Professional Documents

Culture Documents

Procedimiento de Ajuste de Freno de Motor C-15, C-16 and C-18 Engines

Uploaded by

Jose MontoyaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Procedimiento de Ajuste de Freno de Motor C-15, C-16 and C-18 Engines

Uploaded by

Jose MontoyaCopyright:

Available Formats

Slave Piston Lash - Adjust

SMCS - 1119-025

To prevent possible injury, do not use the starter to turn the flywheel.

Hot engine components can cause burns. Allow additional time for the

engine to cool before measuring valve clearance.

This engine uses high voltage to control the fuel injectors.

Disconnect electronic fuel injector enable circuit connector to prevent

personal injury.

Do not come in contact with the fuel injector terminals while the engine

is running.

NOTICE

Failure to follow the recommended procedure or the specified tooling

that is required for the procedure could result in damage to

components.

To avoid component damage, follow the recommended procedure

using the recommended tools.

The engine valve lash and the injector lash must be within specifications prior to adjusting

the compression brake slave piston lash. Refer to Testing and Adjusting, "Engine Valve

Lash - Inspect/Adjust" for the correct procedure for inspection of the engine valve lash.

Refer to Testing and Adjusting, "Electronic Unit Injector - Adjust" for the proper procedure

for inspection of the injector lash adjustment.

Note: The slave piston lash adjustment must be performed while the engine is cold. If

the engine is warm, allow the engine to cool prior to performing the following

adjustments.

Use the following procedure to adjust the slave piston lash on cylinders 1, 3, and 5:

Put the No. 1 piston at the top center position on the compression stroke. See Testing and

Adjusting, "Finding Top Center Position for No. 1 Piston" for further details.

Jake Brake Compression Brake Adjustment

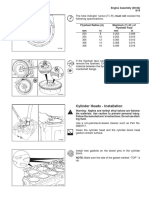

Illustration 1

g00596577

Typical configuration for Jake Brake engine compression brake

(1) Adjustment screw for the slave piston

(2) Slave piston

(3) Rocker arm

NOTICE

Prior to adjusting the lash setting for the engine compression brake,

check the identification plate that is on the compression brake casting

in order to determine the model that is installed on your engine. You

must have this model number and the engine serial number prefix in

order to determine the lash setting for your engine.

Table 1

Slave Piston Lash Setting

Jake Brake Compression Brakes

Serial Number Prefix and Model

Number

(1)

Horsepower Rating Slave Piston Lash Setting

2WS1-UP

Jake Brake 340B

410 hp or less

0.94 0.08 mm (0.037 0.003

inch)

435-550 hp

0.84 0.08 mm (0.033 0.003

inch)

2WS1-UP

Jake Brake 340C

410 hp or less

0.94 0.08 mm (0.037 0.003

inch)

435-550 hp

0.84 0.08 mm (0.033 0.003

inch)

6NZ1-UP

Jake Brake 340C

410 hp or less

0.94 0.08 mm (0.037 0.003

inch)

435 hp or more

0.84 0.08 mm (0.033 0.003

inch)

375/435 hp Multitorque

rating

0.84 0.08 mm (0.033 0.003

inch)

1MM1-UP

All ratings

7CZ1-UP

5DS1-UP

Jake Brake 340C

0.94 0.08 mm (0.037 0.003

inch)

1LW1-UP

Jake Brake 340C

410 hp or less

0.84 0.08 mm (0.033 0.003

inch)

435 hp or more

0.68 0.08 mm (0.027 0.003

inch)

5EK1-UP

(2)

6TS1-UP

Jake Brake 340A

410 hp or less

0.68 0.08 mm (0.027 0.003

inch)

435 hp or more

0.76 0.08 mm (0.030 0.003

inch)

5EK1-UP

(2)

Jake Brake 340

435 hp or more

0.68 0.08 mm (0.027 0.003

inch)

1LW1-UP

6NZ1-UP

7CZ1-UP

Jake Brake 340D

All ratings

0.64 0.08 mm (0.025 0.003

inch)

CJP1-UP

MDP1-UP

MEP1-UP

W1A1-UP

Jake Brake 340C

All ratings

1.02 0.08 mm (0.040 0.003

inch)

MBN1-UP

Jake Brake 340D

All ratings

0.76 0.08 mm (0.030 0.003

inch)

BXS1-UP

Jake Brake 340C

All ratings

0.89 0.08 mm (0.035 0.003

inch)

BXS1-UP

Jake Brake 340E

All ratings

0.84 0.08 mm (0.033 0.003

inch)

( 1 )

Check the identification plate that is on the compression brake casting in order to determine the model

that is installed on your engine.

