Professional Documents

Culture Documents

Smoke Management Control

Uploaded by

Abemar GegantoniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Smoke Management Control

Uploaded by

Abemar GegantoniCopyright:

Available Formats

Building Smoke Management

March 2010

By: Felipe Agustin

Toxic Gas;

CO;

Narcotic gas

Hydrogen Cyanide;

Acidic halides; and

Acrolein

Reduced oxygen level;

High Temperatures;

Reduced Visibility.

Hinder escape;

Hinder Rescue

Contain the smoke within the source of fire

and avoid spreading out to other rooms;

Minimize the production of smoke;

Maintain tenable environment within all exit

access and area of refuge access path for

the time necessary to allow occupants to

reach an exit or area of refuge.

Atriums;

Large Void Spaces;

Areas of Refuge;

Corridors;

Lift lobbies;

Fire compartment

Stairwell Pressurization

Smoke Production;

Type, location and quantity of fuel;

Height cross sectional area and area (volume) of the area to be protected;

Volume of unseparated space that communicates with another large volume

area;

Type & location of occupancies;

Barriers separating adjacent spaces from a large volume space;

Egress routes from large volume space and any communicating space;

Areas of refuge.

Standard Fire Exhaust system

Stop air supply to fire effected floors;

Supply air to all fire unaffected floors;

Extract from fire effected floors;

Stop all extract from fire effected floors;

Maintain 20 Pa Pressure differential

between fire effected and unaffected

floors.

*Uses Larger riser sizes.

Alternative Fire Exhaust system:

Stop air supply to fire affected floors;

Supply air to immediate (one only) floor

above and below fire affected floors;

Extract from fire affected floor;

Stop all extract from immediate (one

only) floor above and below fire affected

floors;

All other floors, stop supply and extract.

Central VAV system:

Stop air supply to all floors;

Extract air from fire affected floor;

Stop all extract from all unaffected

floors;

Use fire rated exhaust fan.

Floor by Floor VAV system:

Supply & Exhaust air shafts sized for

minimum outside air only;

Fire rated exhaust fan to be fitted with

VSD or 2 speed motor control;

Supply air fan to be fitted with VS

controller;

During fire mode: both supply and

extract fan to enable at high speed;

Air exhaust from fire affected floor;

Supply to immediate floor above and

below.

Tempered Outside Air Supplied with Chilled

Beams:

Supply & Exhaust air shafts sized for

minimum outside air only;

Fire rated exhaust fan;

During fire mode MO1 to close MO2 to

open;

Outside air fan supply air to affected

floor above & below fire affected floor for

pressurization;

Return air fan fitted with VS Controller;

Fan to run high speed for exhaust from

fire affected floor.

Design Limitations (NFPA 92B):

Smoke Layer depth = 20% of floor to ceiling

height (rule of thumb not to exceed 1meter;

Based on Engineering Analysis;

Make-up air velocity not to exceed 1.02 m/s to

avoid smoke disruption and spreading;

Door opening shall not force door opening to

pressure limit (max 50 Pa).

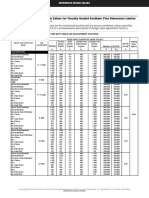

Minimum Design Pressure Difference Across

Barriers as per NFPA 92A:

Building Type Ceiling Height Design Pressure

Difference (in w.g.)

AS

Any 0.05 or (12.5 Pa)

NS

9 ft or 2.7 meter 0.10 or (25 Pa)

NS 15 ft or 4.6 meters 0.14 or (35 Pa)

NS

21 ft or 6.4 meters 0.18 or (45 Pa)

Note: AS Sprinklered; NS Non Sprinklered

ALGEBRAIC EQUATIONS

REFER TO CHAPTER 6

OF NFPA 92B;

SCALE MODELLING

REFER TO SECTION 5.6

OF NFPA 92B;

COMPUTATIONAL FLUID

DYNAMICS COMPUTER

SIMULATION

Smoke Dampers Shall be listed in accordance with ANSI/UL 555S;

Control System shall be listed in accordance with ANSI/UL 864

Standard for Control Units and Accessories for Fire Alarm Systems;

Smoke Detectors

Conventional type

Beam type:

Projected; and

Optical;

