Professional Documents

Culture Documents

ECIV 3316 - Chapter 05 - Shear in Beams + Example

Uploaded by

buffyto5377Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ECIV 3316 - Chapter 05 - Shear in Beams + Example

Uploaded by

buffyto5377Copyright:

Available Formats

CHAPTER FIVE SHEAR IN BEAMS 1

4 CHAPTER 5: SHEAR IN BEAMS

5.1 Introduction

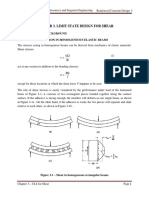

Loads applied to beams produce bending moments, shearing forces, as shown in Figure 5.1,

and in some cases torques. Design for bending has been elaborately discussed in chapter 4

and torsion will be discussed in chapter 6. In this chapter, design of beams for shear will be

dealt with.

(a) (b)

Figure 5.1: Shear in beams: (a) loaded beam; (b) internal forces at

section A-A

Beams are usually designed for bending moment first; thus cross sectional dimensions are

evaluated along with the required amounts of longitudinal reinforcement. Once this is done,

sections should be checked for shear to determine whether shear reinforcement is required

or not. This by no means indicates that shear is less significant than bending. On the

contrary, shear failure which is usually initiated by diagonal tension is far more dangerous

than flexural failure due to its brittle nature.

5.2 Shear in Homogeneous, Elastic Beams

For good understanding of the subject, consider a simply supported beam subjected to a

uniformly distributed load as shown in Figure 5.2.a. Furthermore, it is assumed that the

beam is made of elastic, homogeneous material.

CHAPTER FIVE SHEAR IN BEAMS 2

Figure 5.2.a : Loaded beam and orientation of cracks

The normal stresses

x

f resulting from bending are given by the following equation as

proved by the classical bending theory;

x

x

x

I

y M

f = ( 5.1)

where

x

M is the bending moment at the section under consideration, y is the distance from

the point under consideration to the neutral axis, and

x

I is the moment of inertia about the

neutral axis.

The shearing stresses

x

are given by the following equation proved in the most classical

mechanics of materials books:

b I

Q V

x

x x

x

= ( 5.2)

where

x

V is the shearing force at the considered section,

x

Q is the moment of the area of

the section located between the point where the shearing stresses are calculated and the

extreme fiber of the section about the neutral axis,

x

I is the moment of inertia about the

neutral axis, and b is the width of the section at the point where shearing stresses are

calculated.

In an attempt to establish the cracking pattern, four elements situated at different distances

from the neutral axis are studied.

Element (1):

It is subjected only to normal, tensile stresses resulting from bending, as shown in Figure

5.2.b. The principal tensile stress is in the same direction as the normal tensile stress. Thus

cracking takes place on a vertical plane due to the weakness of concrete in tension.

CHAPTER FIVE SHEAR IN BEAMS 3

Figure 5.2.b: Principal stresses on elements 1,2,3 and 4

Element (2):

Element (2) that is located below the neutral axis is subjected to normal tensile stresses in

addition to shearing stresses. The cracking surface makes an angle larger than 45 degrees

with the horizontal axis. Cracking takes place on a plane perpendicular to the plane on

which principal tensile stresses occur. See Figure 5.2.b for the orientation of principal

tension stresses along a diagonal crack.

Element (3):

Element (3) that is located at the neutral axis is only subjected to pure shearing stresses.

The cracking surface makes an angle of 45 degrees with the horizontal axis. Thus cracking

takes place on a plane perpendicular to the principal tensile stress, as shown in Figure.5.2.b.

Element (4):

Element (4) that is located above the neutral axis is subjected to normal compressive

stresses in addition to shearing stresses. The cracking surface makes an angle smaller than

45 degrees with the horizontal axis. Cracking takes place on a plane perpendicular to the

CHAPTER FIVE SHEAR IN BEAMS 4

plane on which principal tensile stresses occur. See Figure 5.2.b for the orientation of

principal tension stresses along a diagonal crack.

It is concluded that the shearing force acting on a vertical section in a reinforced concrete

beam does not cause direct rupture of that section. Shear by itself or in combination with

flexure may cause failure indirectly by producing tensile stresses on inclined planes. If

these stresses exceed the relatively low tensile strength of concrete, diagonal cracks

develop. If these cracks are not checked, splitting of the beam or what is known as diagonal

tension failure will take place.

5.3 Types of Shear Cracks

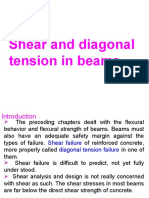

Two types of inclined cracking occur in beams: flexure-shear cracking and web-shear

cracking, shown in Figure 5.3.

A. Flexure-Shear Cracks

The most common type, develops from the tip of a flexural crack at the tension side of the

beam and propagates towards mid depth until it is checked on the compression side of the

beam. For these cracks to form, the bending moment must exceed the cracking moment of

the cross section and a significant shear must exist.

CHAPTER FIVE SHEAR IN BEAMS 5

Figure 5.3: Types of cracks and associated internal forces: (a) orientation

of cracks; (b) shear force diagram; (c) bending moment diagram

B. Web Shear Cracks

Web shear cracking begins from an interior point in a member at the level of the centroid of

uncracked section and moves on a diagonal path to the tension face when the diagonal

tensile stresses produced by shear exceed the tensile strength of concrete. This type of

cracking is common on beams with thin webs and in regions of high shear and small

moment. This combination exists adjacent to simple supports or at points of inflection in

continuous beams.

5.4 Nominal Shear Stress

The only equation available to relate shear stress to shearing force is derived for a beam of

constant cross section constructed of a homogeneous elastic material. Unfortunately, Eq.

(5.2) can not be applied to reinforced concrete beams for the following reasons:

Reinforced concrete is non-homogeneous material.

