Professional Documents

Culture Documents

Selection of Gas Compressor-1

Uploaded by

dhanu_aquaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Selection of Gas Compressor-1

Uploaded by

dhanu_aquaCopyright:

Available Formats

WORLD PUMPS May 2011

Feature

24 24 24

www.worldpumps.com 0262 1762/11 2011 Elsevier Ltd. All rights reserved

Compressors

Selection of gas

compressors: part 1

Gas compressors find a wide range of uses, from internal combustion

engines and industrial processes to domestic gas supply and refrigeration.

In this first article of a nine-part series, Eduardo Larralde and Rafael

Ocampo set out the basics, discussing the theoretical laws that govern the

behaviour of compressors and the parameters fundamental to their design.

G

as compressors are used in a

wide range of applications, such

as refrigeration cycles; gas

turbines; combustion processes;

turbochargers and superchargers in

internal combustion engines; pipeline

transport of domestic gas; and pneu-

matic conveyance systems, ejection and

air service (pneumatic tools, workshop

equipment, instrument drives, cleaning,

atomizing, drying and lling/emptying).

In industry, compressors also play a very

important role in chemical, petrochemical

and rening processes.

This series of articles is intended to give

engineers in charge of compressor selec-

tion and other readers the basic laws

regarding compressor design, guidance

on the application of dierent types

of compressors, and the procedure for

selecting optimum compressor congura-

tions and auxiliaries.

Compression processes

From the thermodynamic standpoint,

compression processes can occur in

several dierent ways, namely isothermal,

isentropic or polytropic, as expressed in

Table 1.1.

The isentropic exponent k is the ratio

of the specic heat at constant pressure

to the specic heat at constant volume.

Its value is easily found from tables of

gas properties or suitable software. In

contrast, the polytropic exponent value

n is inuenced by several factors and is

rather dicult to calculate.

The compression processes described

in Table 1.1 are represented in the p-V

diagram shown in Figure 1.1.

Compressor head

Compressor head, as well as ow rate,

is a key parameter in the performance

of the machine. It represents the work

developed by the compressor per unit

of weight of the handled uid. It is

expressed in metres or feet (kgm/kg or

lbft/lb) and is dened as:

H = 101,972v.dp (1.1)

where H is the head in metres (m), v

the specic volume (m

3

/kg) and p the

absolute pressure (MPa). Specic volume

(v) can be directly obtained from gas

tables or calculated from the inverse of

density ().

After substituting and transforming, the

following equations are obtained:

H

p

= 101,972[n/(n1)]p

1

v

1

[(p

2

/p

1

)

(n1/n)

1]

(1.2)

H

p

= 101.972[n/(n1)]ZRT

1

[(p

2

/p

1

)

(n1/n)

1]

(1.3)

where H

p

is the polytropic head (m);

R the gas constant (kJ/kg.K); T

1

the

intake temperature (K); and Z the mean

compressibility factor. R = 8.3142/MW

where MW is the molecular weight of

the gas.

Equation 1.2 should be used when the

value of the compressibility factor is one.

The mean compressibility factor may be

used in Equation 1.3 with negligible error

in those instances where its deviation

is not large, i.e. where the average Z

varies between 0.95 and 1.02 or where

it remains fairly constant over the range

of compression. In other instances, the

following formula should be used:

Table 1.1. Types of compression processes

Type of process Main feature Equation

Isothermal No temperature change pV = C

Isentropic

Gas neither absorbs nor emits heat and

entropy remains constant (adiabatic reversible)

pV

k

= C

Polytropic Continuous real process pV

n

= C

WORLD PUMPS May 2011

Feature

25

www.worldpumps.com

H

p

= 101,972log(p

2

/p

1

)

[(p

2

v

2

p

1

v

1

)/log(p

2

v

2

/p

1

v

1

)] (1.4)

Equation 1.4 is of particular utility for hydro-

carbon gases at moderate or high pressures

and/or low temperatures.

