finishes. The printing

system most used with it is usually offset, although in the case of coloured products it is

necessary to know how the colour has been applied in terms of the use of the different

inks.

In the case of certain products, the colour comes from the coating mix

itself. In this case, the product can be printed on with the same inks as if

it were white. In other cases, the colour is applied through a printing

system that totally closes up the pores of the paper, and for this reason it

is necessary to use inks with completely oxidative drying processes.

3.1. Types of cast coated products

Within the market for cast coated paper there are various different products, as

described below:

Standard cast coated paper. This is used in the markets for labels (with low

substances) and for packaging (for high substances). Printing is usually by the

offset process.

Fig. 7: Applications of cast coated paper.

About Paper

Coated products

www.torraspapel.com

12

WS cast coated paper. As has already been noted, products classified by the

designation "WS" are used for the labelling of "returnable bottles". In this market,

this product is less frequently found than "1/s WS cast coated paper" due to its

high price, although it is also used, especially for bottling high-quality products.

Fig. 8: Applications of WS cast coated paper.

Cast coated paper for self-adhesive products. This product is intended for

manufacturers of self-adhesive products, including Adestor. As has already been

noted with reference to 1/s cast coated paper, the product needs to have a

greater tensile strength than standard paper types in order to be able to

withstand the matrix stripping that takes place in reel printing machines. It can

also be used in the same way as the "WS" paper type if it is intended to be used

for the labels of returnable bottles.

Cast coated board. This product takes the form of folding boxboard or folding

carboard (the product type will be defined later in this unit) with cast coating. It is

used for packaging, but is found less and less frequently.

About Paper

Coated products

www.torraspapel.com

13

Fig. 9: Applications of cast coated cardboard.

Cast coated coloured paper. This variety is manufactured exclusively with a

substance of 250 g/m

2

, and is used for packaging, menus, invitations, etc. As

has been already noted, it is important to know the colour is added, so as to use

the right ink for the printing process.

Fig. 10: Applications of cast coated coloured paper.

2/s cast coated paper. This product is not very frequently found, but it is

sometimes used purely for advertising purposes, and thus its final uses are a

little different from the most common applications of 1/s cast coated products. In

some cases, the production process simply consists of sticking together the

reverse sides of two 1/s cast coated products; in other cases, the product is cast-

coated separately on each of its sides.

About Paper

Coated products

www.torraspapel.com

14

Fig. 11: Application of 2/s cast coated paper.

In the following table there is a summary of the end uses of cast coated products, with

coating on one side and also on both sides.

PRINCIPAL APPLICATIONS OF

CAST COATED PAPER

1/s cast coated 2/s cast coated

Labels for spirits, wine,

champagne, etc.

Gift wrapping-paper

Bags

Decorative packaging

High-quality advertising

Displays

Boxes for luxury gifts

Brochures

Files

4. Carbonless coated paper

Carbonless paper is defined as paper that is capable of producing copies without the

need to use carbon paper. In some markets it is also sometimes known as chemical

paper, since copies are produced as a consequence of a chemical reaction between a

layer of "transmitting" coating and another layer of "reactive" (or "receiving") coating.

About Paper

Coated products

www.torraspapel.com

15

The transmitting layer is formed by microcapsules containing the colour former, which is

given this name (rather than that of colouring) because the colour is produced in the

copy as soon as the colour former reacts with the coating of the receiving sheet.

The copy is usually black, although in some countries, a blue copy is produced, even if

this is becoming less and less common. The only difference is in the colour former

used.

Although carbonless paper also belongs to the sector of coated products, with this type

of paper the aim of the layer of coating is not to obtain a higher quality of printing, but

simply to produce copies.

According to the paper's intended use, we have the following types of carbonless

coated paper:

CB (coated back) paper. In the market this is also sometimes known as "first-

sheet paper", and represents the original of which the copy is required. On the

reverse side it carries the layer of microcapsules that contains the colour former

of the transmitting layer. It is produced in 56, 60, 70, 80 and 90 g/m

2

.

CF (coated front) paper. It is also sometimes known as "third-sheet paper", and

is the paper that carries the reactive (or receiving) layer that reacts with the

colour former in the microcapsules. It is produced in 57, 70, 80, 90 and 173 g/m

2

.

CFB (coated front and back) paper. Is also called "second sheet paper" and is

used when more than one copy is to be made. All the remaining copies will be

formed by this sheet, which carries the reactive layer on the front side, and the

transmitting layer on the reverse side. It is usually produced in 45, 53, 60 and 70

g/m

2

. Normally, the lower the substance of the paper, the larger the number of

copies that it will be possible to make, although it is unusual to use more than

five copies, with rare exceptions.

When the original and one copy are required, a CB and a CF sheet are used,

respectively. If more than one copy is required, a CFB sheet is used for

each of the intermediate sheets.

Torraspapel's commercial brand name for carbonless paper is Eurocalco. In the

following illustration the operating system for these products is shown.

Fig. 12: Use of carbonless paper.

About Paper

Coated products

www.torraspapel.com

16

4.1. Types of carbonless coated paper

We shall now look at some specialized types of carbonless products:

CB Plus paper. This is a sheet of CB paper which on the front side is coated

with "conventional coating". What is the purpose of this type of product? The

answer is simple: when the user of the end product uses CB paper to issue an

invoice, the front side of the sheet is uncoated, which reduces the quality of the

print. If a sheet is used which is coated on the front side, it is guaranteed that the

final recipient will receive a document with a higher quality of print.

ORC (Optical Character Recognition) CB paper. This is a product of a quality

especially designed for optical character recognition, and in which use is not

made of fluorescent whitening agent, which could interfere with the reading due

to the machines used in these processes.

Self-contained coated paper. This product has the two layers of coating, i.e.,

the transmitting and receiving layers, on the front side of the sheet. This enables

it to be used as a "third sheet", with a first sheet made out of ordinary paper, i.e.,

paper which is not carbonless.

Torraspapel's commercial brand name for its self-contained carbonless paper is UNIT

(fig. 13).

Fig. 13: The use of self-contained coated paper

(Eurocalco UNIT).

CB self-contained carbonless coated paper. In this case, the self-contained

carbonless product could act as a second sheet in a set of three sheets, in which

the first sheet would be ordinary paper and the third sheet a normal CF product,

as shown in figure 14.

About Paper

Coated products

www.torraspapel.com

17

Fig. 14: The use of self-contained carbonless paper

(Eurocalco UNIT CB).