(b)

(a)

(c)

CHAPTER FIVE SHEAR IN BEAMS 6

Concrete is not elastic.

Variable extent of cracking along the length of a beam, making it impossible to

determine cross-sectional properties.

Therefore, the ACI Code has adopted a simple procedure for establishing the magnitude of

shear stress v on a cross section

d b

V

v

w

= ( 5.3)

where

v = nominal shear stress

V = shearing force at specified section

w

b = width of web of cross section

d = effective depth of the section.

5.5 Current Shear Design Philosophy

The current ACI Code shear design procedure is based on the assumption that for beams

with no shear reinforcement, failure takes place on a vertical plane when the factored shear

force on this plane exceeds the fictitious shear strength of concrete. The fictitious shear

strength of concrete is evaluated from empirical expressions specified within the ACI Code.

This simplification is done due to the following reasons:

Strength of concrete in tension is highly variable, making it hard to evaluate a

sustainable diagonal tension.

Non-homogeneity of reinforced concrete which makes accurate computation of shear

stresses on a particular section a tough task.

Shear failures occur on diagonal planes as they are usually initiated by diagonal

tension.

According to ACI Code 11.1.1, design of cross sections subject to shear should be based on

the following equation.

u n

V V ( 5.4)

where

u

V = factored shear force at section considered

CHAPTER FIVE SHEAR IN BEAMS 7

n

V = nominal shear strength

= strength reduction factor for shear = 0.75

The nominal shear force is generally resisted by concrete and shear reinforcement or,

s c n

V V V + = ( 5.5)

where

c

V = nominal shear force resisted by concrete

s

V = nominal shear force resisted by shear reinforcement

5.6 Internal Forces in a Beam without Shear Reinforcement

The shear strength of a reinforced concrete beam without shear reinforcement is attributed

to three main sources, shown in Figure 5.4.

z c

V is the shear in the uncracked concrete in the

compression zone,

a

V is the vertical component of the shear transferred across the crack by

interlock of the aggregate particles on the two faces of the crack, and

d

V is the dowel action

of the longitudinal reinforcement. The ACI Code considers the three components combined

as the shear force resisted by concrete

c

V , or

d a z c c

V V V V + + = ( 5.6)

Figure 5.4: Behavior of beams failing in shear

5.7 Strength of Concrete in Shear

Shear strength of concrete

c

V is evaluated by loading a plain concrete beam to failure.

Shear stresses are computed by dividing the shearing force resisted by concrete

c

V by

d b

w

. Strength of concrete in shear is directly proportional to the strength of concrete in

CHAPTER FIVE SHEAR IN BEAMS 8

tension, inversely proportional to the magnitude of bending moment at the section under

consideration, and directly proportional to the reinforcement ratio of flexural reinforcement.

For the sake of simplicity

c

V is assumed to be the same for beams with or without shear

reinforcement.

For members subject to shear and bending only, ACI Code 11.2.1.1 gives the following

equation for evaluating

c

V

d b ' f 53 . 0 V

w c c

= ( 5.7)

Eq. (5.7) assumes a constant value of

c

V for all sections along the length of the beam.

A more exact formula is specified by ACI Code 11.2.2.1, given by Eq. (5.8)

d b

M

d V

176 ' f 5 . 0 V

w

u

u

w c c

+ = ( 5.8)

where

u

V is the factored shearing force,

u

M is the factored bending moment occurring

simultaneously with

u

V at section considered,

w

is the reinforcement ratio of the web, and

d is the effective depth of the beam. In Eq. (5.8)

u

u

M

d V

should not exceed 1.0, and

c

V

should not exceed d b ' f 93 . 0

w c

.

For members subject to axial compression plus shear, ACI Code 11.2.1.2 gives the

following equation for evaluating

c

V

d b ' f

A 140

N

1 53 . 0 V

w c

g

u

c

+ = ( 5.9)

where

u

N is the factored axial load normal to the cross section occurring simultaneously

with

u

V , and

g

A is the gross area of the cross section. In Eq. (5.9) the shearing force resisted

by concrete

c

V is increased due to the presence of axial compression since the diagonal

tension is decreased.

ACI Code 11.2.2.2 specifies that for members subject to axial compression, it shall be

permitted to compute

c

V using Eq. (5.8) with

m

M substituted for

u

M and

u

u

M

d V

not then

limited to 1.0,

CHAPTER FIVE SHEAR IN BEAMS 9

( )

8

d h 4

N M M

u u m

= (5.10)

where h is overall height of member and

c

V shall not be greater than

g

u

w c c

A 35

N

1 d b ' f 93 . 0 V + = (5.11)

When

m

M as computed by Eq. (5.10) is negative,

c

V shall be computed by Eq. (5.11).

For members subject to axial tension plus shear, ACI Code 11.2.1.3 states that

c

V shall be

taken as zero unless a more detailed analysis is made using ACI 11.2.2.3.

ACI 11.2.2.3 gives the following equation for evaluating

c

V :

d b ' f

A 35

N

1 53 . 0 V

w c

g

u

c

+ = (5.12)

where

u

N is the factored axial load normal to the cross section occurring simultaneously

with

u

V and is taken negative,

g

A is the gross area of the cross section and

c

V shall not be

less than zero.

In Eq. (5.12) the shearing force resisted by concrete

c

V is decreased due to presence of

axial tension which causes widening of cracks.

According to ACI Code 11.2.3, for circular members, the area used to compute

c

V is taken

as the product of the diameter and effective depth of the concrete section. It is permitted to

take d as 0.80 times the diameter of the concrete section.

5.8 Strength Provided by Shear Reinforcement

When the nominal shearing force

n

V exceeds the shearing force that can be resisted by

concrete alone

c

V , shear reinforcement, in any of the forms shown in the following section,

can be used.

