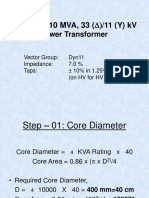

Professional Documents

Culture Documents

Independent test lab accredited for HV and LV equipment

Uploaded by

cerkadilerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Independent test lab accredited for HV and LV equipment

Uploaded by

cerkadilerCopyright:

Available Formats

Independent test laboratory, accredited by Deutsche Akkreditierungsstelle Technik (DATech) e.V. in the fields of h.v.

apparatus

and switchgear, power cables and power cable accessories, l.v. apparatus and switchgear, installation equipment and

switching and control equipment.

Institut Prffeld fr elektrische Hochleistungstechnik GmbH (IPH Berlin) is a subsidiary of CESI S.p.A, Milan.

I ndependent, accredi ted testi ng stati on Member l aboratory of STL and LOVAG

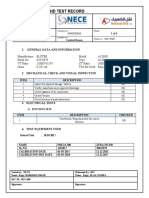

TYPE TEST REPORT

NO. 3149.2090352.0530

HES Hacilar Elektrik Sanayi ve Ticaret A..

Erciyes Mah. HES Cad. No:22

38210 Kayseri

TURKEY

CLIENT

HES Hacilar Elektrik Sanayi ve Ticaret A..

MANUFACTURER

Medium voltage cross-linked PE (SLPE) insulated power cable

TEST OBJECT

YXC7V-R (N2XSY) 1x35/16 mm 20.3/35 kV

TYPE

Test sample

SERIAL NO.

Rated voltage

Max. operating voltage

Uo/Um

Um

20.3/35

42

kV

kV

RATED

CHARACTERISTICS

GIVEN BY THE

CLIENT

IEC 60502-2: 2005-03

NORMATIVE

DOCUMENT

Type tests on cable

RANGE OF TESTS

PERFORMED

May 2009 to July 2009

DATE OF TEST

The tests have been PASSED.

TEST RESULT

H. ZINNBAUER

Head of Centre of Competence

High-Power/High-Voltage

G. BROSE

Test engineer in charge

Berlin, 21 October 2009

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 2

This test document consists of 28 sheets.

Distribution Copy No. 1

Copy No. 1 in English: HES Hacilar Elektrik Sanayi ve Ticaret A..

The test results relate only to the object tested.

This document is confidential. Its transfer to third parties as well as its reproduction in extracts require the consent of the client.

Contents Sheet

1. Present at the test............................................................................................................................................................. 3

2. Place of test ........................................................................................................................................................................... 3

3. Identity of test object...................................................................................................................................................... 3

4. Type tests, electrical on the cable......................................................................................................................... 4

4.1 Partial discharge test at ambient temperature.................................................................................................................................................... 5

4.2 Bending test followed by a partial discharge test ......................................................................................................................................... 6

4.3 Tan measurement at 5 C to 10 C above the maximum conductor temperature........................ 7

4.4 Heating cycle test followed by a partial discharge test......................................................................................................................... 8

4.5 Lightning impulse voltage test at a maximum conductor temperature ranging from

95 C to 100 C.................................................................................................................................................................................................................................................. 9

4.6 Power-frequency voltage test for 4 h............................................................................................................................................................................. 11

4.7 Resistivity of semi-conducting screens before and after the ageing treatment.......................................... 12

5. Type tests, non-electrical on the cable........................................................................................................... 13

5.1 Measurement of thicknesses and check of cable construction....................................................................................... 14

5.2 Tests for determining the mechanical properties of the insulation before and after

ageing............................................................................................................................................................................................................................................................................. 17

5.3 Tests for determining the mechanical properties of the PVC oversheath before and after

ageing............................................................................................................................................................................................................................................................................. 18

5.4 Ageing tests on pieces of complete cables to check compatibility of materials..................................... 19

5.5 Loss of mass test on PVC oversheath of type ST

2

....................................................................................................................................... 20

5.6 Pressure test at high temperature on the PVC oversheath.......................................................................................................... 20

5.7 Test on sheath at low temperature.................................................................................................................................................................................. 21

5.8 Test for resistance of PVC sheath to cracking (heat shock test) .......................................................................................... 21

5.9 Hot set test for XLPE insulations.............................................................................................................................................................................................. 22

5.10 Water absorption test on insulation................................................................................................................................................................................ 23

5.11 Flame spread test on single cables.................................................................................................................................................................................. 23

5.12 Shrinkage test for XLPE insulation........................................................................................................................................................................................ 24

6. Sketches/Drawings/Data sheet......................................................................................................................... 25

7. Photo....................................................................................................................................................................................... 28

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 3

1. Present at the test

Mr. Brose IPH test engineer in charge

2. Place of test

IPH, High-voltage test laboratory, test bay no. 1, test bay no. 3, high-voltage hall no. 2

3. Identity of test object

The tests were carried out on a cable sample with markings of manufacturer and year of

manufacture as follows:

00966 HES YXC7V-R 1x35/16 mm 20.3/35 kV TSEK 22/03/2009 01 TEDAS.

Construction, please see attached sketch.