The correct determination of the polytropic

exponent is an extremely important matter

if Equations 1.2 and 1.3 are to be success-

fully applied. To this end, the hydraulic or

polytropic eciency of the compressor is

determined from the following equation:

= 1,000vdp/h (1.5)

where is the hydraulic or polytropic

eciency; and h the enthalpy dierence

(kJ/kg).

The change of enthalpy during compression is:

h = 1,000[k/(k1)]p

1

v

1

[(p

2

/p

1

)

(n1/n)

1]

(1.6)

Leading to:

= [(k1)/k]/[(n1)/n] (1.7)

From Equation 1.7 and knowing or assuming

the polytropic eciency, the polytropic

index can be calculated. Polytropic eciency

is generally a function of the compressor

capacity at suction conditions for a given

compressor and can be determined through

testing. Medium-size centrifugal compressors

using 2D impellers can reach a polytropic

eciency between 72% and 80%. Large

machines using 3D impellers can reach 83%

and large axial compressors 85%.

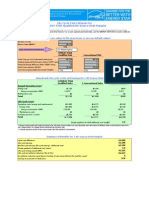

Figure 1.2 shows general approximated

values of polytropic efficiency as a func-

tion of suction capacity for multistage

centrifugal compressors equipped with

2D impellers. Obviously these values can

vary according to the specific design

Isothermal (n = 1)

Isentropic (n = k)

Polytropic (n < k)

Polytropic (n > k)

P

r

e

s

s

u

r

e

,

p

Volume, V

Figure 1.1. p-V diagram for dierent compression processes.

WORLD PUMPS May 2011

Feature

26 26 26

www.worldpumps.com

and construction of the compressor,

particularly the impellers, so the curve

in Figure 1.2 should be used just as a

guide to start the calculation procedure.

When performing economic analysis for

long periods of time, the efficiency values

derived from Figure 1.2 should be reduced

by several percentage points, mainly due

to the influence of the wear of the laby-

rinth seals.

In order to facilitate calculations, charts

usually give the value of (n1)/n after

entering the isentropic exponent k for

dierent values of suction capacity or

polytropic eciency. An example will be

presented in Figure 7.1, in part 7 of this

series of articles.

For positive displacement compressors, the

compression process is nearly isentropic and

the corresponding equation can be applied

with fairly good results. The same is true

for centrifugal compressors using cooled

diaphragms:

H

a

= 101,972[k/(k1)]p

1

v

1

[(p

2

/p

1

)

(k1/k)

1]

(1.8)

H

a

= 101.972[k/(k1)]ZRT

1

[(p

2

/p

1

)

(k1/k)

1]

(1.9)

where H

a

is the isentropic head in metres.

The equations given above assume a

single-phase gas. If the compressor inlet

stream contains gas and liquid (i.e. wet

gas), these equations must be modified

1

.

The use of Equations 1.8 and 1.9 has the

same restrictions as Equations 1.2 and 1.3

regarding the values of the compress-

ibility factor. Besides, when dealing with

non-perfect gases, the isentropic index

may vary as the compression process

develops. When the values of k at the

beginning and at the end of the compres-

sion differ by a small amount, the two

figures can be averaged. For other

instances it will be necessary to pick

an appropriate equation of state or to

establish a single compression exponent

() through the calculation of the final

temperature by using a Mollier diagram

and the use of the following equation

2

:

= ln(p

2

/p

1

)/[ln(p

2

/p

1

) ln(T

2

/T

1

)] (1.10)

Not every engineer in charge of

compressor selection achieves coincidence

when selecting the type of compres-

sion process, the type of efficiency (i.e.

isentropic, isothermal or polytropic) and

the formulae to be used in calculations of

performance. Some prefer the isentropic

process for any type of air compressor, for

single-stage centrifugals and for dry screw

compressors. Some engineers even choose

isothermal compression for calculations

concerning piston compressors with inten-

sive cooling or oil-injected screw compres-

sors. There are manufacturers who use

the isentropic cycle for their whole range

of centrifugal compressors. Whatever the

case, the efficiency type must correspond

to the compression process selected.