5.8.1 Types of Shear Reinforcement

When shear reinforcement is required, the following types of shear reinforcement are

permitted by ACI Code 11.4.1, as shown in Figure 5.5.

a. Vertical Stirrups;

CHAPTER FIVE SHEAR IN BEAMS 10

b. Inclined stirrups making an angle of 45 degree or more with longitudinal tension

reinforcement;

c. Longitudinal reinforcement with bent portion making an angle of 30 degree or

more with the tension reinforcement;

d. Spirals, circular ties, or hoops;

e. Combination of stirrups and bent longitudinal reinforcement.

f. Welded wire reinforcement with wires located perpendicular to axis of member.

Before diagonal cracking occurs, the stirrups remain unstressed. After cracking, the stress

in the stirrups increases as they pick up a portion of the load formerly carried by the

uncracked concrete.

CHAPTER FIVE SHEAR IN BEAMS 11

Figure 5.5: Types of shear reinforcement: (a) vertical stirrups; (b) inclined

stirrups; (c) bent-up bars (two groups); (d) bent-up bars (three groups)

In Figure 5.6, assume an inclined crack making an angle of 45 degree with the longitudinal

reinforcement and extending from the longitudinal reinforcement to the compression zone

of the beam. For the shear reinforcement to be effective, it should intersect this diagonal

crack. Let n be the number of shear reinforcing bars intersecting such crack. The shearing

force resisted by shear reinforcing bars across the crack

s

V is given by

(b)

(a)

(c)

(d)

CHAPTER FIVE SHEAR IN BEAMS 12

Figure 5.6: Shear resisted by stirrups

sin T V

s

= (5.13)

where T is the resultant of the forces in the shear reinforcement across the crack and given

by

yt v

f A n T = (5.14)

where

v

A is the total area of shear reinforcement within a distance S ,

and

yt

f is the yield stress of the shear reinforcement.

n is given by

( )

S

d

S

d

S

S

n

) 1 (cot 45 cot cot

1

+

=

+

= =

o

(5.15)

Substituting Eq. (5.14) and Eq. (5.15) into Eq. (5.13), one gets

( ) ( )

S

cos sin d f A

S

f sin A 1 cot d

V

yt v yt v

s

+

=

+

= (5.16)

For vertical stirrups, is equal to 90 degrees, and Eq. (5.16) takes the following form

S

d f A

V

yt v

s

= (5.17)

Eq. (5.18) is valid for inclined stirrups and longitudinal bars bent at more than one point.

When longitudinal reinforcement is bent at a single point,

s

V is given by

d b ' f 8 . 0 sin f A V

w c y v s

= (5.18)

where is the angle between bent-up reinforcement and longitudinal axis of the member.

CHAPTER FIVE SHEAR IN BEAMS 13

5.8.2 Minimum Amount of Shear Reinforcement

The instant diagonal crack forms, the tension carried by the concrete must be transferred to

the stirrups if the beam is not to split into two sections. To ensure that the stirrups will have

sufficient strength to absorb the diagonal tension in the concrete, ACI Code 11.4.6 states

that a minimum area of shear reinforcement is to be provided in concrete members where

the factored shearing force

u

V exceeds half the shear strength provided by concrete

c

V 50 . 0 , except for the following:

Footings and solid slabs.

Concrete joist construction.

Beams with h not greater than 25 cm.

Beams integral with slabs with h not greater than 60 cm and not greater than the lrger

of 2.5 times thickness of flange, and 0.5 times width of web

These exceptions were made because there is a possibility of load sharing between weak

and strong areas.

Where shear reinforcement is required by ACI 11.4.6.1 or for strength and where ACI

11.5.1 allows torsion to be neglected, ACI Code 11.4.6.3 requires that the minimum area of

shear reinforcement,

min , v

A is computed by

yt

w

c min , v

f

S b

' f 2 . 0 A = (5.19)

but not less than be less than

yt

w

min , v

f

S b 5 . 3

A =

where

min , v

A is the minimum area of shear reinforcement within a distance S ,

w

b is the

web width, S is the spacing of shear reinforcement, and

yt

f is the yield stress of the shear

reinforcement.

5.8.3 Maximum Stirrup Spacing

The assumption made in Eq. (5.17) is that one or more stirrups cross each potential

diagonal crack in order to prevent the beam from splitting into two sections between

stirrups. To ensure that, this requirement is satisfied, ACI Code 11.4.5.1 through 11.4.5.3

specifies the following limits for maximum spacing of shear reinforcement.

CHAPTER FIVE SHEAR IN BEAMS 14

A. Vertical Stirrups:

When d b f V

w c s

,

max

S is limited to the smaller of d/2 or 60 cm. This ensures

that at least one stirrup with adequate anchorage will be available to hold the upper

and lower sections together.

When d b f V d b f

w c s w c

> > 10 . 2 ,

max

S is limited to the smaller of d/4 or 30

cm, to ensure that each potential diagonal crack will be crossed by approximately

three stirrups. See Figure 5.7 for schematic representation.

B. Inclines stirrups and Bent-up Bars:

When d b f V

w c s

, inclined stirrups and bent-up longitudinal bars are spaced such that

every 45-degree line, extending toward the reaction from mid depth of member d/2 to

longitudinal tension reinforcement, is to be crossed by at least one stirrup or bent-up bar. If

d b f V d b f

w c s w c

> > 10 . 2 , the line is to be crossed by at least two stirrups or two

groups of bent up bars.

The limit on maximum stirrup spacing serves to limit diagonal crack widths and to provide

a better anchorage for the longitudinal reinforcement against breaking through the concrete

cover or loss of bond with the concrete around the bars.