( 2 )

Some of the early 3406E Engines , 5EK1-01820 were built with either the 340 or the 340A compression

brakes.

Note: The slave piston lash settings are specific to the model number of the compression

brake and to the serial number prefix of the engine. Use these settings only for the

compression brakes and serial number prefixes that are specified in the table.

340D Compression Brakes

1. Loosen adjustment locknut (1) and back out the adjustment screw until the slave piston is

not in contact with the exhaust valve rocker arm.

2. Insert the appropriate feeler gauge between the foot of the slave piston (2) and the rocker

arm (3) . Refer to Table 1 for the correct slave piston lash setting.

3. Turn the adjustment screw for the slave piston in a clockwise direction until the slave

piston tightens against the feeler gauge. A slight drag should be felt on the feeler gauge.

4. Tighten the adjustment locknut (1) to a torque of 34 5 Nm (25 4 lb ft). Recheck the

adjustment after you tighten the locknut. If necessary, repeat this procedure.

340, 340A, 340B, 340C, and 340E Compression Brakes

1. Loosen adjustment locknut (1) and back out the adjustment screw until the slave piston is

not in contact with the exhaust valve rocker arm.

2. Insert the appropriate feeler gauge between the foot of the slave piston (2) and the rocker

arm (3) . Refer to Table 1 for the correct slave piston lash setting.

3. Turn the adjustment screw for the slave piston in a clockwise direction until the slave

piston tightens against the feeler gauge. Tighten the adjustment screw for one additional

turn in the clockwise direction. The valve spring should start to compress. Allow the oil to

be purged from the autolash assembly of the compression brake for 30 seconds.

Note: All of the oil must be allowed to drain from the autolash assembly of the

compression brake. If the temperature of the oil is below 16 C (60 F), allow the

oil to be purged for an additional 2 minutes. Serious engine damage may occur if

the oil is not properly purged from the autolash assembly.

4. Slowly turn the adjustment screw counterclockwise until the slave piston begins to loosen

against the feeler gauge. A slight drag should be felt on the feeler gauge when the

adjustment is correct.

Note: Do not overshoot the setting of the slave piston during adjustment. If you

overshoot the setting, this procedure must be repeated.

5. Tighten the adjustment locknut (1) to a torque of 34 5 Nm (25 4 lb ft). Recheck the

adjustment after tightening the locknut. If necessary, repeat the procedure.

Adjust the slave piston lash settings for cylinders 3 and 5 prior to rotating the engine.

After you adjust cylinders 1, 3, and 5, reset the timing pin and turn the flywheel for 360

degrees in the direction of engine rotation. This will position the No. 6 piston at the top

center on the compression stroke. Ensure that the timing pin has located the timing hole that

is in the flywheel.

Continue to perform the adjustment procedure for the slave piston lash settings on cylinders

2, 4, and 6.

Remove the timing pin from the flywheel after all adjustments have been performed.

Reinstall the timing cover.

Pacbrake Compression Brake Adjustment

Illustration 2

g00975814

Typical configuration for Pacbrake's engine compression brake

(1) Adjustment screw for the slave piston

(2) Slave piston

(3) Rocker arm

Table 2

Slave Piston Lash Setting

Pacbrake Compression Brakes

Serial Number Prefix and Model

Designation

Horsepower

Rating

Slave Piston Lash Setting

5EK1-UP

6TS1-UP

Pacbrake P-39A

410 or less

0.685 0.076 mm (0.027 0.003

inch)

435 or higher

0.762 0.076 mm (0.030 0.003

inch)

1LW1-UP

5DS1-UP

Pacbrake P-39A

All ratings

0.762 0.076 mm (0.030 0.003

inch)

2WS1-UP

1MM1-UP

Pacbrake P-39A

410 or less

1.066 0.076 mm (0.042 0.003

inch)

435 or higher

0.762 0.076 mm (0.030 0.003

inch)

6NZ1-UP

All ratings

7CZ1-UP

Pacbrake P-39A

0.762 0.076 mm (0.030 0.003

inch)

5EK1-UP

6TS1-UP

1LW1-UP

5DS1-UP

2WS1-UP

1MM1-UP

6NZ1-UP

7CZ1-UP

Pacbrake P-39B

All ratings

0.838 0.076 mm (0.033 0.003

inch)

6NZ1-UP

7CZ1-UP

Pacbrake P-39C

N/A Product Campaign

(1)

MBN1-UP

Pacbrake P-39D

All ratings

0.97 0.08 mm (0.038 0.003

inch)

BXS1-UP

Pacbrake P-39E

(1)

All ratings

0.71 0.08 mm (0.028 0.003

inch)

( 1 )

Contact Pacbrake for information that relates to the product campaign.

