Professional Documents

Culture Documents

Flow - Medium Pressure Function

Uploaded by

manu_chatOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flow - Medium Pressure Function

Uploaded by

manu_chatCopyright:

Available Formats

Cerrar SS

Pantalla anterior

Bienvenido: cr080jiva

Producto: EXCAVATOR

Modelo: 365C EXCAVATOR ELC00191

Configuracin: 365C L Excavator ELC00001-UP (MACHINE) POWERED BY C-15 Engine

Pruebas y Ajustes

365C Excavator Hydraulic System

Nmero de medio -RENR7305-10 Fecha de publicacin -01/12/2012 Fecha de actualizacin -06/12/2012

i03489003

Flow (Medium Pressure Function) - Test and Adjust

SMCS - 3206-081-FW ; 5064-081-FW

NOTICE

Care must be taken to ensure that fluids are contained during

performance of inspection, maintenance, testing, adjusting and repair

of the product. Be prepared to collect the fluid with suitable containers

before opening any compartment or disassembling any component

containing fluids.

Refer to Special Publication, NENG2500, "Caterpillar Dealer Service

Tool Catalog" for tools and supplies suitable to collect and contain

fluids on Caterpillar products.

Dispose of all fluids according to local regulations and mandates.

Personal injury can result from hydraulic oil pressure and hot oil.

Hydraulic oil pressure can remain in the hydraulic system after the

engine has been stopped. Serious injury can be caused if this pressure is

not released before any service is done on the hydraulic system.

Make sure all of the work tools have been lowered to the ground, and

the oil is cool before removing any components or lines. Remove the oil

Pagina 1 de 6 365C L Excavator ELC00001-UP (MACHINE) POWERED BY C-15 Engine(SEB...

21/12/2013 https://sis.cat.com/sisweb/sisweb/techdoc/techdocprintpage.jsp?returnurl/sisweb/si...

filler cap only when the engine is stopped, and the filler cap is cool

enough to touch with your bare hand.

Table 1

Required Tools

Part Number Description Qty

6V-8398 O-Ring Seal 3

4C-9910

(1)

Portable Hydraulic Tester (Flow Meter) 1

4C-9436 Flow Meter 1

4C-9438 Cable 1

4C-9623 Transducer 1

8T-7968 Connector 2

3D-2824 O-Ring Seal 2

( 1 )

Optional equipment 131-5050 DataView Tool Gp

Adjustment of the Flow Rate

Note: The signal relieI valves must be set to the correct speciIication beIore the Ilow rate can be

tested. ReIer to Testing and Adjusting, "RelieI Valve (Signal) - Test and Adjust".

Note: The line relieI valves Ior the rotate control valve are preset at a speciIic pressure. The line

relieI valves are not adjustable.

Pagina 2 de 6 365C L Excavator ELC00001-UP (MACHINE) POWERED BY C-15 Engine(SEB...

21/12/2013 https://sis.cat.com/sisweb/sisweb/techdoc/techdocprintpage.jsp?returnurl/sisweb/si...

Illustration 1 g01810874

(11) Hose

(12) Hose

(13) 6V-8398 O-Ring Seal

(14) 8T-7968 Connector

(15) 3D-2824 O-Ring Seal

(16) 4C-9436 Flow meter

(17) 4C-9623 Transducer

(18) 4C-9438 Cable

(19) 4C-9910 Flow meter

1. Disconnect hoses (11) and (12) Irom the rotator motor.

2. Install O-ring seals (13) and (15) on connectors (14). Install connectors (8) in each end oI

Ilow meter (16) .

3. Connect hoses (11) and (12) to Ilow meter (16) .

4. Connect transducer (17) to Ilow meter (16). Connect cable (18) to transducer (17) and Ilow

meter (19) .

Pagina 3 de 6 365C L Excavator ELC00001-UP (MACHINE) POWERED BY C-15 Engine(SEB...

21/12/2013 https://sis.cat.com/sisweb/sisweb/techdoc/techdocprintpage.jsp?returnurl/sisweb/si...