CHAPTER FIVE SHEAR IN BEAMS 15

Figure 5.7: Maximum stirrup spacing

5.8.4 Ensuring Ductile Behavior

To prevent a shear-compression failure caused by diagonal compression stresses in the

compression zone above the tip of a diagonal crack, ACI Code 11.4.7.9 requires that the

maximum force resisted by shear reinforcement

s

V is not to exceed d b ' f 2 . 2

w c

. Since

diagonal tensile stresses develop in the direction perpendicular to the compressive stresses,

the compressive strength of the concrete will be less than that based on the

Uniaxial test. This is done to ensure a ductile mode of failure by forcing the shear

reinforcement to yield before the concrete starts to crush.

CHAPTER FIVE SHEAR IN BEAMS 16

5.9 Critical Section for Shear

According to ACI Code 11.1.3.1, sections located less than a distance d from face of

support are permitted to be designed for the same shear as that calculated at a distance d.

Conditions for the validity of ACI Code 11.1.3.1 are listed in ACI Code 11.1.3 and given

here:

Loads applied near the top of the member, shown in 5.8.a and 5.8.b.

No concentrated loads are applied between the face of support and a distance d from

it, shown in 5.8.c. Otherwise the critical section for shear is taken at the face of the

support.

Support reaction in direction of applied shear, introducing compression into the end

region of the member, shown in 5.8.d. If tension is introduced, the critical section is

taken at the face of the support.

Figure 5.8: Location of critical section for shear

This provision recognizes that a crack adjacent to a support whose reaction induces

compression into a beam will have a horizontal projection of at least d; therefore the

maximum shear force that must be transmitted across the potential failure plane closest to

the support will be equal to the reaction R reduced by any external forces applied to the

beam with a distance d from the support.

(b)

(d) (c)

(a)

CHAPTER FIVE SHEAR IN BEAMS 17

5-10 Punching (Two-way) Shear

When loads are applied over small areas to slabs and footings with no beams, punching

failure may occur. The sloping failure surface takes the shape of a truncated pyramid in

case of rectangular or square columns and a truncated cone in case of circular columns, as

shown in Figure 5.9.

Figure 5.9: Punching shear: (a) punching shear failure of an isolated

footing; (b) actual failure surface; (c) assumed failure surface

The ACI Code R11.11.1.2 assumes that failure takes place on vertical planes located at

distance d/2 from faces of column. In ACI Code 11.11.2.1, the punching shear strength

c

V

is given by the smallest of:

d b

2

1 ' f 53 . 0 V

c c o

+ = (5.20)

d b ' f V

c c o

= (5.21)

d b ' f 2

b

d

27 . 0 V

c

s

c o

o

+ = (5.22)

where

o

b is the perimeter of the critical punching shear section for slabs and footings, d is

the effective depth,

c

is the ratio of long side to short side of column, and

s

is a constant

dependent on the location of the column relative to the slab or footing; is equal to 40 for

interior columns, 30 for side columns, and 20 for corner columns.

(b)

(c)

(a)

CHAPTER FIVE SHEAR IN BEAMS 18

For interior square columns, the perimeter of the critical section ) ( 4 d c b

o

+ = , for

rectangular columns, ) 2 ( 2 d c c b

o

+ + = , and for circular columns, ) ( d D b

o

+ = , where c,

c , and D are column cross sectional dimensions for rectangular and circular columns

respectively. (see Figure 5.10).

(a)

CHAPTER FIVE SHEAR IN BEAMS 19

(b)

Figure 5.10: Punching shear surface for isolated footings:

(a) rectangular column; (b) circular column

The design equation is given here

c u

V V (5.23)

where

u

V is the factored shearing force, is the strength reduction factor for shear, and

c

V

is the nominal punching shear provided by concrete.

5.11 Summary of ACI Shear Design Procedure for Beams

Once the beam is designed for moment, thus establishing the concrete dimensions and the

required longitudinal reinforcement, the beam is designed for shear as explained in the next

steps.

1. Draw the shearing force diagram and establish the critical section for shear.

2. Calculate the nominal capacity of concrete in shear,

c

V .

3. Check whether the chosen concrete dimensions are adequate for ensuring a ductile

mode of failure. If not satisfied, the concrete dimensions should be increased.

4. Classify the factored shearing forces acting on the beam according to the following

categories:

CHAPTER FIVE SHEAR IN BEAMS 20

For

c u

V V 50 . 0 , no shear reinforcement is required.

For

c u c

V V V > > 50 . 0 , minimum shear reinforcement is required.

For

c u

V V shear reinforcement is required. When more than one type of shear

reinforcement is used to reinforce the same portion of a beam, shear strength

s

V is

calculated as the sum of the

s

V values evaluated from each type.

5. Check the spacing between shear reinforcement according to ACI Code limits

discussed earlier in this chapter.

6. Sketch the shear reinforcement along the length of the beam.

1

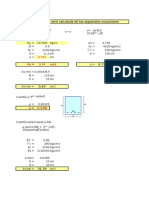

Example (5.1):

A rectangular beam has the dimensions shown in the figure and is loaded with a 40 ton

concentrated factored load at the middle of the span. Design the necessary shear

reinforcement given that

2

/ 250 cm kg f

c

= and

2

/ 4200 cm kg f

y

= . Width of support is

equal to 30 cm.

Solution:

Assuming 8 mm stirrups,

cm d 95 . 63 25 . 1 80 . 0 4 70 = =

1- Draw shearing force diagram:

Shearing force diagram is shown in the figure.

