Professional Documents

Culture Documents

Hot Work

Uploaded by

Siddharth0 ratings0% found this document useful (0 votes)

150 views12 pagesHot workssjs

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHot workssjs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

150 views12 pagesHot Work

Uploaded by

SiddharthHot workssjs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 12

Hot Work Permit Program

Hot Work Permit Program

Department of Environmental Health and Safety

2809 Daley Drive Ames, Iowa 50011-3660

(515) 294-5359 www.ehs.iastate.edu

Environmental Health and Safety Statement

lowa State University strives to be a model for environmental, health and safety

excellence in teaching, research, extension, and the management of its facilities.

Faculty, staff and students are responsible for establishing and promoting practices that

ensure safety, protect health and minimize the institution's impact on the environment.

As an institution of higher learning, lowa State University

fosters an understanding of and a responsibility for the environment;

encourages individuals to be knowledgeable about environmental, health

and safety issues that affect their discipline;

shares examples of superior environmental health and safety performance

with peer institutions, the State of lowa and the local community.

As a responsible steward of facilities and the environment, lowa State University

strives to provide and maintain safe working environments that minimize

the risk of injury or illness for employees, students and the public;

continuously improves operations, with the goal of meeting or exceeding

authorized and applicable environmental, health and safety regulations,

rules, policies, or voluntary standards;

employs innovative strategies of waste minimization and pollution

prevention to reduce the use of toxic substances, promote reuse, and

encourage the purchase of renewable, recyclable and recycled materials.

It is the intent of this statement to promote environmental stewardship, protect health,

and encourage safe work practices within the lowa State University community.

Dr. Gregory L. Geoffroy

President

1

Introduction

Hot work operations include tasks such as welding, brazing, torch cutting,

grinding, and torch soldering. These operations create heat, sparks and hot slag

that have the potential to ignite ammable and combustible materials in the area

surrounding hot work activities. The United States averages 12,630 hot work res,

$308.9 million in property damages and 31 deaths per year. A single hot work re

can be devastating, as seen in the hot work re pictured above. The repairs and

restoration work associated with this re resulted in the expenditure of over $5

million.

Hot work is frequently performed in Iowa State University facilities. The university

Hot Work Permit Program was developed in accordance with OSHA regulations

and NFPA recommendations with the goal of preventing hot work res. The

purpose of this booklet is to outline the requirements of the Iowa State University

Hot Work Permit Program.

Fire caused by hot work

2

Whos involved in the Hot Work Permit process?

Department Supervisors oversee the Hot Work Permit program for hot work

operations under their supervision. Supervisors are responsible for designating

employees as Permit Authorizing Individuals (PAI), who will issue Hot Work

Permits. Any employee who has successfully completed hot work safety training

may be a PAI. Hot Work Operators are allowed to be PAI, but they are not allowed

to issue their own Hot Work Permits.

A Permit Authorizing Individual

(PAI) inspects hot work sites prior to

the start of hot work operations using

the checklist found on the Hot Work

Permit Form. When a re watch is

required, the PAI will designate an

employee to serve as Fire Watch.

Once all requirements on the form

have been satised and the form

is signed by a PAI, the document

becomes a Hot Work Permit and

must be posted in the area where

hot work is to be performed.

Hot Work Operators (HWOs) are

employees who perform hot work

operations. A HWO must always

obtain a Hot Work Permit before

beginning hot work.

A Fire Watch is posted to monitor

the safety of hot work operations

and watch for res. Fire Watches are

posted by a PAI if the situation requires one, during hot work, and for at least 30

minutes after work has been completed. Any employee who has successfully

completed hot work safety training can serve as the Fire Watch. See page 6 for

information regarding when a Fire Watch is required.

A Hot Work Operator performing hot work.

3

What is the process for obtaining a Hot Work

Permit?

A Hot Work Operator determines a need for hot work.

The Hot Work Operator ensures the area around hot work activities is

in compliance with the safety requirements of the Hot Work Permit.

The Hot Work Operator contacts a Permit Authorizing Individual.

The Permit Authorizing Individual inspects the hot work site

and completes the Hot Work Permit Form.

The Permit Authorizing Individual posts a Fire Watch

if the situation requires one.

Once all permit safety guidelines are satised, the

Permit Authorizing Individual signs and posts the permit.

