Professional Documents

Culture Documents

Water quality monitoring in power plants

Uploaded by

Aurenio RibeiroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water quality monitoring in power plants

Uploaded by

Aurenio RibeiroCopyright:

Available Formats

Power No. 12 www.hachultra.

com Page 1

Application Note

Power No. 12

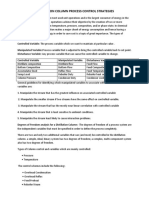

Steam generation in power plants

Application description

Water quality within power plants is of critical importance in maintaining efficient

operation and in limiting downtimes due to corrosion or preventative maintenance. The

major phases and stages where water quality is measured are discussed in this

application note along with the parameters measured.

Steam generation (drum boilers)

Page 2 www.hachultra.com Power No. 12

Water treatment plant

The purity of make-up water is critical in maintaining steam quality and in limiting boiler

blowdown.

Raw water pre-treatment

Raw water contains organic matter, inorganic salts, bacteria which need to be removed

before being purified.

Main steps:

1. Disinfection by chlorination (1-2 ppm) for preventing microbiological growth.

Parameters:

Chlorine monitoring

Redox can also be monitored at the raw water inlet point where oxidants

(chlorine, bromine) are added (potential about 600 mV)

2. Softening by hardness removal (calcium and magnesium).

Two processes can be performed:

Lime soda process where calcium is precipitated into carbonates and

magnesium into magnesium hydroxide. These are then settled and filtered.

Sodium cationic exchange, usually used in power because it prevents scaling

(sodium ion). Calcium, magnesium and other cations (iron, aluminum) are

exchanged into sodium. Conductivity is quite high at the outlet of the softening

resin.

3. Dechlorination

Carbon beds: eliminates organics and chloride. This does not offer a high

performance for removing the organics and is a source of biological

contamination.

Addition of bisulphate, oxidized into sulphates (removed by anionic exchangers).

Power No. 12 www.hachultra.com Page 3

Water purification process

A demineralization plant usually consists of 2 specific ionic exchangers and by a mixed

bed exchanger:

Demineralization plant

Cationic exchanger

The first ion exchanger removes all the cationic species (e.g. Ca

2+

from CaCO

3

) and

exchanges them into H

+

(pH about 3-4). The H

2

CO

3

is degassed before the second ionic

exchanger. In case of cationic exchanger exhaustion, the first ionic leakage will be

sodium because of its lower charge density.

Cationic exchangers are regenerated by HCl, H

2

SO

4

: all cationic species trapped in the

resin are removed and replaced by H

+

. After the completion of the regeneration, the

resin is full of H

+

sites to be exchanged with cations again.

Parameters:

Sodium measurement for immediate detection of Na+ leakage (ppb level)

Page 4 www.hachultra.com Power No. 12

Anionic exchanger

The second ion exchanger removes all the anionic species (nitrate, chloride, sulphates,

silicate) and exchanges them into OH

-

. Water molecules are produced (H

+

from the

cationic outlet and OH

-

from the anionic outlet).

Conductivity is about 2 S/cm (because of some ppb ionic species that are not

completely exchanged) and the pH is about 7.8 - 8.

In case of anionic exchanger exhaustion, the first leakage will be chloride because of its

lower charge density. Anionic exchangers are regenerated by NaOH, removing all

anions trapped by OH

-

. When generation is completed, the resin is full of OH

-

sites.

Parameters:

Conductivity will clearly indicate ionic leakage if it reaches 5 - 6 S. If

conductivity reaches 5 - 6 S, this is a clear indication of ionic leakage.

pH levels also indicate leaks: If pH is about 8.9 - 9.0, this indicates sodium leaks.

If pH decreases, this indicates chloride leaks.

Therefore conductivity and pH are complementary measurements at this stage.

Silica is sometimes monitored for diagnosing anionic bed exhaustion.

Mixed bed

For minimizing the effect of ionic leakage, a mixed bed is used for polishing

demineralized water.

The mixed bed is a mixture of anion exchange and cationic exchange resin particles and

allows high purity water to be produced.

Conductivity should be near 0.055 S/cm and pH equal to 7.

Parameters:

Conductivity is measured for ensuring the final water quality (no ionic leakage,

< 0.2 S/cm)

pH is not so often monitored at this stage but rather at the outlet of the anionic

bed.

Silica is also measured at the outlet of the mixed bed.

Other demineralization systems use reverse osmosis with one or two stages for

removing 95% of the organics as well as ionic species.

Redox or chlorine can be measured before reverse osmosis to ensure the oxidant

(chlorine) removal (200 mV, 20 ppb max) is complete. This protects the osmosis

membrane.

Conductivity is also used for monitoring the efficiency of reverse osmosis upstream and

downstream.

Storage

Demineralized water is then stored before being fed into the circuitry.