Illustration 2 g01826621

Rotate control valve

(20) Locknut

(21) Adjustment screw

(22) Locknut

(23) Adjustment screw

Note: Machine conIigurations can vary. VeriIy that the lines Ior clockwise rotation and

counterclockwise rotation are identiIied prior to adjusting the valve.

5. Start the engine.

6. Place the machine controls at the Iollowing settings: engine speed dial "10" and AEC switch

OFF. ReIer to Testing and Adjusting, "Engine PerIormance - Test (Engine Speed)" Ior

engine rpm settings.

7. Increase the hydraulic oil temperature to 55 + 5C (131 + 9F).

8. Put the hydraulic activation control lever in the UNLOCKED position. Depress the device

Ior activation Ior clockwise rotation.

9. Record the Ilow rate.

Pagina 4 de 6 365C L Excavator ELC00001-UP (MACHINE) POWERED BY C-15 Engine(SEB...

21/12/2013 https://sis.cat.com/sisweb/sisweb/techdoc/techdocprintpage.jsp?returnurl/sisweb/si...

Note: The Ilow rate is adjusted by limiting the spool travel by using adjustment screws (21)

and (23) .

10. In order to adjust the Ilow Ior clockwise rotation, loosen locknut (20). Turn adjustment

screw (21) in order to adjust the Ilow rate. Adjust the Ilow to the manuIacturer's

speciIications.

Note: Turn the adjustment screw clockwise in order to reduce the Ilow. Turn the adjustment

screw counterclockwise in order to increase the Ilow.

11. Repeat Steps 5 through 9 using the switch Ior counterclockwise rotation in order to test the

Ilow rate.

12. In order to adjust the Ilow Ior counterclockwise rotation, loosen locknut (22). Turn

adjustment screw (23) in order to adjust the Ilow rate. Adjust the Ilow to the manuIacturer's

speciIications.

Note: Turn the adjustment screw clockwise in order to reduce the Ilow. Turn the adjustment

screw counterclockwise in order to increase the Ilow.

13. Disconnect the lines Irom the Ilow meter. Reconnect the lines to the rotator motor.

Adjustment of the Flow Rate (Optional test)

In some cases, the manuIacturer oI the work tool will speciIy the speed or RPM Ior the work tool

that is being installed. II this speciIication is provided, use the Iollowing procedure:

1. Suspend the tool in the air.

2. Start the engine.

3. Place the machine controls at the Iollowing settings: engine speed dial "10" and AEC switch

OFF. ReIer to Testing and Adjusting, "Engine PerIormance - Test (Engine Speed)" Ior

engine rpm settings.

4. Increase the hydraulic oil temperature to 55 + 5C (131 + 9F).

5. Put the hydraulic activation control lever in the UNLOCKED position. Depress the device

Ior activation Ior clockwise rotation.

6. Record the RPM.

7. In order to adjust the RPM Ior clockwise rotation, loosen locknut (20). Turn adjustment

screw (21) in order to adjust the RPM. Adjust the RPM to the manuIacturer's speciIications.

Note: Turn the adjustment screw clockwise in order to decrease the RPM. Turn the

adjustment screw counterclockwise in order to increase the RPM.

8. Repeat Steps 1 through 6 using the switch Ior counterclockwise rotation in order to test the

RPM.

9. In order to adjust the RPM Ior counterclockwise rotation, loosen locknut (22). Turn

adjustment screw (23) in order to adjust the RPM. Adjust the RPM to the manuIacturer's

speciIications.

Pagina 5 de 6 365C L Excavator ELC00001-UP (MACHINE) POWERED BY C-15 Engine(SEB...

21/12/2013 https://sis.cat.com/sisweb/sisweb/techdoc/techdocprintpage.jsp?returnurl/sisweb/si...

Note: Turn the adjustment screw clockwise in order to decrease the RPM. Turn the

adjustment screw counterclockwise in order to increase the RPM.

Copyright 1993 - 2013 Caterpillar Inc.

Todos los derechos reservados.

Red privada para licenciados del SIS.

Sat Dec 21 11:13:25 PST 2013

cr080jiva

Pagina 6 de 6 365C L Excavator ELC00001-UP (MACHINE) POWERED BY C-15 Engine(SEB...