( 1 )

C15 Engines only

Note: The slave piston lash settings are specific to the serial number of the engine.

Ensure that the slave piston lash setting that is being used is correct for the serial

number of your engine.

P39A Compression Brakes

1. Loosen adjustment locknut (1) and back out the adjustment screw until the slave piston is

not in contact with the exhaust valve rocker arm.

2. Insert the appropriate feeler gauge between the foot of the slave piston (2) and the rocker

arm (3) . Refer to Table 2 for the correct slave piston lash settings.

3. Turn the adjustment screw for the slave piston in a clockwise direction. Tighten the

adjustment screw for the slave piston beyond the point of contact with the exhaust valve

rocker arm. This will allow the oil to be purged from the slave piston. Once the oil has

been purged from the piston, turn the adjustment screw for the slave piston in a

counterclockwise direction until the feeler gauge is loose between the adjustment screw

and the rocker arm.

4. Again, turn the adjustment screw for the slave piston in a clockwise direction until a slight

drag is felt on the feeler gauge.

5. Tighten the adjustment locknut (1) to a torque of 34 5 Nm (25 4 lb ft).

Adjust the slave piston lash settings for cylinders 3 and 5 prior to rotating the engine.

P39B, P39D, and P39E Compression Brakes

1. Loosen adjustment locknut (1) and back out the adjustment screw until the slave piston is

not in contact with the exhaust valve rocker arm.

2. Insert the appropriate feeler gauge between the foot of the slave piston (2) and the rocker

arm (3) . Refer to Table 2 for the correct slave piston lash settings.

3. Turn the adjustment screw for the slave piston in a clockwise direction until the slave

piston tightens against the feeler gauge. Tighten the adjustment screw for one additional

turn in the clockwise direction. The valve spring should start to compress. Allow the oil to

be purged from the components of the compression brake for 1 minute.

4. Slowly turn the adjustment screw counterclockwise until a slight drag is felt on the feeler

gauge.

Note: Do not overshoot the setting of the slave piston during this adjustment. If

you overshoot the setting, this procedure must be repeat.

5. While you hold the screw of the adjuster, tighten the adjustment locknut (1) to a torque of

34 5 Nm (25 4 lb ft).

Note: Do not place excessive torque on the locknut that is on the adjustment

screw. If excessive torque is placed on the adjustment screw, damage to the

components of the compression brake may result.

6. Recheck the adjustment after tightening the locknut. If a slight drag is not felt on the

feeler gauge, repeat the adjustment procedure.

Adjust the slave piston lash settings for cylinders 3 and 5 prior to rotating the engine.

After you adjust cylinders 1, 3, and 5, reset the timing pin and turn the flywheel for 360

degrees in the direction of engine rotation. This will position the No. 6 piston at the top

center on the compression stroke. Ensure that the timing pin has located the timing hole that

is in the flywheel.

Continue to perform the adjustment procedure for the slave piston lash settings on cylinders

2, 4, and 6.

Remove the timing pin from the flywheel after all adjustments have been performed.

Reinstall the timing cover.

You might also like

- Ajuste Freno de MotorDocument8 pagesAjuste Freno de MotorAlvaro Escalona GtzNo ratings yet

- Calibracion Valvulas Motor C12 CaterpillarDocument5 pagesCalibracion Valvulas Motor C12 CaterpillarRamón José Aponte Franco100% (9)

- CTC12Document2 pagesCTC12Joffre Lautaro Benavides SeminarioNo ratings yet

- n14 Cylinder Head InstallationDocument3 pagesn14 Cylinder Head InstallationOumarba KamandaNo ratings yet

- Calibración de InyectoresDocument3 pagesCalibración de InyectoresAbdel Alvarez67% (3)

- Meritor Rockwell ZF 9 Speed RMX9 145BDocument203 pagesMeritor Rockwell ZF 9 Speed RMX9 145BCarlos Chavez100% (2)