4.2. Uses of carbonless paper

The most frequent applications of carbonless paper are included in the following table:

PRINCIPAL APPLICATIONS OF

CARBONLESS PAPER

Forms

Delivery-notes and invoices

Chequebooks

Carbonless paper normally involves the use of a certain number of special products:

Self-separating glue

De-sensitizing ink

Sprays or felt-tipped markers

The organizations that supply carbonless paper also sell these products. We shall now

briefly look at their methods of use.

A. Self-separating glue

When chequebooks are produced using carbonless paper, this glue is used to facilitate

the separation between the different sets. Imagine that the finished product is a set of

three sheets, i.e., one original and two copies. The printer will therefore buy the same

quantity of each of the three sheets, will print them and will subsequently carry out the

gathering, i.e., will insert each type of sheet in the correct order to make up successive

sets.

In figure no.15 we can see a set of three sheets: CB, CFB and CF. Before this set a CF

sheet from the previous set will have been placed, and after it, a CB from the following

set. Once the gathering has taken place, the sheets will be guillotined along the side on

which they will need to be glued together so that they are all well aligned, and the glue

will then subsequently be applied by brush.

About Paper

Coated products

www.torraspapel.com

18

Fig. 15: Separation of sets of sheets by means of self-separating glue.

If we look at Figure No. 15 again, we can see that, just where one set of sheets ends

and the next one begins there is an uncoated area. At this point the glue will penetrate

very little, whilst in the coated areas the glue will penetrate much more, with the result

that the sheets will be strongly glued together within the same set, but only slightly with

the previous and following sheets. It is precisely for this reason that this type of glue is

known as self-separating glue, because it sticks together the sets of sheets and makes

it easy to separate each set from the others.

B. De-sensitizing ink

This is a colourless type of ink that is used when we require that some of the receiving

sheets have areas in which we do not want the copy to be seen, which occasionally

occurs.

Let us imagine an order form where we do not want the price to be visible

on the sheet sent to the factory. The printer will then apply de-sensitizing

ink to this area of the form, and in this way will prevent it from being

copied.

C. Revealing sprays or felt-tipped markers

Since the de-sensitizing ink is colourless, sprays or markers are used to check that the

ink has been properly applied. Thus, once the ink has been applied, if we spray the

area to which the ink has been applied or we pass the marker pen over it, this will show

any areas to which the ink has not been applied, which will turn black or blue, according

to the colour former which has been used.

If in the area where the ink has been applied black or blue stains appear, this will

indicate that we are applying insufficient ink. On the other hand, if in areas where the

de-sensitizing product has not been applied small colourless areas appear, this means

that an excessive quantity is being applied, and therefore that de-sensitizing ink is being

applied to areas where it is not required.

About Paper

Coated products

www.torraspapel.com

19

5. Thermal paper

Thermal paper is another type of coated paper that has undergone a process of

constant evolution in the last few years. This is a type of paper on which printing takes

place through the effects of heat.

Thermal paper also has two layers of coating (see fig. 16) on the same side of the

paper, although the two layers do not react between each other.

The undercoating (or " U.C." ). This is the lower layer that guarantees a uniform,

smooth surface on which the thermal coating (or thermal layer) is applied. It also

helps provide high resolution and a high quality of image, and prevents the heat

reaching the paper.

The thermal coating. This is the top layer, which is made up of a large number

of chemical compounds that, when subjected to heat, react among themselves

and develop the image without interacting at all with the U.C. layer. The main

components of this layer are: a colouring, a sensitizer (or coreactant) and a

colour former.

Fig. 16: The composition of thermal paper.

The activation of the thermal layer will be triggered by a thermal header (fig. 17) that will

liquefy the layer by making the colouring react with the colour former, thus forming the

final image.

Fig. 17: Printing on thermal paper.

About Paper

Coated products

www.torraspapel.com

20

5.1. Types of thermal paper

Apart from layers of coating, the various types of thermal paper sometimes may have

special protective treatment, whether it be against heat, grease, plasticizers, etc.,

depending on their final use, as well as types of treatment to allow printing.

Furthermore, these types of paper can be classified into non top coated, semi-

topcoated and top coated varieties.

The following table lists the range of thermal papers sold under Torraspapel's Termax

brand-name, according to the substance in which they are manufactured and the use to

which they are put. In this case all the varieties can be classified as "non top

coated", except the last one (Termax TRO), which is "semi-top coated".

TYPES OF THERMAL PAPER (TORRASPAPEL)

Characteristics and

applications

Substance

Termax SF1

Thermal paper for faxes and

standard applications.

Colour: white.

55 g/m

2

Termax SF1C

Thermal paper for receipts

and standard applications.

Colours: yellow, pink, green

and blue.

55 g/m

2

Termax LNC

(Label Non Coated)

Non-protected thermal paper

for labels and self-adhesive

applications.

74 and 105 g/m

2

Termax ONC

(Offset Non Coated)

Thermal paper that is

guaranteed for offset printing

on the thermal side of the

sheet, suitable for receipts,

bank statements and labels.

57 and 77 g/m

2

Termax PRN

(PRinter Non Coated)

Non-protected high-

sensitivity thermal paper.

Suitable for receipts and

tickets.

80 g/m

2

Termax PHR Heat-resistant thermal paper 55 and 75 g/m

2

About Paper

Coated products

www.torraspapel.com

21

(Printer Heat Resistant) used for parking metres and

other applications which

require heat-resistance.

Termax TRO

(Ticket Resistant Offset)

Semi-protected thermal

paper that is resistant to

heat, light and plasticizers,

and which is guaranteed for

offset printing on the thermal

side of the sheet. Its principal

applications are for tickets for

entertainment and labels.

105 g/m

2

All varieties of thermal paper are suitable for printing on, but for certain

types of printing some kind of special protection is required.

6. Metallized paper

Metallized paper has a layer of aluminium on top of the layer of coating. In the following

illustration the structure of metallized paper is shown in schematic form.

Fig. 18: The structure of metallized paper.

The quantity of aluminium used depends on whether we are dealing with metallized

paper with face material or with high-vacuum metallized paper. We shall talk about the

latter case because this is the variety that we produce, although we use both types as

release liners for self-adhesive products.

In the case of high-vacuum metallized paper, the quantity of aluminium that it contains

varies between approximately 0.08 and 0.1 g/m

2

. Our product has the brand-name

Metalvac, and may be either smooth or embossed. Smooth varieties can have a mirror

or matt finish, and in colour are usually either silver (aluminiums normal colour) or gold

(dyed using a special colouring).