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 4

4. Type tests, electrical on the cable

Tests performed

a) Partial discharge (PD) test

b) Bending test followed by a partial discharge test

c) Tan measurement at 5 C to 10 C above the maximum conductor temperature

d) Heating cycle test followed by a partial discharge test at ambient temperature

e) Lightning impulse test at elevated maximum conductor temperature followed by a voltage test

f) Power-frequency voltage test for 4 h

g) Resistivity of semi-conducting screens

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 5

4.1 Partial discharge test at ambient temperature

Normative document

IEC 60502-2: 2005-03, Sub-clause 18.1.4

Test and measuring circuits

Technical data of test circuit

Test transformer: Rated voltage 125 kV

Rated power 100 kVA

Rated frequency 50 Hz

Damping resistance 0.67 kOhm

Technical data of measuring circuit

Meas.

point

Measured quantity Measuring sensor/device Technical parameters

1 Test voltage Capacitive divider with MU11

(TuRD) peak voltmeter

Ratio 864

2 Partial discharge

level

- Coupling capacitor

- CPL 542A quatripole (mtronix)

MPD 540 PD measuring system

(mtronix)

- Calibrator of Cal 542 type

(mtronix)

C

k

= 1 nF

Output 10 pC

E Supply

PTr Test transformer with variable transformer connected in series

Z

s

Blocking impedance

C

k

Coupling capacitor

Z

m

Measuring impedance

C-T. Capacitive divider

HE Auxiliary sealing end

1, 2 Measuring points

PO Test object

Z

s

2

Z

m

1

HE HE

PO

E PTr C

k

C-T.

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 6

Measured values

The calibration was at 5 pC.

Test voltage

in kV

Noise level

in pC

PD initiation

in kV

PD at test

voltage

in pC

PD

interruption

in kV

Required

sensitivity

in pC

2xUo 40.6

1)

1.73xU

0

= 35.2

1 pC - 1.2 pC - 5 pC

1) Measured value during 2Uo 40.6 for 10 sec.

Test results

The test has been PASSED.

4.2 Bending test followed by a partial discharge test

Normative document

IEC 60502-2: 2005-03, Sub-clause 18.1.3

The test was carried out at IPH. The cable sample with a length of more than 10 m was three

times bended around a test cylinder and unwound in each direction around the required test

diameter at ambient temperature.. For this, each sample part was bend and afterwards unwound

and again bend and unwound in the opposite direction.

Required test parameters

The bending diameter was calculated using the equation D 20 (d + D) 5 %.

D = cable diameter

in mm

d = conductor diameter

in mm

Bending diameter

in mm

Chosen diameter

in mm

33.5 7.4 817 803

Partial discharge test at ambient temperature after bending test

Technical data of measurement circuit

See Sub-clause 4.1

Measured values

The calibration was at 5 pC.

Test voltage

in kV

Noise level

in pC

PD initiation

in kV

PD at test

voltage

in pC

PD

interruption

in kV

Required

sensitivity

in pC

2xUo 40.6

1)

1.73xU

0

= 35.2

1 pC -

1.2 pC

also

- 5 pC

1) Measured value during 2Uo 40.6 for 10 sec.

Test results

The test has been PASSED.

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 7

4.3 Tan measurement at 5 C to 10 C above the maximum conductor temperature

Normative document

IEC 60502-2: 2005-03, Sub-clause 18.1.5

Test and measuring circuits

Technical data of test circuit

Test transformer: Rated voltage 100 kV

Rated power 100 kVA

Rated frequency 50 Hz

Technical data of measuring circuit

Measured quantity Measuring sensor/device Technical parameters

Test voltage HV divider (Haefely)

Inv. No. 11228/6, Cal. No. 12315

MU11 peak voltmeter (TUR Dresden)

-

Tan MWB measuring bridge

Cal. No. 7524

-

Standard capacitor Compressed gas capacitor

Cal. No. 12314

C = 57.02 pF

Tr High-voltage test transformer with variable transformer

C-T. Capacitive divider

P Peak voltmeter PO Test object

C Standard capacitor tan tan- measuring bridge

HT Heating transformer T Temperature measurement

Measured values

Test temperature: 95 C to 100 C

Test voltage Measured tan tan required

3 kV 10.3 x 10

-4

40 x 10

- 4

Test results

The test has been PASSED.

Tr

C-T.

P

HT

C

PO

tan

T

Dummy

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 8

4.4 Heating cycle test followed by a partial discharge test

Normative document

IEC 60502-2: 2005-03, Sub-clause 18.1.6

Test and measuring circuits

PO Test object S Copper screen

H T Heating transformers T Temperature measurement

Number of cycles: 20

Minimum 5-hours heating period, minimum 3-hours natural cooling

Test temperature: 95 C to 100 C at the conductor

The test set-up was subjected to 20 heating cycles. During the cyclic load, the cable was heated

to a minimum conductor temperature ranging from 95 C to maximum 100 C. The temperature

was maintained constant for 2 hours. Subsequently, the cable was naturally cooled during 3 hours.

The conductor temperature was continuously checked at the dummy.

Partial discharge test at ambient temperature after heating cycle

Technical data of measurement circuit

See Sub-clause 4.1

Measured values

The calibration was at 5 pC.

Test voltage

in kV

Noise level

in pC

PD initiation

in kV

PD at test

voltage

in pC

PD

interruption

in kV

Required

sensitivity

in pC

2xUo 40.6

1)

1.73xU

0

= 35.2

1 pC -

1.2 pC

also

- 5 pC

1) Measured value during 2Uo 40.6 for 10 sec.

