Professional Documents

Culture Documents

Timers Cycle

Uploaded by

don121don121Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Timers Cycle

Uploaded by

don121don121Copyright:

Available Formats

S

w

i

t

c

h

e

s

&

P

i

l

o

t

L

i

g

h

t

s

S

i

g

n

a

l

i

n

g

L

i

g

h

t

s

R

e

l

a

y

s

&

S

o

c

k

e

t

s

T

i

m

e

r

s

C

o

n

t

a

c

t

o

r

s

T

e

r

m

i

n

a

l

B

l

o

c

k

s

C

i

r

c

u

i

t

B

r

e

a

k

e

r

s

RTE

Timers Timers

RTE

RTE Series Analog Timers

Key features:

20 time ranges and 10 timing functions

Time delays up to 600 hours

Space-saving package

High repeat accuracy of 0.2%

ON and timing OUT LED indicators

Standard 8- or 11-pin and 11-blade termination

2 form C delayed output contacts

10A Contact Rating

Cert. No. E9950913332316 (EMC, RTE)

Cert. No. BL960813332355 (LVD, RTE)

UL Listed

File No. E66043

General Specications Contact Ratings

Operation System Solid state CMOS Circuit

Contact Conguration

2 Form C, DPDT

(Delay output)

Allowable Voltage /

Allowable Current

240V AC, 30V DC / 10A

Maximum Permissible

Operating Frequency

1800 cycles per hour

Rated

Load

Resistive 10A 240V AC, 30V DC

Inductive 7A 240V AC, 30V DC

Horse Power

Rating

1/6 HP 120V AC, 1/3 HP 240V AC

Life

Electrical 500,000 op. minimum (Resistive)

Mechanical 50,000,000 op. minimum

Operation Type Multi-Mode

Time Range 0.1sec to 600 hours

Pollution Degree 2 (IE60664-1)

Over voltage category III (IE60664-1)

Rated Operational Voltage

AF20 100-240V AC(50/60Hz)

AD24 24V AC(50/60Hz)/24V DC

D12 12V DC

Voltage Tolerance

AF20 85-264V AC(50/60Hz)

AD24 20.4-26.4V AC(50/60Hz)/21.6-26.4V DC

D12 10.8-13.2V DC

Input off Voltage Rated Voltage x10% minimum

Ambient Operating Temperature -20 to +65C (without freezing)

Ambient Storage and Transport Temperature -30 to +75C (without freezing)

Relative Humidity 35 to 85%RH (without condensation)

Atmospheric Pressure 80kPa to 110kPa (Operating), 70kPa to 110kPa (Transport)

Reset Time 100msec maximum

Repeat Error 0.2%, 20msec*

Voltage Error 0.2%, 20msec*

Temperature Error 0.5%, 20msec*

Setting Error 10% maximum

Insulation Resistance 100M minimum (500V DC)

Dielectric Strength

Between power and output terminals: 2000V AC, 1 minute

Between contacts of different poles: 2000V AC, 1 minute

Between contacts of the same pole:1000V AC, 1 minute

Vibration Resistance 10 to 55Hz amplitude 0.5mm

2

hours in each of 3 axes

Shock Resistance

Operating extremes: 98m/sec

2

(10G)

Damage limits: 490m/sec

2

(50G)

3 times in each of 3 axes

Degree of Protection IP40 (enclosure) (IEC60529)

Power Consumption

(Approx.)

TYPE RTE-P1, -B1 RTE-P2, -B2

*For the value of the error against a preset

time, whichever the largest, applies.

AF20

120V AC/60Hz 6.5VA 6.6VA

240V AC/60Hz 11.6VA 11.6VA

24V AC 60Hz/DC 3.4VA/1.7W 3.5VA/1.7W

D12 1.6W 1.6W

Mounting Position Free

Dimensions

RTE-P1, P2 40Hx 36W x 77.9D mm

RTE-B1, B2 40Hx 36W x 74.9D mm

Weight (Approx.)

RTE-P1 RTE-P2 RTE-B1, -B2

87g 89g 85g

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

S

w

i

t

c

h

e

s

&

P

i

l

o

t

L

i

g

h

t

s

S

i

g

n

a

l

i

n

g

L

i

g

h

t

s

R

e

l

a

y

s

&

S

o

c

k

e

t

s

T

i

m

e

r

s

C

o

n

t

a

c

t

o

r

s

T

e

r

m

i

n

a

l

B

l

o

c

k

s

C

i

r

c

u

i

t

B

r

e

a

k

e

r

s

RTE

Timers

Part Numbering Guide

RTE series part numbers are composed of 4 part number codes. When ordering a RTE series part, select one code from each category.

Example: RTE-P1AF20

RTE P 1 AF20

j Series k Terminal

Style

l Function

Group

m Input Voltage

Part Numbers: RTE Series

Description Part Number Code Remarks

j Series RTE series RTE For internal circuits, see next page.

k Terminal Style

Pin P

Select one only.

Blade B

l Function Group

ON-delay, interval, cycle OFF, cycle ON 1 Each function group has different timing functions.