A polytropic process is more dicult to

analyse than a system assumed to be

isentropic. The diculty arises from the fact

that heat ows in and out of the system,

and this added energy changes some of

the basic gas properties, specically the

ratio of specic heats. For a polytropic

process, each new calculation requires a

new value for this ratio

3

.

However, the polytropic compression

process is generally selected for rotody-

namic compressors as it is better suited to

handling the wide range of gases used in

industry

3,4

, while the performance of posi-

tive displacement compressors is calculated

using the isentropic cycle

5,6

.

Required power

The power required to compress a gas is

calculated via the expression:

GKW = wh/3,600 (1.11)

where GKW is the gas power (kW) and

w the gas mass ow rate (kg/h).

For polytropic compression, substitution

yields:

GKW

p

= wH

p

/(367,200) (1.12)

And for isentropic compression:

GKW

a

= wH

a

/367,200 (1.13)

Also by substitution, the general expressions

for gas power required in polytropic and

isentropic compression processes respec-

tively can be obtained:

GKW

p

= [n/(n1)][wZRT

1

/(3,600)]

[(p

2

/p

1

)

(n1/n)

1] (1.14)

GKW

a

= [k/(k1)][wZRT

1

/3,600]

[(p

2

/p

1

)

(k1/k)

1] (1.15)

By substituting the Equation of State:

GKW

p

= 0.2777[n/(n1)][p

1

Q

1

/]

[(p

2

/p

1

)

(n1/n)

1] (1.16)

GKW

a

= 0.2777[k/(k1)][p

1

Q

1

][(p

2

/p

1

)

(k1/k)

1]

(1.17)

where Q

1

is the gas volume ow rate at

suction conditions, (m

3

/h).

For centrifugals, the rated power at the

compressor shaft (KW) is:

KW = GKW/

m

(1.18)

where

m

is the mechanical eciency.

0.82

0.80

0.78

0.76

0.74

0.72

0.70

0.68

0.66

0.64

0.62

0.60

1,000 10,000 100,000

Capacity, Q (m

3

/h)

E

c

i

e

n

c

y

,

1,000,000

Table 1.2. Usual mechanical efficiency ranges for compressors

Centrifugal

Without speed reducer/multiplier 9899%

With speed reducer/multiplier 9697%

Piston

Directly coupled large compressors with low

pressure rates

9098%

Small compressors with high pressure rates 8489%

Belt transmission 9298%

Figure 1.2. General approximated values of polytropic eciency for centrifugal compressors.

WORLD PUMPS May 2011

Feature

27

www.worldpumps.com

For reciprocating machines, the mechanical

eciency should be multiplied by the

cylinder eciency (

c

), which is introduced

to correct the ideal conditions by consid-

ering incremental cylinder sizes and allow-

able rod loading

2

:

KW = GKW/(

m

c

) (1.19)

Typical ranges for mechanical eciency are

presented in Table 1.2.

Approximated values for cylinder eciency

can be obtained via the pressure ratio by

using the curve in Figure 1.3. Compressor

power is also inuenced by gas specic

gravity and inlet pressure. Correction factors

can be found in the specialist literature

2

.

Discharge temperature

Outlet gas temperature is calculated from

the equations:

T

2

= T

1

(p

2

/p

1

)

(n1/n)

for polytropic compression

(1.20)

T

2

= T

1

(p

2

/p

1

)

(k1/k)

for isentropic compression

(1.21)

where T

1

and T

2

are the inlet and

discharge temperature, respectively, in K.