Test results

The test has been PASSED.

HT

PO

Dummy T

HT

PO

Dummy T

S

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 9

4.5 Lightning impulse voltage test at a maximum conductor temperature ranging from

95 C to 100 C

The test circuit was heated to a conductor temperature of (95+5) C. After the conductor

temperature had stabilized at least 2 h, a lightning impulse voltage test according to IEC 60060

and IEC 60230 was carried out, i.e. the test circuit was subjected to 10 impulses of each polarity,

U

p

= 190 kV (2.62/49.6 s).

Normative document

IEC 60502-2: 2005-03, Sub-clause 18.1.7

Impulse voltage test at high temperature followed by a voltage test

Technical data of test circuit

Impulse circuit: Number of stages n = 2

Impulse capacitance C

S

= 70 nF

Loading capacitance C

B

= 1.5 nF

Damping resistance R

D

= 130

Discharge resistance R

E

= 1100

Technical data of measuring circuit

Measuring point Measured quantity Measuring sensor/device Technical parameters

1 Test voltage R divider of SMR 10/770 type (TuRD)

with digital measuring instrument of

DMI 551 type (Haefely) and TDS 220

digital oscilloscope (made by Tektronix)

Ratio 466.9

Gl Rectifier C

B

Loading capacitance

C

S

Impulse capacitance PO Test object

ZFS Spark gap 1 Measuring point

R

E

Discharge resistance HT Heating transformers

R

D

Damping resistance T Temperature measurement

HT

PO

Dummy

T

C

S

R

E

C

B

+ / -

Gl ZFS

R

D

~ 1

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 10

Measured values

Test voltage

U

p

in kV

Lightning impulse

voltage,

positive polarity

Lightning impulse

voltage,

negative polarity

Number of

impulses

Result

x 10

190

x 10

No disruptive,

no discharge

Power-frequency voltage test during the cooling

Test voltage AC 71 kV for 15 min.

Test results

No breakdown was occurred. The test has been PASSED.

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 11

4.6 Power-frequency voltage test for 4 h

Normative document

IEC 60502-2: 2005-03, Sub-clause 18.1.8

Test and measuring circuits

Technical data of test circuit

Single-phase AC voltage source

Test transformer: Rated voltage 125 kV

Rated power 100 kVA

Rated frequency 50 Hz

Damping resistance 0.67 kOhm

Technical data of measuring circuit

Measuring point Measured quantity Measuring sensor/device Technical parameters

1 Test voltage Capacitive divider with MU11

(TuRD) peak voltmeter

Ratio 864

E Supply

PTr Test transformer with variable transformer connected in series

R

D

Damping resistance

P Peak voltmeter

PO Test object

Power-frequency voltage test

Test voltage AC 81.2 kV for 4 h

Test results

The test has been PASSED.

P

PTr

E

R

D

PO

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 12

4.7 Resistivity of semi-conducting screens before and after the ageing treatment

Normative document

IEC 60502-2: 2005-03, Sub-clause 18.1.9

Test arrangement

As described in IEC 60502-2, Annex C

Test equipment and measuring instruments

Heating cabinet No. 18 for ageing treatment, calibration No. 9977

Heating cabinet No. 21 for measurement, calibration No. 10060

DC voltage supply HP E 3610A, Inv. No. 10642/01

Multimeter Fluke 8050A Inv. No. 10866/02, calibration No. 9762

Measured values

Resistance in Ohm m Semi-conducting screen

Before ageing After ageing at 100 C Requirement

Inner 676 602 1000

Outer 44 43 500

Test results

The test has been PASSED.

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 13

5. Type tests, non-electrical on the cable

Test performed

a) Measurement of thicknesses and check of cable construction

b) Tests for determining the mechanical properties of insulation before and after ageing

c) Tests for determining the mechanical properties of the PVC oversheath before and after ageing

d) Ageing tests on cables to check compatibility of materials

e) Loss of mass test on PVC sheaths of type ST

2

f) Pressure test at high temperature on sheath

g) Test on sheath at low temperature

h) Test for resistance of PVC sheath to cracking (heat shock test)

i) Hot set test for XLPE insulations

j) Water absorption test on insulation

k) Flame spread test on single cables

l) Shrinkage test for XLPE insulation

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 14

5.1 Measurement of thicknesses and check of cable construction

Normative document

IEC 60502-2: 2005-03, Sub-clauses 19.1, 19.2

Measuring instruments

Profile projector

PVC oversheath

Marking

00966 HES YXC7V-R 1x35/16 mm 20.3/35 kV

TSEK 22/03/2009 01 TEDAS

Colour Red

Material PVC

Diameter

mm

Thickness

mm

Measured values 33.21 33.95 33.79

2.19 2.11 2.18

2.08 2.36 2.48

Required nominal value

by IEC 60502-2

Without 2.0

Required nominal value

by manufacturer

34 2 2.0

Measured average value 33.65 2.23

Measured minimum value 33.2 2.08

Required minimum value

by IEC 60502-2

Without 1.61

Tape

Measured values Nominal values

Number of tapes 1 No data

Width x thickness mm 60 x 0.05 No data

Overlap mm 8 No data

Copper screen

Measured values Nominal values

given by manufacturer

Wires

Diameter over screen mm 29 Approx. 30.2

Number of wires 60 60

Diameter of wires mm 0.57 0.55

Copper helix

Number of tapes 1 1

Width x thickness mm 10 x 0.1 10 x 0.1

Cross section

inclusive copper helix

mm 16.3 Min. 16

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 15

Semi conductive tape

Measured values Nominal values

Number of tapes 1 No data

Width x thickness mm 50 x 0.2 No data

Overlap 0 No data

Dimension of core

Measuring instruments

Profile projector inventory No. 10609/01 with calibration disk, inventory No. 10614/01