ON-delay, cycle OFF, cycle ON, signal ON/

OFF delay, OFF-delay, one-shot

2 See page 832.

m Input Voltage

100 to 240V AC(50/60Hz) AF20

24V AC(50/60Hz)/24V DC AD24

12V DC D12

Part Numbers

Voltage

Power Triggered Start Input Triggered

8-Pin Blade 11-Pin Blade

12V DC RTE-P1D12 RTE-B1D12 RTE-P2D12 RTE-B2D12

24V AC/DC RTE-P1AD24 RTE-B1AD24 RTE-P2AD24 RTE-B2AD24

100-240V AC RTE-P1AF20 RTE-B1AF20 RTE-P2AF20 RTE-B2AF20

Time Range Determined by Time Range Selector and Dial Selector

Dial 0 - 1 0 - 3 0 - 10 0 - 30 0 - 60

R

a

n

g

e

Second 0.1 sec - 1 sec 0.1 sec - 3 sec 0.2 sec - 10 sec 0.6 sec - 30 sec 1.2 sec - 60 sec

Minute 1.2 sec - 1 min 3.6 sec - 3 min 12 sec - 10 min 36 sec - 30 min 1.2 min - 60 min

Hour 1.2 min - 1 hr 3.6 min - 3 hr 12 min - 10 hr 36 min - 30 hr 1.2 hr - 60 hr

10 Hours 12 min - 10 hr 36 min - 30 hr 2 hr - 100 hr 6 hr - 300 hr 12 hr - 600 hr

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

S

w

i

t

c

h

e

s

&

P

i

l

o

t

L

i

g

h

t

s

S

i

g

n

a

l

i

n

g

L

i

g

h

t

s

R

e

l

a

y

s

&

S

o

c

k

e

t

s

T

i

m

e

r

s

C

o

n

t

a

c

t

o

r

s

T

e

r

m

i

n

a

l

B

l

o

c

k

s

C

i

r

c

u

i

t

B

r

e

a

k

e

r

s

RTE

Timers

Timing Diagrams

RTE-P1, -B1

RTE-P2

11

10

9

1

2

3

4

5

6

7

8

(~/-) (~/+)

start

RTE-B2

2 3

A B

9

1

(~/-) (~/+)

4 5 6

7 8

2 3

A B

9

1

(~/-) (~/+)

4 5 6

7 8

RTE-B1

1

2

3

4 5

6

7

8

(~/-) (~/+)

RTE-P1

start

external

control

si gnal

external

control

si gnal

RTE-P2

11

10

9

1

2

3

4

5

6

7

8

(~/-) (~/+)

start

RTE-B2

2 3

A B

9

1

(~/-) (~/+)

4 5 6

7 8

2 3

A B

9

1

(~/-) (~/+)

4 5 6

7 8

RTE-B1

1

2

3

4 5

6

7

8

(~/-) (~/+)

RTE-P1

start

external

control

si gnal

external

control

si gnal

1. RTE-B1: Do not apply voltage to terminals #2, #5 & #8.

2. IDEC sockets are as follows: RTE-P1: SR2P-06* pin type socket,

RTE-B1: SR3B-05* blade type socket, (*-may be followed by sufx

letter A,B,C or U).

A: ON-Delay 1 (power start)

Set timer for desired delay, apply power to coil. Contacts transfer after preset time has elapsed, and

remain in transferred position until timer is reset. Reset occurs with removal of power.

Item Terminal Number Operation

Power

(1) 2 - 7

(2) A - B

Delayed

Contact

(1) 1 - 4, 5 - 8

(2) 1 - 7, 3 - 9

(NC)

(1) 1 - 3, 6 - 8

(2) 4 - 7, 6 - 9

(NO)

Indicator

PWR

OUT

Set Time

T

C: Cycle 1 (power start, OFF rst)

Set timer for desired delay, apply power to coil. First transfer of contacts occurs after preset delay has

elapsed, after the next elapse of preset delay contacts return to original position. The timer now cycles

between on and off as long as power is applied (duty ratio 1:1).

Item Terminal Number Operation

Power

(1) 2 - 7

(2) A - B

Delayed

Contact

(1) 1 - 4, 5 - 8

(2) 1 - 7, 3 - 9

(NC)

(1) 1 - 3, 6 - 8

(2) 4 - 7, 6 - 9

(NO)

Indicator

PWR

OUT

Set Time

T T

B: Interval (power start)

Set timer for desired delay, apply power to coil. Contacts transfer immediately, and return to original

position after preset time has elapsed. Reset occurs with removal of power.

Item Terminal Number Operation

Power

(1) 2 - 7

(2) A - B

Delayed

Contact

(1) 1 - 4, 5 - 8

(2) 1 - 7, 3 - 9

(NC)

(1) 1 - 3, 6 - 8

(2) 4 - 7, 6 - 9

(NO)

Indicator

PWR

OUT

Set Time

T

C: Cycle 3 (power start, ON rst)

Functions in same manner as Mode C, with the exception that rst transfer of contacts occurs as soon

as power is applies. The ratio is 1:1. Time On = Time Off

Item Terminal Number Operation

Power

(1) 2 - 7

(2) A - B

Delayed

Contact

(1) 1 - 4, 5 - 8

(2) 1 - 7, 3 - 9

(NC)

(1) 1 - 3, 6 - 8

(2) 4 - 7, 6 - 9

(NO)