About Paper

Coated products

www.torraspapel.com

22

The end uses of this product are varied, although the most important ones are listed

below:

MAIN USES OF

METALLIZED PAPER (METALVAC)

Labels

Cigarettes and tobacco

Self-adhesive products

Gifts

Packaging

Foodstuffs

6.1. Types of metallized paper

Within the range of Metalvac metallized products there are several different varieties,

which we shall describe below:

Metalvac E. This product is used for non-returnable bottles, for example, for

spirits, wines, etc. It is produced in substances of 75, 85 and 95 g/m

2

, and can be

printed on using any printing system.

Metalvac E UV grade is used when printing takes place using UV curing inks.

Metalvac E WS. The initials "WS" ("Wet Strength") indicate that the paper is

resistant when wet. Given that aluminium tends to form a closed-in layer, and

that together with the inks used can make it difficult to remove labels or, on the

other hand, can cause excessive dirtying of the washing basins, there exists a

series of special products that we list below:

Metalvac E WS QR Plus. This product is designed for labels of returnable

containers requiring conventional offset printing. The initials "QR" stand

for "quick removal", i.e., this product is specially designed to allow for

rapid removal of labels in bottle-washing machines without dirtying the

basin. In this case printing on paper with an embossed finish is

recommended.

Metalvac E WS IR. This product is specially designed for rotogravure

printing. Embossing after printing facilitates the removal of labels. The

initials "IR" ("ink retention") indicate that the product has high resistance to

About Paper

Coated products

www.torraspapel.com

23

the loss of ink, which makes it possible to minimize the dirtying of basins

during the washing process.

Metalvac E WS UV. This product grade is suitable for labels that need to

be resistant to humidity and are going to be printed on with UV-curing

inks. It is not appropriate for labels intended for returnable bottles.

The Metalvac E WS grade is produced in 60, 65, 70 and 75 g/m

2

. Substances of 60 and

65 g/m

2

are normally used for bottle neck-labels, whilst 70 and 75 g/m

2

substances are

used for bottles' main front-labels.

Metalvac A. This product is intended for self-adhesive labels. As in other cases,

the product needs to have special tensile strength to withstand the matrix

stripping that takes place during printing of the reels. It is produced in 85 g/m

2

.

Metalvac A WS. This is similar to the previous product, but with a special

treatment to enable it to be used with returnable bottles. Like the previous

product, it is produced in 85 g/m

2

.

Metalvac T. A product which is used as the inside wrapping in cigarette

packets. Its main characteristic is that it must not give off metal dust during the

process of forming the packet, thus avoiding contamination from small particles

of aluminium. It is likewise produced using water-based glaze so as to avoid the

transmission of any type of odour or flavour. It is produced in 50 and 60 g/m

2

,

and is not printed on.

Metalvac R. Is used for gift wrapping, bags and linings for gift boxes, as well as

for decoration. It has a high level of mechanical resistance and a very glossy

finish, and it is compatible with all printing systems. It is produced in 50, 55, 60,

65 and 70 g/m

2

.

Metalvac F. This is used for the production of wrapping for chocolate and for

food products in general. Its main difference in relation to other products in the

range is its special treatment which guarantees the non-diffusion of odours or

flavours that could have a detrimentary effect on the foodstuffs. It can be printed

using any system of printing, including ultraviolet-cured inks. It is produced in

grammages of 85 and 95 g/m

2

.

Metalvac B. This type of paper is specially designed for tablecloths, trimmings

and trays for pastry and confectionery. In addition to not passing odours or

flavours to foodstuffs, it also has special treatment to avoid deterioration when in

contact with alcohol. It is not recommended for printing, and it is produced in 55,

60, 65 and 70 g/m

2

.

Metalvac CS. This is a metallized cardboard specially designed for luxury

packaging for products such as perfumes, cosmetics, champagnes, wines, etc. It

can be printed on using any printing system and it is produced in 300 g/m

2

.

About Paper

Coated products

www.torraspapel.com

24

In the following illustration are shown some of the uses of metallized paper of which we

have already spoken.

Fig. 19: Different uses of metallized paper.

7. Solid Bleached Board (SBB)

The word cardboard is, without any doubt, a word that can cause an enormous amount

of confusion, especially for anybody who does not work in the commercial

department, and the fact is that printers tend to use this name for any product with a

substance higher than 160 or 180 g/m

2

. Given that at the same time there exist other

products, both coated and non-coated, that are known specifically by the term

"cardboard", this causes the confusion of which we have spoken above.

In this section, however, we shall deal exclusively with the types of cardboard known

internationally as SBB (Solid Bleached Board) and which are produced from bleached

chemical pulp.

The first thing to note about this type of product is that the material of which the

cardboard is made is not one single layer as in the case of paper, but is made up of

several layers (it can consist of between 3 and 5 layers of fibre), of which the top layer

is named the "face", the bottom layer is called the "reverse", and the middle layers the

"belly".

Fig. 20: The basic layers of SBB cardboard.

About Paper

Coated products

www.torraspapel.com

25

This multi-layer material of which SBB cardboard is made is produced in a machine with

a humid section that is somewhat different from the conventional paper machine. In

Figure no. 21 is shown a diagram of this type of machine, which is made up of three

entry boxes (C1, C2 and C3) and three webs (T1, T2 and T3). With the left-hand box

(C1) the "face" is produced on the web T1; with box C2, the "belly" on web T2; and with

box C3, the "reverse" on web T3. In some machines the belly is produced with three

entry boxes and three webs, but there will always be a minimum of at least three layers.

Fig. 21: Flat table for the production of cardboard.

This method of production is essentially due to the following reasons:

With high-substance products, as is the case here, it is difficult to obtain a

smooth finish. By using three layers, the grammage of the material is

divided among them, which makes it possible to produce three thinner layers

that therefore have a higher degree of smoothness, leading to a better product

when it is coated.

The stiffness of the final product is increased.

It is possible to combine layers with different types of fibres: e.g., with all the

layers made of chemical pulp; or with some of chemical and others of

mechanically-produced pulp; or even with layers made from recycled paper.

7.1. Types of SBB cardboard

SBB cardboard can be coated on one side or on both, although the basic market

requirement is for one side only. Cardboard coated on one side can occasionally have a

small layer of coating on the reverse side, designed to improve the printing quality on

that side if it has to be printed on, but they are nevertheless two different layers of

coating, so that such a product is still considered as coated on one side only. SBB

cardboard is occasionally also sold uncoated.