Fire Curtains - Shall be listed in accordance with ANSI/UL 268;

Fans

SAVES LIFE;

CAN BE INTEGRATED WITH MECHANICAL

VENTILATION SYSTEMS;

CAN BE DESIGNED TO ASSIST

EMERGENCY RESPONSE PERSONNEL;

CAN BE USED AS POST FIRE SMOKE

REMOVAL

You might also like

- Staircase PressurizationDocument8 pagesStaircase PressurizationSimon LawNo ratings yet

- Hot Vs Cold Aisle Containment For DCDocument13 pagesHot Vs Cold Aisle Containment For DCtommylaw100% (1)

- FALAR IntroductionDocument18 pagesFALAR IntroductionjbonvierNo ratings yet

- SCA Guide Vent Systems Loading Bays and Coach Parks - 29.10.10Document35 pagesSCA Guide Vent Systems Loading Bays and Coach Parks - 29.10.10Ramkrishna MahatoNo ratings yet

- Civil Defense ExamDocument3 pagesCivil Defense Exammkm_shahbazNo ratings yet

- Gaseous Extinguishing SystemsDocument45 pagesGaseous Extinguishing SystemsbinsNo ratings yet

- Fläkt Woods Car Park Ventilation PDFDocument20 pagesFläkt Woods Car Park Ventilation PDFSrki MenNo ratings yet

- Basic Concepts of Stairwell PressurizationDocument4 pagesBasic Concepts of Stairwell PressurizationHugo Mario Ariza PalacioNo ratings yet

- Atrium Smoke Management System Design: Reputation Resources ResultsDocument4 pagesAtrium Smoke Management System Design: Reputation Resources Resultsabb_jrhvacfireNo ratings yet

- Space Pressurization Concept PracticeDocument23 pagesSpace Pressurization Concept PracticeADsupermanNo ratings yet

- Vertical Openings Prevention: Means of EgressDocument23 pagesVertical Openings Prevention: Means of EgressAhmed SowilemNo ratings yet

- Integration - H VAC Fans and Smoke Control - Control EngineeringDocument5 pagesIntegration - H VAC Fans and Smoke Control - Control EngineeringMohamedAhmedFawzyNo ratings yet

- Guidance - Pressure Relief and Post Discharge Venting of Enclosures Protected by Gaseous Fire Fighting SystemsDocument25 pagesGuidance - Pressure Relief and Post Discharge Venting of Enclosures Protected by Gaseous Fire Fighting Systemsbetterone100% (1)

- Overview of Smoke Control System DesignDocument7 pagesOverview of Smoke Control System DesignTony GallacherNo ratings yet

- Simultaneous Heating & Cooling With ChillersDocument23 pagesSimultaneous Heating & Cooling With ChillersashishtanjeaaNo ratings yet

- Fire Protection Engineering PrinciplesDocument19 pagesFire Protection Engineering PrinciplesHenry Humberto Mesa JimenezNo ratings yet

- HVAC For PrisonsDocument5 pagesHVAC For Prisonsengamer80No ratings yet

- 3150 Verifying Fire Safety Design in Sprinklered Buildings PDFDocument141 pages3150 Verifying Fire Safety Design in Sprinklered Buildings PDFKyaw Myo ThuNo ratings yet

- Foam Fire Protection SystemDocument4 pagesFoam Fire Protection Systemkenoly123No ratings yet

- Smoke Control Hotels PDFDocument9 pagesSmoke Control Hotels PDFsajuhereNo ratings yet

- HVAC Report FINALDocument65 pagesHVAC Report FINALIanNo ratings yet

- Fire & Smoke ControlDocument7 pagesFire & Smoke ControlAnkit JainNo ratings yet

- Fire Safety Norms FinalDocument44 pagesFire Safety Norms FinalShashank SinhaNo ratings yet

- MIFireE Application Form & Annexes April 09Document18 pagesMIFireE Application Form & Annexes April 09nseeboruth1000No ratings yet

- Passive Fire ProtectionDocument28 pagesPassive Fire ProtectionBFP PANGLAONo ratings yet

- ADC Flexible Duct Performance & Installation Standards. Installation Guidelines. 4th Ed.Document8 pagesADC Flexible Duct Performance & Installation Standards. Installation Guidelines. 4th Ed.John EvansNo ratings yet