Indicator

PWR

OUT

Set Time

T T

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

S

w

i

t

c

h

e

s

&

P

i

l

o

t

L

i

g

h

t

s

S

i

g

n

a

l

i

n

g

L

i

g

h

t

s

R

e

l

a

y

s

&

S

o

c

k

e

t

s

T

i

m

e

r

s

C

o

n

t

a

c

t

o

r

s

T

e

r

m

i

n

a

l

B

l

o

c

k

s

C

i

r

c

u

i

t

B

r

e

a

k

e

r

s

RTE

Timers

Timing Diagrams cont

RTE-P2, -B2

RTE-P2

11

10

9

1

2

3

4

5

6

7

8

(~/-) (~/+)

start

RTE-B2

2 3

A B

9

1

(~/-) (~/+)

4 5 6

7 8

2 3

A B

9

1

(~/-) (~/+)

4 5 6

7 8

RTE-B1

1

2

3

4 5

6

7

8

(~/-) (~/+)

RTE-P1

start

external

control

si gnal

external

control

si gnal

RTE-P2

11

10

9

1

2

3

4

5

6

7

8

(~/-) (~/+)

start

RTE-B2

2 3

A B

9

1

(~/-) (~/+)

4 5 6

7 8

2 3

A B

9

1

(~/-) (~/+)

4 5 6

7 8

RTE-B1

1

2

3

4 5

6

7

8

(~/-) (~/+)

RTE-P1

start

external

control

si gnal

external

control

si gnal

1. RTE-P2: Do not apply voltage to terminals #5, #6 & #7.

2. RTE-B2: Do not apply voltage to terminals #2, #5 & #8.

3. IDEC sockets are as follows: RTE-P2: SR3P-05* pin type socket,

RTE-B2: SR3B-05* blade type socket, (*-may be followed by sufx

letter A,B,C or U).

A: ON-Delay 2 (signal start)

When a preset time has elapsed after the start input turned on while power is on, the NO output

contact goes on.

Item Terminal Number Operation

Power

(A) 2 - 10

(B) A - B

Start

(A) 5 - 6

(B) 2 - 5

Delayed

Contact

(A) 1 - 4, 8 - 11

(B) 1 - 7, 3 - 9

(NC)

(A) 1 - 3, 9 - 11

(B) 4 - 7, 6 - 9

(NO)

Indicator

PWR

OUT

Set Time

T

C: Cycle 4 (signal start, ON rst)

When the start input turns on while power is on, the NO contact goes on. The output oscillates at a

preset cycle (duty ratio 1:1).

Item Terminal Number Operation

Power

(A) 2 - 10

(B) A - B

Start

(A) 5 - 6

(B) 2 - 5

Delayed

Contact

(A) 1 - 4, 8 - 11

(B) 1 - 7, 3 - 9

(NC)

(A) 1 - 3, 9 - 11

(B) 4 - 7, 6 - 9

(NO)

Indicator

PWR

OUT

Set Time

T T T T T T T T Ta

E: Signal OFF-Delay

When power is turned on while the start input is on, the NO output contact goes on. When a preset

time has elapsed after the start input turned off, the NO output contact goes off.

Item Terminal Number Operation

Power

(A) 2 - 10

(B) A - B

Start

(A) 5 - 6

(B) 2 - 5

Delayed

Contact

(A) 1 - 4, 8 - 11

(B) 1 - 7, 3 - 9

(NC)

(A) 1 - 3, 9 - 11

(B) 4 - 7, 6 - 9

(NO)

Indicator

PWR

OUT

Set Time

T Ta T Ta

B: Cycle 2 (signal start, OFF rst)

When the start input turns on while power is on, the output oscillates at a preset cycle (duty ratio 1:1),

starting while the NO contact off.

Item Terminal Number Operation

Power

(A) 2 - 10

(B) A - B

Start

(A) 5 - 6

(B) 2 - 5

Delayed

Contact

(A) 1 - 4, 8 - 11

(B) 1 - 7, 3 - 9

(NC)

(A) 1 - 3, 9 - 11

(B) 4 - 7, 6 - 9

(NO)

Indicator

PWR

OUT

Set Time

T T T T T T T T T Ta

D: Signal ON/OFF-Delay

When the start input turns on while power is on, the NO output contact goes on. When a preset time

has elapsed while the start input remains on, the output contact goes off. When the start input turns

off, the NO contact goes on again. When a preset time has elapsed after the start input turned off, the

NO contact goes off.

Item Terminal Number Operation

Power

(A) 2 - 10

(B) A - B

Start

(A) 5 - 6

(B) 2 - 5

Delayed

Contact

(A) 1 - 4, 8 - 11

(B) 1 - 7, 3 - 9

(NC)

(A) 1 - 3, 9 - 11

(B) 4 - 7, 6 - 9

(NO)

Indicator

PWR

OUT

Set Time

T T Ta T T Ta

F: One-Shot (signal start)

When the start input turns on while power is on, the NO output contact goes on. When a preset time

has elapsed, the NO output contact goes off.

