Professional Documents

Culture Documents

OHS Workplace Inspection Workshop

Uploaded by

Rustam360 ratings0% found this document useful (0 votes)

176 views5 pagesOccupational health and safety inspection at work place

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentOccupational health and safety inspection at work place

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

176 views5 pagesOHS Workplace Inspection Workshop

Uploaded by

Rustam36Occupational health and safety inspection at work place

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

safety.unimelb.edu.

au OHS WORKPLACE INSPECTION CHECKLIST WORKSHOP AREAS 1

Date: Version: Authorised by: Next Review:

Template Date: 3 July 2012 Template Version: 1.3 Template authorised by: Director, OHS and Injury Management Template Next Review: 3 July 2015

The University of Melbourne Uncontrolled when printed.

OHS WORKPLACE INSPECTION CHECKLIST

Workshop areas

1. DIVISION/DEPARTMENT INFORMATION

Building: Department: Location:

2. INSPECTED BY

Supervisor: OHS management rep: Employee/HSR:

NAME SIGNATURE NAME SIGNATURE NAME SIGNATURE

Personnel working in area who were involved in the inspection:

NAME NAME NAME NAME NAME

ELEMENT Y N N/A COMMENTS/HAZARDS PERSON RESPONSIBLE DATE BY:

1 Layout

1.1 Area is tidy and well kept

1.2 Adequate storage area provided

1.3 Floor is free of obstructions

1.4 Floor coverings in good condition

2 Environment

2.1 Temperature is comfortable

2.2 Lighting is adequate

2.3 Lighting covers and fittings are secure

2.4 Area is free from odours

2.5 Noise level is acceptable/adequately controlled (L)

2.6 Ventilation is adequate

3 Emergency Procedures

3.1 Written procedures posted

3.2 Fire Extinguisher of appropriate type easily

accessible (L)

3.3 Tag on extinguisher has been checked in the last

DATE

safety.unimelb.edu.au OHS WORKPLACE INSPECTION CHECKLIST WORKSHOP AREAS 2

Date: Version: Authorised by: Next Review:

Template Date: 3 July 2012 Template Version: 1.3 Template authorised by: Director, OHS and Injury Management Template Next Review: 3 July 2015

The University of Melbourne Uncontrolled when printed.

ELEMENT Y N N/A COMMENTS/HAZARDS PERSON RESPONSIBLE DATE BY:

6 months (L)

3.4 Visitor Emergency Guides are available at

reception areas

3.5 Alarm can be heard in the area (if applicable)

3.6 Escape routes are clear (L)

3.7 Emergency and hazard signage is clearly visible (L)

4 First Aid Facilities

4.1 Kits accessible within 5 minutes (L)

4.2 Kits are stocked and contents are in-date (L)

4.3 Names and contacts of first aiders displayed (L)

5 General Facilities

5.1 Washing facilities are clean and functional (L)

5.2 Lockers or equivalent available for staff (L)

5.3 Area is clean

5.4 Chemicals are labeled (L)

5.5 OHS posters and information are displayed (L)

6 Manual Handling

6.1 Frequently used items are within easy access

between knee and shoulder (PL)

6.2 Heavy items stored at waist height (PL)

6.3 Stepladders or safe steps available to access

items stored on high shelves (PL)

6.4 Trolleys are available for heavy items and loads

(PL)

6.5 Standard Operating Procedures (SOPs) are available

where applicable

6.6 Personnel in inspection area are following

applicable SOPs

7 Environmental Issues

7.1 Recycling posters and information displayed

7.2 Paper, Toner and Commingle recycling bins are

provided

7.3 Notice to encourage double sided photocopying

and printing is displayed

8 Electrical Safety

8.1 Portable equipment has current test tags

safety.unimelb.edu.au OHS WORKPLACE INSPECTION CHECKLIST WORKSHOP AREAS 3

Date: Version: Authorised by: Next Review:

Template Date: 3 July 2012 Template Version: 1.3 Template authorised by: Director, OHS and Injury Management Template Next Review: 3 July 2015

The University of Melbourne Uncontrolled when printed.