- Fire Damper 5Document44 pagesFire Damper 5Nedunuri.Madhav MurthyNo ratings yet

- Cooling Capacity Calculation PrintingDocument1 pageCooling Capacity Calculation PrintingJay PatelNo ratings yet

- Smoke Control WarehousesDocument24 pagesSmoke Control WarehousespsmanasseNo ratings yet

- Heat Gain From Electrical and Control Equipment in Industrial Plants, Part II, ASHRAE Research Project RP-1395Document4 pagesHeat Gain From Electrical and Control Equipment in Industrial Plants, Part II, ASHRAE Research Project RP-1395Michael LagundinoNo ratings yet

- TraneDocument8 pagesTraneLuis CarlosNo ratings yet

- Car Park Systems 2011-08 en E4081 KleinDocument16 pagesCar Park Systems 2011-08 en E4081 Kleinvarshneyrk@rediffmail.comNo ratings yet

- Chapter3 CompressorDocument36 pagesChapter3 CompressorSaiful AzrieNo ratings yet

- Chapter 7 (ACMV)Document140 pagesChapter 7 (ACMV)engkankwNo ratings yet

- 33 Sprinkler Design AS2118.1 2006Document2 pages33 Sprinkler Design AS2118.1 2006Pete Kardum100% (1)

- Considerations in The Design of Smoke Management Systems For AtriumsDocument11 pagesConsiderations in The Design of Smoke Management Systems For AtriumsBenjamin Estrellado100% (1)

- 101 170905 1031313131 Fire Briefing 30082017Document186 pages101 170905 1031313131 Fire Briefing 30082017Lee TaiNo ratings yet

- Fire Rated Duct PDFDocument6 pagesFire Rated Duct PDFa.m.zainNo ratings yet

- Eurovent Test StandardsDocument12 pagesEurovent Test StandardsMiki SinghNo ratings yet

- HVAC Design & Drafting Per ASHRAEDocument8 pagesHVAC Design & Drafting Per ASHRAESuresh Velu100% (1)

- State of The Art Atrium Smoke ControlDocument12 pagesState of The Art Atrium Smoke ControlBasil OguakaNo ratings yet

- Topic4a Fire SafetyDocument56 pagesTopic4a Fire SafetyOlivia SimNo ratings yet

- Sprinkler System DesignDocument19 pagesSprinkler System DesignRajahi Moahmed100% (1)

- Fire Report in AtriumDocument22 pagesFire Report in AtriumkarlamoraNo ratings yet

- Fire ControlDocument4 pagesFire ControlCau VoNo ratings yet

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideFrom EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideNo ratings yet

- MEBS6006 Advanced PsychrometryDocument52 pagesMEBS6006 Advanced Psychrometryahtin618100% (2)

- Tyco - Window Sprinklers As An Alternative To Fire PDFDocument19 pagesTyco - Window Sprinklers As An Alternative To Fire PDFingenierosunidosNo ratings yet

- 136-Smoke Management System DesignDocument4 pages136-Smoke Management System DesignAmr KamelNo ratings yet

- Air Handling UnitsDocument29 pagesAir Handling UnitsRa ArNo ratings yet

- NAFFCO Smoke Management PresentationDocument54 pagesNAFFCO Smoke Management PresentationDesigner ForeverNo ratings yet

- Chapter 10 Smoke Control and Smoke Management SystemsDocument50 pagesChapter 10 Smoke Control and Smoke Management SystemsCarlo Ray SelabaoNo ratings yet

- Sprinkler System Plans and Calculations Check ListDocument6 pagesSprinkler System Plans and Calculations Check Listengineertalat100% (1)

- Session 07 - Staircase Pressurization SystemDocument47 pagesSession 07 - Staircase Pressurization SystemacwfllsaNo ratings yet

- Sprinkler 001Document66 pagesSprinkler 001Kevin Tsui100% (1)

- Stairwell PR SyDocument21 pagesStairwell PR SySameera GamageNo ratings yet

- Mebs7014 2223 06Document72 pagesMebs7014 2223 06Yuki ChanNo ratings yet

- Ducts and Diffusers DesignDocument106 pagesDucts and Diffusers Designmister_no34No ratings yet