Item Terminal Number Operation

Power

(A) 2 - 10

(B) A - B

Start

(A) 5 - 6

(B) 2 - 5

Delayed

Contact

(A) 1 - 4, 8 - 11

(B) 1 - 7, 3 - 9

(NC)

(A) 1 - 3, 9 - 11

(B) 4 - 7, 6 - 9

(NO)

Indicator

PWR

OUT

Set Time

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

S

w

i

t

c

h

e

s

&

P

i

l

o

t

L

i

g

h

t

s

S

i

g

n

a

l

i

n

g

L

i

g

h

t

s

R

e

l

a

y

s

&

S

o

c

k

e

t

s

T

i

m

e

r

s

C

o

n

t

a

c

t

o

r

s

T

e

r

m

i

n

a

l

B

l

o

c

k

s

C

i

r

c

u

i

t

B

r

e

a

k

e

r

s

RTE

Timers

Temperature Derating Curves

Mounting A

50C 65C

10A

7A

Ambient Temperature

A

l

l

o

w

a

b

l

e

C

u

r

r

e

n

t

Mounting A

Derating Curve

Mounting B

50C 65C

7A

5A

Ambient Temperature

A

l

l

o

w

a

b

l

e

C

u

r

r

e

n

t

Mounting B

Derating Curve

Instructions

Installation of Hold-Down Springs

DIN Rail Mount Socket

Socket SR2P-06 Hold-down Spring (sold separately)

SFA-202 (use two springs)

Insert the springs into the outer

slots with the projections

facing inside.

Socket SR2P-05

Insert the springs

into the slots.

Hold-down Spring (sold separately)

SFA-203 (use two springs)

Switch Settings

jOperator Mode Selector

kScale Selector

lTime Range Selector

j

k

l

1. Turn the selectors securely using a at screw-

driver 4mm wide (maximum).

Note that incorrect setting may cause malfunc-

tion. Do not turn the selectors beyond their limits.

2. Since changing the setting during timer operation

may cause malfunction, turn power off before

changing.

Safety Precautions

Special expertise is required to use Electronic Timers.

All Electronic Timers are manufactured under IDECs rigorous quality control

system, but users must add a backup or fail safe provision to the control

system when using the Electronic Timer in applications where heavy damage

or personal injury may occur should the Electronic Timer fail.

Install the Electronic Timer according to instructions described in this catalog.

Make sure that the operating conditions are as described in the specica-

tions. If you are uncertain about the specications, contact IDEC in advance.

In these directions, safety precautions are categorized in order of importance

under Warning and Caution.

Warnings

Warning notices are used to emphasize that improper operation may cause

severe personal injury or death.

Turn power off to the Electronic timer before starting installation, removal,

wiring, maintenance, and inspection on the Electronic Timer.

Failure to turn power off may cause electrical shocks or re hazard.

Do not use the Electronic Timer for an emergency stop circuit or inter-

locking circuit. If the Electronic Timer should fail, a machine malfunction,

breakdown, or accident may occur.

Caution

Caution notices are used where inattention might cause personal injury or dam-

age to equipment.

The Electronic Timer is designed for installation in equipment. Do not install

the Electronic Timer outside equipment.

Install the Electronic Timer in environments described in the specications. If

the Electronic Timer is used in places where it will be subjected to high-tem-

perature, high-humidity, condensation, corrosive gases, excessive vibrations,

or excessive shocks, then electrical shocks, re hazard, or malfunction could

result.

Use an IEC60127-approved fuse and circuit breaker on the power and output

line outside the Electronic Timer.

Do not disassemble, repair, or modify the Electronic Timer.

When disposing of the Electronic Timer, do so as industrial waste.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

S

w

i

t

c

h

e

s

&

P

i

l

o

t

L

i

g

h

t

s

S

i

g

n

a

l

i

n

g

L

i

g

h

t

s

R

e

l

a

y

s

&

S

o

c

k

e

t

s

T

i

m

e

r

s

C

o

n

t

a

c

t

o

r

s

T

e

r

m

i

n

a

l

B

l

o

c

k

s

C

i

r

c

u

i

t

B

r

e

a

k

e

r

s

RTE

Timers

Accessories

DIN Rail Mounting Accessories

DIN Rail/Surface Mount Sockets and Hold-Down Springs

DIN Rail Mount Socket Applicable Hold-Down Springs

Style Appearance Use with Timers Part Number Appearance Part Number

11-Pin Screw Terminal

(dual tier)

RTE-P2 SR3P-05

SFA-203

11-Pin FingerSafe Socket RTE-P2 SR3P-05C

8-Pin Screw Terminal

RTE-P1

SR2P-06

SFA-202 8-Pin Fingersafe Socket SR2P-05C

11-Blade Screw Terminal

RTE-B1

RTE-B2

SR3B-05

DIN Mounting Rail

Length 1000mm

BNDN1000

Panel Mounting Accessories

Flush Panel Mount Adapter and Sockets that use an Adapter

Accessory Description Appearance Use with Part No.

Panel Mount Adapter

Adaptor for ush panel

mounting RTE timers

All RTE timers RTB-G01

Sockets for use with

Panel Mount Adapter

8-pin screw terminal

(Shown: SR6P-M08G Wiring Socket Adapter)

RTE-P1 SR6P-M08G

11-pin screw terminal RTE-P2 SR6P-M11G

8-pin solder terminal RTE-P1 SR6P-S08

11-pin solder terminal RTE-P2 SR6P-S11

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

S

w

i

t

c

h

e

s

&

P

i

l

o

t

L

i

g

h

t

s

S

i

g

n

a

l

i

n

g

L

i

g

h

t

s

R

e

l

a

y

s

&

S

o

c

k

e

t

s

T

i

m

e

r

s

C

o

n

t

a

c

t

o

r

s

T

e

r

m

i

n

a

l

B

l

o

c

k

s

C

i

r

c

u

i

t

B

r

e

a

k

e

r

s

RTE

Timers

Dimensions

36.0

77.9

4

0

.

