Professional Documents

Culture Documents

6 Cube Barrel Blast "S": "Blasting Solutions"

Uploaded by

elias0311Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6 Cube Barrel Blast "S": "Blasting Solutions"

Uploaded by

elias0311Copyright:

Available Formats

6 Cube Barrel Blast S

FEATURES

Automatic Timer Control Machine Warranty

Air Operated Power Door Quick Cleaning Cycle

Continuous Molded Rubber Mill Belt Safety Interlocks

15 HP Direct Drive Blast Wheel Abrasive Resistant Liners

Rubber Mill Belt 800 lb. Load Capacity

Blasting Solutions

GOFF AIRLESS BLAST WHEEL

BLAST WHEEL: The direct drive blast wheel revolves

at 3600 RPM for maximum abrasive velocity. 12 diameter

wheel with 8 curved blades 3 wide is standard. Balanced

wheel components assure smooth operation.

BLADES: Cast from abrasive resistant alloy to insure

maximum life. Curved blade design provides maximum

abrasive control.

CONTROL CAGE: Dial type cage.

WHEEL HOUSING: Fabricated from 1/4 wear resis-

tant steel plate. Housing is lined with cast interlocking abra-

sive resistant liners.

CABINET CONSTRUCTION

CABINET: Pitless type, all welded structurally rein-

forced cabinet is fabricated from 3/8 steel plate and manga-

nese plate.

POWER LOCK DOOR: Electronically controlled

with fingertip action. Pneumatically operated air cylinder

provides opening/closing action of power door for full access

to blast chamber.

MILL CONSTRUCTION

RUBBER TUMBLE BELT: Continuous molded

rubber tumble belt has 4 ply construction with 5/16 abrasive

drain holes. Raised rubber tumbling ridges are molded di-

rectly to belt.

CONVEYOR ROLLERS: Heavy duty rollers have 2

diameter solid shafts and mounted to the cabinet with stan-

dard (4) bolt flange bearings.

LINERS: 28 diameter barrelheads are 5/8 abrasive re-

sistant steel with special forged retainer bolts. Tight sealing

3/8 alloy steel cabinet liners are standard.

CAPACITY: 6 cu. feet, 800 pounds nominal.

CONVEYOR SPEED: 12 feet per minute.

MILL BELT JAM PROTECTION: Damage to the

tumble belt and liners, due to internal jamming of parts, is re-

duced by an electronic jam monitor.

BARREL SIZE: 38-3/4 wide x 28 diameter.

ABRASIVE RECYCLING SYSTEM

ELEVATOR: Centrifugal discharge belt and bucket eleva-

tor is dust tight. Quick clamped removable cover permits ser-

vice and inspection. All shaft bearings are exterior mounted for

extended life. Screw adjusted take-up provide positive belt ad-

justment.

SCREENING: Primary screen in cabinet protects elevator

from large objects. A secondary screen in storage hopper pro-

vides positive blast wheel protection.

ABRASIVE REQUIRED: 400 pounds initial.

ABRASIVE CONTROL: Fully adjustable air actuated

butterfly valve provides precise flow control of abrasive. To-

tally enclosed design means maximum noise suppression.

SEPARATOR: 14 gravity lip separator has adjustable

abrasive spreader and adjustable refuse gate for maximum con-

taminate removal.

VENTILATION

DUST COLLECTOR: Optional 800 CFM dust collector

contains eight (8) cartridge elements which are cleaned auto-

matically by an air pulse unit. Requires 80 to 110 PSI of air at 2

CFM.

ELECTRICS

NEMA type 12 electrical enclosure, fusible disconnect switch,

thermal overload protection on all motors, 230/460 volt primary,

115 volt secondary control transformer, oil tight push buttons

controls. Blast cycle timer controls for abrasive flow and blast

wheel motor. Mill lockout for blast pattern test. End cycle alarm

signal and hour meter standard.

All motors TEFC, ball bearing, 230/460 volt, 3 phase.

SAFETY FEATURES

Blast wheel operational only when front power door is closed

and secure. Automatic power shutdown if internal jamming

occurs. Electric solenoid prevents cabinet door from opening

during blast cycle.

NOISE LEVEL: Approx. 85 DB.

Specifications subject to change without notice.

Goff, Inc.

12216 NS3520

PO Box 1607

Seminole, Oklahoma 74818-1607

USA

Tel 405-382-6900

Tel 800-654-4633

Fax 405-382-7013

www.goff-inc.com

goff@goff-inc.com

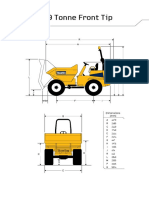

EQUIPMENT DIMENSIONS

6BB 816DC

Width 62 310

Height 123 68

Length 61 45

Weight 5600 lbs. 900 lbs.