ELEMENT Y N N/A COMMENTS/HAZARDS PERSON RESPONSIBLE DATE BY:

8.2 Power leads in good condition

8.3 Power leads are off the floor or placed away from

walkways

8.4 Power boards used (not double adaptors)

8.5 Faulty equipment is tagged out (L)

8.6 Standard Operating Procedures (SOPs) are available

where applicable

8.7 Personnel in inspection area are following

applicable SOPs

9 General Workshop

9.1 Warning and Safety signage in good condition

9.2 Procedure, plant and equipment manuals are

current and available

9.3 Laboratory free of food and drink

10 Chemical Aspects

10.1 Chemical Inventory and MSDSs available (L)

10.2 Spill kits are available and maintained (L)

10.3 Containers are labeled with chemical name and

Class diamonds (L)

10.4 Chemicals are stored correctly, bunded and

segregated from all drains (L)

10.5 Gas cylinders stored securely (L)

10.6 Chemicals labeled (L)

10.7 Standard Operating Procedures (SOPs) are available

where applicable

10.8 Personnel in inspection area are following

applicable SOPs

11 Plant/Equipment

11.1 Area around plant clean

11.2 Access to plant is clear

11.3 Plant locked/can not be accessed when left

unattended (L)

11.4 Plant and equipment maintained and in good

condition (L)

11.5 Emergency stops are working (L)

11.6 Plant guarding in place (L)

safety.unimelb.edu.au OHS WORKPLACE INSPECTION CHECKLIST WORKSHOP AREAS 4

Date: Version: Authorised by: Next Review:

Template Date: 3 July 2012 Template Version: 1.3 Template authorised by: Director, OHS and Injury Management Template Next Review: 3 July 2015

The University of Melbourne Uncontrolled when printed.

ELEMENT Y N N/A COMMENTS/HAZARDS PERSON RESPONSIBLE DATE BY:

11.7 Standard Operating Procedures (SOPs) are available

where applicable

11.8 Personnel in inspection area are following

applicable SOPs

12 Waste Disposal

12.1 Waste containers are provided and labeled with

Class Diamonds (L)

12.2 Waste is segregated and stored appropriately

away from drains (L)

12.3 Spill kits are available (L)

12.4 Standard Operating Procedures (SOPs) are available

where applicable

12.5 Personnel in inspection area are following

applicable SOPs

13 Personal Protective Equipment

13.1 Correctly stored

13.2 Well maintained and in good condition

13.3 Signage of PPE requirements displayed

13.4 Required PPE available (L)

13.5 Standard Operating Procedures (SOPs) are available

where applicable

13.6 Personnel in inspection area are following

applicable SOPs

14 Painting

14.1 Ventilation is adequate for spray painting

operations (L)

14.2 Respiratory equipment is maintained

14.3 Paint and thinners labeled (L)

14.4 Paint and thinners stored correctly, bunded and

segregated from drains (L)

14.5 Standard Operating Procedures (SOPs) are available

where applicable

14.6 Personnel in inspection area are following

applicable SOPs

safety.unimelb.edu.au OHS WORKPLACE INSPECTION CHECKLIST WORKSHOP AREAS 5

Date: Version: Authorised by: Next Review:

Template Date: 3 July 2012 Template Version: 1.3 Template authorised by: Director, OHS and Injury Management Template Next Review: 3 July 2015

The University of Melbourne Uncontrolled when printed.

OTHER COMMENTS

RECOMMENDATIONS

KEY

(L): Legal requirement. There are specific legal requirements relevant to this inspection item.

(PL): Possible legal requirement. Refer to Legal requirement above.

For use in conjunction with the Workplace inspection OHS requirements procedure. For further information, refer to

http://safety.unimelb.edu.au/tools/risk/inspection/ or contact your local OHS practice expert.

You might also like

- General Chemical Safety Inspection ChecklistDocument6 pagesGeneral Chemical Safety Inspection ChecklistWaqas Saeed100% (1)

- Safety Department Checklist FormatDocument32 pagesSafety Department Checklist Formatrockyvinoo100% (18)

- Corrective Actions Tracking RegisterDocument1 pageCorrective Actions Tracking RegisterYasir MushtaqNo ratings yet

- Spie Hse TrainingDocument107 pagesSpie Hse TrainingMuhammad Atif Qaim Khani100% (2)

- Weekly excavator checklist template for construction projectsDocument4 pagesWeekly excavator checklist template for construction projectssamiran RouthNo ratings yet

- PPE MatrixDocument1 pagePPE MatrixcaptainphihungNo ratings yet

- HSE Chemical Store ChecklistDocument2 pagesHSE Chemical Store Checklistf.B100% (1)

- PPE TrainingDocument23 pagesPPE TrainingShadeed SalemNo ratings yet

- Permit To Work Flow ChartDocument2 pagesPermit To Work Flow ChartDesmond ChangNo ratings yet