- Ducts and Diffusers Design PDFDocument106 pagesDucts and Diffusers Design PDFsiroliver39No ratings yet

- Lesson 1 - Architectural Design ProcessDocument33 pagesLesson 1 - Architectural Design ProcessAbemar GegantoniNo ratings yet

- Quotes From Famous ArchitectsDocument22 pagesQuotes From Famous ArchitectsAbemar GegantoniNo ratings yet

- Lesson 3 - Architectural Design Process & Design ParadigmDocument26 pagesLesson 3 - Architectural Design Process & Design ParadigmAbemar GegantoniNo ratings yet

- Lesson 4 - Ergonomics and ProxemicsDocument28 pagesLesson 4 - Ergonomics and ProxemicsAbemar GegantoniNo ratings yet

- Max Fajardo Simplified Methods On Building Construction PDFDocument360 pagesMax Fajardo Simplified Methods On Building Construction PDFOdyssey Bartolome100% (3)

- Lesson 2 - Architectural Design ProcessDocument36 pagesLesson 2 - Architectural Design ProcessAbemar GegantoniNo ratings yet

- Tad PresentationDocument59 pagesTad PresentationAbemar GegantoniNo ratings yet

- 17 31 1 SMDocument17 pages17 31 1 SMAbemar GegantoniNo ratings yet

- Architectural Theories of Design - George SalvanDocument514 pagesArchitectural Theories of Design - George SalvanOyo-gelo Cueco97% (63)

- Elevators, Escalators and AirconditioningDocument88 pagesElevators, Escalators and AirconditioningAbemar GegantoniNo ratings yet

- ACC PDF # 5 (Plumbing Fixtures)Document49 pagesACC PDF # 5 (Plumbing Fixtures)Abemar GegantoniNo ratings yet

- Standards of Professional Practice QuestionDocument4 pagesStandards of Professional Practice QuestionAbemar GegantoniNo ratings yet

- Semiotic of ColorsDocument21 pagesSemiotic of ColorsAbemar GegantoniNo ratings yet

- The Burra Charter 2013 Adopted 31 - 10 - 2013 PDFDocument12 pagesThe Burra Charter 2013 Adopted 31 - 10 - 2013 PDFClara Marques0% (1)

- LAMPSDocument3 pagesLAMPSArki TektureNo ratings yet

- Means of Egress: March 2010 By: Felipe Agustin Usgbc-Leed APDocument15 pagesMeans of Egress: March 2010 By: Felipe Agustin Usgbc-Leed APAbemar GegantoniNo ratings yet

- Pro Active Fire Protection SystemDocument25 pagesPro Active Fire Protection SystemAbemar GegantoniNo ratings yet

- National Plumbing Code Fo The PhilippinesDocument57 pagesNational Plumbing Code Fo The Philippinesjayson_pam98% (40)

- Pressure Piping System3Document43 pagesPressure Piping System3Abemar GegantoniNo ratings yet

- Falar 1Document30 pagesFalar 1Abemar GegantoniNo ratings yet

- Pressure Piping System3Document43 pagesPressure Piping System3Abemar GegantoniNo ratings yet

- Solar Heating: Design and InstallationDocument25 pagesSolar Heating: Design and InstallationAbemar GegantoniNo ratings yet

- Pressure Piping SystemDocument27 pagesPressure Piping SystemAbemar GegantoniNo ratings yet

- Architects Code of EthicsDocument9 pagesArchitects Code of EthicsAbemar GegantoniNo ratings yet

- Elec Cable Bus EtcDocument1 pageElec Cable Bus EtcArki TektureNo ratings yet

- Architects Code of EthicsDocument9 pagesArchitects Code of EthicsAbemar GegantoniNo ratings yet

- UAP Docs 200-208Document85 pagesUAP Docs 200-208Julia Esquivias-Virtucio60% (5)

- Design Equations For Flexural Strengthening of Singly Reinforced RC Rectangular Section With Steel PlatesDocument9 pagesDesign Equations For Flexural Strengthening of Singly Reinforced RC Rectangular Section With Steel PlatesMagdy Bakry100% (1)