- CAT Compression Brake Lash - AdjustDocument2 pagesCAT Compression Brake Lash - Adjustbenge henrique100% (2)

- Adjust The Valves and N3 Fuel Injector Settings As Follows:: Series 60 Service ManualDocument4 pagesAdjust The Valves and N3 Fuel Injector Settings As Follows:: Series 60 Service ManualJavier Leyva Yuco100% (1)

- Procedimiento de Calibracion de Valvulas Del Motor Cummins 5.9Document1 pageProcedimiento de Calibracion de Valvulas Del Motor Cummins 5.9Edwin Gomez100% (1)

- Tabla Timing Isx CumminsDocument3 pagesTabla Timing Isx CumminsRonald Gomez100% (3)

- 790/795/797 Series: Jacobs Engine BrakeDocument20 pages790/795/797 Series: Jacobs Engine BrakeJohanny Hurtado BarreraNo ratings yet

- RTLO-18918B Manual PartsDocument40 pagesRTLO-18918B Manual PartszaidsantoyoNo ratings yet

- Relacion de Numeros de Serie para Motores Detroit Diesel.: Serie. D.D.E.C. Modelo. Potencia. P/N. TorqueDocument10 pagesRelacion de Numeros de Serie para Motores Detroit Diesel.: Serie. D.D.E.C. Modelo. Potencia. P/N. TorquePhước Hoàng100% (1)

- Caja de Super 10Document178 pagesCaja de Super 10AnGel Amaya100% (1)

- Series 60 - Section 1.11 Gear Case Cover Exhaust Gas Recirculation (EGR) ModelDocument14 pagesSeries 60 - Section 1.11 Gear Case Cover Exhaust Gas Recirculation (EGR) ModelJuan RiveraNo ratings yet

- 1868 - Cascadia Star Point, Detroit Share Point PDFDocument2 pages1868 - Cascadia Star Point, Detroit Share Point PDFMarvin Melendez VanegasNo ratings yet

- Arranque Dificil Dd15Document8 pagesArranque Dificil Dd15nicix100% (1)

- Harness 286-8224 & 290-8615 Connector TablesDocument2 pagesHarness 286-8224 & 290-8615 Connector Tablesharleypks100% (3)

- Fault Codes DD 1-50g60gts-02a PDFDocument42 pagesFault Codes DD 1-50g60gts-02a PDFAlex Robledo Olarte0% (1)

- Jacobs Brake Caterpillar C10 & C12 Installation Instructions 021222BDocument19 pagesJacobs Brake Caterpillar C10 & C12 Installation Instructions 021222Bviemey1952100% (8)

- Camshaft List DetroitDocument6 pagesCamshaft List Detroitcristian picadoNo ratings yet

- SPN 931 FMI 3 - EFP Short To PWRDocument3 pagesSPN 931 FMI 3 - EFP Short To PWRNestorAdanMerazNo ratings yet

- CPC Veh Int PDFDocument1 pageCPC Veh Int PDFHạcLãoNo ratings yet

- Fault Code 951 Cylinder Power Imbalance DetectedDocument5 pagesFault Code 951 Cylinder Power Imbalance DetectedAhmedmahNo ratings yet

- 2006 Navistar DT466 Engine Torque ValuesDocument5 pages2006 Navistar DT466 Engine Torque ValuesMeadows TruckNo ratings yet

- SPN 625/fmi 9 - Epa07Document4 pagesSPN 625/fmi 9 - Epa07Hyo Won LeeNo ratings yet

- Rtoc 16909a 0711Document36 pagesRtoc 16909a 0711Олег КоваленкоNo ratings yet

- Section 1.13 Gear Case Exhaust Gas Recirculation (EGR) ModelDocument10 pagesSection 1.13 Gear Case Exhaust Gas Recirculation (EGR) ModeldanyNo ratings yet

- Calibracion Serie 60 DetroitDocument15 pagesCalibracion Serie 60 DetroitCe Bayona100% (31)

- Eaton Fuller Rtx-14715Document43 pagesEaton Fuller Rtx-14715davidbeju100% (1)

- Ddec IiDocument1 pageDdec IiEduardo PerezNo ratings yet

- DTC Codes Maxxforce Jpro ReportsDocument3 pagesDTC Codes Maxxforce Jpro ReportsHilario Gayosso Cruz100% (3)