21/12/2013 https://sis.cat.com/sisweb/sisweb/techdoc/techdocprintpage.jsp?returnurl/sisweb/si...

You might also like

- Tanques Hidroneumaticos WellmateDocument1 pageTanques Hidroneumaticos Wellmatemanu_chatNo ratings yet

- Analyse de Cycle de Vie-L PDFDocument29 pagesAnalyse de Cycle de Vie-L PDFmanu_chatNo ratings yet

- Heavy DutyDocument2 pagesHeavy Dutymanu_chatNo ratings yet

- F. Is.20. Quejas Sobre El Freno Motor. Edicion 1. (Ingles)Document9 pagesF. Is.20. Quejas Sobre El Freno Motor. Edicion 1. (Ingles)manu_chat0% (1)

- CM1010 Utilizing SDGEDocument3 pagesCM1010 Utilizing SDGEmanu_chatNo ratings yet

- Generators Provide Power : in This IssueDocument12 pagesGenerators Provide Power : in This Issuemanu_chatNo ratings yet

- Too Much VibrationDocument8 pagesToo Much Vibrationmanu_chatNo ratings yet

- Current Best PracticesDocument8 pagesCurrent Best Practicesmanu_chatNo ratings yet

- Heavy DutyDocument2 pagesHeavy Dutymanu_chatNo ratings yet

- Acera Mark 8 Excavator Tier III Maintenance ItemsDocument645 pagesAcera Mark 8 Excavator Tier III Maintenance Itemsmanu_chat97% (35)

- CM1010 Utilizing SDGEDocument3 pagesCM1010 Utilizing SDGEmanu_chatNo ratings yet

- CM1004 Balance UnbalancedDocument4 pagesCM1004 Balance Unbalancedmanu_chatNo ratings yet

- Understanding ISO 4406 CodesDocument2 pagesUnderstanding ISO 4406 CodesOwen Hizriawan100% (3)

- CM5012 Petrochem RefineryDocument2 pagesCM5012 Petrochem Refinerymanu_chatNo ratings yet

- Selectind AccelerometersDocument8 pagesSelectind Accelerometersmanu_chatNo ratings yet

- CM3067 On-Line GearboxesDocument8 pagesCM3067 On-Line Gearboxesmanu_chatNo ratings yet

- MINING TRUCK 793 C (Camion Minero)Document24 pagesMINING TRUCK 793 C (Camion Minero)Christian KariNo ratings yet

- 60 Question For Lube SuppliersDocument12 pages60 Question For Lube SuppliershungNo ratings yet

- CM3002 Sensors in CMDocument3 pagesCM3002 Sensors in CMmanu_chatNo ratings yet

- T7 CompressorDocument4 pagesT7 Compressormanu_chatNo ratings yet

- Principios de ElectricidadDocument15 pagesPrincipios de Electricidadmanu_chatNo ratings yet

- NPR Information in SISDocument10 pagesNPR Information in SISmanu_chatNo ratings yet

- Iso1219 SymbolsDocument20 pagesIso1219 Symbolsjafornelas100% (2)

- Motor Acert C4.C6Document20 pagesMotor Acert C4.C6manu_chatNo ratings yet

- Flir 12 Things To Consider Before Buying An Infrared CameraDocument19 pagesFlir 12 Things To Consider Before Buying An Infrared Cameramanu_chatNo ratings yet

- T400 Datasheet APACDocument3 pagesT400 Datasheet APACmanu_chatNo ratings yet

- Codigos STWDocument37 pagesCodigos STWmanu_chat100% (1)

- Story of Vibration AnalysisDocument14 pagesStory of Vibration AnalysisCrusherjpNo ratings yet

- Software APT-Maintenance BrochureDocument2 pagesSoftware APT-Maintenance Brochuremanu_chat100% (1)

- 2 Future of MonitoringDocument4 pages2 Future of MonitoringWILLSONQYNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Job Opportunities in MyanmarDocument4 pagesJob Opportunities in MyanmarThein ZawNo ratings yet