Parameters:

Conductivity: at the outlet of the storage tank, < 1 S/cm (CO

2

influence)

Power No. 12 www.hachultra.com Page 5

Neutralization of effluents

Without proper treatment, the effluent from the regeneration of ionic exchanger resins

does not always conform to consents for discharge into the environment (river for

example).

The addition of a neutralizing reagent is often obligatory.

pH measurement (use in the case of a 8350 probe) monitor the pH of those effluents.

When it reaches the allowable limit, the effluent can be sent to the river.

Steam generation process

Operating principle

Market: All industries using steam (power plants, co-generation units)

The main concerns in power generation are the availability, reliability and life cycle of

plants with one major objective: savings costs.

The operating principle is based on an energy source: gas, carbon, fuel or nuclear.

Water is vaporized in a boiler and steam heated which passes through a turbine, linked

to an alternator, producing electricity.

Steam is condensed and condensates recovered.

As circuit is principally made of carbon steel or copper alloy, corrosion and corrosion

product deposition are the focal points at high temperature and pressure. The

generalization of local corrosion induces stress cracking at high temperature.

Any organic or inorganic impurities in the water circuitry can seriously damage the

components of the boiler and turbines since water, steam, fuel and air carry over all

contaminants.

Specific limits are set for the different parameters measured. 3 different safety levels are

usually defined:

Above the level 1, the power plant must return to a normal level within one week.

Above the level 2, within 24 hours.

Above the level 3, a shutdown within few hours is mandated to avoid corrosion

damage.

Due to improvements in the design of power plants, the requirements of water purity and

water treatment equipment become more and more challenging.

Page 6 www.hachultra.com Power No. 12

Major source of plant failure

Main source of contaminants inleakage:

Make up water: demineralization plants failure, resin fines Silica reduces

turbine efficiency; sodium (NaOH, NaCl) corrodes boiler tubes and turbine

blades. Sulfate comes from residual chemicals used for regenerating ionic

exchangers.

Cooling water inleakage: Introduces raw water (organic and inorganic) into the

process. Inter-granular stress corrosion cracking can occur. Chloride, sulfate

creates corrosion cracking in the turbine and in the boilers.

Air inleakage: source of dissolved oxygen (DO) and CO

2

. DO promotes

corrosion and CO

2

accelerates the attack on any copper alloy tubes

(pH decreases).

Corrosion:

A layer of magnetite (Fe

3

O

4

) protects the circuitry against corrosion which should not be

removed or altered. The pH value in the process must minimize the solubility of the

magnetite.

NaOH: At low temperature, steel corrosion is inhibited by Hydroxyl alkalinity

(NaOH). At high temperature, magnetite can be destroyed by high concentration

of accumulated NaOH in crevices.

Acid can produce H

2

reacting with the carbon to form methane (CH

4

), weakening

the metal.

Sodium and potassium salts react with sulfur oxide and form sulphates. The

molten sulphates dissolve protective oxide scale, prevent its reformation:

Deposits can penetrate the metal structure of the hot section components and

weaken the alloys.

Microbiological induced corrosion is due to aerobic microbes which create anodic

areas by consuming oxygen (the metal loses electrons and dissolves)

Deposits:

Calcium sulphates, calcium carbonate, silica, iron oxide can deposit on airfoils or blades

and drastically reduce the power plant efficiency.

Water treatment principle:

Therefore high purity water is essential in preventing the introduction of impurities into

the water circuitry. As pure water is very corrosive, conditioning is needed. This varies

from plant to plant depending on the alloy used and the type of plant (pressure, pre-

treatment, potential of feed water contamination).

Equilibrium phosphate treatment (trisodium phosphate) EPT

This precipitates calcium and magnesium (hardness) to avoid deposits (calcium

carbonate) on the heat exchanger.

At high temperature, trisodium phosphate forms NaOH which can corrode the

circuitry.

Power No. 12 www.hachultra.com Page 7

For limiting free NaOH and reducing corrosion risks , the pH of the process should

be below the curve 2.6 NaPO

4

(congruent sodium-phosphate ratio) but above the

curve 2.1 Na-PO

4

for preventing acid attack (H

3

PO

4

formation)

All Volatile Treatment (AVT): Addition of ammonia, amines, morpholine, oxygen

scavenger (hydrazine ...) at the condensate pump discharge.

Ammonia: It has a very volatile partition into steam and can reach high

concentration in condensate.

It does not prevent corrosion in the water. It has the highest neutralizing capacity

(ppm CO

2

per amine).

It dissolves copper: pH should be between 8.8 and 9.2, for preventing copper

corrosion and remain high enough for protecting iron surfaces.

If the circuitry has no copper components, the pH can be a little higher: pH 9.45 - 9.6

(2 ppm ammonia)

But 2 ppm ammonia masks the presence of impurities at ppb level.

Thats why the cationic conductivity is so important:

Cationic conductivity is a conductivity measurement after cation exchange: All

cations, and therefore ammonium ions (NH

4

+

), are removed and converted into

Hydrogen ions (H

+

). Inorganics (chloride, sulfates) and organics (acetate, formate)

anions present (counter ion of cations, Cl

-

, SO

4

2-

, .) can be easily determined

because they are in their highly conductive acidic form (H

+

, Cl

-

; 2H

+

, SO

4

2-

).