- Inyector n3 TorquesDocument2 pagesInyector n3 TorquesDiego MonroyNo ratings yet

- Qdoc - Tips Ddec IV Oem Wiring DiagramDocument1 pageQdoc - Tips Ddec IV Oem Wiring DiagramAlberto Rodríguez0% (1)

- E7 TiempoDocument12 pagesE7 TiempoJonatan Arango Gomez67% (3)

- MaxxForce 5 Diagnostic Trouble Codes (EGES395 - DTC)Document6 pagesMaxxForce 5 Diagnostic Trouble Codes (EGES395 - DTC)Enrrique Lara100% (1)

- Diagrama de 3406b PDFDocument2 pagesDiagrama de 3406b PDFIgnacio Cano100% (1)

- Motor CAT C13 AcertDocument3 pagesMotor CAT C13 AcertJosé Gonzalez100% (3)

- C-10, C-12, 3406E, C-15, and C-16 Electrical System On-Highway EngineDocument2 pagesC-10, C-12, 3406E, C-15, and C-16 Electrical System On-Highway Engineигорь100% (1)

- C10 Al C-16 DiagramaDocument2 pagesC10 Al C-16 DiagramaFrancisco Vidal100% (1)

- 2013 PX9 Spec Sheet 102512 1109amDocument2 pages2013 PX9 Spec Sheet 102512 1109amGerardo CarmonaNo ratings yet

- Mack MP8 Cabeza de Cilindros CambioDocument15 pagesMack MP8 Cabeza de Cilindros Cambiohamilton mirandaNo ratings yet

- Fault Code 432 Accelerator Pedal or Lever Idle Validation Circuit - Out of CalibrationDocument10 pagesFault Code 432 Accelerator Pedal or Lever Idle Validation Circuit - Out of CalibrationAhmedmahNo ratings yet

- Cummins ISX CM870 EGR Delete Kit Installation GuideDocument8 pagesCummins ISX CM870 EGR Delete Kit Installation Guidejames santiagoNo ratings yet

- 3122 ISX CM570 CM870 CM871 Static Injection Timing MeasureDocument7 pages3122 ISX CM570 CM870 CM871 Static Injection Timing Measureralph aris100% (1)

- Intake Valve Actuator Response - Test 385Document39 pagesIntake Valve Actuator Response - Test 385amateur123456100% (2)

- DD15 and DD16 Axial Power Turbine Gear Box ManualDocument7 pagesDD15 and DD16 Axial Power Turbine Gear Box ManualRaul Gerardo Delatour CarreroNo ratings yet

- Detroit - Motor Diesel - Serie 60 - ManualDocument24 pagesDetroit - Motor Diesel - Serie 60 - ManualCarlos Valencia100% (1)

- 2007-Current MaxxForce Engine Breakout Harness Reference (EGES545)Document14 pages2007-Current MaxxForce Engine Breakout Harness Reference (EGES545)Enrrique Lara100% (1)

- Ajuste de Piston Esclavo Freno MotorDocument4 pagesAjuste de Piston Esclavo Freno MotorMuriel RembertoNo ratings yet

- Procedimiento de Ajuste de Freno de Motor C-15 Engines NXS (SENR9692)Document6 pagesProcedimiento de Ajuste de Freno de Motor C-15 Engines NXS (SENR9692)Carlos U. CallirgosNo ratings yet

- Engine Valve Lash - Inspect Adjust (SENR9939-32)Document3 pagesEngine Valve Lash - Inspect Adjust (SENR9939-32)Guido Emanuel SteinbachNo ratings yet

- Engine Valve Lash - Inspect AdjustDocument3 pagesEngine Valve Lash - Inspect AdjustRay CapriNo ratings yet

- Manual Oficina c4.2 c6.4 CaterpillaDocument177 pagesManual Oficina c4.2 c6.4 CaterpillaIvo Silva88% (52)

- Bridge and Valve Adjustment ProcedureDocument10 pagesBridge and Valve Adjustment ProcedureW Morales90% (42)

- Testing and Adjusting Cat 3412 SN 3fzDocument21 pagesTesting and Adjusting Cat 3412 SN 3fzEd Calhe100% (11)

- Cat 3400 AdjustingDocument7 pagesCat 3400 AdjustingaliNo ratings yet

- Adjust Valve C9Document3 pagesAdjust Valve C9JebrodNo ratings yet

- 3116 Cat Valvuklas Calibre PDFDocument4 pages3116 Cat Valvuklas Calibre PDFsergio blandon lNo ratings yet