Outer semi-conducting screen

Diameter

in mm

Thickness

in mm

Measured values 27.41 27.49 27.79 0.57 0.59 0.54 0.48

0.46 0.58

Nominal value

required by manufacturer

27.4 0.6

Minimum measured value -- 0.46

Average 27.6 0.54

Maximum measured value -- 0.59

XLPE insulation

Diameter

in mm

Thickness

in mm

Measured values 26.36 26.44 26.66 8.78 8.89 9.25 9.53

9.32 9.17

Nominal value

required by manufacturer

Approx. 26.2 9.0

Minimum value

to IEC 60502-2

-- 8.0

Minimum measured value 26.36 8.78

Average measured value 26.5 9.13

Centricity -- 0.08

Requirement -- 0.15

Inner semi-conducting screen

Diameter

in mm

Thickness

in mm

Measured values 8.23 8.23 8.24 0.54 0.55 0.54 0.55

0.55 0.55

Nominal value

required by manufacturer

8.2 0.6

Minimum value

required by manufacturer

-- 0.3

Average measured value 8.23 0.6

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 16

Stranded copper conductor

Measured values Required values

by IEC 60228

Diameter measured value 7.17 mm 7.01 mm --

Diameter average value 7.09 mm Min. 6.6 mm Max. 7.5 mm

Number of core conductors 7 7

Conductor resistance

Normative document

IEC 60502-2: 2005-03; IEC 60228

Measured values at ambient temperature

Measured value

/km at 20 C

Max. permissible value

/km at 20 C

0.512 0.524

Test results

The test has been PASSED.

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 17

5.2 Tests for determining the mechanical properties of the insulation before and after

ageing

Type of compound: XLPE

Normative documents

IEC 60502-2: 2005-03, Sub-clause 19.3

Testing device

Tensile test machine Zwick Z 1435, heating cabinet No. 4

Measured values before ageing

Sample No. Tensile strength

in N/mm

Elongation at break

in %

1 17.16 455

2 22.76 503

3 17.05 451

4 16.45 437

5 20.21 483

6 18.99 477

Median 18.07 466

Requirements Min. 12.5 Min. 200

Measured values after ageing treatment

Treatment: 135 C, 7 days

Sample No. Tensile strength

in N/mm

Elongation at break

in %

1 18.55 493

2 21.07 510

3 17.60 490

4 19.41 503

5 18.99 496

6 20.06 505

Median 19.20 499

Measured variation 6.3 % 7.1 %

Requirements Max. 25 % Max. 25 %

Test results

The test has been PASSED.

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 18

5.3 Tests for determining the mechanical properties of the PVC oversheath before and

after ageing

Type of compound: ST

2

Normative documents

IEC 60502-2: 2005-03, Sub-clause 19.4

Testing device

Tensile test machine Zwick Z 1435, heating cabinet No. 14

Measured values before ageing

Sample No. Tensile strength

in N/mm

Elongation at break

in %

1 16.03 241

2 13.25 238

3 12.90 166

4 12.90 231

5 13.47 238

6 13.59 222

Median 13.36 234

Requirements Min. 12.5 % Min. 150 %

Measured values after ageing treatment

Treatment: 100 C, 7 days

Sample No. Tensile strength

in N/mm

Elongation at break

in %

1 12.24 193

2 12.86 202

3 12.42 216

4 12.99 204

5 12.71 177

6 11.99 183

Median 12.56 197

Requirements Min. 12.5 Min. 150

Variation -6.0 % 15.8 %

Requirements Max. 25 % Max. 25 %

Test results

The test has been PASSED.

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 19

5.4 Ageing tests on pieces of complete cables to check compatibility of materials

Normative document

IEC 60502-2: 2005-03, Sub-clause 19.5

Testing device

Tensile test machine Zwick Z 1435, heating cabinet No. 13

XLPE insulation

Treatment: 100 C, 7 x 24 h

Sample No. Tensile strength

in N/mm

Elongation at break

in %

1 15.71 434

2 15.26 423

3 16.21 431

4 16.98 448

5 18.47 463

6 16.52 444

Median 16.36 439

Variation -9.5 % -5.8 %

Requirements Max. 25 % Max. 25 %

PVC oversheath

Treatment: 100 C, 7 x 24 h

Sample No. Tensile strength

in N/mm

Elongation at break

in %

1 14.05 2,15

2 14.36 218

3 12.00 177

4 12.14 142

5 13.00 166

6 13.93 203

Median 13.46 190

Variation -9.5 % -5.8 %

Requirements Max. 25 % Max. 25 %

Test results

The test has been PASSED.

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 20

5.5 Loss of mass test on PVC oversheath of type ST

2

Normative document

IEC 60502-2: 2005-03, Sub-clause 19.6

Testing device

Laboratory balance, heating cabinet No. 4

Treatment: 100 C, 7 days

Sample Loss of mass

mg/cm

Requirement

mg/cm

1 0.94

2 1.12

3 1.12

1.5

Test results

The test has been PASSED.