SPECIFICATIONS6BB

Blasting Solutions

You might also like

- Velan Forged Steel Gate, Globe & ChecksDocument25 pagesVelan Forged Steel Gate, Globe & Checksmhorst1No ratings yet

- QY50K Truck Crane Technical SpecificationDocument9 pagesQY50K Truck Crane Technical Specificationkim alfonsoNo ratings yet

- Specification of GHR 1520 - 3BDDocument3 pagesSpecification of GHR 1520 - 3BDDoãn VănNo ratings yet

- Angle Seat Valve: High Cycle-Life On/Off Control ValveDocument6 pagesAngle Seat Valve: High Cycle-Life On/Off Control ValveIbhar Santos MumentheyNo ratings yet

- BL53 Industrial Gate OperatorDocument2 pagesBL53 Industrial Gate Operatorosto72No ratings yet

- Cokebuster: A Proven SolutionDocument11 pagesCokebuster: A Proven Solutionengg_mech77No ratings yet

- 318C L 318C LN: Hydraulic ExcavatorDocument24 pages318C L 318C LN: Hydraulic ExcavatorJose Antonio Temoche Ruiz100% (1)

- 623CT Sales Specification NewDocument19 pages623CT Sales Specification NewDaniel Alejandro Navarro Jara100% (1)

- Laundry DesignDocument11 pagesLaundry DesignrajevskumarNo ratings yet

- Terex Al 5: EngineDocument4 pagesTerex Al 5: EngineIBJSC.comNo ratings yet

- HITACHI - Clamshell Telescopic Arm KA-En072Document4 pagesHITACHI - Clamshell Telescopic Arm KA-En072fvmattosNo ratings yet

- Emtech MFRDocument1 pageEmtech MFRpitung82No ratings yet

- Pulsating Vacuum Sterilizer Technical SpecificationsDocument7 pagesPulsating Vacuum Sterilizer Technical SpecificationsSivaNo ratings yet

- Cool Machines CM 1500 Insulation Blowing Machine DatasheetDocument2 pagesCool Machines CM 1500 Insulation Blowing Machine Datasheetbrooklynarmstrong487No ratings yet

- 6HI Reversible Cold Rolling 1350 MM, 550 MPM: Client: PLASTOCHEM India Pvt. LTDDocument58 pages6HI Reversible Cold Rolling 1350 MM, 550 MPM: Client: PLASTOCHEM India Pvt. LTDSANTOSH TIWARINo ratings yet

- Atlas Copco Explorac 220RC - Reverse Circulation Drilling RigsDocument4 pagesAtlas Copco Explorac 220RC - Reverse Circulation Drilling Rigsவிமல் அந்தோணி100% (1)

- Kunkle OverviewDocument8 pagesKunkle Overviewsamix999No ratings yet

- Gr-300ex S G PDFDocument12 pagesGr-300ex S G PDFnorsallim syamsuddinNo ratings yet

- Aplus CompactorDocument8 pagesAplus CompactorAlex ChewNo ratings yet

- VOLVO EC290B EXCAVATOR SPECSDocument12 pagesVOLVO EC290B EXCAVATOR SPECSfilipericardodi124780% (5)

- Turbo GeneratorDocument7 pagesTurbo GeneratorSagar KhandelwalNo ratings yet

- RT870 Dimensional and Specifications ChartDocument26 pagesRT870 Dimensional and Specifications ChartFabian Andres CelyNo ratings yet

- Vio38U: Call For Yanmar SolutionsDocument8 pagesVio38U: Call For Yanmar SolutionsTomy Abad AbadNo ratings yet

- EX 2500 Especificaciones TecnicasDocument16 pagesEX 2500 Especificaciones TecnicasElvis Eberth Huanca Machaca100% (2)

- Wa 800 Catalogo Komatsu CargadorDocument12 pagesWa 800 Catalogo Komatsu CargadorElvis Eberth Huanca MachacaNo ratings yet

- VaraCorp 5 H.P. Turbine Aeration System PDFDocument2 pagesVaraCorp 5 H.P. Turbine Aeration System PDFCesarNo ratings yet

- DELFICO-GENERAL TRADING LLC RIG SPECIFICATIONSDocument31 pagesDELFICO-GENERAL TRADING LLC RIG SPECIFICATIONSAdhie Waelacxh100% (1)