The Hot Work Operator can then begin hot work.

4

What safety measures are required by the Hot

Work Permit?

The 35-Foot Rule

All ammable and combustible materials within a 35-foot radius of hot work

must be removed.

When ammable and combustible materials within a 35-foot radius of hot

work cannot be removed they must be covered with ame retardant tarps

and a re watch must be posted.

Floors and surfaces within a 35-foot radius of the hot work area must be

swept free of combustible dust or debris.

All openings or cracks in the walls, oors, or ducts that are potential travel

passages for sparks, heat and ames must be covered.

Fire Detection and Suppression

A re extinguisher must be readily available and accessible.

Entire building smoke detection and alarms systems cannot be shut down.

Instead smoke detectors in the area of hot work may be covered for the

duration of hot work to prevent false alarms.

Automatic sprinkler systems may not be shut down to perform hot work.

Instead, individual sprinkler heads in the area of hot work may be covered

with a wet rag to prevent accidental activation.

Fire Watch

A Fire Watch must be posted by a PAI if the following conditions exist:

combustible materials cannot be removed from within a 35-foot radius of

the hot work

wall or oor openings within a 35-foot radius of hot work expose combustible

materials in adjacent areas, including concealed spaces in walls or oors

combustible materials are adjacent to the opposite side of partitions, walls,

ceilings or roofs and are likely to be ignited

5

General Guidelines

Work should be performed using alternative methods other than hot work

whenever possible.

Hot work should be performed in designated hot work rooms whenever it is

practical.

A Hot Work Permit is valid for one day and one area and should be posted

in the area of hot work for the duration of the activity.

A copy of every permit shall be led by the PAI in a location designated by

their supervisor and kept for a period of at least 6 months.

Hot work performed next to a re extinguisher

6

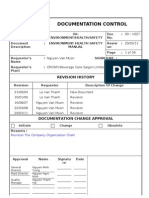

A Sample Hot Work Permit

Date:

Permit Checklist

___ Flammable and combustible materi-

als within a 35-foot radius of hot work

have been removed or covered with

re retardant tarps or metal shields.

___ All oors and surfaces within a 35-

foot radius of the hot work area have

been swept free of combustible dust

or debris.

___ Any openings or cracks in the walls,

oors, or ducts that are potential

travel passages for sparks, heat and

ames have been covered.

___ An operable re extinguisher is near-

by and accessible.

___ Sprinkler heads that could be activat-

ed by hot work have been covered

with a wet rag.

___ Smoke detectors in the area of hot

work have been covered to prevent

false alarms.

___ A Fire Watch has been posted, if it is

required, during hot work operations

anf for 30 minutes after work has

been completed.

Building:

Location:

Description of hot work:

Name of Hot Work Operator:

Is a Fire Watch required?

_____Yes

_____No

A Fire Watch should be posted if

combustible materials within a 35-foot

radius of hot work cannot be removed

wall or oor openings within a 35-foot

radius of hot work expose combustible

materials in adjacent areas, including

concealed spaces in walls or oors

combustible materials are adjacent to

the opposite side of partitions, walls,

ceilings or roofs and are likely to be ig-

nited

it is deemed necessary by the Permit

Authorizing Individual

AUTHORIZATION: The information on this permit has been evaluated, the site

has been examined and all safety measures are in place.

Signed: ___________________________________________________

Permit Authorizing Individual

7

Is a Hot Work Permit always required?

Designated Hot Work Rooms

A designated hot work room is a

permanent location designed for hot

work. These rooms do not require a

permit to perform hot work. For a room

to be classied as a designated hot

work room, it must meet the following

requirements:

It must be of noncombustible re-

resistive construction, essentially

free of combustible and ammable

contents.

It must be suitably segregated from adjacent areas.

It must be equipped with re extinguishers.

It must be inspected and approved by EH&S.

Operations Not Requiring a Hot Work Permit

Operations that produce a ame,

sparks, hot slag or enough heat to

ignite combustible materials should

be considered hot work with a few

exceptions. The following operations do

not require a Hot Work Permit:

bunsen burners in laboratories

xed grinding wheels

electric soldering irons

If you are unsure if an operation is

considered hot work, please contact

Brian Corley at 294-8610 or Troy Carey

at 294-9495.