2- Calculate the shear capacity of concrete:

( ) ( ) tons 06 . 12

1000

95 . 63

30 250 53 . 0 75 . 0 V

c

=

=

(a) Beam and loads; (b) shear force diagram; (c) bending moment

diagram

(a)

(b)

(c)

2

3- Check whether the dimensions of the cross section are adequate for ensuring a

ductile mode of failure:

s c

u

V V

V

+ =

tons 59 . 10

75 . 0

06 . 12

75 . 0

0 . 20

V

s

= =

( ) tons 59 . 10 tons 74 . 66

1000

95 . 63

30 250 2 . 2 d b ' f 2 . 2

w c

> =

=

i.e. cross sectional dimensions are adequate in terms of preventing brittle mode of failure.

4- Classify the factored shear force:

c u

V V >

Trying two-legged 8 mm vertical stirrups, its spacing is evaluated from Eq. (5.17)

( )

( ) ( )

cm / cm 0394 . 0

95 . 63 4200

1000 59 . 10

d f

V

S

A

2

yt

s v

= = =

The required shear reinforcement is not to be less than the larger of:

( )

cm / cm 0226 . 0

4200

30 250 20 . 0

f

b ' f 20 . 0

S

A

2

yt

w c

min

v

= = =

and

( )

cm / cm 0025 . 0

4200

30 5 . 3

f

b 5 . 3

S

A

2

yt

w

min

v

= = =

cm / cm 0394 . 0

2

< O.K.

5- Check stirrups spacing:

( ) tons 59 . 10 tons 37 . 33

1000

95 . 63

30 250 1 . 1 d b ' f 1 . 1

w c

> =

=

Maximum stirrup spacing is not to exceed the smaller of d/2 = 31.97 cm or 60 cm.

Use 8 mm vertical stirrups spaced at 25 cm.

6- The shear reinforcement is drawn in the figure.

3

Shear reinforcement

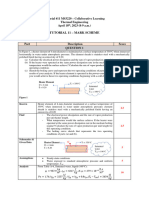

Example (5.2):

A rectangular beam has the dimensions shown in the figure and is loaded with a uniform

service dead load of 4.0 t/m (including own weight of beam) and a service live load of 2.5

t/m. Design the necessary shear reinforcement given that

2

/ 280 cm kg f

c

= and

2

/ 4200 cm kg f

y

= . Width of support is equal to 30 cm.

(a) Beam and loads; (b) shearing force diagram

Solution:

1- Draw shearing force diagram:

The shearing force diagram is shown in the figure.

Shear force at the centerline of the support is given as:

(b)

(a)

4

( ) ( ) [ ]( ) tons 8 . 30 2 / 7 5 . 2 6 . 1 4 2 . 1 V

u

= + =

Critical section for shear is located at a distance of 54.2 cm from the face of support. From

similar triangles, design shear force is equal to 24.71 tons.

2- Calculate the shear capacity of concrete:

( ) ( ) tons 82 . 10

1000

2 . 54

30 280 53 . 0 75 . 0 V

c

=

=

tons 41 . 5

2

V

c

=

s c

u

V V

V

+ =

tons 52 . 18

75 . 0

82 . 10

75 . 0

71 . 24

V

s

= =

3- Check whether the dimensions of the cross section are adequate for ensuring a

ductile mode of failure:

( ) tons 52 . 18 tons 86 . 59

1000

2 . 54

30 280 2 . 2 d b ' f 2 . 2

w c

> =

=

i.e. cross sectional dimensions are adequate in terms of preventing brittle mode of failure.

4- Classified the factored shear forces:

The forces are shown in the figure.

Shear force zone classification

Zone (A):

2

c

u

V

V

5

No shear reinforcement is required, but it is recommended to use minimum area of shear

reinforcement.

Trying 8 mm vertical stirrups

( ) ( )

( )

cm 83 . 41

30 280 2 . 0

4200 50 . 0 2

S

1

= =

( ) ( )

( )

cm 0 . 40

30 5 . 3

4200 50 . 0 2

b 5 . 3

f A

S

w

yt min , v

= = =

Maximum stirrup spacing:

Maximum stirrup spacing is not to exceed the smaller of d/2 = 27.1 cm or 60 cm. So, use

8 mm vertical stirrups spaced at 25 cm.

Zone (B):

2

c

u c

V

V V

> > , minimum shear reinforcement is required.

Use two-legged 8 mm vertical stirrups spaced at 25 cm similar to zone A.

Zone (C):

c u

V V >

s c

u

V V

V

+ =

tons 52 . 18 V

s

=

Trying two-legged 8 mm vertical stirrups, its spacing is evaluated from Eq. (4.15)

( ) ( ) ( )

( )

cm 29 . 12

1000 52 . 18

2 . 54 4200 50 . 0 2

V

d f A

S

s

yt v

= = =

( ) tons 52 . 18 tons 93 . 29

1000

2 . 54

30 280 1 . 1 d b ' f 1 . 1

w c

> =

=

Maximum stirrup spacing is not to exceed the smaller of d/2 = 27.1 cm or 60 cm. Use 8

mm vertical stirrups spaced at 12 cm.

5- Check stirrups spacing

Stirrups spacing is checked for all the zones.

6

Shear reinforcement

6- The shear reinforcement is shown in the figure.

7

Problems

P.1 Design shear reinforcement required for the beam shown in Figure P.1. The beam

carries a uniformly distributed service dead load of 2.0 t/m, including own weight of beam,

and a service live load of 2.5 t/m, in addition to two concentrated service live loads, 2.5 tons

each, distanced at 1.50 m from the supports.

Use

2

/ 250 cm kg f

c

= and

2

/ 4200 cm kg f

y

= .

Figure P4.1

P.2 The 3.0 m-long cantilever beam shown in Figure P.2 carries service loads consisting of

0.80 t/m (own weight is not included), and 2.0 ton concentrated live load at the free end.

Design the required shear reinforcement.