- OH&S Objective Action Taken Resources Responsible Timeline Leading Indicators Lagging IndicatorsDocument1 pageOH&S Objective Action Taken Resources Responsible Timeline Leading Indicators Lagging IndicatorsdnmuleNo ratings yet

- Workshop Inspection ChecklistDocument10 pagesWorkshop Inspection ChecklistVikas Singh100% (1)

- PPE MatrixDocument4 pagesPPE Matrixb_chiradipNo ratings yet

- Fork Lift Daily Check: (Only For FL Operated by Batery)Document1 pageFork Lift Daily Check: (Only For FL Operated by Batery)Martin CabelloNo ratings yet

- Life Saving Rules Speaker Support Pack Jan 2012Document33 pagesLife Saving Rules Speaker Support Pack Jan 2012Muhammed AliNo ratings yet

- Health & Safety Induction ChecklistDocument2 pagesHealth & Safety Induction ChecklistSharani KamaludinNo ratings yet

- Monthly HSE report summaryDocument5 pagesMonthly HSE report summaryNiraNo ratings yet

- Ladder Safety RecordsDocument4 pagesLadder Safety RecordssalmanNo ratings yet

- Contractor Health Safety Information BookletDocument14 pagesContractor Health Safety Information BookletDharmendra Khatri100% (1)

- Air CompressorDocument1 pageAir CompressorImad ChaudharyNo ratings yet

- Njqs Core Audit Module - Rev1.6cDocument14 pagesNjqs Core Audit Module - Rev1.6cNene UmohNo ratings yet

- First Aid Cases RecordDocument1 pageFirst Aid Cases RecordFrancis Enriquez TanNo ratings yet

- Welding Checklist 9195Document3 pagesWelding Checklist 9195Michael PenaNo ratings yet

- Pre-Use Welding ChecklistDocument2 pagesPre-Use Welding ChecklistNuno LopesNo ratings yet

- Health Safety Committee Meeting MinutesDocument3 pagesHealth Safety Committee Meeting MinutesMuhammad Iqbal NiyaziNo ratings yet

- Employee Safety Inspection ChecklistDocument2 pagesEmployee Safety Inspection ChecklistEvert W. VanderBerg100% (1)

- Fork Lift Truck Daily ChecklistDocument4 pagesFork Lift Truck Daily ChecklistRameeSahibaNo ratings yet

- Functions of Safety CommitteeDocument2 pagesFunctions of Safety CommitteenayakyaNo ratings yet

- Check Hard Hat Expiry Dates Before UseDocument1 pageCheck Hard Hat Expiry Dates Before UsetimbulNo ratings yet

- Lathe Risk Assessment DysonDocument4 pagesLathe Risk Assessment DysonAnkit Mohapatra100% (1)

- PPE ChecklistDocument3 pagesPPE ChecklistAtique Ur Rehman KhattakNo ratings yet

- Safe Working PracticesDocument7 pagesSafe Working PracticesDiana ParkerNo ratings yet

- Chemical&Oil Spillage Drill Report 04-02-2022Document7 pagesChemical&Oil Spillage Drill Report 04-02-2022Thomas100% (1)

- 015 CH 10 Tool InspectionDocument3 pages015 CH 10 Tool InspectionLinda BooysenNo ratings yet

- Environmental Site Inspection ChecklistDocument2 pagesEnvironmental Site Inspection ChecklistSaravanan Kulothungan100% (1)

- First Aid Box EmptyDocument1 pageFirst Aid Box Emptylez2No ratings yet

- Hot Work PermitDocument2 pagesHot Work PermitAndiWSutomoNo ratings yet

- Cold Work Permit New PDFDocument2 pagesCold Work Permit New PDFNazzta allezNo ratings yet

- Hse Policy StatementDocument1 pageHse Policy StatementVICTORNo ratings yet

- Compressed Gas Cylinder StorageDocument4 pagesCompressed Gas Cylinder StorageNoel WengNo ratings yet

- Safety Inspection ChecklistDocument3 pagesSafety Inspection ChecklistVivienne IrvingNo ratings yet

- Toolbox Talk - Mounting and Dismounting EquipmentDocument1 pageToolbox Talk - Mounting and Dismounting Equipmentsl1828No ratings yet

- Site HSE Inspection ChecklistDocument6 pagesSite HSE Inspection Checklistjonathan cambaNo ratings yet