5.6 Pressure test at high temperature on the PVC oversheath

Type of compound: ST

2

Normative documents

IEC 60502-2: 2005-03, Sub-clause 19.7

Testing device

Heating cabinet No. 21, measuring projector

Treatment: 90 C, 6 h

Sample No. Thickness of sheath Engaged depth

mm mm %

1 2.30 0.62 27

2 2.31 0.54 26

3 2.44 0.63 23

Requirements None None Max. 50

Test results

The test has been PASSED.

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 21

5.7 Test on sheath at low temperature

Type of compound: ST

2

Normative documents

IEC 60502-2: 2005-03, Sub-clause 19.7

Testing device

Cooling chamber, elongation test machine

Treatment: -15 C

Length

pre elongation

Length

after elongation

Sample No.

mm mm %

1 20 34 70

2 20 40 100

3 20 41 105

4 20 44 120

5 20 44 120

6 20 34 70

Requirements -- -- --

Test results

The test has been PASSED.

5.8 Test for resistance of PVC sheath to cracking (heat shock test)

Type of compound: ST

2

Normative documents

IEC 60502-2: 2005-03, Sub-clause 19.9

Testing device

Heating cabinet No. 22

Treatment: 150 C, 1 h

Test results

None cracks were seen.

The test has been PASSED.

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 22

5.9 Hot set test for XLPE insulations

Normative documents

IEC 60502-2: 2005-03, Sub-clause 19.11

Test temperature

200 C

Testing device

Heating cabinet No. 21, length measurement system (for example a steel measuring tape)

Measured values

Treatment: 200 C, 15 minutes, 5 minutes

Sample No.

Elongation

under load

Permanent elongation

after cooling

in % in %

1 38 4.8

2 33 2.4

3 38 2.4

4 32 2.4

5 32 2.4

6 33 2.4

Requirements Max. 175 Max. 15

Test results

The test has been PASSED.

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 23

5.10 Water absorption test on insulation

Type of compound: XLPE

Normative document

IEC 60502-2: 2005-03, Sub-clause 19.13

Testing device

Low-pressure oven No. 30, laboratory balance, inventory No. 1132/05

Measured values

Sample

No.

Weight

M1

of dry

pieces

Weight

M2

of wet

pieces

Weight

M3

of dry

pieces

Area

cm

Result

mg/cm

Requirement

mg/cm

1 0.3225 0.3245 0.3224 10.2672 0.20

2 0.3306 0.3317 0.3306 10.2880 0.11

< 1

Test results

The test has been PASSED.

5.11 Flame spread test on single cables

Type of compound: ST

2

Normative document

IEC 60502-2: 2005-03, Sub-clause 19.14

Testing device

As described in IEC 60332-1-2

Test results

The PVC sheathed cable sample has PASSED the test.

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 24

5.12 Shrinkage test for XLPE insulation

Normative document

IEC 60502-2: 2005-03, Sub-clause 19.16

Testing device

Oven No. 21, steel tape measure

Measured values

Sample

No.

Distance

before ageing

mm

Distance

after cooling

mm

Result

%

Requirement

%

1 200 197.5 1.3 Max. 4

Test results

The test has been PASSED.

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 25

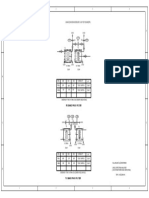

6. Sketches/Drawings/Data sheet

Figure 1: Sketch of the tested cable

POLYESTER TAPE

COPPER TAPE

SCREEN (COPPER WIRES)

SEMI CONDUCTIVE TAPE

INSULATION SCREEN(XLPE)

INSULATION (XLPE)

CONDUCTOR

OUTER SHEATH

COPPER CONDUCTOR

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 26

Figure 2: Data sheet of tested cable

1 - GENERAL

- Producer : HES HACILAR ELEKTRK SAN. VE TC. A..

- Cable Code : YXC7V-R (YE3SV)-N2XSY

- Aplied Standards : IEC 60502-2

- Rated Voltage (U0/Um) (kV) : 20.3/35

- Max. Operating Voltage (Um) (kV) : 42

2 - STRUCTURAL PROPERTIES

2.1 CONDUCTOR

. Type : Compacted Conductor

. Material : Annealed Electroltyic Copper

. Cross-sectional Area (mm) : 1x35/16

. Number of Wires : 7

. Type of Stranding : Circular

. Outer Diameter of Strand (max) (mm) : 7,0

2.2 INNER SEMICONDUCTING SCREEN

. Material : Semiconductive XLPE

. Nominal Thickness (mm) : 0,6

. Minimum Thickness (mm) : 0,3

. Outer Diameter of Screen (Approx.) (mm) : 8,2

2.3 INSULATION

. Material : XLPE

. Nominal Thickness (mm) : 9,0

. Minimum Thickness (mm) : 8,0

. Outer Diameter of Insulatio (Approx.) (mm) : 26,2

2.4 OUTER SEMICONDUCTING SCREEN

. Material : Semiconductive XLPE

. Nominal Thickness (mm) : 0,6

. Minimum Thickness (mm) : 0,3

. Outer Diameter of Screen (Approx.) (mm) : 27,4

2.5 METALLIC SCREEN

. Material : Copper

. Type : Wire & Tape

. Number & Diameter of Wires (mm) : 60x0.55

. Number of Copper Tape & Dimensions (mm) : 1 - (0.1x10)