0

13.0

7.3

13.7

RTE-P1 (8 pin) Terminal Style

RTE-P2 (11 pin)Terminal Style

RTE-B1/RTE-B2 (11 blade) Terminal Style

Panel Mount Adapter

RTE Timer, 8-Pin and 11-Pin with SR6P-S08 or SR6P-S11

Back Wiring Socket

1

.

7

48

4

8

11 61.2

Panel Thickness 0.8 to 5mm

4

2

.

5

98 maximum

RTE Timer, 8-Pin with SR6P-M08G

3.6 min.

8-M3.5 Terminal Screw

2 1 8 7

3 4 5 6

6.9 max.

3

0

.

4

4

4

.

6

Panel Thickness 0.8 to 5mm

80.5

7

9.8 x 3

44.6

3.5 max. 5.6 min.

RTE Timer, 11-Pin with SR6P-M11G

3.6 min.

11-M3.5 Teminal Screws

6.9 max.

92

4 3 8 9 10

2 11

5

1 7 6

3.5 max. 5.8 min.

30.5 7

8.5 x 4

16.7

45

3

4

4

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

S

w

i

t

c

h

e

s

&

P

i

l

o

t

L

i

g

h

t

s

S

i

g

n

a

l

i

n

g

L

i

g

h

t

s

R

e

l

a

y

s

&

S

o

c

k

e

t

s

T

i

m

e

r

s

C

o

n

t

a

c

t

o

r

s

T

e

r

m

i

n

a

l

B

l

o

c

k

s

C

i

r

c

u

i

t

B

r

e

a

k

e

r

s

General Instructions

Timers

General Instructions for All Timer Series

Load Current

With inductive, capacitive, and incandescent lamp loads, inrush current more

than 10 times the rated current may cause welded contacts and other undesired

effects. The inrush current and steady-state current must be taken into consider-

ation when specifying a timer.

Contact Protection

Switching an inductive load generates a counter-electromotive force (back EMF)

in the coil. The back EMF will cause arcing, which may shorten the contact life

and cause imperfect contact. Application of a protection circuit is recommended

to safeguard the contacts.

Temperature and Humidity

Use the timer within the operating temperature and operating humidity ranges

and prevent freezing or condensation. After the timer has been stored below

its operating temperature, leave the timer at room temperature for a sufcient

period of time to allow it to return to operating temperatures before use.

Environment

Avoid contact between the timer and sulfurous or ammonia gases, organic sol-

vents (alcohol, benzine, thinner, etc.), strong alkaline substances, or strong acids.

Do not use the timer in an environment where such substances are prevalent. Do

not allow water to run or splash on the timer.

Vibration and Shock

Excessive vibration or shocks can cause the output contacts to bounce, the

timer should be used only within the operating extremes for vibration and shock

resistance. In applications with signicant vibration or shock, use of hold down

springs or clips is recommended to secure a timer to its socket.

Time Setting

The time range is calibrated at its maximum time scale; so it is desirable to use

the timer at a setting as close to its maximum time scale as possible. For a more

accurate time delay, adjust the control knob by measuring the operating time

with a watch before application.

Input Contacts

Use mechanical contact switch or relay to supply power to the timer. When

driving the timer with a solid-state output device (such as a two-wire proximity

switch, photoelectric switch, or solid-state relay), malfunction may be caused by

leakage current from the solid-state device. Since AC types comprise a capaci-

tive load, the SSR dielectric strength should be two or more times the power

voltage when switching the timer power using an SSR.

Generally, it is desirable to use mechanical contacts whenever possible to apply

power to a timer or its signal inputs. When using solid state devices, be cautious

of inrushes and back-EMF that may exceed the ratings on such devices. Some

timers are specially designed so that signal inputs switch at a lower voltage

than is used to power the timer (models designated as B type).

Timing Accuracy Formulas

Timing accuracies are calculated from the following formulas:

Repeat Error

= 1 x Maximum Measured Value Minimum Measured Value x 100%

2 Maximum Scale Value

Voltage Error

= Tv - Tr x 100%

Tr

Tv: Average of measured values at voltage V

Tr: Average of measured values at the rated voltage

Temperature Error

= Tt - T20 x 100%

T20

Tt: Average of measured values at C

T20: Average of measured values at 20C

Setting Error

= Average of Measured Values - Set Value x 100%

Maximum Scale Value

General Instructions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

You might also like

- Switching & Controls Timers Selection GuideDocument68 pagesSwitching & Controls Timers Selection GuideDraj CahyaNo ratings yet

- Taylor Contactor Open Transition Tech DataDocument17 pagesTaylor Contactor Open Transition Tech DataAdewunmi AdeoluwaNo ratings yet

- Timing Diagram Timers CycleDocument1 pageTiming Diagram Timers Cycledon121don121No ratings yet

- General Description: 13 March 2014 Product Data SheetDocument14 pagesGeneral Description: 13 March 2014 Product Data SheetRafael AndréNo ratings yet