- PPE PolicyDocument4 pagesPPE PolicyalbertNo ratings yet

- Chemical Manifest and Hazardous Chemical Substance List KathuDocument13 pagesChemical Manifest and Hazardous Chemical Substance List KathuVictorNo ratings yet

- 14.daily HSE Inspection Check ListDocument6 pages14.daily HSE Inspection Check ListSABITH KHNo ratings yet

- Saf 113 A Daily She Inspection Report 1Document4 pagesSaf 113 A Daily She Inspection Report 1saravana3kumar3ravic100% (1)

- Hse Audit Checklist PDFDocument6 pagesHse Audit Checklist PDFnorlieNo ratings yet

- General work permitDocument1 pageGeneral work permitgurvinder singhNo ratings yet

- Title:: SMS Form Fire Extinguisher Inspection RegisterDocument1 pageTitle:: SMS Form Fire Extinguisher Inspection RegisterRich Mae Dizon-HalogNo ratings yet

- Safety Inspection Checklist Abrasive Wheel Grinders Bench and PedestalDocument1 pageSafety Inspection Checklist Abrasive Wheel Grinders Bench and PedestalSanthosh Kumar100% (1)

- ELECTRICAL SAFETY CHECKLISTDocument1 pageELECTRICAL SAFETY CHECKLISTnlt_admin100% (1)

- Generic Mechanical Workshop Risk AssessmentDocument6 pagesGeneric Mechanical Workshop Risk AssessmentMohammad Abubakar SiddiqNo ratings yet

- HS32A HSE Audit ChecklistDocument3 pagesHS32A HSE Audit ChecklistsunilNo ratings yet

- Safety ObservationDocument48 pagesSafety Observationpooloo70100% (1)

- Workplace Inspection ChecklistDocument64 pagesWorkplace Inspection ChecklistMHDNo ratings yet

- QHSE Requiremnts TataDocument5 pagesQHSE Requiremnts TataparthaNo ratings yet

- Brief HSE Procedures ContentsDocument2 pagesBrief HSE Procedures Contentsarifayee-1No ratings yet

- HSE Alert - Property Damage - Drill Pipe Fell - JDE # 747806Document1 pageHSE Alert - Property Damage - Drill Pipe Fell - JDE # 747806Edwin M. MolinaNo ratings yet

- Load Distribution During Top and Tailing: Angle From Horiz (Deg)Document2 pagesLoad Distribution During Top and Tailing: Angle From Horiz (Deg)Rustam36No ratings yet

- Common Guide Dropped Object Surveys Issue 02Document76 pagesCommon Guide Dropped Object Surveys Issue 02sajid4scb100% (2)

- Top and TailDocument2 pagesTop and TailRustam36No ratings yet

- Crane & Load CalculatorDocument2 pagesCrane & Load CalculatorRustam360% (1)

- MODU SPEC Action StatusDocument4 pagesMODU SPEC Action StatusRustam36No ratings yet

- Roles and Responsibility of H2S EngineerDocument9 pagesRoles and Responsibility of H2S EngineerRustam36No ratings yet

- WinchcalDocument2 pagesWinchcalMaja TodorovskaNo ratings yet

- Load-Calculator 4 Points Rev 8 ProtectedDocument4 pagesLoad-Calculator 4 Points Rev 8 ProtectedSalah InhgaruoNo ratings yet

- LP-0008 - Load and Off-Load Rental MEWP 17teDocument6 pagesLP-0008 - Load and Off-Load Rental MEWP 17teRustam36No ratings yet

- Presentation - H2S Training REV.2 - End User (English) ANSI-Z390Document34 pagesPresentation - H2S Training REV.2 - End User (English) ANSI-Z390Rustam36No ratings yet

- Rig Fire Drill: Recognized and ExtinguishedDocument5 pagesRig Fire Drill: Recognized and ExtinguishedRustam36No ratings yet

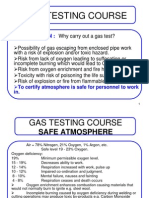

- Gas Testing Course PPT May 2008Document15 pagesGas Testing Course PPT May 2008Rustam36No ratings yet

- Automotive Workshop SafetyDocument44 pagesAutomotive Workshop Safetynewairley70% (10)

- H2S Exposure Limits and Health Effects ChartDocument2 pagesH2S Exposure Limits and Health Effects ChartRustam36No ratings yet

- Smoke Detectors Check ListDocument2 pagesSmoke Detectors Check ListRustam36No ratings yet