In the following example some of these types of cardboard are listed.

About Paper

Coated products

www.torraspapel.com

26

EXAMPLES OF TYPES OF SBB CARDBOARD

GZ, 1/s, SBB cardboard (coated on one side)

GZ, 2/s, SBB cardboard (coated on both sides)

UZ cardboard (uncoated)

The initials GZ indicate that the finish is cast coated, a subject to which we have already

referred above, although this type is used less and less frequently as a form of

packaging. Nevertheless, we also include it here because this type of product still

competes in some markets, although less and less frequently.

There is also another variety of this type of cardboard that is plasticized on one or both

sides with different coats of film (polyethylene, polypropylene, polyester, etc.) and which

is intended for the packaging of frozen or pre-cooked products. It also plays an

important part in the cigarette market as far as hard packets are concerned.

Types of cardboard that are plasticized are not normally coated. The plasticization of

these products is usually carried out before printing; it is occasionally carried out after

printing, but only with the aim of protecting or embellishing, as in the case for example

of postcards.

If plasticization is to be carried out before printing, the product will be treated in the

factory, and, as we have noted above, this will be the case especially for products

designed for use with foodstuffs. They can also have metallized treatment suitable for

high-quality packaging. Plasticization on site in a factory can be carried out on both

sides of the product, in which case the coating on the upper side is usually of higher

quality so as to enhance the quality of the printing, whilst the coating on the reverse

side is applied only through the need for protection (to act as a barrier against too much

light, hot air, grease, etc.).

The plastics most used are polyethylene, polypropylene and polyester. The choice of

using one or the other, or the quantity to be used, depends on the needs of the product

that is to be packaged, as well as the possible uses to be made of the product by the

final customer (for example, the same plastic will not be used for a tray that is going to

be heated in a conventional oven as for one that is going to be heated in a micro-wave,

where the temperatures are lower). Likewise, the degree of resistance to grease

required by a type of cardboard will decide which type of plastic is to be used.

The main uses of SBB cardboard are listed in the following table:

About Paper

Coated products

www.torraspapel.com

27

THE MAIN USES OF

SBB CARDBOARD

Book covers

Catalogues

Postcards and

greetings cards

Advertising material

Cigarettes (hard

packets)

Pacaging for perfumes

and cosmetics

Files

Index cards

Food products

Glasses, plates

Pre-frozen foods

Pharmaceutical

products

8. Folding boxboard

Folding boxboard is a product with the same production system as the various types of

cardboard, but is distinguished from the latter by the fact that the middle layer (belly) is

made from mechanically-produced pulp, which results in greater caliper for the same

grammage, which therefore gives greater stiffness.

Since folding boxboard is a product with a high degree of stiffness it is

used essentially for packaging of products for which a high level of

productivity is required, such as pharmaceutical products, some types of

foodstuffs, etc.

One characteristic of folding boxboard is that the reverse side can be either white or

wood-coloured, giving two different products with the following international

designations:

GC1 (white backed folding boxboard). This product can, in certain market

conditions, replace cardboard. It should nevertheless be borne in mind that the

core of this product is yellow due to the mechanically-produced pulp, and for

certain uses, such as for postcards, a yellowing effect can be produced through

contact with sunlight when the product is placed on public view.

As can be seen in Figure no.22, white backed folding boxboard can be coated on

the reverse side with a thin layer of coating in case it needs to be printed on. It

About Paper

Coated products

www.torraspapel.com

28

does not however always have this coating; this will depend on the individual

manufacturer.

Fig. 22: The structure of white backed folding boxboard.

GC2 (wood backed folding boxboard). This product is used essentially for

packaging. It can sometimes be cast coated, as was mentioned in the section

dealing with this product. The "wood" colour is obtained by reducing the

thickness of the reverse side, thus showing the "belly", which already has the

yellowish colour typical of mechanically-produced pulp.

Fig. 23: The structure of wood backed folding boxboard.

Folding boxboard can also be plasticized at point of manufacture so as to be used for

food packaging requiring this type of protection. In the same way, when both sides are

plasticized, the same criteria are followed as with cardboard varieties.

The two products mentioned above are the types of folding boxboard sold by our

different distributors. Nevertheless, there are also other products existing on the market

with different structures, and which are listed in the box below:

EXAMPLES OF FOLDING BOXBOARD

Kraft floating boxboard, SUS

Non-coated white backed folding boxboard, UC1

About Paper

Coated products

www.torraspapel.com

29

Non-coated wood backed folding boxboard, UC2

AZ folding boxboard (identical to Eurokote CS)

Finally, in the following box is a list of the main end uses of folding boxboard.

MAIN USES

OF FOLDING BOXBOARD

Packaging for pharmaceutical products

Cosmetics

Sweets and confectionery

Cigarettes

Wines and liqueurs

Refrigerated products

Pre-cooked foods

9. Boxboard

Boxboard is a product that is produced with the same structure as folding

boxboard, except that instead of using virgin fibres, use is made of a large amount of

recycled fibres (and sometimes up to 100%). They are essentially used for the

packaging of cleaning products.

In the past there also used to be recycled folding boxboard and cardboard varieties,

although it should be added that since this type of product always needs to be produced

using primary fibres, sales are becoming less and less frequent, although they still

continue.

For identifying varieties of cardboard, folding boxboard and boxboard a

special naming system is used which makes it possible to find out what

type of product it is and what treatment it has received.

About Paper

Coated products

www.torraspapel.com

30

Boxboards can be of two types:

Coated boxboards. Within this category the following are worthy of note:

GT boxboard: this group can be sub-divided into GT1, GT2 and GT3.

GD boxboard: can be subdivided into GD1, GD2 and GD3.

In the following box are listed the characteristics which differentiate each of these types

of coated boxboard.

TYPES OF BOXBOARD

Coated GT Coated GD

GT1 GT2 GT3 GD1 GD2 GD3

Specific

volume

(cm

3

/g)

1.45 1.45 - 1.30 1.30 1.45 1.45 - 1.30 1.30

Whiteness

(%)

82 80 - 81

78 - 80

Elrepho

82 80 - 81

78-80

Elrepho

Reverse

colour

White/

Wood

Wood/

kraft

Wood Grey Grey Grey

Non-coated boxboard. The main products in this group are:

UT boxboard

UD boxboard.