- Technical Specifications For Centrifugal Pumps PDFDocument12 pagesTechnical Specifications For Centrifugal Pumps PDFVicky GautamNo ratings yet

- 40867Document6 pages40867showvik_1962No ratings yet

- D75KS Data Sheet PDFDocument14 pagesD75KS Data Sheet PDFJuan Ayala100% (1)

- The World Leader in Affordable Asphalt Plants Under 40 CharactersDocument6 pagesThe World Leader in Affordable Asphalt Plants Under 40 CharactersLenin Jhair Valderrama SeguraNo ratings yet

- Clarkson KGFDocument8 pagesClarkson KGFJorge Castro CucurellaNo ratings yet

- Flyer, Truck ShopsDocument12 pagesFlyer, Truck ShopsSteve Frank Matco ToolsNo ratings yet

- Hitachi Wire Rope HoistDocument50 pagesHitachi Wire Rope HoistVananh Nguyen100% (2)

- Technical Specification For 750hp Drilling Rig PackageDocument25 pagesTechnical Specification For 750hp Drilling Rig PackageAli mohammad100% (1)

- 50DB Rig SpecificationDocument31 pages50DB Rig Specificationmartahan manurung100% (1)

- RH Series Coiled Tubing Hangers - Wellhead Control ProductsDocument29 pagesRH Series Coiled Tubing Hangers - Wellhead Control Productsclaudio godinezNo ratings yet

- MX Series Barrier GateDocument1 pageMX Series Barrier GateferdyhernawanNo ratings yet

- Vacuum Packaging Machine: 250 Standard FeaturesDocument2 pagesVacuum Packaging Machine: 250 Standard FeaturesAliArababadiNo ratings yet

- GR-750XL-2: 75 Ton Capacity (68 Metric Tons) Hydraulic Rough Terrain CraneDocument16 pagesGR-750XL-2: 75 Ton Capacity (68 Metric Tons) Hydraulic Rough Terrain CraneJustin MorseNo ratings yet

- Komatsu PC1250-8 SpecsDocument20 pagesKomatsu PC1250-8 SpecsStephen Holley100% (3)

- Celtic Pride Manufacturing LTD CP80 MANUAL - May 5 2012Document12 pagesCeltic Pride Manufacturing LTD CP80 MANUAL - May 5 2012Jamal EldebaisNo ratings yet

- Atlas Copco TH60DH Water Well Drill SpecificationsDocument12 pagesAtlas Copco TH60DH Water Well Drill Specificationsanemoss100% (1)

- 3022 B4ce78acDocument12 pages3022 B4ce78acmmkattaNo ratings yet

- YB4408 ADocument14 pagesYB4408 Ag665013No ratings yet

- Backhoe VolvoDocument12 pagesBackhoe Volvonadinhata100% (1)

- Alldrive 9 Tonne Front Tip SpecsDocument2 pagesAlldrive 9 Tonne Front Tip SpecsQuelmis De La Cruz Vilca AmesquitaNo ratings yet

- Siemens GISDocument18 pagesSiemens GISimtiaz5100% (1)

- Alternators ISKRADocument21 pagesAlternators ISKRAhelp3rNo ratings yet

- D75KS Data SheetDocument14 pagesD75KS Data SheetGrabiela Hidalgo MedinaNo ratings yet

- 9 Tonne Front Tip Specs: MACH2090 Dimensions & CapacitiesDocument2 pages9 Tonne Front Tip Specs: MACH2090 Dimensions & CapacitiesQuelmis De La Cruz Vilca AmesquitaNo ratings yet

- P H Omega T 250 25 TonDocument9 pagesP H Omega T 250 25 TonUday Pratap0% (1)

- 4530 Spec SheetDocument2 pages4530 Spec SheetLye YpNo ratings yet

- Pitman's Motorists Library - The Book of the Austin Ten - A Fully Illustrated Instruction Book for All Owners of Models from 1932 to 1939From EverandPitman's Motorists Library - The Book of the Austin Ten - A Fully Illustrated Instruction Book for All Owners of Models from 1932 to 1939No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Manajemen Berbasis Nilai, Studi Atas Penerapan Manajemen Berbasis NilaiDocument20 pagesManajemen Berbasis Nilai, Studi Atas Penerapan Manajemen Berbasis NilaitsfNo ratings yet

- SWOT) Analysis, Marketing Process, Marketing PlanDocument24 pagesSWOT) Analysis, Marketing Process, Marketing PlanSagar Patil100% (2)