Designated hot work room

A worker using a xed grinding wheel

8

Are there any situations when hot work is not

allowed?

Non-permissible Hot Work Situations

Hot work is not permitted when the following conditions exist:

In sprinklered buildings where the entire sprinkler system is impaired.

When an entire building re detection system is shut down.

In the presence of explosive atmospheres, where mixtures of ammable

gases, vapors, liquids or dusts may exist.

In tanks, drums or other containers and equipment that contain or previously

contained materials that could create explosive atmospheres.

Hot work equipment

9

What hot work safety training is required?

EH&S Training

Individuals involved in hot work are required to complete hot work training including

Supervisors, Permit Authorizing Individuals, Hot Work Operators and Fire Watch

personnel. The following EH&S courses must be completed:

Hot Work Permit Training Required upon initial assignment and refresher

training required every 5 years.

Fire Extinguisher Training Required once a year. The hands-on classroom

training must be completed for the initial class. The online re extinguisher

training course may be completed for the yearly refresher requirement.

Departmental Training

Managers shall train employees on departmental Hot Work Permit procedures and

specic safety procedures for the type of hot work equipment used. This training

shall be completed upon initial assignment and cover the following subjects:

Safety procedures specic to the equipment used

Required personal protective equipment for job tasks

Identication of Permit Authorizing Individuals and how they can be

contacted

Where to le copies of completed Hot Work Permits

Locations of designated hot work rooms where a Hot Work Permit is not

required

10

Are there hot work requirements for contractors?

Outside contractors working on the Iowa State University

campus are required to have hot work safety procedures as a

part of their project safety programs. Contractors working on

capital projects at Iowa State University are required to follow

the hot work guidelines outlined in project specications.

Do you have hot work related questions?

If you have any questions regarding hot work or would like

more information call Brian Corley at 294-8610 or Troy Carey

at 294-9495.

Hot Work Fire Facts

The top ten materials rst ignited by welding torches in non-residential

structure res:

1. Thermal or acoustical insulation (11%)

2. Unclassied form of material (9.8%)

3. Structural member or framing (9.6%)

4. Rubbish, trash or waste (6.7%)

5. Dust, ber or lint (6.6%)

6. Exterior roof covering or nish (5.8%)

7. Accelerant or other gas or liquid in or from pipe or container (4.0%)

8. Fuel (3.9%)

9. Interior wall covering (3.9%)

10. Box, carton or bag (3.7%)

The top ten areas of re origin for non-residential welding torch structure res:

1. Maintenance shop or area (11.9%)

2. Process or manufacturing area (8.8%)

3. Attic, ceiling/roof assembly or concealed space (6.5%)

4. Wall assembly or concealed space (6.5%)

5. Garage (6.5%)

6. Machinery room or area (5.6%)

7. Product storage area, tank or bin (4.9%)

8. Exterior roof surface (4.6%)

9. Exterior wall surface (3.6%)

10. Duct (3.0%)

A contractor performing hot work

You might also like

- Hot Works SafetyDocument33 pagesHot Works Safetypammu18No ratings yet

- WB 2731 - HotWorkProgram 2Document12 pagesWB 2731 - HotWorkProgram 2pikas100% (1)

- Hot Work Permit ProgramDocument3 pagesHot Work Permit ProgramCara CarlsonNo ratings yet

- Hot Work: Presented By: Rizwan AkramDocument22 pagesHot Work: Presented By: Rizwan AkramRizwan AkramNo ratings yet

- Hot Work Permit Presentation SummaryDocument26 pagesHot Work Permit Presentation SummaryKushan MondalNo ratings yet

- Hot Work Permit ProgramDocument24 pagesHot Work Permit ProgramJorge Cronwell Montaño VásquezNo ratings yet

- Working at Heights - Training PowerpointDocument89 pagesWorking at Heights - Training PowerpointZubair KhawarNo ratings yet

- Hot WorkDocument18 pagesHot WorkHafizah Mohd100% (1)

- Ladder SafetyDocument27 pagesLadder SafetyKama Efendiyeva100% (1)

- Tower Climbing ProcedureDocument33 pagesTower Climbing ProcedurePyara Kamboj50% (2)

- Safe Use of Ladders: Personnel DivisionDocument6 pagesSafe Use of Ladders: Personnel DivisionKheireddine AounallahNo ratings yet