- Multi-Function Analogue Timer: WarningDocument2 pagesMulti-Function Analogue Timer: WarningdimasNo ratings yet

- Navtex NCR333Document80 pagesNavtex NCR333Sang Aji Jaya Suseno100% (2)

- 2N6399Document7 pages2N6399Fernando J. TapiaNo ratings yet

- RE7ML11BU TelemecaniqueDocument22 pagesRE7ML11BU TelemecaniqueHugo FermartiNo ratings yet

- China TV Chassis 3Y11Document29 pagesChina TV Chassis 3Y11dl1476No ratings yet

- IRFL9110Document8 pagesIRFL9110Vũ Công ChínhNo ratings yet

- SANYO Semiconductor Specifications and STK404-120N-E Audio ICDocument11 pagesSANYO Semiconductor Specifications and STK404-120N-E Audio ICgapjgNo ratings yet

- Digital Motor Protection Relay GuideDocument16 pagesDigital Motor Protection Relay GuideSukant Kumar MohantyNo ratings yet

- ¡ Semiconductor: MSM80C88A-10RS/GS/JSDocument37 pages¡ Semiconductor: MSM80C88A-10RS/GS/JSZarate BismkNo ratings yet

- H3C-R Multi-Function Analogue TimerDocument4 pagesH3C-R Multi-Function Analogue TimerdimasNo ratings yet

- Omron h3cr-g TimerDocument7 pagesOmron h3cr-g TimerRiky HidayatNo ratings yet

- Stp8Nc50 - Stp8Nc50Fp Stb8Nc50-1: N-Channel 500V - 0.7 - 8A To-220/To-220Fp/I2Pak Powermesh Ii MosfetDocument11 pagesStp8Nc50 - Stp8Nc50Fp Stb8Nc50-1: N-Channel 500V - 0.7 - 8A To-220/To-220Fp/I2Pak Powermesh Ii Mosfetmiguel angel jaramilloNo ratings yet

- SG1844/SG1845 Series: C M PWM CDocument13 pagesSG1844/SG1845 Series: C M PWM CAldo HernandezNo ratings yet

- STK433 060 eDocument11 pagesSTK433 060 eGustavo EndeNo ratings yet

- 10 Ats8w, 11W PDFDocument4 pages10 Ats8w, 11W PDFhanief sasongkoNo ratings yet

- Timers, Time, Switches, Hour Meters & Supply MonitorsDocument24 pagesTimers, Time, Switches, Hour Meters & Supply MonitorsnogeshwarNo ratings yet

- Anly Timer: Amy/Amy-NDocument2 pagesAnly Timer: Amy/Amy-NdimasNo ratings yet

- Fast Speed IGBT with 600V Breakdown VoltageDocument8 pagesFast Speed IGBT with 600V Breakdown VoltageLidystonPeronNo ratings yet

- SIemens TimerDocument4 pagesSIemens Timervaithy1990No ratings yet

- Ah3 GBDocument2 pagesAh3 GBJerry HalibasNo ratings yet

- Low-Power Economy Bicmos Current-Mode PWMDocument26 pagesLow-Power Economy Bicmos Current-Mode PWMmigsayalNo ratings yet

- SG3842Document14 pagesSG3842sveta9733276100% (1)

- STK433-090-E: 2-Channel Class AB Audio Power IC, 80W+80WDocument11 pagesSTK433-090-E: 2-Channel Class AB Audio Power IC, 80W+80Wcarlosgabriel1971No ratings yet

- CA3059, CA3079: Description FeaturesDocument12 pagesCA3059, CA3079: Description FeaturesMiltongrimi GrimilNo ratings yet

- Part Numbering Guide Timers CycleDocument1 pagePart Numbering Guide Timers Cycledon121don121No ratings yet

- Service Manual: 14" CTV-37V10, 37V20, 37X10 21" CTV-55V10, 55S10, 55X10, 55Z10Document11 pagesService Manual: 14" CTV-37V10, 37V20, 37X10 21" CTV-55V10, 55S10, 55X10, 55Z10NeutrinosoNo ratings yet

- Obsolete Product(s) - Obsolete Product(s)Document10 pagesObsolete Product(s) - Obsolete Product(s)patopickNo ratings yet

- P4NC60Document9 pagesP4NC60Gabino OrtizNo ratings yet

- QH 10kA Miniature Circuit Breakers & RCBO GuideDocument20 pagesQH 10kA Miniature Circuit Breakers & RCBO Guidemehdi_mehdiNo ratings yet

- Electric TimerDocument40 pagesElectric TimergamasistemNo ratings yet

- N - Channel 800V - 1.8 - 5A - To-220/To-220Fp Powermesh MosfetDocument10 pagesN - Channel 800V - 1.8 - 5A - To-220/To-220Fp Powermesh MosfetHerpadianaNo ratings yet

- 1M110ZS5 Diodo ZenerDocument10 pages1M110ZS5 Diodo Zenerconti51No ratings yet

- Qt-Series Possenti Heat Relequick RelaysDocument2 pagesQt-Series Possenti Heat Relequick Relaysapi-28269646No ratings yet

- Timing issues in digital ASIC designDocument101 pagesTiming issues in digital ASIC designnsai_vs1513No ratings yet