- Strategies in LightDocument32 pagesStrategies in Lightsang_halNo ratings yet

- Anderson Greenwood POPRV Catalog - Series 200, 400, 500, 700 & 800Document64 pagesAnderson Greenwood POPRV Catalog - Series 200, 400, 500, 700 & 800Federico MoranNo ratings yet

- Waste Heat Recovery in Cement Plant IJERTV3IS051014 PDFDocument5 pagesWaste Heat Recovery in Cement Plant IJERTV3IS051014 PDFDurjoy ChakrabortyNo ratings yet

- 4 App Physics 22EL Q I VDocument17 pages4 App Physics 22EL Q I VRizwan MNo ratings yet

- Char Waste As Road Material: A Case StudyDocument34 pagesChar Waste As Road Material: A Case StudyUmer FarooqNo ratings yet

- Plasma or Flame Spraying SynthesisDocument6 pagesPlasma or Flame Spraying SynthesisOmeyya TanveerNo ratings yet

- Grape County Resort NasikDocument1 pageGrape County Resort Nasikaugupta2001No ratings yet

- 0843 SigmatexDocument2 pages0843 SigmatexAhmed SakrNo ratings yet

- Unit 3 BIGDocument3 pagesUnit 3 BIGVasanth KumarNo ratings yet

- Astm 524-96Document8 pagesAstm 524-96JOSEPH REFUERZONo ratings yet

- Ac Dur Sba G PDFDocument2 pagesAc Dur Sba G PDFbhagwatpatilNo ratings yet

- NDS 2015 Supplement Table 4B - SYP Material PropertiesDocument1 pageNDS 2015 Supplement Table 4B - SYP Material PropertiesTariqul IslamNo ratings yet

- Macmat R-Erosion Control MatDocument4 pagesMacmat R-Erosion Control MatfelixjoseNo ratings yet

- Causes and Prevention of Cracks in BuildingDocument34 pagesCauses and Prevention of Cracks in Buildingvatika100% (2)

- Floating Head Heat ExchangerDocument5 pagesFloating Head Heat ExchangerniralNo ratings yet

- Chapter 30 - : Punch ListDocument8 pagesChapter 30 - : Punch ListAkunda AmaniNo ratings yet

- Meyco Segment HR PDFDocument16 pagesMeyco Segment HR PDFFabioSoaresNo ratings yet

- Company: 4 Seasons Climate ComfortDocument39 pagesCompany: 4 Seasons Climate ComforttvassilopoulosNo ratings yet

- Gruvlok Water-Wastewater ProductsDocument16 pagesGruvlok Water-Wastewater Productsmax_powerNo ratings yet

- Trane Air-To-Water HP Application GuideDocument28 pagesTrane Air-To-Water HP Application GuideCarlos NetoNo ratings yet

- DDM04 S310 16 SupplementDocument4 pagesDDM04 S310 16 SupplementmojeebmashalNo ratings yet

- Cost Configuration: Total Haulage Cost/quantityDocument11 pagesCost Configuration: Total Haulage Cost/quantityObinna ObiefuleNo ratings yet

- Is 2062 1999Document2 pagesIs 2062 1999Vishal BhapkarNo ratings yet

- PCM-Based Building Envelope Systems: Benjamin DurakovićDocument201 pagesPCM-Based Building Envelope Systems: Benjamin DurakovićLam DesmondNo ratings yet

- JL-89-January-February Lateral Stability of Long Prestressed Concrete Beams-Part 1Document20 pagesJL-89-January-February Lateral Stability of Long Prestressed Concrete Beams-Part 1Dong-Yong KimNo ratings yet

- Ursa Major Elementary School Collapse Prevention Findings ReportDocument33 pagesUrsa Major Elementary School Collapse Prevention Findings ReportAlaska's News SourceNo ratings yet

- Windposts and Masonry Reinforcement: For The Construction IndustryDocument12 pagesWindposts and Masonry Reinforcement: For The Construction IndustryKelvin bongNo ratings yet

- Calculation Standards For Safety Relief ValvesDocument2 pagesCalculation Standards For Safety Relief ValvesJulio SaldanhaNo ratings yet

- Property Tables and Charts (Siunits) : AppendixDocument27 pagesProperty Tables and Charts (Siunits) : AppendixlemonNo ratings yet