Any increase in cationic conductivity highlights anionic contamination.

It indicates trend variations but does not specify which anions are present.

Specific conductivity measures all ionic species and is located before any ionic

exchanger. It is always greater than cationic conductivity in power process water (not

in the demineralization plant)

Amines (such as morpholine): show lower volatility than ammonia and can protect

against boiler corrosion and condensate (water phases).

Morpholine decomposes into acetate (acid effect) but compensates the acidity of

boric acid and acetate.

They can produce a filming effect avoiding water coming into contact with the

circuitry.

The aim is to minimize the corrosion of iron (optimal pH about 9).

Oxygen scavengers such as hydrazine remove dissolved oxygen and limit the risk

of corrosion.

1 ppb DO produces about 80 kg rust per year.

Hydrazine is decomposed into ammonia in the boiler which increases the pH and

acts as protector against corrosion.

Other reducers (sodium bisulfate) can be used but because of their highly corrosive

decomposition (sulfur dioxide, hydrogen sulfide), they are not advised for use in

plants operating at high pressure.

Page 8 www.hachultra.com Power No. 12

Sampling points and key measurements

Condensates

Condensates are the major source of contamination because they are in contact with the

external source of pollution (raw water) when there are condenser tube leaks.

Condensates can destroy the effectiveness of boiler water treatment, leading to damage

to the boiler if they are reused without proper treatment.

Condensate water is used for cooling LP turbine sprays during start up: it can cause

pitting and then stress corrosion cracking.

Condensate polishers are used to remove ionic impurities. In this case, the limits of

water quality (cationic conductivity) are not so stringent in the condensates (before the

polisher).

Parameters:

Conductivity measurements (specific and cationic): in each hot well

compartment; at the condensate pump discharge, at the inlet/outlet of

condensate polisher (if any);

Specific conductivity:

Expected value: 2.5 S/cm to 11 S/cm if CCPP (LP drum and HP once through)

2 S/cm 6 S/cm (copper alloy tube condenser), 3 S/cm 11 S/cm

(stainless steels or titanium) if drum boilers.

Cation conductivity:

Expected value < 0.2 S/cm; level 1 < 0.5 S/cm; level 2: 0.5 to 1 S/cm;

level3 > 1 S/cm

pH measurements: condensate pump discharge, or after condensate polisher.

pH would decrease if there is a brackish water ingress. pH: 8.8 to 9.3 if copper

tubes condenser; 9 to 9.6 if steel.

Sodium measurements (1 ppb): at condensate pump discharge for monitoring

any sodium inleakage from condenser tubes more accurately and quickly than

specific conductivity. The sodium concentration must be the same in the

condenser and in the steam. If not , there is either a sodium inleakage in the

condenser (sodium in condenser > sodium in steam phase), or a sodium deposit

on turbine blades (sodium in steam > sodium in condenser)

Silica measurements: for preventing as soon as possible any deposit risk (level

< 20 ppb, drum boiler plants)

Oxygen measurements: at the condensate pump for checking any condenser air

inleakage. The deaerator eliminates dissolved gas (air inleakage).

Oxygen measurements: inlet and outlet of deaerator (< 0 ppb) for checking its

efficiency.

Power No. 12 www.hachultra.com Page 9

Feedwater (economizer inlet)

For optimizing the efficiency of the boiler, extending its lifespan and ensuring the steam

quality, quality requirements of feed water are essential. It controls the pre-boiler

corrosion risks and should an acidic condition occur, there would be rapid tube boiler

damage and immediate shutdown.

Feed water is also sprayed for control of steam temperature at superheated and

reheated outlets.

Conductivity measurements:

Levels are globally equivalent to those of condensates.

Specific: between 2 S/cm to 11 S/cm (drum boiler)

Degassed Cationic: it indicates all non volatile anions (< 0.2 S/cm)

pH measurements:

The pH of the feed water must be greater than the pH of the boiler in the case of

ammonia conditioning (volatile). If not, there are some hydroxyl ions (OH

-

) in the

liquid phases of the boiler due to raw water inleakage( HCO

3

into CO

2

(steam) +

OH

-

(liquid))

Iron systems: 9.3 to 9.6 pH

Iron/copper: 8.8 to 9.2 pH

Oxygen measurements : < 20 ppb

Silica < 20 ppb if once through steam generator (OSTG)

Hydrazine : < 20 ppb for an accurate dosing

Boiler water

Scale formation due to hardness, silica, and corrosion product deposits can decrease

the heat exchange capacity and global efficiency of the boiler.

Steam quality varies with the concentration of impurities in the boiler and the potential

mechanical carryover of boiler water droplets into the steam.

The higher the operating pressure of the boiler, the higher the purity requirements since

contaminant carryover is promoted.