From the design point of view, the discharge

temperatures are generally limited as follows:

Reciprocating: 150C

Centrifugals and axial: 195C

Integrally geared: 250C

Dry screw: 288C

However, maximum discharge tempera-

ture can be limited by several factors. For

reciprocating machines, the maximum

predicted discharge temperature must

not exceed 150C and must not exceed

135C for hydrogen-rich service (MW of

12 or less). Compressor cylinders with

gas discharge temperatures of 118C or

less tend to experience longer wear life

for cylinder parts

7

. It is generally recom-

mended that the discharge temperature

be far lower than these limits. Several

design solutions, such as the use of

multiple-stage compression and interstage

cooling or intensive cooling of the gas

during the compression, can be used to

reduce the discharge temperature.

Reference conditions for gases

The normal or standard condition (Nm

3

/h:

normal cubic metres per hour; sm

3

/h:

standard m

3

/h; scfm; standard cubic feet

per minute) varies according to the branch

of industry and the specifying authority.

More frequently used values for standard

conditions according to ISO/CAGI/PNEUROP

are: pressure 1 bar, temperature 293 K and

C

y

l

i

n

d

e

r

e

c

i

e

n

c

y

Pressure ratio

1.5

0.90

0.85

0.80

0.75

0.70

2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0

Figure 1.3. Cylinder eciency for piston compressors.

WORLD PUMPS May 2011

Feature

28 28 28

www.worldpumps.com

0% relative humidity (dry). However, values

established by API are: pressure 1.014 bar

(1 ata), temperature 288.5 K and 0% relative

humidity (dry)

8

.

The real condition (m

3

/h; am

3

/h: actual

m

3

/h; acfm: actual cubic feet per minute)

refers to the gas pressure and temperature

existing at the compressor inlet.

For a given compressor running at a given

speed, the ow rate remains constant regard-

less of the temperature, atmospheric pressure

or altitude. Several mistakes have been made

because this convention has not been taken

into account. The conditions that apply to

the state of the gas must be known in order

to make the necessary corrections through

the characteristic equation of a perfect gas. It

should also be remembered that, for the same

geographic zone, the higher the altitude the

lower the barometric pressure and therefore

the lower the quantity of air (mass ow rate)

admitted by the compressor.

Capacity and volumetric efciency

The capacity of a compressor is the real

quantity of gas delivered but measured

at the inlet pressure and temperature and

expressed as units of volume per unit of

time (usually m

3

/h or cfm). Volumetric

eciency is dened as the ratio of the real

capacity of the compressor (Q) to its piston

displacement (v

d

):

v

= Q/v

d

(1.22)

The capacity of a piston compressor is given

by Equation 1.23 for single-acting cylinders

and by Equation 1.24 for double-acting

cylinders:

Q = 15D

2

LN

v

(1.23)

Q = 15(2D

2

d

2

)LN

v

(1.24)

where Q is the compressor capacity (m

3

/h);

D the cylinder internal diameter (m); d the

piston rod diameter (m); L the piston stroke

(m); and N the rotating speed (rpm).

Multistage compression

Optimum interstage pressures can be

obtained by the formulation and optimization

of performance as well as by investment in

compressor and interstage facilities. Interstage

pressures based just on the compressor

without respect to the interstage facilities are

not justied. Multistage compression (Figure

1.4) has the following advantages:

Greater volumetric eciency than that of a

single-cylinder machine of the same

clearance and the same total pressure ratio.

Lower nal temperatures.

The possibility of using an intercooler to

lower the gas temperature between stages,

which yields a power saving because the

combined compression process over all

stages is near an isothermal line (repre-

sented by the blue line in Figure 1.4).

When the same amount of work is done

in each cylinder this minimizes the work

to compress a particular mass of gas. For

ideal conditions the optimum intermediate

pressures for any number of compression

stages can be obtained:

(p

d

/p

s

) = (p

f

/p

i

)

1/z

(1.25)

where p

d

and p

s

are the discharge and

suction pressure for each stage, respec-

tively; p

f

and p

i

are the compressors final

and initial pressure, respectively; and z is

the number of stages.