Use

2

/ 250 cm kg f

c

= and

2

/ 4200 cm kg f

y

= .

Figure P.2

P.3 The beam shown in Figure P.3 supports a factored dead load of 0.75 t/m (own weight of

beam is included) and a factored live load of 4.25 t/m. Design the required shear

reinforcement.

Use

2

/ 280 cm kg f

c

= and

2

/ 4200 cm kg f

y

= .

8

Figure P.3

P.4 For the beam shown in Figure P.4, design the required shear reinforcement to resist the

given factored load.

Use

2

/ 280 cm kg f

c

= and

2

/ 4200 cm kg f

y

= .

Figure P.4

P.5 For the beam shown in Figure P.5, design the required shear reinforcement to resist the

given factored loads.

Use

2

/ 250 cm kg f

c

= and

2

/ 4200 cm kg f

y

= .

9

Figure P.5

P.6 The beam shown in Figure P.6 contains four bars each is 25 mm in diameter out of

which two bars are bent up at 45 degree angle near the support. Design the required shear

reinforcement to resist the given load.

Use

2

/ 300 cm kg f

c

= and

2

/ 4200 cm kg f

y

= .

Figure P.6

P.7 For the two isolated footings shown in Figure P.7, check whether the provided depths

are adequate for resisting punching shear for the given service loads. The allowable net soil

pressure is equal to 1.5 kg/cm

2

. Use

2

/ 250 cm kg f

c

= .

10

(a) (b)

Figure P.7

You might also like

- Triplex Pump Part 1Document30 pagesTriplex Pump Part 1Rodolfo Castro86% (7)

- Behaviour of Box Girder BridgesDocument14 pagesBehaviour of Box Girder BridgesSachin MoreNo ratings yet

- LBSC Steam CraneDocument7 pagesLBSC Steam CraneSantiago Londoño LopezNo ratings yet

- Behaviour of Concrete Box Girder Bridges of Deformable Cross-SectionDocument14 pagesBehaviour of Concrete Box Girder Bridges of Deformable Cross-SectionTaiCheong Lee50% (2)

- Reinforced Concrete Shear Design PrinciplesDocument27 pagesReinforced Concrete Shear Design PrinciplesFekadu DebelaNo ratings yet

- Bearing CapacityDocument6 pagesBearing CapacityFEL-ESTEBAN100% (1)

- Bored Pile Design - Deep FoundationDocument6 pagesBored Pile Design - Deep Foundationbuffyto5377No ratings yet

- Ubc Seismic CalculationsDocument44 pagesUbc Seismic Calculationsbuffyto5377No ratings yet

- Strength of Materials: An Introduction to the Analysis of Stress and StrainFrom EverandStrength of Materials: An Introduction to the Analysis of Stress and StrainRating: 5 out of 5 stars5/5 (1)

- General Physics 1 Week 3Document5 pagesGeneral Physics 1 Week 3Levi AckermanNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- DTC P1120/19 Accel. Position Sensor Circuit (Open/Short)Document7 pagesDTC P1120/19 Accel. Position Sensor Circuit (Open/Short)Jehuty88No ratings yet

- DESIGN and DETAILING For TORSION - 'Guidelines and Rules For Detailing of Reinforcement in Concrete Structures' - by ChalmersDocument23 pagesDESIGN and DETAILING For TORSION - 'Guidelines and Rules For Detailing of Reinforcement in Concrete Structures' - by ChalmersJulianNo ratings yet

- Chapter 5 Shear, Bond and TorsionDocument82 pagesChapter 5 Shear, Bond and TorsiondavidNo ratings yet

- Chapter Five, Torsion of BeamsDocument7 pagesChapter Five, Torsion of BeamsTemesgenAbiyNo ratings yet

- CIV6235 - Shear (MG)Document26 pagesCIV6235 - Shear (MG)friendycalls100% (1)

- GPG291 Designer's Guide To The Options For Ventilation and Cooling 2001Document40 pagesGPG291 Designer's Guide To The Options For Ventilation and Cooling 2001IppiNo ratings yet

- Beam On Elastic Foundation AnalysisDocument5 pagesBeam On Elastic Foundation Analysisbuffyto5377100% (1)

- Design of Shear Reinforcement in RCC Structures: Intended Learning Outcomes (ILO)Document16 pagesDesign of Shear Reinforcement in RCC Structures: Intended Learning Outcomes (ILO)anirbanpwd76No ratings yet

- rc-1 2015-16 Chapter Three 080116Document28 pagesrc-1 2015-16 Chapter Three 080116ABAMELANo ratings yet

- Chapter 5 - Shear and Diagonal Tension On Beams PDFDocument55 pagesChapter 5 - Shear and Diagonal Tension On Beams PDFJhe Taguines100% (1)

- Physics Practical Project For Class XIIDocument19 pagesPhysics Practical Project For Class XIIPallab Samanta66% (129)

- Chp5 Shear in BeamsDocument20 pagesChp5 Shear in BeamsRocio LiscanoNo ratings yet

- Chapter 5: Shear in Beams: Figure 5.1: Shear in Beams: (A) Loaded Beam (B) Internal Forces at Section A-ADocument20 pagesChapter 5: Shear in Beams: Figure 5.1: Shear in Beams: (A) Loaded Beam (B) Internal Forces at Section A-Aravi1214No ratings yet

- Chapter 5: Shear in Beams: Figure 5.1: Shear in Beams: (A) Loaded Beam (B) Internal Forces at Section A-ADocument20 pagesChapter 5: Shear in Beams: Figure 5.1: Shear in Beams: (A) Loaded Beam (B) Internal Forces at Section A-AIraya DavidNo ratings yet