- Air Compressor WP400Document137 pagesAir Compressor WP400Estephan Reyes100% (6)

- Reluctance MotorDocument27 pagesReluctance MotorMax Sedric L LaylayNo ratings yet

- A89307 ETDoc PKG Rev 1Document6 pagesA89307 ETDoc PKG Rev 1santhosha rkNo ratings yet

- Building Design To Foster A Quality and Sustainable Built EnvironmentDocument10 pagesBuilding Design To Foster A Quality and Sustainable Built EnvironmentkevinbovoNo ratings yet

- Graphical Symbols For General Engineering PDFDocument46 pagesGraphical Symbols For General Engineering PDFJohn Anthoni0% (1)

- Solar PV Lab 2Document21 pagesSolar PV Lab 2Michael Calizo PacisNo ratings yet

- G10 Mock Test 3Document8 pagesG10 Mock Test 3yasserNo ratings yet

- Technical Specification PC 5: Atlas Copco PowercrusherDocument4 pagesTechnical Specification PC 5: Atlas Copco PowercrusheralmirNo ratings yet

- 11ADocument2 pages11ALorenzo Daniel Antonio67% (3)

- R.J. Gayler - BG Tuning ManualDocument68 pagesR.J. Gayler - BG Tuning ManualRajat NanchahalNo ratings yet

- IP Price List August 2020 (All)Document72 pagesIP Price List August 2020 (All)wandererNo ratings yet

- Che323 Lecture 2 Humidification Wet BulbDocument19 pagesChe323 Lecture 2 Humidification Wet Bulbifiok100% (1)

- AIITS 2019 HCT V JEEM - Main - Questions - PAPERDocument21 pagesAIITS 2019 HCT V JEEM - Main - Questions - PAPERNagendra SinghNo ratings yet

- Unit 6Document13 pagesUnit 6VeronicaNo ratings yet

- Orb Energy SolarDocument41 pagesOrb Energy SolarVrd SrinivasNo ratings yet

- Energy in Pressure Vessel: Energy Released During Failure of CNG CylinderDocument2 pagesEnergy in Pressure Vessel: Energy Released During Failure of CNG CylinderAsim Riaz100% (1)

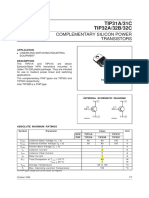

- TIP31C DatasheetDocument5 pagesTIP31C DatasheetCataNo ratings yet

- LPG Vaporizer LPG Vaporizer LPG Vaporizer LPG Vaporizer: Type Keywords Here. .Document3 pagesLPG Vaporizer LPG Vaporizer LPG Vaporizer LPG Vaporizer: Type Keywords Here. .Khin Aung ShweNo ratings yet

- Ultrasonic Cleaner S 700 HM PDFDocument109 pagesUltrasonic Cleaner S 700 HM PDFJulian Andrés FajardoNo ratings yet

- Kiln QuestionsDocument234 pagesKiln Questionsbasavaraju535100% (2)

- Fuller-Kinyon Pump: Dry Material Line ChargerDocument6 pagesFuller-Kinyon Pump: Dry Material Line ChargerRushdan ZaimNo ratings yet

- EarthingDocument43 pagesEarthingabinash pradhanNo ratings yet

- EEE 103 LC 3 - Load Flow AnalysisDocument117 pagesEEE 103 LC 3 - Load Flow AnalysisKouji TomasNo ratings yet

- Aker Solutions LNGDocument27 pagesAker Solutions LNGruov100% (1)

- Catalog Business and Economics and Finance and AccountingDocument13 pagesCatalog Business and Economics and Finance and AccountingCarlos AyalaNo ratings yet

- Head Gasket DissertationDocument17 pagesHead Gasket DissertationDanno NNo ratings yet

- Nonrenewable ResourcesDocument44 pagesNonrenewable ResourcesRuth MeloNo ratings yet

- Eaton Poe Ups enDocument2 pagesEaton Poe Ups enThanh Vinh NguyenNo ratings yet

- Cet Unit 2Document36 pagesCet Unit 2Geetha MenonNo ratings yet