In the following box the end uses of the various types of boxboard are indicated:

MAIN USES OF

BOXBOARD VARIETIES

Cleaning products

Detergents

About Paper

Coated products

www.torraspapel.com

31

In some cases a layer of 200 or 220 g/m

2

boxboard is combined with micro-channel

board. Although the market for corrugated board is different, in some cases this

combination is used, since in view of the fact that the boxboard is coated, the quality of

the printing is much better. It is very common to find this type of product in packaging

for biscuits.

The reason for this combination is that the final product is cheaper, but nevertheless

gives greater stiffness. Its structure can be seen in the following illustration. The

microchannel board is nearly always made from recycled paper, whilst the basic paper

may be made from recycled or virgin fibre, according to the stiffness required for the

end product.

Fig. 24: The structure of boxboard combined with microchannel board.

10. Self-adhesive products

During the course of this unit we have talked about labels and we have seen that many

types of coated paper (1/s, cast coated types, thermal and metallized paper, etc.) can

also be used in self-adhesive form for the production of self-adhesive labels.

Nevertheless, it should be noted that in these cases it is the end users of the products

who have to put the glue on the paper before attaching it to the relevant release-liner.

In the case of self-adhesive products, the glue is already on the product. Obviously, this

will involve using different types of machines to apply the products (see Fig. 25), as well

as a different variety of release liner.

Fig. 25: Machine for applying self-adhesive labels.

About Paper

Coated products

www.torraspapel.com

32

A self-adhesive product is made up of three component parts (see Fig. 26): the face

material, the adhesive and the release liner. The face material is the product that

finishes up as the label, whilst the release liner, which needs to be silicon-coated so that

the self-adhesive adheres to the face product only, will be disposed of after the label

has been stuck to the relevant surface.

Fig. 26: The structure of a self-adhesive product.

Self-adhesive products can be produced in sheets or in reels. In the case of production

in sheets, printing is normally carried out in offset, although it can also sometimes take

place using the silkscreen printing technique, especially when plastic or metallized

release liners are used. In the case of production in reels, the most important printing

system used is flexography, although some letterpress, rotogravure and silkscreen

printing are also used. There are now machines on the market for printing self-

adhesives in reels in which different printing systems are combined.

The main end uses of self-adhesive products are listed in the following table:

MAIN USES OF SELF-

ADHESIVE PRODUCTS

Labels for publicity campaigns

Computer labels

Price-labels

Children's stickers and games

Labels for perfumes, cleaning

products, etc.

It should also be noted that there are products in which basic labels co-exist with self-

adhesive labels, just as there are markets where one of the two products is more

important than the other. Let us give an example.

If we look at the market for " cava" (Spanish champagne-style wine), we can

see that the two types of label co-exist. Thus when talking of the production

About Paper

Coated products

www.torraspapel.com

33

of large quantities of bottles, the labels will be normal; on the other hand, if

we are talking of shorter production lines, the normal practice is to use self-

adhesive labels which, although they are more expensive, are also cleaner

and easier to apply.

If we turn to the market for pharmaceutical products, for cleaning products

or for fruit, etc., the type of label most frequently used is the self-adhesive

variety, whilst in the case of beer or soft drinks, normal labels are the type

most commonly found.

10. 1. Types of self-adhesive product

The different types of self-adhesive product which are produced vary according to the

type of face material, adhesive and release liner used. We list the different types of

product below.

A. Types of face material

Face material for self-adhesives can be obtained from the following types of paper:

FACE MATERIAL USED IN SELF-ADHESIVE PRODUCTS

Uncoated

Double-layer matt coated

Double-layer gloss coated

Triple-layer gloss coated

WS (Wet Strength) coated

High gloss

Colour coated

Fluorescent coated

Matt and gloss laminates

Matt and gloss metallized

coated

Polypropylenese

Opaque polyethylene

Transparent polyethylene

Acetates

CF carbonless

Coated cardboard

Parchment-style paper

Thermal paper

About Paper

Coated products

www.torraspapel.com

34

B. Types of release liner

In the case of release liners we need to distinguish between those used for sheets and

those used for reels, and the different varieties are shown in the following table:

TYPES OF RELEASE LINER FOR SELF-ADHESIVE

PRODUCTS

Sheets

Kraft 80 g/m

2

.

Kraft 87 g/m

2

(yellow).

Kraft 90 g/m

2

.

Kraft 130 g/m

2

for plastic

release liners.

Reels

Glassine 62 g/m

2

(yellow, white

or blue).

Glassine 80 g/m

2

(white).

Kraft 55, 74, 80, 90 and 130

g/m

2

.

The use of the various different release liners depends on the type of face material

used, the system used for applying the label, etc.

C. Types of adhesive

The adhesives used can vary according to the system of application used, the surface

concerned, the end uses, etc. We list the most frequently used adhesives below:

Removable adhesives. Those that can be removed after they have been

applied.

Permanent adhesives. Those that cannot be removed once they have been

applied. Their most frequent uses are:

Stickers.

Fruit.

Returnable bottles.

Non-returnable bottles.

Frozen foods.

Solubles in water.

About Paper

Coated products

www.torraspapel.com

35

Depending on the end use, and on the system used to apply the adhesive, certain

characteristics can be varied. For example, we need to be able to remove a sticker if we

make a mistake when attaching it, and so for this reason it will have a low rate of "tack"

(or initial adhesiveness). On the other hand, in the case of an orange, where the label is

applied automatically, it is important for the label to remain attached to the orange when

it touches it, since otherwise the orange will have no label. This will require a high rate

of "tack". In both cases the adhesives are permanent, but with different characteristics.

Super-permanent adhesives. These are used when the surface to which we

attach the label presents problems of adhesiveness.

About Paper

Coated products

www.torraspapel.com

36

Summary

Coated

products

Those products which have a surface coating (or "coating

mix") made up of a series of mineral and organic

components, and which is applied in order to improve their

printing characteristics.

Coated paper Depending on the number of layers of coating, the method of

presentation and the type of printing system used, the

following types of product can be distinguished:

Art paper. This type of paper has three layers of

coating on each side, which gives a very high quality

of printing. There is usually a choice between gloss,

semi-matt or embossed finishes, and it is printed in

sheets with the offset system. It is mainly used for

advertising purposes and, exceptionally, for very high

quality books.

Triple layer. This type is available with a gloss, semi-

matt or embossed finish, and is mainly printed in

sheets with the offset system, although on occasions

rotogravure or flexography may also be used. It is

mainly used for advertising and, occasionally, for high

quality book publishing.