The concentration of impurities after each evaporation cycles is discarded by blowdown

in drum boilers (curative and preventive actions). If impurity concentrations becomes

greater than its solubility (the lower the pressure, the lower the solubility), deposits may

occur. Evaporation, drying of moisture and chemical reactions on surfaces, or in metal

oxide can lead to deposits too.

As deposits can be very adhering, anti-scalant reagents are added to help remove them.

Page 10 www.hachultra.com Power No. 12

When quality limits are exceeded, blowdowns are increased, power reduction initiated

(level 1 of safety procedure) up to hot standby (level 2 of safety procedure) if

measurements are far too high.

Conductivity measurements :

Specific (Boiler):

Estimated limits depending upon the steam quality

For pressure < 300 psig : < 7 mS/cm; up to 600 psig: 800/5400 S;

at 1500 psig : < 100 S

In low pressure boiler:

Cationic conductivity (Blowdown): < 0.8 S/cm

Level 1 if > 0.8 S: small condenser leaks, impurity incursions

Level 2 If > 2 S: power reduction by 30%: sufficient flow for automatic control,

impurities can be located and treated (heat exchange rate has been decreased)

Level 3 if > 7 S/cm: immediate shutdown, steam generator corrosion

pH measurements:

Iron systems: pH9

Copper systems: 8.6 to 9 pH

The corrosion rate of carbon steel is minimal between pH 8.5 to 9.2

Level 1: > 8 but < 8.5 or > 9.2 but < 9.4: Chemical feed, blowdown adjusted

Power reduction by 35%

Level 2 < 8 or > 9.4: hot standby

Silica measurements (drum boiler blowdown): silica build-up in the boiler

depends on the drum pressure, < 5 ppb

Power No. 12 www.hachultra.com Page 11

Main steam, reheat steam (heat recovery steam generator)

Boiler specifications do not ensure the quality of turbine steam. The solubility limits in the

turbine define the feed water impurity levels.

The conformance with the steam limits contributes to minimize boiler blowdowns.

Steam is a good solvent at high pressure and carries over oxide, silicates, sulphates,

carbonates, aluminates and chlorides, which can corrode the turbine.

Low level of impurity is mandatory; CO

2

interference must also be avoided.

As water can be directly injected into the turbine for increasing the power output, its

quality must obviously be under control.

The gas turbine compressor can also be washed for removing fouling deposits if

increased back pressure, and decreased power output are noticed.

The quality of water must conform to the following limits: 8 S/cm and 6.5 to 7.5 pH.

pH measurements:

Copper tube condenser: 8.8 to 9.3 pH

Stainless steel tube condenser: 9 to 9.6 pH

If CCPP (LP drum and HP once through): LP main steam at boiler outlet: 9.5 to

9.9 pH

HP main steam at once through steam generator (OSTG): 9 to 9.4 pH

Conductivity measurements:

Specific:

If CCPP (LP drum and HP once through): LP main steam at boiler outlet:

< 20 S/cm

HP main steam at once through steam generator (OSTG): < 10 S/cm

Cationic:

< 0.2 S/cm

Sodium measurement: < 5 ppb

Silica measurement: < 5 ppb, deposit on turbine blades

Page 12 www.hachultra.com Power No. 12

Cooling water

Operating principle

Cooling water uses raw water for cooling the condenser tubes and maintaining their

efficiency. At the inlet of the condenser, the cooling water is quite cold, depending on the

temperature of the river.

After having cooled the condenser, it returns to the cooling tower at a higher temperature

than that at the inlet of the condenser where it is sprayed in the cooling tower and cooled

via air.

Excess energy in the form of heat is evaporated through the top of the cooling tower

(look at the water vapor!). As there are evaporation cycles in the cooling tower, there is a

concentration effect of the water.

Concentration cycles

Depending on the construction material of the cooling systems, limits in the cycles of

concentration are fixed (concentration rate of 1.2 /1.7). For this reason, blowdowns of

cooling water are performed and key parameters monitored.

Inductive conductivity can also be used for monitoring the concentration cycles and

Alkalinity (P and M), and hardness are monitored in the largest cooling towers to

evaluate the calcium carbonate precipitation risk.

pH measurement must be less than the critical pH (8.3) where the calcium carbonate

begins to precipitate: H

2

SO

4

is injected for decreasing the TAC (total alkalinity

carbonates) according to the SALE factor (depending on the TAC, calcium hardness and

the ionic strength (conductivity).

Nevertheless, if the pH level rises above 8.3 (irrespective of the SALE factor), H

2

SO

4

is

injected to avoid the precipitation of calcium carbonate.

Sometimes, if the TAC of the raw water used is too high, the injection of H

2

SO

4

does not

avoid the precipitation of CaCO

3

. For this reason, the volume of fresh raw water is

reduced.

Microbiological induced corrosion

Raw water contains a large amount of nutrients, algae and bacteria. Algae produce

oxygen and accelerate corrosion; dead algae lead to fouling, act as food for bacteria,

and absorb biocides.