For the particular case of a two-stage

compression, the interstage pressure p

x

is:

p

x

= (p

f

p

i

)

1/2

(1.26)

Obviously, a pressure drop in the intercooler

should be spread either side of the ideal

values obtained from these equations. It will

be demonstrated in parts 8 and 9 of this

series that the optimum interstage pres-

sure for real conditions is dierent from that

obtained via the ideal approach. Preliminary

optimum pressure drop values are:

Intercooler: 0.0450.075 MPa

Pulsation dampeners and suppression

devices: total pressure drop less than 1%

of the inlet pressure.

Part 2 of this series will deal with the clas-

sication of compressors and will also review

the main technical features of each type. n

References

[1] L. Brenne et al., Performance evaluation

of a centrifugal compressor operating under

wet gas conditions, Proceeding of the Thirty-

Fourth Turbomachinery Symposium, Turboma-

chinery Laboratory, Texas A&M University,

College Station, TX, USA, pp. 111120, (2005).

[2] R.N. Brown, Compressors: Selection and

Sizing, 3rd Edn, p. 35, Gulf Professional

Publishing, (2005).

[3] G. McKenzie, How to Calculate Poly-

tropic Eciency, http://www.ehow.com/

how_5393724_calculate-polytropic-eciency.

html

[4] API Standard 617, Axial and Centrifugal

Compressors and Expander-compressors for

Petroleum, Chemical and Gas Industry Services,

7th Edn, (July 2002, rearmed January 2009).

[5] API Standard 618, Reciprocating Compres-

sors for Petroleum, Chemical and Gas Service

Industries, 5th Edn, (December 2007).

[6] Gas Processors Suppliers Association,

GPSA Engineering Data Book, 12th Edn, GPSA

Press, (2004).

[7] A. Almasi, Reciprocating Compressor

Optimum Design and Manufacturing with

Respect to Performance, Reliability and Cost,

World Academy of Science, Engineering and

Technology, 52, pp. 4853, (2009).

[8] Sullair, Glosario, http://www.sullair.com/

corp/details/0,10294,CLI57_DIV61_ETI6257,00.

html [in Spanish & English].

Figure 1.4. p-V diagram for multistage compression, where p

i

and p

f

are the initial and nal pressures, respectively, and p

x

is

the interstage value.

P

r

e

s

s

u

r

e

,

p

Volume, V

p

f

p

x

p

i

Isothermal

Isentropic

Contact

Eduardo Larralde

Email: larralde@quimica.minbas.cu

Rafael Ocampo

Email: rocampod@gmail.com

You might also like

- Selection of Gas CompressorsDocument5 pagesSelection of Gas CompressorsstreamtNo ratings yet

- Air Separation Plants History and Technological Progress 2019 Tcm19 457349Document28 pagesAir Separation Plants History and Technological Progress 2019 Tcm19 457349Jambanlaya JasdNo ratings yet

- Site Performance Review - Gas TurbineDocument10 pagesSite Performance Review - Gas TurbinemishraenggNo ratings yet

- Comparative Evaluation of Cryogenic Air SeparationDocument21 pagesComparative Evaluation of Cryogenic Air SeparationmuratNo ratings yet

- Modern short-stroke compressors offer lower costs for downstream applicationsDocument5 pagesModern short-stroke compressors offer lower costs for downstream applicationsthirumalaiNo ratings yet

- Selection of Gas CompressorsDocument4 pagesSelection of Gas CompressorsDiegoNo ratings yet

- 2.heat-Exchangers From Ch6 - Mihir's HandbookDocument12 pages2.heat-Exchangers From Ch6 - Mihir's HandbookThế Quang LêNo ratings yet

- Industrial GasesDocument20 pagesIndustrial GasesRiazNo ratings yet

- O2 SafetyDocument3 pagesO2 Safetyrajpatil0007No ratings yet

- Furnace Heater DesignDocument7 pagesFurnace Heater DesignAaAaA_88No ratings yet