Double layer. Can be found with a gloss, semi-matt,

matt, and even thick matt finish. Is used for

publishing, magazines, colour supplements,

catalogues, etc. Can be printed in sheets or reels,

mainly in offset printing.

1/s. Usually has a gloss or (occasionally) embossed

finish, as well as a special treatment on the reverse

side to avoid curling at the edges. Is used mainly for

labels, but also for cigarette packets, chocolate

wrappers, book covers, etc.

Cast coated

products

With this product type, coating is carried out mainly on one

side only of the sheet (rarely on both sides), and the gloss

finish is obtained through a heat treatment. It can be printed

in colour and the printing system most frequently used is

offset. There are various different types: standard, WS, self-

adhesive, cardboard, colour, 2/s.

About Paper

Coated products

www.torraspapel.com

37

Its use is mainly for labels (especially self-adhesives),

although it is also still frequently used in high grammages for

packaging, files, menus, etc.

Carbonless

products

These are used to copy original documents by means of a

chemical reaction between a transmitting layer of coating

(made up of micro-capsules that contain the colour former)

and another reactive layer of coating (which reacts with the

colour former).

There are basically three varieties of this product: The CB

or "first sheet" (the original that has the transmitting layer on

its reverse side), the CF or "third sheet" (which has the

reactive layer on the upper face), and the CFB or "second

sheet" (used when there is more than one copy, with a

reactive layer on the top side and a transmitting layer on the

bottom side.

Some varieties of carbonless paper are: CB plus, CB ORC,

self-contained, self-copying self-contained CB. Its basic uses

are for forms, delivery-notes, invoices and cheque-books.

Thermal paper This product has two layers of coating on the same side of

the sheet: a layer of undercoating (UC) and a thermal layer

that contains the components that will react to implement the

printing process. Printing takes place through the effect of

heat by means of a thermal header that activates the thermal

layer. This product sometimes includes special types of

treatment for protection and for printing.

The different types of thermal paper are: Termax SF1,

Termax SF1C, Termax LNC, Termax ONC, Termax PRN,

Termax PHR, and Termax TRO. They are mainly used for

faxes, receipts, labels, etc.

Metallized

paper

This product has a layer of aluminium on top of a layer of

coating, and can be divided into metallized paper with face

material, or high-vacuum metallized paper. The latter

varieties can be smooth or embossed.

The most important uses of metallized paper include: labels,

cigarettes, self-adhesive products, gifts, packaging and other

uses connected with foodstuffs.

Solid Bleached

Board (SBB)

Types of cardboard with high grammages produced from

bleached chemical pulp and characterized by a high level of

About Paper

Coated products

www.torraspapel.com

38

stiffness. They are made up of various layers of fibre: the

face (top layer), the reverse side (bottom layer) and the belly

(the central layer).

This type of cardboard is usually coated, although it can

sometimes be sold without coating. It can also be plasticized,

in which case it is not usually coated. Its uses are highly

varied: book covers, catalogues, postcards and greetings

cards, advertising material, cigarettes (in hard packets),

packaging for perfumes and cosmetics, files, index-cards,

food products, glasses and plates, frozen food, and

pharmaceutical products.

Folding

boxboard

This is a product that is similar to SBB, but with the

difference that the central layer (belly) is made up of

mechanically-made pulp, which gives a greater calibre for

the same level of grammage, and thus a higher degree of

stiffness. The reverse side may be white (GC1) or wood-

coloured (GC2).

Its main uses are: packaging for pharmaceutical products,

cosmetics, sweets and confectionery, cigarettes, wines and

spirits, and for refrigerated and pre-cooked foods. Folding

boxboard can also be plasticized at the point of production

for use in food packaging.

Boxboard This product is produced with the same structure as folding

boxboard, but using a large amount of recycled fibres.

Boxboard can be of two types: coated (GT and GD) and non-

coated (UT and UD). It is basically used for packaging for

cleaning products and detergents.

Self-adhesive

products

These are products to which glue is applied during their

production. They are made up of three parts: the face

material (uncoated, double-layer coated, metallized, cast

coated, etc.), the release liner (for sheets or reels) and the

adhesive (removable, permanent or super-permanent).

Their main uses are: promotional labels, computer labels,

price labels, stickers and children's games, labels for

perfumes, cleaning materials, etc.

TORRASPAPEL, S.A. - Llull, 331 - 08019 Barcelona

2008 TORRASPAPEL, S.A.

Complete or partial reproduction of this document, without express

previous and written authorisation, is strictly prohibited.

You might also like

- Affidavit of Truth TempleteDocument4 pagesAffidavit of Truth TempleteWilliam Tezak82% (11)

- Indian Printing Industry Profile 2010Document36 pagesIndian Printing Industry Profile 2010Anil YadavNo ratings yet

- BR Tamboli UV Basics 22.04.2016Document47 pagesBR Tamboli UV Basics 22.04.2016sambasivaNo ratings yet

- Free Resin Jewelry Making EbookDocument15 pagesFree Resin Jewelry Making Ebookjodaka80% (5)

- CHAPTER 3.0 - GravureDocument10 pagesCHAPTER 3.0 - GravureGiha Tardan100% (1)

- Printing Inks - Issues, Guidance and RegulationsDocument93 pagesPrinting Inks - Issues, Guidance and RegulationsDinesh RajputNo ratings yet

- Kraft Paper Industry Project ReportDocument9 pagesKraft Paper Industry Project ReportAKSHAT SHAHNo ratings yet

- BaSO4 Fillers in Printing InksDocument161 pagesBaSO4 Fillers in Printing InksMia ElliläNo ratings yet

- Air Resistance of Paper (Gurley Method) t460Document19 pagesAir Resistance of Paper (Gurley Method) t460Gustavo Sánchez100% (1)

- Valmet Tissue Services Offering CatalogueDocument190 pagesValmet Tissue Services Offering CataloguenotengofffNo ratings yet

- Alum Rosin SizingDocument9 pagesAlum Rosin SizingAnkit JainNo ratings yet

- Printing Ink Technology: A Guide to Raw Materials, Manufacture and ApplicationsDocument13 pagesPrinting Ink Technology: A Guide to Raw Materials, Manufacture and ApplicationsD Rong saNo ratings yet

- Calander PDFDocument14 pagesCalander PDFansari_poly5264No ratings yet

- Adhesive Tape Manufacturing Industry in India CombineDocument21 pagesAdhesive Tape Manufacturing Industry in India Combinemayur473No ratings yet