If the biological activity in a power plant is misunderstood, the availability of the power

plant can be drastically reduced. Biocides must be added to the raw water to avoid

bacteria ingress in the cooling system which could rapidly damage the power plant (raw

water inleakage in the condenser) - this minimizes microbiological induced corrosion.

If biocides are underfed, the microbiological growth can occur and if it is overfed, it costs

more money to optimize the application of biocides, redox, chlorine, and ozone can be

Power No. 12 www.hachultra.com Page 13

monitored at the raw water inlet point where oxidants (chlorine and bromine) are added

to kill micro-organisms.

Conductivity measurement can reliably detect 2 to 5 ppm of Sodium while Sodium

measurement detects 2 to 5 ppb, that's 1000 times lower. This sensitivity allows

chemists to follow trend changes before any leakage requires major immediate action.

This sensitivity advantage can be converted over time to analyse the origin of the

leakage and to plan either a production reduction, or even to stop production far enough

in advance to avoid costly, unexpected emergency shut downs.

The analyser and installation

The analyzer requires a sample at low pressure (below 6 bar) and cooled below 40C

(104F). Usually a sampling panel already exists for conductivity measurements and

these samples can be used in parallel for the Sodium analyzer. Several local or

international panel manufacturers are able to offer such systems. The Sodium analyzer

sends an analogue 4-20 mA signal to the DCS:

A trend analysis over a given rolling time period allows a 'trend warning: if the

rate of raise exceeds a pre-set value of, for example, 1 ppb per hour, then a

warning is given independently of the absolute actual sodium value.

A limit from the absolute value is set according to the accepted limit level of

pollution, for example, 100 ppb or 1 ppm, where the 'sodium alarm' will be

activated for immediate action.

Both warnings and alarms can be combined if the rate of increase becomes too

high showing a significant problem in the near term.

Material installed

POLYMETRON 9245 Sodium analyzer

Polymetron Conductivity Monec 9125 with sensor 8310 (as spare wheel!)

Comments

In several pulp mills in Scandinavia, Hach Ultra is in the phase of replacing many early

Sodium analysers with the new POLYMETRON 9245.

Most of these facilities, having old boilers, will be either closed or revamped with new

cogeneration plants. These new modern cogeneration plants operate at a high pressure

and require much higher levels of monitoring regarding the steam quality. These

upgrades are linked to new demin-plants that produce high quality pure water in terms of

conductivity and Sodium concentration.

This application is of interest for the pulp and paper industry (presence of white, green or

black liquor), in some metal production (aluminium, zinc, all extractions using caustic

solutions), in chemical plants producing or using caustic soda (sodium hypochlorite,

Solvay process) as well as for the boilers located close to the sea and/or using sea or

brackish water as cooling water.

You might also like

- 17.4 Boiler and Feed-Water TreatmentDocument28 pages17.4 Boiler and Feed-Water Treatmentnomeacuerdo1No ratings yet

- Corrosion CAUSES and MECHANISM Arumugam Anna University, Chennai, IndiaDocument76 pagesCorrosion CAUSES and MECHANISM Arumugam Anna University, Chennai, Indiadeviprasadh.a100% (3)

- PGA2012 Hyflux Hurn Hagedorn.Document32 pagesPGA2012 Hyflux Hurn Hagedorn.Uhrin ImreNo ratings yet

- Pipeline DesignDocument110 pagesPipeline DesignShaka Shalahuddin Shantika PutraNo ratings yet

- Corrosion Protection of CondesateDocument8 pagesCorrosion Protection of CondesateArselan Mustafa KhanNo ratings yet

- Age10506 PDFDocument29 pagesAge10506 PDFrichard nagilusNo ratings yet

- Achieving Sustained Benefits from Advanced Process ControlDocument10 pagesAchieving Sustained Benefits from Advanced Process ControlKumar GanapathyNo ratings yet

- Membranes For Hydrogen Separation 2007 PDFDocument33 pagesMembranes For Hydrogen Separation 2007 PDFRavi Mohan Prasad100% (1)

- R 482Document9 pagesR 482Andre Osmond Nugraha SimorangkirNo ratings yet

- Steam Generating System - Operation OverviewDocument21 pagesSteam Generating System - Operation Overviewritesh MishraNo ratings yet

- Process DescriptionDocument9 pagesProcess DescriptionnoelNo ratings yet

- Process Control Unit 4 NotesDocument21 pagesProcess Control Unit 4 NotesiamananujrNo ratings yet

- Boiler Water Treatment: Deposit ControlDocument5 pagesBoiler Water Treatment: Deposit ControlKrishna RayuduNo ratings yet

- Cathodic Protection - Rev 1Document162 pagesCathodic Protection - Rev 1Mohammed almarhabiNo ratings yet

- Split Range Control Loop - EnggcyclopediaDocument6 pagesSplit Range Control Loop - EnggcyclopediasgrsthNo ratings yet