- RG Integrally Geared Compressors PDFDocument6 pagesRG Integrally Geared Compressors PDFJaswindersingh BhatiaNo ratings yet

- Sizing Forced Draft Fans For Fired HeatersDocument5 pagesSizing Forced Draft Fans For Fired Heatersdlalameen4471No ratings yet

- Isobutane Butane Fractionator PDFDocument7 pagesIsobutane Butane Fractionator PDFhoustonmathNo ratings yet

- Engro's Experience With Implementation of A S-300 Converter During A Normal T/ADocument10 pagesEngro's Experience With Implementation of A S-300 Converter During A Normal T/Avaratharajan g rNo ratings yet

- Vent Sizing Applications For Reactive SystemsDocument10 pagesVent Sizing Applications For Reactive SystemsAritraDalalNo ratings yet

- Calculate Horizontal Cylinder VolumeDocument10 pagesCalculate Horizontal Cylinder VolumearifcoyNo ratings yet

- IR HL Heatless DryerDocument1 pageIR HL Heatless DryerYing Kei ChanNo ratings yet

- AmmoniaDocument33 pagesAmmoniaWilly ChandraNo ratings yet

- Lecture13-CombinedCycle With MP SteamDocument5 pagesLecture13-CombinedCycle With MP SteamIjazzzAliNo ratings yet

- Isentropic Efficiencies of Turbines, Compressors and NozzlesDocument24 pagesIsentropic Efficiencies of Turbines, Compressors and NozzlesgrandecaciqueNo ratings yet

- 1 s2.0 S1226086X14001221 MainDocument6 pages1 s2.0 S1226086X14001221 MainJorge Rodriguez HerreraNo ratings yet

- KRES TechnologyDocument10 pagesKRES TechnologyabubakarNo ratings yet

- Truck Loading Arms (D 32)Document7 pagesTruck Loading Arms (D 32)Elias EliasNo ratings yet

- Specific Heat Ratios For HydrocarbonsDocument3 pagesSpecific Heat Ratios For HydrocarbonsChristian CândidoNo ratings yet

- Economic Optimization of Pipe Diameter For Complete TurbulenceDocument4 pagesEconomic Optimization of Pipe Diameter For Complete Turbulenceazamshafiq100% (1)

- Waterhammer in Condensate Return LinesDocument5 pagesWaterhammer in Condensate Return LinesAatish ChandrawarNo ratings yet

- Equilibria in The Ammonium Carbamate Urea-Water System: K. G. Clark, L. C. DDocument5 pagesEquilibria in The Ammonium Carbamate Urea-Water System: K. G. Clark, L. C. DjcortezcNo ratings yet

- BN-EG-UE109 Guide For Vessel SizingDocument34 pagesBN-EG-UE109 Guide For Vessel SizingShameer MajeedNo ratings yet

- Prico Process PDFDocument13 pagesPrico Process PDFcorkynhoNo ratings yet

- Linde Air HeaterDocument24 pagesLinde Air HeaterjmsmechNo ratings yet

- Dynamic Modeling of Heat Exchanger Tube RaptureDocument20 pagesDynamic Modeling of Heat Exchanger Tube RaptureRajesh NimmakayalaNo ratings yet

- Updating The Rules For Pipe SizingDocument5 pagesUpdating The Rules For Pipe SizingBehroozRaadNo ratings yet

- 880 Series Inverted Bucket Steam TrapsDocument2 pages880 Series Inverted Bucket Steam TrapsCherbee FerrerNo ratings yet

- Cubic Equations of State-Which Is BestDocument17 pagesCubic Equations of State-Which Is BestvenkieeNo ratings yet

- Minimize Evaporation Losses by Calculating Boiloff Gas in LPG Storage TanksDocument6 pagesMinimize Evaporation Losses by Calculating Boiloff Gas in LPG Storage TanksSumit KaushikNo ratings yet