- 40 Seconds of Scrum InstructionsDocument18 pages40 Seconds of Scrum InstructionsR. Gesit Prasasti AlamNo ratings yet

- Rheology in Paper and Paperboard Coating: Pekka KomulainenDocument102 pagesRheology in Paper and Paperboard Coating: Pekka KomulainenjjccmmaaNo ratings yet

- Book - Paper Products Physics and Technology PDFDocument356 pagesBook - Paper Products Physics and Technology PDFVuNo ratings yet

- Stora Enso's Guide to Paperboard Materials and ProcessesDocument60 pagesStora Enso's Guide to Paperboard Materials and Processespakzeeshan1100% (2)

- Packaging of Food in Paperboard Containers - 2020Document40 pagesPackaging of Food in Paperboard Containers - 2020fernandoluisNo ratings yet

- 07 NipcoFlex Shoe Press En-1 21Document4 pages07 NipcoFlex Shoe Press En-1 21venkNo ratings yet

- The Chemistry of Paper - MakingDocument548 pagesThe Chemistry of Paper - MakingVendula BazalováNo ratings yet

- Paper Fan PumpsDocument8 pagesPaper Fan PumpsnazeerNo ratings yet

- Major Sources of Waste in Pulp & Paper IndustryDocument26 pagesMajor Sources of Waste in Pulp & Paper Industrynancyy8No ratings yet

- Sizing With Alkyl Ketene DimerDocument10 pagesSizing With Alkyl Ketene DimerPaperManNo ratings yet

- Critical Attributes of Folding Cartons 2Document8 pagesCritical Attributes of Folding Cartons 2Wanda Yee100% (1)

- Pulp&Paper Vol1Document169 pagesPulp&Paper Vol1dude100% (1)

- Applications of Sodium CarboxyMethyl Cellulose in The Paper Industry PDFDocument3 pagesApplications of Sodium CarboxyMethyl Cellulose in The Paper Industry PDFmeennoyNo ratings yet

- Paper Pulp DeinkingDocument4 pagesPaper Pulp Deinkingcoppi4No ratings yet

- Calendering Is Still King For High Volume PVCDocument9 pagesCalendering Is Still King For High Volume PVCOSIIQPGRISNo ratings yet

- Full Text 01Document80 pagesFull Text 01Francesca PorcelliNo ratings yet

- Effect of Surface Size With StarchDocument4 pagesEffect of Surface Size With Starchcahya indhartaNo ratings yet

- Paper Coating and Printability: Understanding Surface InteractionsDocument13 pagesPaper Coating and Printability: Understanding Surface InteractionsHgagselim SelimNo ratings yet

- Enercon Uv Flexo Ink Adhesion For Flexible PackagingDocument8 pagesEnercon Uv Flexo Ink Adhesion For Flexible PackagingAndrei PaunNo ratings yet

- Crowning Benefits - Paper, Film & Foil ConverterDocument3 pagesCrowning Benefits - Paper, Film & Foil ConverteravgpaulNo ratings yet

- 9 Finishing 4Document68 pages9 Finishing 4anhduckondeNo ratings yet

- Valmet's Recent Calender Technologies: High Bulk Calendering and OptiCalender CompactDocument21 pagesValmet's Recent Calender Technologies: High Bulk Calendering and OptiCalender Compactsukallan dharNo ratings yet

- A to Z guide to practical paper chemistryDocument437 pagesA to Z guide to practical paper chemistryArnoldo Sánchez D100% (1)

- Feasibility of Dried Leaves in The Production of PaperDocument14 pagesFeasibility of Dried Leaves in The Production of PaperA - CAYAGA, Kirby, C 12 - Hermon100% (2)

- Surface Sizing BasicsDocument4 pagesSurface Sizing BasicsPeter de ClerckNo ratings yet

- Shoe PressDocument4 pagesShoe Presssushil kumar0% (1)

- Fiber Consumption in Nonwovens1Document12 pagesFiber Consumption in Nonwovens1gowrikathirNo ratings yet

- Advanced Training Course On Deinking - Dispersion and KneadingDocument38 pagesAdvanced Training Course On Deinking - Dispersion and KneadingGuido PeraltaNo ratings yet

- Additives Used in Pulping ProcessesDocument22 pagesAdditives Used in Pulping ProcessesDesi Puryani100% (2)

- Radiation Curing: Update and Outlook: Sandy Morrison, Member of Specialchem Technical Expert TeamDocument9 pagesRadiation Curing: Update and Outlook: Sandy Morrison, Member of Specialchem Technical Expert Teampakde jongkoNo ratings yet

- Air in Pulp & PaperDocument72 pagesAir in Pulp & PaperGirish ShenaiNo ratings yet

- General Instructions: Stock Corporation: General Information Sheet (Gis)Document1 pageGeneral Instructions: Stock Corporation: General Information Sheet (Gis)Alea Mae Therese BermejoNo ratings yet

- Transhipment Process FlowDocument5 pagesTranshipment Process FlowAndri Lesmana100% (1)

- New Developments in Paper and Board DryingDocument10 pagesNew Developments in Paper and Board DryingSahil DesaiNo ratings yet

- Wet End Chemistry Quick ReviewDocument36 pagesWet End Chemistry Quick ReviewSam Lua100% (1)

- Surface Sizing Basics PDFDocument4 pagesSurface Sizing Basics PDFPeter de ClerckNo ratings yet

- Paperboard Grades Cheat Sheet GuideDocument1 pagePaperboard Grades Cheat Sheet GuideEva Kovač Brčić100% (2)

- Grades of PaperDocument25 pagesGrades of PaperRohit SinghNo ratings yet

- Starch For CorrugatingDocument20 pagesStarch For Corrugatingsyifa latifa zahidaNo ratings yet

- Adhesive Bopp Tape PDFDocument8 pagesAdhesive Bopp Tape PDFjitendrajain161050% (2)

- Technology, Energy Efficiency and Environmental Externalities in The Pulp and Paper Industry - AIT, ThailandDocument140 pagesTechnology, Energy Efficiency and Environmental Externalities in The Pulp and Paper Industry - AIT, ThailandVishal Duggal100% (1)

- Oji Fuji PM N 2 (New Machine (Twogether Report) )Document8 pagesOji Fuji PM N 2 (New Machine (Twogether Report) )duducastroNo ratings yet

- BindersDocument4 pagesBindersSariyyaHeydarovaNo ratings yet

- Process Flow in ExcelDocument18 pagesProcess Flow in ExcelNadim MiaNo ratings yet