- Top DRiveDocument10 pagesTop DRiveRustam36No ratings yet

- Plastic Mixed Reinforced ConcreteDocument10 pagesPlastic Mixed Reinforced ConcreteUmange RanasingheNo ratings yet

- West Bengal Municipal Building Rules SummaryDocument94 pagesWest Bengal Municipal Building Rules SummaryKeke0% (1)

- Acon Software Configuration 025-9529 PDFDocument464 pagesAcon Software Configuration 025-9529 PDFSohaib Omer SalihNo ratings yet

- A Low-Cost Automated Sorting Recycle Bin Powered by Arduino MicrocontrollerDocument6 pagesA Low-Cost Automated Sorting Recycle Bin Powered by Arduino MicrocontrollerciaoNo ratings yet

- Re-Usable Packaging: 1. Description of The Loop ModelDocument3 pagesRe-Usable Packaging: 1. Description of The Loop ModelEtHical EmoTionNo ratings yet

- Presentation On Health and HygieneDocument14 pagesPresentation On Health and HygieneShekh Muhsen Uddin Ahmed100% (1)

- Ca 04c OprDocument42 pagesCa 04c OprAlexeyNo ratings yet

- Kettuvallom Kerala House Boat Design and ConstructionDocument13 pagesKettuvallom Kerala House Boat Design and ConstructionAshok Kamath0% (1)

- PileBuck 2013v29i4Document56 pagesPileBuck 2013v29i4bobbyccwNo ratings yet

- Uppdrag Hotte Aspirante Murale - AA 1378040 2Document56 pagesUppdrag Hotte Aspirante Murale - AA 1378040 2adamNo ratings yet

- Community Survey ToolDocument10 pagesCommunity Survey ToolDranreb Berylle MasangkayNo ratings yet

- Sustainable NeighborhoodsDocument22 pagesSustainable Neighborhoodslokesh singhNo ratings yet

- CD e N - 2016Document8 pagesCD e N - 2016AstritTahiriNo ratings yet

- Online Application for Hazardous Waste Generator DENR-IDDocument1 pageOnline Application for Hazardous Waste Generator DENR-IDDivine ProvidenceNo ratings yet

- Standard Cost Coding System (SCCS)Document326 pagesStandard Cost Coding System (SCCS)mirakulNo ratings yet

- Group 3 - Final - Infrastructure - Kumar, Shivani, Bhuvnesh, Bhavin, HemangDocument155 pagesGroup 3 - Final - Infrastructure - Kumar, Shivani, Bhuvnesh, Bhavin, HemangRiDh's TubeNo ratings yet

- Marketing Principles SummaryDocument58 pagesMarketing Principles SummaryAira Evangelista100% (1)

- RMIT PCPM Awards Night Posters 2011Document13 pagesRMIT PCPM Awards Night Posters 2011RMITDSCNo ratings yet

- Ecobags Brochure 2015Document13 pagesEcobags Brochure 2015EcobagsNo ratings yet

- Detailed Lesson Plan in ScienceDocument6 pagesDetailed Lesson Plan in ScienceNyca PacisNo ratings yet

- Cbse Class 6 Social Science Political Science Chapter 7 NotesDocument8 pagesCbse Class 6 Social Science Political Science Chapter 7 Notesboyboystar98No ratings yet

- Salient Features SWM RulesDocument3 pagesSalient Features SWM RulesVivianNo ratings yet

- Full Body Burden by Kristen Iversen - ExcerptDocument17 pagesFull Body Burden by Kristen Iversen - ExcerptCrown Publishing GroupNo ratings yet

- Manual de UtilizareDocument68 pagesManual de UtilizareGeo DonNo ratings yet

- Two-Stage O2 Delignification System: Cuts Mill's Chemical Use, Boosts Pulp QualityDocument5 pagesTwo-Stage O2 Delignification System: Cuts Mill's Chemical Use, Boosts Pulp QualityLucyana Can D Vith100% (1)

- The Audition: An Actress' Solo PerformanceDocument0 pagesThe Audition: An Actress' Solo PerformanceMicky MihalacheNo ratings yet

- Energy Saving Tips at HomeDocument7 pagesEnergy Saving Tips at HomeSaadia TariqNo ratings yet

- Latihan Soal Kelas 11 BINGDocument5 pagesLatihan Soal Kelas 11 BINGAzzaNo ratings yet

- Dryer Siemens Iq500Document40 pagesDryer Siemens Iq500albucurNo ratings yet

- Additives in AsphaltsDocument38 pagesAdditives in Asphaltsalfredo torresNo ratings yet