- Non-Dimensional Aerodynamic Design of A Centrifugal Compressor ImpellerDocument12 pagesNon-Dimensional Aerodynamic Design of A Centrifugal Compressor ImpellerSubhash PadmanabhanNo ratings yet

- Sizing Calculations For Pressure Relief Valves - Chemical Engineering (2013)Document8 pagesSizing Calculations For Pressure Relief Valves - Chemical Engineering (2013)Jim WesnorNo ratings yet

- Crude Preheat Train With Fired HeaterDocument3 pagesCrude Preheat Train With Fired HeaterhaosfNo ratings yet

- Nozzle flange pressure calculationDocument2 pagesNozzle flange pressure calculationsudokuNo ratings yet

- GoyalDocument3 pagesGoyalVan LeNo ratings yet

- For Exchanger Tube Rupture PDFDocument3 pagesFor Exchanger Tube Rupture PDFNikhil DivateNo ratings yet

- Summary of ASME BPVC Section VIII Div 1 (Part 2) - Welding & NDTDocument14 pagesSummary of ASME BPVC Section VIII Div 1 (Part 2) - Welding & NDTTin Aung KyiNo ratings yet

- Topsoe EFUELS Technology For Converting CO2 To Renewable Synthetic FuelDocument19 pagesTopsoe EFUELS Technology For Converting CO2 To Renewable Synthetic FuelBen PowersNo ratings yet

- Flow Special - Sizing Orifice Plates - ISADocument4 pagesFlow Special - Sizing Orifice Plates - ISAamarnethaNo ratings yet

- Centrifugal Compressor Inducer PDFDocument11 pagesCentrifugal Compressor Inducer PDFmistrycsNo ratings yet

- Tech Memo - y FactorDocument4 pagesTech Memo - y FactorsumitrochakrabortiNo ratings yet

- Flow Instabilities in A Horizontal Thermosyphon Reboiler LoopDocument22 pagesFlow Instabilities in A Horizontal Thermosyphon Reboiler Loopwylie01No ratings yet

- 1 Chaker - Evaporative Cooling of Gas Turbine EnginesDocument12 pages1 Chaker - Evaporative Cooling of Gas Turbine Engineshermez19No ratings yet

- Vacuum Systems PDFDocument12 pagesVacuum Systems PDFSnigdha YadavNo ratings yet

- Compressor Station Optimization Using Simulation-Based OptimizationDocument10 pagesCompressor Station Optimization Using Simulation-Based OptimizationAmbrish SinghNo ratings yet

- Project of CarbonizatorDocument88 pagesProject of CarbonizatorLuan Bezerra SilvaNo ratings yet

- FluidFlow QuestionsDocument2 pagesFluidFlow Questionssonaldiv100% (2)

- Advanced Process Control of A Propylene Refrigeration SystemDocument11 pagesAdvanced Process Control of A Propylene Refrigeration SystemCal100% (1)

- White Paper - Calculating Safe NPSH (A)Document3 pagesWhite Paper - Calculating Safe NPSH (A)Stephen BeasleyNo ratings yet

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7From EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7No ratings yet

- Multiphase Flow 1995From EverandMultiphase Flow 1995A. SerizawaNo ratings yet

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationFrom EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNo ratings yet

- International Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectFrom EverandInternational Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectNo ratings yet

- Hydraulic Calculations Manual (Rev 3) PDFDocument6 pagesHydraulic Calculations Manual (Rev 3) PDFsauroNo ratings yet

- Escalators - How To Plan, Design and Update 1Document5 pagesEscalators - How To Plan, Design and Update 1sauroNo ratings yet

- Eaching High-Rise Plumbing DesignDocument19 pagesEaching High-Rise Plumbing Designm_salah20202000No ratings yet

- Hose Usage ChartDocument1 pageHose Usage ChartsauroNo ratings yet

- MGP Chapter3 Wastewater Treatment Overview Jan 2005Document8 pagesMGP Chapter3 Wastewater Treatment Overview Jan 2005sauroNo ratings yet