. Geometrical Area (mm) : 16

. Outer Diameter (Approx.) (mm) : 30,2

2.6 OUTER SHEATH

. Material : PVC

. Colour : Red

. Nominal Thickness (mm) : 2,00

. Minimum Thickness (mm) : 1,40

.Outer Diameter of Cable (mm) : 34 2

MEDIUM VOLTAGE CROSS-LINKED PE (XLPE) INSULATED POWER CABLE 1x35/16 mm

2

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 27

Figure 3: Chart of heating cycle test

Conductor temperature

Sheath temperature

TYPE TEST REPORT NO. 3149.2090352.0530 SHEET 28

7. Photo

Figure 4: Cable samples after flame spread test

35 mm

You might also like

- Disconnector PDFDocument8 pagesDisconnector PDFgloby_pnbNo ratings yet

- NZ7 ATSE (CB Class)Document17 pagesNZ7 ATSE (CB Class)Rahmat Nur IlhamNo ratings yet

- Validating Surge TestDocument9 pagesValidating Surge Testquality10No ratings yet

- Current Transducer - LTS 6-NPDocument2 pagesCurrent Transducer - LTS 6-NPFadhil Tresna NugrahaNo ratings yet

- 1SCA104902R1001 Ot40f3 Switch DisconnectorDocument3 pages1SCA104902R1001 Ot40f3 Switch DisconnectorhandyalhabsyiNo ratings yet

- Manual Surge Test Baker St106aDocument2 pagesManual Surge Test Baker St106aDiego AndradeNo ratings yet

- Controlled Switching of High-Voltage Circuit-BreakersDocument8 pagesControlled Switching of High-Voltage Circuit-BreakersBaris GurbuzNo ratings yet

- Borri Modular UPSDocument4 pagesBorri Modular UPSKonikaHossainNo ratings yet

- TR 2000 Data SheetDocument2 pagesTR 2000 Data SheetJorge Fernando FloresNo ratings yet

- TR100+ Data BulletinDocument2 pagesTR100+ Data BulletinhazimeNo ratings yet

- Catalogue SGF Eng PDFDocument8 pagesCatalogue SGF Eng PDFrimce77No ratings yet

- TR2000 AmetekDocument2 pagesTR2000 AmetekbabisoNo ratings yet

- ABB - DS 3 PoleDocument31 pagesABB - DS 3 PoleVictor HutahaeanNo ratings yet

- Surge Arrester PDFDocument5 pagesSurge Arrester PDFSwarup NayakNo ratings yet

- Evolution of Fatigue Damage in Flexible Phovotovoltaic ModulesDocument16 pagesEvolution of Fatigue Damage in Flexible Phovotovoltaic ModulesClaudia BorriNo ratings yet

- Power System StabilityDocument29 pagesPower System StabilityRanieri BenčićNo ratings yet

- Technical Specification of 2 Core LT Aerial Bunched CableDocument9 pagesTechnical Specification of 2 Core LT Aerial Bunched CableRamesh Arjun TNo ratings yet

- Resistivity PDFDocument12 pagesResistivity PDFYogi EriawanNo ratings yet

- Physics of Contact ResistanceDocument17 pagesPhysics of Contact ResistanceSurajit DasNo ratings yet

- AMETEK210073Document2 pagesAMETEK210073hazimeNo ratings yet

- New GIS SPEC For 220kV 132kV & 66kV Ammended Type Test 10yrs May 2018 PDFDocument37 pagesNew GIS SPEC For 220kV 132kV & 66kV Ammended Type Test 10yrs May 2018 PDFp_kashyapNo ratings yet

- Schneider Electric - Preventa Safety Switches XCSDMDocument24 pagesSchneider Electric - Preventa Safety Switches XCSDMJohnNo ratings yet

- The Critical Radius of InsulationDocument2 pagesThe Critical Radius of InsulationAlejandroNo ratings yet

- ANSI - IEEE STD 535-1986 LEAD Acid BatteryDocument14 pagesANSI - IEEE STD 535-1986 LEAD Acid Batteryjm.mankavil6230No ratings yet

- GCE7002397R0122 Auxiliary Switch s1 s4 s5 PDFDocument1 pageGCE7002397R0122 Auxiliary Switch s1 s4 s5 PDFMahyar MashayekhiNo ratings yet

- Auxiliary Switch AdjustmentsDocument3 pagesAuxiliary Switch Adjustmentsමාධව නදුන්මල්.No ratings yet

- MVC4 User Manual - 1.0 - 7.2kV Motortronics REV6.16Document112 pagesMVC4 User Manual - 1.0 - 7.2kV Motortronics REV6.16Ariel SierraNo ratings yet

- MVC4 User Manual - 10 - 13.8kV Motortronics REV6.22Document113 pagesMVC4 User Manual - 10 - 13.8kV Motortronics REV6.22rafael_faresNo ratings yet

- ABB System Pro. M Compact, Miniature Circuit BreakersDocument75 pagesABB System Pro. M Compact, Miniature Circuit BreakersEliasNo ratings yet