- 74HC14Document15 pages74HC14Adilson LucaNo ratings yet

- IGBT de Plasma Samsung RJP30E2DPK 360V - 35ampDocument7 pagesIGBT de Plasma Samsung RJP30E2DPK 360V - 35ampAntonio ChavezNo ratings yet

- Panasonic SAPT 760 P Service Manual 1Document154 pagesPanasonic SAPT 760 P Service Manual 1Jonathan HuelsrnNo ratings yet

- Pin Description Features: P-Channel Enhancement Mode MOSFETDocument0 pagesPin Description Features: P-Channel Enhancement Mode MOSFETShaher Bano KazmiNo ratings yet

- ULN2803A Darlington Transistor Arrays: Features DescriptionDocument14 pagesULN2803A Darlington Transistor Arrays: Features DescriptionJohn Joshua MontañezNo ratings yet

- MCP9800 Digital Temperature SensorDocument42 pagesMCP9800 Digital Temperature SensorNeeraj AdsulNo ratings yet

- Data SheetDocument6 pagesData SheetCarlos Andres Cerón PugaNo ratings yet

- 2 N 6344Document8 pages2 N 6344lgrome73No ratings yet

- Moc 3021Document8 pagesMoc 3021Adrian Jose Costa OspinoNo ratings yet

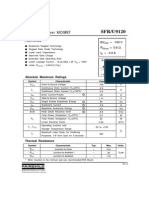

- SFR/U9120: Advanced Power MOSFETDocument7 pagesSFR/U9120: Advanced Power MOSFETJavier BendekNo ratings yet

- Dual SCR Isolated Module: Pow-R-BlokDocument5 pagesDual SCR Isolated Module: Pow-R-BlokCarlos OlivaNo ratings yet

- Generator Relay ProtectionDocument374 pagesGenerator Relay ProtectionAnonymous BBX2E87aHNo ratings yet

- Transistor Electronics: Use of Semiconductor Components in Switching OperationsFrom EverandTransistor Electronics: Use of Semiconductor Components in Switching OperationsRating: 1 out of 5 stars1/5 (1)

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1From EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Rating: 4.5 out of 5 stars4.5/5 (3)

- Field Terminal BoxDocument1 pageField Terminal Boxdon121don121No ratings yet

- Flow Measurement FundamentalsThis concise title summarizes the key topic of the document - flow measurement fundamentals - . It starts with "TITLEDocument5 pagesFlow Measurement FundamentalsThis concise title summarizes the key topic of the document - flow measurement fundamentals - . It starts with "TITLEKHairil AdZharNo ratings yet

- Voltage Drop Calculation of HT MotorsDocument7 pagesVoltage Drop Calculation of HT MotorsGAGAN100% (1)

- Chapter 14 Cable Support SystemsDocument24 pagesChapter 14 Cable Support SystemsjoorgesilvaNo ratings yet

- PT TT Compensation Basics For DP TransmitterDocument3 pagesPT TT Compensation Basics For DP Transmitterdon121don121No ratings yet

- Universal Temperature Transmitter E&hDocument18 pagesUniversal Temperature Transmitter E&hdon121don121No ratings yet

- Tefal Fuzzy Rice CookerDocument69 pagesTefal Fuzzy Rice Cookerdon121don121No ratings yet

- EasyPact EZC - EZC100H3075Document2 pagesEasyPact EZC - EZC100H3075don121don121No ratings yet

- MTL7700 Series Shunt-Diode Safety Barrier (INTRINSICALLY SAFE LOOP)Document24 pagesMTL7700 Series Shunt-Diode Safety Barrier (INTRINSICALLY SAFE LOOP)don121don121No ratings yet

- THe Manual For Cropping The Fixed One JHFH PDFDocument6 pagesTHe Manual For Cropping The Fixed One JHFH PDFdon121don121No ratings yet

- Temperature Transmitter III YTA320 CatalogueDocument9 pagesTemperature Transmitter III YTA320 Cataloguedon121don121No ratings yet

- Api 2540Document8 pagesApi 2540biondimi100% (1)

- Instrument Cables SpecificationDocument12 pagesInstrument Cables Specificationdon121don121No ratings yet

- 4-20ma Output For Temperature Transmitter Head RequirementDocument10 pages4-20ma Output For Temperature Transmitter Head Requirementdon121don121No ratings yet

- Quick Time 7 User GuideDocument63 pagesQuick Time 7 User GuideChristine AmakerNo ratings yet

- The Flow Guide For PT TT Compensation For Crude Oil ManualDocument32 pagesThe Flow Guide For PT TT Compensation For Crude Oil Manualdon121don121No ratings yet

- Cable Schedule AppendixDocument8 pagesCable Schedule Appendixdon121don121No ratings yet

- Density Correction Factor For Diesel Vs TemeperatureDocument3 pagesDensity Correction Factor For Diesel Vs Temeperaturedon121don121No ratings yet

- X2500 GeneratorDocument5 pagesX2500 Generatordon121don121No ratings yet

- Miniature Circuit-Breakers and Earth Leakage Circuit-Breakers (Mcbs/Elcbs)Document35 pagesMiniature Circuit-Breakers and Earth Leakage Circuit-Breakers (Mcbs/Elcbs)occhityaNo ratings yet