- Chapter 4-Diseño Por CortanteDocument5 pagesChapter 4-Diseño Por CortanteDaniel LopeNo ratings yet

- 5-Shear Design of BeamsDocument53 pages5-Shear Design of Beamshamadamjad047No ratings yet

- Shear and Diagonal Tension in BeamsDocument13 pagesShear and Diagonal Tension in Beamsdilnessa azanawNo ratings yet

- Design of Rc-Beams For ShearDocument36 pagesDesign of Rc-Beams For ShearAkli Ale ManNo ratings yet

- Chapter Four: Shear and Diagonal Tension in BeamsDocument12 pagesChapter Four: Shear and Diagonal Tension in BeamsMintesnot WondimuNo ratings yet

- LA Clark App BDocument5 pagesLA Clark App Bmatie12345No ratings yet

- Reinforced Concrete Beam Shear DesignDocument46 pagesReinforced Concrete Beam Shear DesignashenafiNo ratings yet

- RCC Lecture Series 4 2018-19Document33 pagesRCC Lecture Series 4 2018-19Mansa ArthurNo ratings yet

- Behavior of Reinforced Concrete ElementsDocument9 pagesBehavior of Reinforced Concrete ElementsAwab AfifiNo ratings yet

- Shear LagDocument17 pagesShear LagSukhwinder Singh GillNo ratings yet

- Chapter 5: TorsionDocument106 pagesChapter 5: Torsionprabin gautamNo ratings yet

- Shear DesignDocument58 pagesShear DesignMuhammad Saeed ZafarNo ratings yet

- Unified Shear DesignDocument6 pagesUnified Shear DesignKemz JancordaNo ratings yet

- TorsionDocument17 pagesTorsionkalpanaadhi100% (1)

- Chapter Six, Deep Beams and CorbelsDocument8 pagesChapter Six, Deep Beams and CorbelsHaftom Gebreegziabiher50% (2)

- Failures Due To ShearDocument70 pagesFailures Due To ShearEr Saurabh Shah100% (1)

- RC II Chapter 5Document18 pagesRC II Chapter 5Wendimu TolessaNo ratings yet

- Design of Reinforced Concrete Struture Lec 02Document238 pagesDesign of Reinforced Concrete Struture Lec 02husseinqahtan09No ratings yet

- Shear and Diagonal Tension in Beams: Lec. Hasanain M. Al-Musawi Reinforced Concrete Design IDocument35 pagesShear and Diagonal Tension in Beams: Lec. Hasanain M. Al-Musawi Reinforced Concrete Design IHasanain AlmusawiNo ratings yet

- 2lec3&4 With Assignment 2 Reinf Conc 412Document42 pages2lec3&4 With Assignment 2 Reinf Conc 412Emmanuel MwabaNo ratings yet

- Chapter 3 STR 3 Beams Shear BondDocument8 pagesChapter 3 STR 3 Beams Shear BonddaniNo ratings yet

- Chap5 1Document53 pagesChap5 1Fernando LopezNo ratings yet

- Design For ShearDocument8 pagesDesign For ShearAdil8686No ratings yet

- Chapter 3Document18 pagesChapter 3gossayeNo ratings yet

- Beam Shear BehaviourDocument10 pagesBeam Shear BehaviourEr Saurabh ShahNo ratings yet

- Chapter - 5 Torsion in Reinforced Concrete MembersDocument8 pagesChapter - 5 Torsion in Reinforced Concrete MembersHelen NegashNo ratings yet

- Shear, Bond and Development Length in RC BeamsDocument35 pagesShear, Bond and Development Length in RC BeamsKishan PurohitNo ratings yet

- Chapter 5Document49 pagesChapter 5ISRAEL HAILUNo ratings yet

- Lecturenote - 1714126640chapter Six, Deep Beams and CorbelsDocument8 pagesLecturenote - 1714126640chapter Six, Deep Beams and CorbelsTmiky GateNo ratings yet

- Chapter5 - Shear Resistance of A RC BeamDocument27 pagesChapter5 - Shear Resistance of A RC BeamHabo TareNo ratings yet

- DCC20053 - Topic 5 Shear Stress in Beam and Connection 2019Document6 pagesDCC20053 - Topic 5 Shear Stress in Beam and Connection 2019nur hidayah08No ratings yet

- MEE 212 Pre - CH 5Document42 pagesMEE 212 Pre - CH 5alhassan Abdul MaleeqNo ratings yet

- Compression Members in Rigid FramesDocument74 pagesCompression Members in Rigid Framesjuan jr lucenaNo ratings yet

- Tension Members - Notes Mohit JaiswalDocument5 pagesTension Members - Notes Mohit JaiswalPiyush GuptaNo ratings yet

- 1) Cross-Section Particularities: Teorie Steel 2 - Partea Lui StefanescuDocument19 pages1) Cross-Section Particularities: Teorie Steel 2 - Partea Lui StefanescuIsmail ErvinNo ratings yet

- RCI Hand Out Chapter 3Document12 pagesRCI Hand Out Chapter 3Nathnael JiaNo ratings yet

- Unit 9Document29 pagesUnit 9Avish GunnuckNo ratings yet

- TorsionDocument69 pagesTorsionpengniumNo ratings yet

- 5.0 Bending PDFDocument9 pages5.0 Bending PDFLEONARD NYIRONGONo ratings yet

- CHAPTER V Engineering Mechanics-I 2015Document16 pagesCHAPTER V Engineering Mechanics-I 2015nvnrevNo ratings yet

- CEGE PPT Notes Shear & DeflectionDocument18 pagesCEGE PPT Notes Shear & DeflectionJemuel FloresNo ratings yet

- ACI TorsionDocument8 pagesACI TorsionNeil Duldulao100% (1)

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- As FlexiónDocument2 pagesAs Flexiónbuffyto5377No ratings yet