- Beckwith-Optimizing Performance of Fast Bus Transfer Scheme PDFDocument5 pagesBeckwith-Optimizing Performance of Fast Bus Transfer Scheme PDFKrishna VenkataramanNo ratings yet

- Serial Rs232Document10 pagesSerial Rs232Soumyaranjan MohantyNo ratings yet

- ABB SwitchLine, Non-Fusible Disconnect SwitchesDocument147 pagesABB SwitchLine, Non-Fusible Disconnect SwitchesEliasNo ratings yet

- Zero Sequence CompensationDocument8 pagesZero Sequence Compensationlapet busukNo ratings yet

- Current Transformer GroundingDocument4 pagesCurrent Transformer GroundingReza MuhammadNo ratings yet

- Power Factor Improvement Using UpfcDocument16 pagesPower Factor Improvement Using UpfcUday Wankar50% (2)

- ABB REM 543 Relay Energy Meter CalibratiDocument10 pagesABB REM 543 Relay Energy Meter CalibratiPrashant GaurNo ratings yet

- DWG Insulator PolymerDocument60 pagesDWG Insulator Polymerbagja wigunaNo ratings yet

- Class PSDocument9 pagesClass PSAdeel RazaNo ratings yet

- Synchronization of GeneratorsDocument3 pagesSynchronization of Generatorsneo_nitinNo ratings yet

- 1E6 Electrical Engineering: DC Circuit Analysis Lecture 2 Resistance and ResistorsDocument9 pages1E6 Electrical Engineering: DC Circuit Analysis Lecture 2 Resistance and ResistorsKandi PrintNo ratings yet

- Final 2319-17 V1 PDFDocument68 pagesFinal 2319-17 V1 PDFMohamedNo ratings yet

- Two-Column Rotary Disconnectors Outdoor InstallationDocument14 pagesTwo-Column Rotary Disconnectors Outdoor InstallationTravis WoodNo ratings yet

- Site Test Report Date: 29/5/2018 Contractor's Name: HADI HAIDER Customer: Sec-Eoa Jubail Commercial Port 115/13.8Kv Ss-2 Tapcon 260 Avr RelayDocument4 pagesSite Test Report Date: 29/5/2018 Contractor's Name: HADI HAIDER Customer: Sec-Eoa Jubail Commercial Port 115/13.8Kv Ss-2 Tapcon 260 Avr RelayMuhammad NasirNo ratings yet

- CT PT SpecificationDocument31 pagesCT PT SpecificationRitesh JaiswalNo ratings yet

- AVRDocument42 pagesAVRMaged Mounir100% (1)

- Design Case StudyDocument14 pagesDesign Case Studyp m yadavNo ratings yet

- Cable Installation Manual For Power and Control CablesDocument102 pagesCable Installation Manual For Power and Control CablesWashington VásquezNo ratings yet

- Analysis and Application of Scott ConnectionDocument11 pagesAnalysis and Application of Scott ConnectionRam Uday MandalNo ratings yet

- 4.various Tests Part 1Document53 pages4.various Tests Part 1Rohit JoshiNo ratings yet

- Site Inspection and Test Record: 1. General Data and InformationDocument5 pagesSite Inspection and Test Record: 1. General Data and InformationSohail AhmedNo ratings yet

- Saturable ReactorDocument2 pagesSaturable ReactorGilberto ManhattanNo ratings yet

- Alfanar Co.: Respon Sibilities Legend CSDDocument5 pagesAlfanar Co.: Respon Sibilities Legend CSDjayabalNo ratings yet

- Diff Protection PDFDocument14 pagesDiff Protection PDFarunNo ratings yet

- TUVDocument72 pagesTUVhardoiseNo ratings yet

- Low-Voltage Switchgear and Controlgear - Part 2: Circuit-BreakersDocument56 pagesLow-Voltage Switchgear and Controlgear - Part 2: Circuit-BreakersVikram Kumar MvsNo ratings yet

- Testing of High Voltage CablesDocument7 pagesTesting of High Voltage CablesYogi Rungi100% (2)

- Type Test Report for AAAC ConductorDocument14 pagesType Test Report for AAAC ConductornigerluvNo ratings yet

- Compact Fluorescent Lamp Test ReportDocument23 pagesCompact Fluorescent Lamp Test Reportabdonrat72No ratings yet

- Audio/video, Information and Communication Technology Equipment Part 1: Safety RequirementsDocument114 pagesAudio/video, Information and Communication Technology Equipment Part 1: Safety RequirementsMohamed HusseinNo ratings yet

- Indice de Relay'sDocument16 pagesIndice de Relay'shectorhscNo ratings yet

- EN: TH Is Dat Asheet Is Present Ed by T He M Anuf Act UrerDocument6 pagesEN: TH Is Dat Asheet Is Present Ed by T He M Anuf Act UrercerkadilerNo ratings yet

- Ieee 1584 Calculo de Arc FlashDocument5 pagesIeee 1584 Calculo de Arc FlashJesus FuentesNo ratings yet

- Test PDFDocument1 pageTest PDFponmalar2No ratings yet

- SysDocument2 pagesSysAbdusamed BegovicNo ratings yet

- Janitza Manual UMG512 UL enDocument124 pagesJanitza Manual UMG512 UL encerkadilerNo ratings yet

- Relay Application Note !!!!!!Document3 pagesRelay Application Note !!!!!!Paolo SuppiNo ratings yet