- Hydrogen As Fuel: Teacher'S GuideDocument8 pagesHydrogen As Fuel: Teacher'S GuideHadi KhanmohammadiNo ratings yet

- DPVC 09 PetrobrasDocument47 pagesDPVC 09 PetrobrasClaudia MmsNo ratings yet

- Feed Water ManagementDocument31 pagesFeed Water ManagementAnmol AgarwalNo ratings yet

- Energy and The New Reality, Volume 2: C-Free Energy Supply Chapter 9: Carbon Capture and StorageDocument80 pagesEnergy and The New Reality, Volume 2: C-Free Energy Supply Chapter 9: Carbon Capture and StorageImane ARNo ratings yet

- Technical Survey Controls Steam Reformer Tube TemperaturesDocument8 pagesTechnical Survey Controls Steam Reformer Tube Temperaturespf06No ratings yet

- Job Description - Project Engineer (TRI000A)Document5 pagesJob Description - Project Engineer (TRI000A)abguyNo ratings yet

- Hazardous Waste Treatment PDFDocument67 pagesHazardous Waste Treatment PDFCharles Arthel ReyNo ratings yet

- AFC Case Study Ammonia ConverterDocument15 pagesAFC Case Study Ammonia ConverterAmmonia 1 EngineersNo ratings yet

- Process Wastewater CharacteristicsDocument12 pagesProcess Wastewater CharacteristicsYeAsin AraFatNo ratings yet

- A Triple Helix Pte LTD Presentation 2011Document32 pagesA Triple Helix Pte LTD Presentation 2011Shreyas BhargavNo ratings yet

- DEMINERALIZATION PROCESSDocument4 pagesDEMINERALIZATION PROCESSJoshuaGideonNo ratings yet

- Cathodic Protection Reversal TheoryDocument19 pagesCathodic Protection Reversal TheoryMuhammad ShafeeqNo ratings yet

- Overview of Petroleum Refining IDocument39 pagesOverview of Petroleum Refining ISai Kiran100% (1)

- Auxiliary System Cooling Water System: Sterling and Wilson Co-Gen SolutionsDocument29 pagesAuxiliary System Cooling Water System: Sterling and Wilson Co-Gen SolutionsKeshav Shrivastava KSNo ratings yet

- EDD Electrostatic De-ionisation DeviceDocument37 pagesEDD Electrostatic De-ionisation DeviceWilliam Burry F. GellaNo ratings yet

- AVoiding Water Hammer in Steam Systems PDFDocument12 pagesAVoiding Water Hammer in Steam Systems PDFBrightwaterprocessNo ratings yet

- The Corrosion of Superduplex SS in Different Types of SeawaterDocument9 pagesThe Corrosion of Superduplex SS in Different Types of SeawaterdevangmajithiaNo ratings yet

- LoSalt Polyamine CustomerDocument21 pagesLoSalt Polyamine CustomerDavid Cruz ZamoraNo ratings yet

- Review of Small Stationary Reformers For Hydrogen ProductionDocument52 pagesReview of Small Stationary Reformers For Hydrogen ProductionSoineth GuzmánNo ratings yet

- Everything You Need to Know About Boiler Water TreatmentDocument11 pagesEverything You Need to Know About Boiler Water TreatmentABDUL HANANNo ratings yet

- Alternative Fuels: By: Anh TranDocument24 pagesAlternative Fuels: By: Anh TransachinleoatgmailNo ratings yet

- Boiler Water Treatment FundamentalsDocument6 pagesBoiler Water Treatment FundamentalsCakrawala TritayasaNo ratings yet

- Corrosion Basics: Types, Causes and Mitigation MethodsDocument16 pagesCorrosion Basics: Types, Causes and Mitigation MethodsM Syifaut TamamNo ratings yet

- BODDocument7 pagesBODIrfan AhmedNo ratings yet

- PPChem 2017 19-02-92-102 Authors Copy PublicDocument11 pagesPPChem 2017 19-02-92-102 Authors Copy PublicJan RusaasNo ratings yet

- Urea Plant National Fertilizers LimitedDocument22 pagesUrea Plant National Fertilizers LimitedSatya Narayan SharmaNo ratings yet

- Treating Water for Power and ProcessDocument153 pagesTreating Water for Power and Processsada sivaNo ratings yet

- Electrochemistry EquilibriaDocument39 pagesElectrochemistry EquilibriaWardahNo ratings yet

- Lesson From Seveso ItalyDocument48 pagesLesson From Seveso ItalyBilal ZamanNo ratings yet

- SURFACE COAL GASIFICATION EXPERIENCE FROM TALCHER FERTILIZER PROJECTDocument37 pagesSURFACE COAL GASIFICATION EXPERIENCE FROM TALCHER FERTILIZER PROJECTAlfin A. N.No ratings yet

- Chloride Attack and Sulfate AttackDocument22 pagesChloride Attack and Sulfate AttackMohammed FaseehullaNo ratings yet