- Continuous Analysis - MS 1-2 DataDocument2 pagesContinuous Analysis - MS 1-2 Databuffyto5377No ratings yet

- WALL PRESSURE ANALYSISDocument6 pagesWALL PRESSURE ANALYSISbuffyto5377No ratings yet

- HB WT Design 01Document14 pagesHB WT Design 01buffyto5377No ratings yet

- Pile StirrupDocument1 pagePile Stirrupbuffyto5377No ratings yet

- Span-Depth Ratios For One-Way Members Based OnDocument10 pagesSpan-Depth Ratios For One-Way Members Based OntrabajosicNo ratings yet

- Reinforced Retainig Walls DesignDocument15 pagesReinforced Retainig Walls Designbuffyto5377No ratings yet

- Deflection Control of Concrete MembersDocument9 pagesDeflection Control of Concrete Membersyrdgcgf5664No ratings yet

- Analysis of GabionsDocument13 pagesAnalysis of Gabionsbuffyto5377No ratings yet

- Ground Anchors 1.6Document79 pagesGround Anchors 1.6buffyto5377No ratings yet

- Behavior of Concrete Beams Reinforced With ASTM A1035 Grade 100 Stirrups Under ShearDocument8 pagesBehavior of Concrete Beams Reinforced With ASTM A1035 Grade 100 Stirrups Under ShearTrong Tuan TranNo ratings yet

- Coefficient MethodDocument3 pagesCoefficient Methodmarx0506No ratings yet

- Andrew Scanlon - Span-Depth Ratios For One-Way Members Based OnDocument10 pagesAndrew Scanlon - Span-Depth Ratios For One-Way Members Based Onbuffyto5377No ratings yet

- Andrew Scanlon - Minimun Thickness - 1 - and - 2 - Way - Slab - 897Document7 pagesAndrew Scanlon - Minimun Thickness - 1 - and - 2 - Way - Slab - 897buffyto5377No ratings yet

- Chapter 1: IntroductionDocument8 pagesChapter 1: IntroductionpraveennagarajanNo ratings yet

- Slender Column Design and AnalysisDocument15 pagesSlender Column Design and Analysiskh.mitesh1904100% (1)

- Heat Load-KitchenDocument1 pageHeat Load-Kitchenrinko447459No ratings yet

- Sample 35313Document16 pagesSample 35313Francis CometaNo ratings yet

- Failure Modes and Criteria of Plastic Structures Under Intense Dynamic Loading: A ReviewDocument9 pagesFailure Modes and Criteria of Plastic Structures Under Intense Dynamic Loading: A ReviewyasameenNo ratings yet

- MAN L28/32H: Imo Tier Ii Project GuideDocument449 pagesMAN L28/32H: Imo Tier Ii Project GuideNazikNo ratings yet

- CHAPTER2 -منهج جديد pdf2- m PDFDocument39 pagesCHAPTER2 -منهج جديد pdf2- m PDFmohammed elobideNo ratings yet

- Mesurement and Inspection SheetDocument3 pagesMesurement and Inspection SheetSaifur RahmanNo ratings yet

- Slab On Grade Reinforcing DesignDocument11 pagesSlab On Grade Reinforcing DesignAti KhongNo ratings yet

- Gupta Et Al-2016-Quality and Reliability Engineering InternationalDocument10 pagesGupta Et Al-2016-Quality and Reliability Engineering InternationalEli PaleNo ratings yet

- Guentner W Shape Units Info enDocument4 pagesGuentner W Shape Units Info enAnonymous 5moojwNo ratings yet

- Introduction to Robotics ME 639Document2 pagesIntroduction to Robotics ME 639Satya SuryaNo ratings yet

- Konceptualni - Titranje I ValoviDocument44 pagesKonceptualni - Titranje I ValoviNikolinaNo ratings yet

- KawasakiTools Vol50Document25 pagesKawasakiTools Vol50ata03003993360No ratings yet

- Tutorial 11 - MS3220 Rekayasa Termal (Mark Scheme)Document6 pagesTutorial 11 - MS3220 Rekayasa Termal (Mark Scheme)i need documentsNo ratings yet

- Ag machineryDocument4 pagesAg machineryvinzyyNo ratings yet

- Laporan Harian WS 34 Dan 15 2021Document2 pagesLaporan Harian WS 34 Dan 15 2021tyok sajaNo ratings yet

- Site Response Analysis: Understanding How Soil Properties Affect Ground MotionsDocument90 pagesSite Response Analysis: Understanding How Soil Properties Affect Ground MotionsM YusupNo ratings yet

- 00 en Drilling 05-2022 No Mark Ups 01Document4 pages00 en Drilling 05-2022 No Mark Ups 01ihydraulicsNo ratings yet

- Boston Export (Profile-Brochure) PDFDocument10 pagesBoston Export (Profile-Brochure) PDFGIRISH RAJ PUROHITNo ratings yet

- Sharing: Thermal KnowledgeDocument5 pagesSharing: Thermal KnowledgeAndresNo ratings yet

- Weld-On Brackets Type 35Document1 pageWeld-On Brackets Type 35Achraf BoudayaNo ratings yet

- Pin MillingDocument16 pagesPin MillingBhavik NagdaNo ratings yet

- Sanwa Export 02 Gate ValveDocument1 pageSanwa Export 02 Gate ValveTou SvnkNo ratings yet

- 750-91 CB - CBLE 250-350 HP (Rev 1997)Document166 pages750-91 CB - CBLE 250-350 HP (Rev 1997)Jonathan GarciaNo ratings yet

- Baja Saeindia 2018 RulebookDocument73 pagesBaja Saeindia 2018 RulebookSrijan VermaNo ratings yet