- Specifications - Flow Meter For DP Transmitter CorrectionDocument2 pagesSpecifications - Flow Meter For DP Transmitter Correctiondon121don121No ratings yet

- Density Correction Factor For Diesel Vs TemeperatureDocument3 pagesDensity Correction Factor For Diesel Vs Temeperaturedon121don121No ratings yet

- Timing Control Enhancement ProgramDocument7 pagesTiming Control Enhancement Programdon121don121No ratings yet

- General Instructions For All Timer Series: Load Current Vibration and ShockDocument1 pageGeneral Instructions For All Timer Series: Load Current Vibration and Shockdon121don121No ratings yet

- Part Numbering Guide Timers CycleDocument1 pagePart Numbering Guide Timers Cycledon121don121No ratings yet

- Cycle Timers Number 1Document1 pageCycle Timers Number 1don121don121No ratings yet

- Relay Super Cycle With TimerDocument8 pagesRelay Super Cycle With Timerdon121don121No ratings yet

- Motor Operated ValveDocument48 pagesMotor Operated Valvedon121don121No ratings yet

- DPP-1 To 8 - Modern Physics - JEEDocument54 pagesDPP-1 To 8 - Modern Physics - JEEKeerthana Reddy DomaNo ratings yet

- ResistanceDocument2 pagesResistanceJude GenovaNo ratings yet

- Ic VivaDocument2 pagesIc VivaSrinivasu RajuNo ratings yet

- Magnetic Circuits PDFDocument58 pagesMagnetic Circuits PDFImtiax LaghariNo ratings yet

- Ansi/nema C84.1-2006Document13 pagesAnsi/nema C84.1-2006larryNo ratings yet

- Noblex: SERVICE MANUAL Colour TelevisionDocument33 pagesNoblex: SERVICE MANUAL Colour TelevisionLeonel FontanaNo ratings yet

- Installation and Estimation of Electrical Load PDFDocument59 pagesInstallation and Estimation of Electrical Load PDFMohd AliNo ratings yet

- Radio Frequency Over Optical FiberDocument31 pagesRadio Frequency Over Optical Fibersiva kumar mandhatiNo ratings yet

- Resistors in Series and in ParallelDocument4 pagesResistors in Series and in ParallelAtif MehfoozNo ratings yet

- CST Microwave StudioDocument28 pagesCST Microwave StudiodheifibraheemNo ratings yet

- Telecom-02-00022-V2Document21 pagesTelecom-02-00022-V2husam hamidNo ratings yet

- Derivation of The Threshold VoltageDocument3 pagesDerivation of The Threshold VoltageRoobert01No ratings yet

- Scitronics - Metal - Detector - TMD1080 1Document4 pagesScitronics - Metal - Detector - TMD1080 1Fernando BarrosNo ratings yet

- Yellow Shaded Questions Are Selected From Ktu Qps Dec 2019, May 2019, Dec 2018Document18 pagesYellow Shaded Questions Are Selected From Ktu Qps Dec 2019, May 2019, Dec 2018ABHIRAM K REJIKUMAR EE19-23No ratings yet

- Chapter 5 Part 2Document10 pagesChapter 5 Part 2george manNo ratings yet

- KAT-KIT Deacy Amp Assembly and Test InstructionsDocument22 pagesKAT-KIT Deacy Amp Assembly and Test InstructionsAntony Sebastián Villalobos CataldoNo ratings yet

- Led Light For Energy EfficencyDocument29 pagesLed Light For Energy EfficencySantanu Kumar RanaNo ratings yet

- ICP MS - TuneSim HelpDocument2 pagesICP MS - TuneSim Help张旭东No ratings yet

- Laser Based Voice and Data CommunicationDocument41 pagesLaser Based Voice and Data Communicationanshu_ranjan180% (5)

- M82 PXCX NOT XxxA XXX CAT2 X eDocument13 pagesM82 PXCX NOT XxxA XXX CAT2 X egerman gualavisi50% (2)

- ABB Surge Arrester MWK - Data Sheet 1HC0075865 E01 ABDocument5 pagesABB Surge Arrester MWK - Data Sheet 1HC0075865 E01 ABeliahudNo ratings yet

- P-Doped Germanium On Circuit BoardDocument3 pagesP-Doped Germanium On Circuit BoardfauziNo ratings yet

- 400kV GIS Technical Data SheetDocument20 pages400kV GIS Technical Data SheetjigyeshNo ratings yet

- Lab Assignment (Iv)Document5 pagesLab Assignment (Iv)Mark Paul Santin Ganzalino100% (1)

- IB DP Physics Past Papers Waves QnsDocument21 pagesIB DP Physics Past Papers Waves QnsJessica GuyNo ratings yet

- Chapter 8: Field Effect Transistors (FETsDocument18 pagesChapter 8: Field Effect Transistors (FETsAeron Chester DinoNo ratings yet

- Antennas 101Document1 pageAntennas 101vijaya36fNo ratings yet

- Testing Instr Ument: Semiconductor Curve TracerDocument1 pageTesting Instr Ument: Semiconductor Curve Tracermohamed ShabaanNo ratings yet

- Max291 Max296Document10 pagesMax291 Max296William PaulNo ratings yet

- Digital Ic Design TutorialDocument4 pagesDigital Ic Design Tutorialkrishna kanthNo ratings yet