- Ahmad Ridzuan Ibrahim (CD 5103)Document24 pagesAhmad Ridzuan Ibrahim (CD 5103)Kabil RajNo ratings yet

- Alley Alka-Seltzer Lab Report TemplateDocument3 pagesAlley Alka-Seltzer Lab Report TemplateAlley FitzgeraldNo ratings yet

- Boeco Mantas de CalentamientoDocument2 pagesBoeco Mantas de CalentamientoJhon VallejoNo ratings yet

- Dome AbcsDocument1 pageDome AbcsRiddhi BhutadaNo ratings yet

- Hydraulic Excavator GuideDocument9 pagesHydraulic Excavator Guidewritetojs100% (1)

- Maharashtra State Electricity Distribution Co - LTD., O & M Division, NANDURBARDocument3 pagesMaharashtra State Electricity Distribution Co - LTD., O & M Division, NANDURBARPuru BornareNo ratings yet

- What is a Gear Motor? - An In-Depth GuideDocument15 pagesWhat is a Gear Motor? - An In-Depth GuidePuneet KumarNo ratings yet

- Schwab Product Catalogue 2015 (53 - 0112 - 14)Document100 pagesSchwab Product Catalogue 2015 (53 - 0112 - 14)andresboy123No ratings yet

- AGA3Document1 pageAGA3Alan BkNo ratings yet

- Low-cost DIY ECG Patient Simulator for under $20Document3 pagesLow-cost DIY ECG Patient Simulator for under $20cv bayariNo ratings yet

- Misuse of Ai in ArtDocument2 pagesMisuse of Ai in ArtjNo ratings yet

- Netapp Simulator - Installation Steps UbuntuDocument2 pagesNetapp Simulator - Installation Steps UbuntukodurumanojkumarNo ratings yet

- Chapter 4 Wastewater Collection and TransportationDocument8 pagesChapter 4 Wastewater Collection and Transportationmulabbi brian100% (1)

- Experiment 1 Phy 360Document14 pagesExperiment 1 Phy 360Mohd Khairul0% (2)

- Practice Exam - CXC CSEC English A Exam Paper 1 - CaribExams2Document6 pagesPractice Exam - CXC CSEC English A Exam Paper 1 - CaribExams2Sam fry0% (1)

- High-Temp, Non-Stick Ceramic Cookware CoatingDocument3 pagesHigh-Temp, Non-Stick Ceramic Cookware CoatingTomescu MarianNo ratings yet

- Preferred Electronic Data Interchange Standards (EDIS) For The Container IndustryDocument51 pagesPreferred Electronic Data Interchange Standards (EDIS) For The Container Industryjuan.vargas.calle6904No ratings yet

- Call of Duty MG08/15 LMG Weapon WikiDocument1 pageCall of Duty MG08/15 LMG Weapon WikiSelin HNo ratings yet

- Fire Safety Equipment SpecificationDocument12 pagesFire Safety Equipment SpecificationRIMEL ASMANo ratings yet

- 13.2EN Funds-Flow-Analysis Final V1-1 PDFDocument2 pages13.2EN Funds-Flow-Analysis Final V1-1 PDFvishnupriyaNo ratings yet

- Plexus 2 DocumentationDocument29 pagesPlexus 2 DocumentationHeberto MonroyNo ratings yet

- CAS PDII - Owners ManualDocument6 pagesCAS PDII - Owners ManualRoberto SalaNo ratings yet

- THE PASSION AND GLOBAL APPROACH DRIVING HONDA MOTORCYCLES TO SUCCESSDocument11 pagesTHE PASSION AND GLOBAL APPROACH DRIVING HONDA MOTORCYCLES TO SUCCESSjatinag990No ratings yet

- Spec - LA 11,22,33 KV LA R1 Sep10Document14 pagesSpec - LA 11,22,33 KV LA R1 Sep10Amarjit KulkarniNo ratings yet

- Monitoring Critical Applications at SeaDocument3 pagesMonitoring Critical Applications at SeaMohamed AliNo ratings yet

- Company Profile - QuosphereDocument5 pagesCompany Profile - QuosphereDivya Rao100% (2)

- Fiat 4061 PDFDocument6 pagesFiat 4061 PDFSamir YehyaNo ratings yet

- Sixth Sense Technology: Submitted By: Sushma Singh EC (B) 0906831087Document23 pagesSixth Sense Technology: Submitted By: Sushma Singh EC (B) 0906831087Swechha KambojNo ratings yet