- Typical Uses for Positive Displacement PumpsDocument3 pagesTypical Uses for Positive Displacement PumpsQasim SarwarNo ratings yet

- BSPT Thread Sizes & TypesDocument3 pagesBSPT Thread Sizes & TypesuttampokharkarNo ratings yet

- Non-Stationary Thermal Model of Indoor Transformer StationsDocument9 pagesNon-Stationary Thermal Model of Indoor Transformer StationssauroNo ratings yet

- CALC Plant Volume SUL-13-212Document1 pageCALC Plant Volume SUL-13-212sauroNo ratings yet

- Improve Your Vehicle Workshop with Nederman SolutionsDocument8 pagesImprove Your Vehicle Workshop with Nederman SolutionssauroNo ratings yet

- Methods and Devices For The Prevention of Backflow and Back-SiphonageDocument9 pagesMethods and Devices For The Prevention of Backflow and Back-SiphonagesauroNo ratings yet

- Ac 3134Document40 pagesAc 3134sauroNo ratings yet

- Compressed Air Installation GuideDocument24 pagesCompressed Air Installation Guidesauro100% (1)

- CALC Pressure Loss SUL-13-214Document1 pageCALC Pressure Loss SUL-13-214sauroNo ratings yet

- Plan Your Plumbing Grey and Black Water LayoutDocument1 pagePlan Your Plumbing Grey and Black Water LayoutsauroNo ratings yet

- Design of SBR Activated Sludge ProcessDocument2 pagesDesign of SBR Activated Sludge ProcesssauroNo ratings yet

- Environmental Risk-Based Approaches For Managing Municipal Wastewater Effluent (MWWE)Document230 pagesEnvironmental Risk-Based Approaches For Managing Municipal Wastewater Effluent (MWWE)sauroNo ratings yet

- Ashp Sav CalcDocument5 pagesAshp Sav CalcsauroNo ratings yet

- Correlating Biochemical and Chemical Oxygen Demand of EffluentsDocument11 pagesCorrelating Biochemical and Chemical Oxygen Demand of EffluentssauroNo ratings yet

- Low-Cost Innovative Solutions For Treating Public Market Wastewater in The PhilippinesDocument6 pagesLow-Cost Innovative Solutions For Treating Public Market Wastewater in The PhilippinessauroNo ratings yet

- Design of Primary Sewage Treatment PlantDocument80 pagesDesign of Primary Sewage Treatment Plant000123456789No ratings yet

- M13L17 Digester DesignDocument12 pagesM13L17 Digester DesignPragathees WaranNo ratings yet

- Dairy Wastewater CharacteristicsDocument189 pagesDairy Wastewater Characteristicsjoozmax6No ratings yet

- Loading S Calculations by Dr. Ghaida Abu Rumman enDocument36 pagesLoading S Calculations by Dr. Ghaida Abu Rumman ensauroNo ratings yet

- Energy Impacts of Chiller Water Piping ArrangementDocument8 pagesEnergy Impacts of Chiller Water Piping ArrangementSharon LambertNo ratings yet

- LC 125 LabGuidelinesStandardsDocument36 pagesLC 125 LabGuidelinesStandardssauroNo ratings yet

- An Intro To Sludge Hand Treat DisposalDocument44 pagesAn Intro To Sludge Hand Treat DisposalEusoofNo ratings yet

- Eqpm Ventilation and Airconditioning PDFDocument79 pagesEqpm Ventilation and Airconditioning PDFRodrigo Alonso Rosales OrtegaNo ratings yet

- 06 Plumbing and CollectionDocument28 pages06 Plumbing and CollectionsauroNo ratings yet

- 03 Sewage Treatment Utilizing SoilDocument41 pages03 Sewage Treatment Utilizing SoilsauroNo ratings yet