- Governor (Types I, II, and Some III) - AdjustDocument8 pagesGovernor (Types I, II, and Some III) - AdjustDaniel TekleNo ratings yet

- 620 640w624BLDimDocument36 pages620 640w624BLDimSal MacNo ratings yet

- How To Use A Vogel CrystalDocument5 pagesHow To Use A Vogel CrystalJorge100% (1)

- Further Notes Concerning The Palming of CardsDocument32 pagesFurther Notes Concerning The Palming of Cardsmunawar50% (2)

- LNL AP Case FeederDocument30 pagesLNL AP Case FeederMoovinTargetNo ratings yet

- Raychem TFT-350R-SGDocument29 pagesRaychem TFT-350R-SGgaraymoises2273No ratings yet

- Stability Control ReportDocument15 pagesStability Control Reportvidic971No ratings yet

- Rotation Mechanism Uses Guide Rollers.: SeriesDocument16 pagesRotation Mechanism Uses Guide Rollers.: SeriesCrrobots SimulateNo ratings yet

- Unit 5: Moments (Answers) Worksheet 2 Level 1 ObjectivesDocument6 pagesUnit 5: Moments (Answers) Worksheet 2 Level 1 ObjectivesJOE ADAIKALARAJNo ratings yet

- Lesson 3 Direction of Lines, Interior and Deflection Angles, Etc.Document8 pagesLesson 3 Direction of Lines, Interior and Deflection Angles, Etc.Prince Eduard ManucumNo ratings yet

- Specification Sheet - 802T-APDocument2 pagesSpecification Sheet - 802T-APchatur mmiNo ratings yet

- 2.2 Describing TransformationsDocument16 pages2.2 Describing Transformationstrmejfitg100% (1)

- Practice Set - 3 (25)Document6 pagesPractice Set - 3 (25)kakakakkaka0% (1)

- Manual Makita hr2510Document8 pagesManual Makita hr2510Burlacu MadalinNo ratings yet

- Kta50 Injector TimingDocument17 pagesKta50 Injector TimingSebastian Nicușor PărăoanuNo ratings yet

- GG Maint (807421) - 4Document100 pagesGG Maint (807421) - 4Fabio GhelfiNo ratings yet

- Foreign Folk Dance TerminologiesDocument23 pagesForeign Folk Dance TerminologiesMhin SarandiNo ratings yet

- Strength of MaterialsDocument5 pagesStrength of MaterialsSajid NazirNo ratings yet

- MSLR PyqDocument133 pagesMSLR Pyqartisttarunsuthar1No ratings yet

- Practice Test 1: Inductive ReasoningDocument31 pagesPractice Test 1: Inductive Reasoningflowealth100% (1)

- Math10 Q3 Module27Document26 pagesMath10 Q3 Module27Reliza SamijonNo ratings yet

- How Upper Level Heights Influence Surface WeatherDocument25 pagesHow Upper Level Heights Influence Surface WeatherNelum PereraNo ratings yet

- 4d94e17 Be2 1 PDFDocument160 pages4d94e17 Be2 1 PDFdend juandiNo ratings yet

- Reverse Dial AlignmentDocument7 pagesReverse Dial AlignmentPopescu CarmenNo ratings yet

- LIbro CompletoDocument122 pagesLIbro CompletoMaru De Las CasasNo ratings yet

- 300zx Timing BeltDocument13 pages300zx Timing BeltVen DezelNo ratings yet

- Tecumseh8to18castiron 1Document78 pagesTecumseh8to18castiron 1taxmacNo ratings yet

- Brown & Sharpe CMM move commands guideDocument9 pagesBrown & Sharpe CMM move commands guidesenthilmechsterNo ratings yet

- 2.4M Antenna 8000450-03 Rev D Type 243Document20 pages2.4M Antenna 8000450-03 Rev D Type 243Jean Wesley ThosiacNo ratings yet

- 4 Ways To Exercise Your Voice - WikiHowDocument4 pages4 Ways To Exercise Your Voice - WikiHowsunny kumarNo ratings yet

- Progress Papers in Non Verbal Reasoning Sample PaperDocument10 pagesProgress Papers in Non Verbal Reasoning Sample Paperjinkiezaragoza1997No ratings yet