- Sun Inbev OMSK cable test reportDocument2 pagesSun Inbev OMSK cable test reportcerkadilerNo ratings yet

- Downbeat Mpcs Design ArticleDocument1 pageDownbeat Mpcs Design ArticleEsteban PascualNo ratings yet

- Section Cover Page: Section 26 13 90 Medium Voltage Power 2008-06-02 System MaintenanceDocument22 pagesSection Cover Page: Section 26 13 90 Medium Voltage Power 2008-06-02 System MaintenancecerkadilerNo ratings yet

- Vedelmek Vizsgateletel1-11Document22 pagesVedelmek Vizsgateletel1-11cerkadiler100% (1)

- LicenseDocument3 pagesLicensecerkadilerNo ratings yet

- Richard GrisenthwaiteDocument25 pagesRichard GrisenthwaitecaarthiyayiniNo ratings yet

- Loop Back DSP Audio AppDocument12 pagesLoop Back DSP Audio AppGytis BernotasNo ratings yet

- Gas SpringsDocument122 pagesGas SpringsslavcecaciNo ratings yet

- Abbreviations GuideDocument12 pagesAbbreviations GuideHosein AsgariNo ratings yet

- Intro to Process Control Part 3 by Omar Y IsmaelDocument25 pagesIntro to Process Control Part 3 by Omar Y IsmaelHATAM TALAL ALINo ratings yet

- Accedian Networks EtherNID MetroNID 2pg FINAL 083112 PDFDocument2 pagesAccedian Networks EtherNID MetroNID 2pg FINAL 083112 PDFMark LamondNo ratings yet

- High-Temperature Quad 2-Inputs OR Gate DatasheetDocument6 pagesHigh-Temperature Quad 2-Inputs OR Gate DatasheetSalim Abdul Rahman Sa'dyNo ratings yet

- Hawker TOLD CardsDocument20 pagesHawker TOLD Cardsapi-3803613100% (1)

- ACSEW Cast Control Centers: Explosionproof, Dust-IgnitionproofDocument24 pagesACSEW Cast Control Centers: Explosionproof, Dust-IgnitionproofDennis MendozaNo ratings yet

- API 5l Grade l245 PipesDocument1 pageAPI 5l Grade l245 PipesMitul MehtaNo ratings yet

- TG Tractor Repair Manual Book 5A - Table of Contents: Description Book Number Section Number NumberDocument200 pagesTG Tractor Repair Manual Book 5A - Table of Contents: Description Book Number Section Number NumberJózsef NagyNo ratings yet

- SY155WDocument4 pagesSY155WLutfi DstrNo ratings yet

- Fuel Pressure Regulator - Remove and InstallDocument3 pagesFuel Pressure Regulator - Remove and InstallGerardo VelazquezNo ratings yet

- U2000 Oss NmsDocument27 pagesU2000 Oss Nmschandan100% (1)

- PROTECTIVE RELAY TYPE CPR FOR RUBBER BAG CONSERVATORDocument5 pagesPROTECTIVE RELAY TYPE CPR FOR RUBBER BAG CONSERVATORAshraf NazifNo ratings yet

- COILDATADocument1 pageCOILDATABarış TaşkınNo ratings yet

- Ignition Characteristics of Cracked JP-7 FuelDocument4 pagesIgnition Characteristics of Cracked JP-7 Fuelfahrul3xNo ratings yet

- Paes 217 1Document18 pagesPaes 217 1Czarina Mae MacaraegNo ratings yet

- TM 9-1340-222-34 - 2.75 - Inch - Low - Spin - Folding - Fin - Aircraft - Rockets - 1994 PDFDocument56 pagesTM 9-1340-222-34 - 2.75 - Inch - Low - Spin - Folding - Fin - Aircraft - Rockets - 1994 PDFWurzel1946No ratings yet

- 2.3 Drawing Operations: Need To See If It Really Works For All Tasks, and If Not Then Get Rid of ItDocument1 page2.3 Drawing Operations: Need To See If It Really Works For All Tasks, and If Not Then Get Rid of ItTrogo BoNo ratings yet

- PDFDocument156 pagesPDFVasilescu Corina100% (1)

- FC100 ServiceManual MG90L102Document209 pagesFC100 ServiceManual MG90L102Said BoubkerNo ratings yet

- Brockcommons Constructionoverview WebDocument28 pagesBrockcommons Constructionoverview WebcauecarromeuNo ratings yet

- 363-5 Machine Ride Control Actuator - Current Below NormalDocument3 pages363-5 Machine Ride Control Actuator - Current Below NormalArtin HykoNo ratings yet

- History Spring08Document7 pagesHistory Spring08Anonymous 9VcxlFErfNo ratings yet

- Blueendo MorcellatorDocument7 pagesBlueendo MorcellatorLia GuslianiNo ratings yet

- ABB MNS System GuideDocument34 pagesABB MNS System GuideLeslie HallNo ratings yet

- Quick install guide for Konica printer control systemDocument2 pagesQuick install guide for Konica printer control systemAsep KurniawanNo ratings yet

- API 6D Valves Bonney Forge PDFDocument12 pagesAPI 6D Valves Bonney Forge PDFSQUALO_122No ratings yet

- Laboratory Design Capacitive Displacement SensorDocument10 pagesLaboratory Design Capacitive Displacement SensorElizabethNo ratings yet