- Cansolv TGT Plus FactsheetDocument2 pagesCansolv TGT Plus FactsheetPe VandeNo ratings yet

- Columns: An Introductory Guide To Columns For Chemical EngineersDocument53 pagesColumns: An Introductory Guide To Columns For Chemical EngineersHerawan Mulyanto100% (1)

- Automatic Sampling BrochureDocument24 pagesAutomatic Sampling Brochurevuong100% (1)

- Nitric AcidDocument4 pagesNitric AcidAłéñà IqbàłNo ratings yet

- Saes A 010Document32 pagesSaes A 010hyderabadNo ratings yet

- Material Balance LectureDocument52 pagesMaterial Balance LectureAsh YehiaNo ratings yet

- Vol 1 - Boiler Guidelines-CombinedDocument56 pagesVol 1 - Boiler Guidelines-CombinedHolayilNo ratings yet

- Dead Leg Rupture HSE 20190829Document3 pagesDead Leg Rupture HSE 20190829kuraimundNo ratings yet

- Cycle Chemistry CommissioningDocument11 pagesCycle Chemistry CommissioningKrishnan Mani100% (1)

- Expert system tutorialDocument9 pagesExpert system tutoriallinanofitaNo ratings yet

- Deionized For Cooling Tower PDFDocument8 pagesDeionized For Cooling Tower PDFThipsuree KornboonraksaNo ratings yet

- Sabp A 056 PDFDocument36 pagesSabp A 056 PDFWalid MegahedNo ratings yet

- SteamDocument9 pagesSteamNESAEIDARYOUSHNo ratings yet

- Manufacture of Soda by Hou Te-PangDocument614 pagesManufacture of Soda by Hou Te-PangAurenio RibeiroNo ratings yet

- Lectuer-11 EvaporatorDocument41 pagesLectuer-11 EvaporatorAurenio RibeiroNo ratings yet

- 5 Main Functions of Salt (Sodium Chloride) In Food - The Food UntoldDocument9 pages5 Main Functions of Salt (Sodium Chloride) In Food - The Food UntoldAurenio RibeiroNo ratings yet

- Dog Repeller-1Document1 pageDog Repeller-1Aurenio RibeiroNo ratings yet

- Let Them Beat CakeDocument3 pagesLet Them Beat CakeAurenio RibeiroNo ratings yet

- Effects of Gas Composition On The Performance and PDFDocument9 pagesEffects of Gas Composition On The Performance and PDFAurenio RibeiroNo ratings yet

- HD2016 Operation Manual V1.0Document43 pagesHD2016 Operation Manual V1.0Dzulham ChaniagoNo ratings yet

- TGA DSC Reading MaterialDocument58 pagesTGA DSC Reading MaterialSaurabh ShashankNo ratings yet

- 5AA BarometCondens PDFDocument12 pages5AA BarometCondens PDFahmed nawazNo ratings yet

- CHAPTER 7 LECTURE NOTES: FARADAY'S LAWS AND ELECTROLYSISDocument3 pagesCHAPTER 7 LECTURE NOTES: FARADAY'S LAWS AND ELECTROLYSISAurenio RibeiroNo ratings yet

- Vacuum Tube Amplifier Circuits and EquationsDocument5 pagesVacuum Tube Amplifier Circuits and EquationsAurenio RibeiroNo ratings yet

- Kern Method Heat ExchangerDocument30 pagesKern Method Heat ExchangerCS100% (3)

- AB Jet Mill - Products - Weifang Jinghua Powder Engineering Equipment CoDocument3 pagesAB Jet Mill - Products - Weifang Jinghua Powder Engineering Equipment CoAurenio RibeiroNo ratings yet

- Perfect Pool GuidebookDocument103 pagesPerfect Pool GuidebookAnonymous FlisDn100% (1)

- Servicing Salt - Pool & Spa NewsDocument4 pagesServicing Salt - Pool & Spa NewsAurenio RibeiroNo ratings yet

- Global Pattern of MP in Food-Grade Salt - ACSDocument10 pagesGlobal Pattern of MP in Food-Grade Salt - ACSAurenio RibeiroNo ratings yet

- Concentration of Solutions and Molarity: What We Need Is A Way of Quantifying The Concentration of A Solution!Document32 pagesConcentration of Solutions and Molarity: What We Need Is A Way of Quantifying The Concentration of A Solution!MohammedNo ratings yet

- Chemical Admixtures - NJIT PDFDocument61 pagesChemical Admixtures - NJIT PDFjuliovechimgmail100% (1)

- Energia Solar 1Document45 pagesEnergia Solar 1Aurenio RibeiroNo ratings yet

- High Range Water ReducerDocument13 pagesHigh Range Water ReducerAurenio RibeiroNo ratings yet

- Effects of Gas Composition On The Performance andDocument9 pagesEffects of Gas Composition On The Performance andAurenio RibeiroNo ratings yet