- Modified GCC Fillers in Printing Paper ProductionDocument7 pagesModified GCC Fillers in Printing Paper ProductionPenkinNo ratings yet

- BASC Pulp and Paper Science Course Revised Syllabus 2012 13Document71 pagesBASC Pulp and Paper Science Course Revised Syllabus 2012 13Vivek Singh100% (2)

- Flexo Printing Machinery Catalog English UpdatedDocument8 pagesFlexo Printing Machinery Catalog English UpdatedOMAR JOSE LEALNo ratings yet

- 14 Pulp and PaperDocument28 pages14 Pulp and PaperAnuj100% (1)

- Paper Manufacturing ProcessDocument20 pagesPaper Manufacturing ProcessMuhammad AhmadNo ratings yet

- Commercial Paper Making With KenafDocument7 pagesCommercial Paper Making With KenafSang Ka KalaNo ratings yet

- OpvDocument11 pagesOpvPankaj KumarNo ratings yet

- 2010-2011 - Helena Wayne Malinowska AmericanEthnologistDocument13 pages2010-2011 - Helena Wayne Malinowska AmericanEthnologistbobokorNo ratings yet

- A Very Short Story of What Is To Come: Alexandre ParadisDocument4 pagesA Very Short Story of What Is To Come: Alexandre ParadisbobokorNo ratings yet

- US942699 BakeliteDocument3 pagesUS942699 BakelitebobokorNo ratings yet

- Improved NewsprintDocument3 pagesImproved NewsprintbobokorNo ratings yet

- GT-I5800 UM Open Eng UK Rev.1.1 100907 CmsDocument128 pagesGT-I5800 UM Open Eng UK Rev.1.1 100907 CmsmarkocohaNo ratings yet

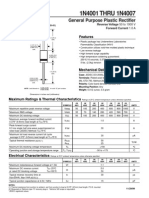

- 1N4001 THRU 1N4007: General Purpose Plastic RectifierDocument2 pages1N4001 THRU 1N4007: General Purpose Plastic RectifierbobokorNo ratings yet

- Product Substance GSM Reel Width CM DiameterDocument3 pagesProduct Substance GSM Reel Width CM DiameterbobokorNo ratings yet

- Prusa Mendel Visual Instructions (High Resolution)Document103 pagesPrusa Mendel Visual Instructions (High Resolution)darkwind311No ratings yet

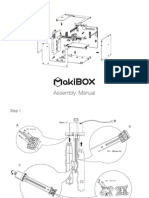

- Makibox Am v3.2 A4Document16 pagesMakibox Am v3.2 A4bobokorNo ratings yet

- Component Manual Out Put v3.1Document13 pagesComponent Manual Out Put v3.1bobokorNo ratings yet

- 1N4001 THRU 1N4007: General Purpose Plastic RectifierDocument2 pages1N4001 THRU 1N4007: General Purpose Plastic RectifierbobokorNo ratings yet

- Fairphone Cost Breakdown and Key Sept2013Document8 pagesFairphone Cost Breakdown and Key Sept2013bobokorNo ratings yet

- E Catalogue20131125Document5 pagesE Catalogue20131125bobokorNo ratings yet

- Universiti Teknologi Mara Common Test 1: Confidential AC/APR 2019/MAF201Document4 pagesUniversiti Teknologi Mara Common Test 1: Confidential AC/APR 2019/MAF201mich maisarahNo ratings yet

- B71 - SBI Bank Clerks' Exam (1) - Original Q & A 2001Document32 pagesB71 - SBI Bank Clerks' Exam (1) - Original Q & A 2001P VenkatesanNo ratings yet

- Markets Analysis: Chapter 4 Aaker (2009)Document37 pagesMarkets Analysis: Chapter 4 Aaker (2009)Wan Muhammad Abdul HakimNo ratings yet

- Specimen Issue 1Document11 pagesSpecimen Issue 1David SanzNo ratings yet

- INVOICE TITLEDocument16 pagesINVOICE TITLEsowmya sNo ratings yet

- Discrepancy Form DTUDocument2 pagesDiscrepancy Form DTUPrashuk JainNo ratings yet

- Waste ManagementDocument1 pageWaste ManagementShukra Daasa100% (1)

- Airasia Press Release - Green24 Movement by Airasia and Airasia X in Kuala Lumpur Inspire Climate ActionDocument2 pagesAirasia Press Release - Green24 Movement by Airasia and Airasia X in Kuala Lumpur Inspire Climate Actionapi-372085080No ratings yet

- The Wall Street Journal 12th October' 2018Document57 pagesThe Wall Street Journal 12th October' 2018Mohit BihaniNo ratings yet

- MusigmaDocument9 pagesMusigmademlaipNo ratings yet

- Twin Wire Formers ExplainedDocument10 pagesTwin Wire Formers ExplainedArunPThomasNo ratings yet

- BALANCING ACT - Accounting Game The Playing BoardDocument7 pagesBALANCING ACT - Accounting Game The Playing BoardSujith Kumar S HNo ratings yet

- Business Studies - XIDocument209 pagesBusiness Studies - XIShweta GaurNo ratings yet

- Impact of Fake Money On Indian EconomyDocument4 pagesImpact of Fake Money On Indian EconomyDivya Keswani100% (1)

- Attach A Pricing CN 1Document46 pagesAttach A Pricing CN 1أبو حمزهNo ratings yet

- SAP - Frequently Used Buttons - Quick ReferenceDocument34 pagesSAP - Frequently Used Buttons - Quick ReferencemotoriderNo ratings yet

- IntroductionDocument12 pagesIntroductionJulian PoerwanjanaNo ratings yet

- Target AudienceDocument5 pagesTarget AudienceFieda Nazari100% (1)

- Self-Adhesive Gold Metallized Paper Technical InformationDocument1 pageSelf-Adhesive Gold Metallized Paper Technical InformationCris AlexandrescuNo ratings yet

- Punjabi University Marks Sheet ResultsDocument2 pagesPunjabi University Marks Sheet ResultsmeenakshiNo ratings yet

- Videojet Excel 2000Document4 pagesVideojet Excel 2000copanskiNo ratings yet

- Special Journals Transactions Source DocumentsDocument11 pagesSpecial Journals Transactions Source DocumentsStpmTutorialClassNo ratings yet

- Full Stratis ProductsDocument20 pagesFull Stratis ProductsThảo Pallet NhựaNo ratings yet