- Measuring H2O2 Mass Percent by TitrationDocument8 pagesMeasuring H2O2 Mass Percent by TitrationAurenio RibeiroNo ratings yet

- Rom Bean To Bar - Image Brochure enDocument20 pagesRom Bean To Bar - Image Brochure enXiaowei Richard WangNo ratings yet

- PHEROMONES - Gas ChromatographyDocument9 pagesPHEROMONES - Gas ChromatographyAurenio RibeiroNo ratings yet

- Precautions SSRDocument9 pagesPrecautions SSRchandushar1604No ratings yet

- USP-06-1 SaltDocument1 pageUSP-06-1 SaltAurenio RibeiroNo ratings yet

- Product Recall ProceduresDocument17 pagesProduct Recall ProceduresAurenio RibeiroNo ratings yet

- Salt From Hot Air - Aproveitamento de Vapor Com Baixa PressãoDocument5 pagesSalt From Hot Air - Aproveitamento de Vapor Com Baixa PressãoAurenio RibeiroNo ratings yet

- Ge 1000 MW Usc TurbineDocument14 pagesGe 1000 MW Usc TurbinetpplantNo ratings yet

- Power Plant ValveDocument63 pagesPower Plant Valvenjc6151100% (2)

- Thermowell Material Selection Guide: Heat TreatingDocument11 pagesThermowell Material Selection Guide: Heat TreatingTelugu MoviesNo ratings yet

- Mustang Skid Steer Loader 2066 2076 2086 Service ManualDocument23 pagesMustang Skid Steer Loader 2066 2076 2086 Service Manualtamaramartinez020802wkb100% (112)

- Biomass-Fired CHP Plant Based On A Screw-Type Engine Cycle"Document4 pagesBiomass-Fired CHP Plant Based On A Screw-Type Engine Cycle"Lahiru BoralugodaNo ratings yet

- Index For StandardsDocument74 pagesIndex For StandardsHani KirmaniNo ratings yet

- Project Report On Thermal PlantDocument58 pagesProject Report On Thermal PlantTech GuruNo ratings yet

- ScanTech Offshore Brochure 2020 OptimisedDocument28 pagesScanTech Offshore Brochure 2020 OptimisedMariana HusainNo ratings yet

- Introduction To Safety ValvesDocument6 pagesIntroduction To Safety Valvesjp mishraNo ratings yet

- Case - Project ProposalDocument6 pagesCase - Project ProposalAnkit Mishra100% (2)

- Indian Boilers Regulations - 1950Document21 pagesIndian Boilers Regulations - 1950dchz_62No ratings yet

- Process DescriptionDocument6 pagesProcess Descriptionافكر اشتري كورياNo ratings yet

- Feed Water ControllDocument21 pagesFeed Water ControllajmalnasirNo ratings yet

- Steam Turbine ManualDocument261 pagesSteam Turbine ManualShivam Kumar67% (3)

- Steam Blowing ProcedureDocument15 pagesSteam Blowing ProcedureDangol100% (14)

- BoilerDocument48 pagesBoilerAbdallah Mansour100% (2)

- CFB Boiler Babcock Br-1629Document9 pagesCFB Boiler Babcock Br-1629Diệp ThắngNo ratings yet

- Energy Efficient HeatingDocument40 pagesEnergy Efficient HeatingzukchuNo ratings yet

- Chapter 8Document7 pagesChapter 8Dwayne BrownNo ratings yet

- Recovering Waste Heat from Navy Boiler StacksDocument99 pagesRecovering Waste Heat from Navy Boiler StacksM.AherNo ratings yet

- Bee045 Power PlantDocument67 pagesBee045 Power PlantMeer khakhal khanNo ratings yet

- Inspections and Survey Procedures in Auxiliary BoilerDocument16 pagesInspections and Survey Procedures in Auxiliary BoilerkrishnaNo ratings yet

- Safety Relief Valves - Installation and MaintenanceDocument3 pagesSafety Relief Valves - Installation and MaintenanceBramJanssen76No ratings yet

- Effect of Water Chemistry On Deposition Rate of Iron Corrosion Products in Boiler TubesDocument6 pagesEffect of Water Chemistry On Deposition Rate of Iron Corrosion Products in Boiler TubesArunkumar ChandaranNo ratings yet

- UFC 3-400-10N Mechanical EngineeringDocument48 pagesUFC 3-400-10N Mechanical EngineeringsabotaaageNo ratings yet

- Rhein StromDocument20 pagesRhein Stromalecugeorgescu100% (1)

- overview of Possible Uses of SawdustDocument194 pagesoverview of Possible Uses of SawdustMoreMoseySpeedNo ratings yet

- Boiler Efficiency ModuleDocument2 pagesBoiler Efficiency ModuleCatalin MunteanuNo ratings yet

- Economizer: Economizers (US andDocument8 pagesEconomizer: Economizers (US andprathapNo ratings yet

- Chapter 8 - SolutionDocument43 pagesChapter 8 - SolutionIzaNo ratings yet