- Hot Work Quiz for EmployeesDocument1 pageHot Work Quiz for EmployeesAmeenudeenNo ratings yet

- BUILDING SERVICES-III FIRE & LIFE SAFETYDocument10 pagesBUILDING SERVICES-III FIRE & LIFE SAFETYNitesh Bhardwaj100% (1)

- Fire ProtectionDocument42 pagesFire Protectionsodalime01No ratings yet

- Aerial Lifts FactsheetDocument2 pagesAerial Lifts Factsheetomar santosNo ratings yet

- Crane Safety Program EssentialsDocument11 pagesCrane Safety Program Essentialssekhargm100% (1)

- Welding PPE GuideDocument9 pagesWelding PPE Guidecyrelle rose jumentoNo ratings yet

- Work at Height Safety EssentialsDocument58 pagesWork at Height Safety EssentialsArdita S IrwanNo ratings yet

- NFPA 101 Life Safety Code Compliance R1sDocument2 pagesNFPA 101 Life Safety Code Compliance R1ssimonsecurityNo ratings yet

- List of Hazards Control MeasuresDocument29 pagesList of Hazards Control Measuresテレブリコ ジェファーソン0% (1)

- Hand and Power Tool SafetyDocument50 pagesHand and Power Tool SafetyAntonio Jose De JesusNo ratings yet

- Module 8 - Tools and Equipment Safety With FireDocument66 pagesModule 8 - Tools and Equipment Safety With FireDaneNo ratings yet

- Construction Safety - Working at Height and Fall Protection Safety (GSG) For PDFDocument79 pagesConstruction Safety - Working at Height and Fall Protection Safety (GSG) For PDFSuresh Gopal100% (1)

- Scaffold SafetyDocument33 pagesScaffold SafetyB3rnard Ma1na100% (1)

- Lift Truck TrainingDocument7 pagesLift Truck TrainingScott Carrison100% (1)

- Sheet: Reducing Falls in Construction: Safe Use of StepladdersDocument2 pagesSheet: Reducing Falls in Construction: Safe Use of StepladdersjefhdezNo ratings yet

- Fire Extinguisher Training Manual v2 1Document12 pagesFire Extinguisher Training Manual v2 1ch_yep100% (1)

- Gas Welding and Cutting Safety PDFDocument55 pagesGas Welding and Cutting Safety PDFGnanasekaran MNo ratings yet

- Walking and Working SurfacesDocument21 pagesWalking and Working Surfacesahmed naveed100% (1)

- Caught-In and Caught-Between HazardsDocument2 pagesCaught-In and Caught-Between HazardsJuan Carlos PlasenciaNo ratings yet

- Working at Height SafetyDocument71 pagesWorking at Height SafetyAtma Prakash SinhaNo ratings yet

- Ladder SafetyDocument10 pagesLadder SafetysachinoakNo ratings yet

- Lockout TagoutDocument20 pagesLockout Tagoutjoenediath9345No ratings yet

- Fall Protection PlanDocument11 pagesFall Protection PlangrantNo ratings yet

- Fire Extinguishers Safety TopicDocument2 pagesFire Extinguishers Safety TopicMarc Vincent Ferrer Cloza100% (1)

- Confined Space Entry Training CourseDocument32 pagesConfined Space Entry Training CourseKhizar Hayat100% (2)

- Extended Service LiferaftsDocument4 pagesExtended Service LiferaftsCrystal FishNo ratings yet

- For Module 3 - Lesson 2Document33 pagesFor Module 3 - Lesson 2Jin Gumahin BanhaoNo ratings yet

- Safety, Health and Environment Manual and ProceduresDocument20 pagesSafety, Health and Environment Manual and ProceduresYan's Senora BescoroNo ratings yet

- Scaffolding SafetyDocument20 pagesScaffolding SafetyKate Ann Baja IINo ratings yet

- Working at Heights Training ManualDocument10 pagesWorking at Heights Training ManualClyde K. LesoleNo ratings yet

- Guidance For Rigging in UK VenuesDocument31 pagesGuidance For Rigging in UK VenuesbulllehNo ratings yet

- AerialLiftSafty PDFDocument9 pagesAerialLiftSafty PDFmaomontesNo ratings yet

- Generic Risk Assessmentsfor EventsDocument5 pagesGeneric Risk Assessmentsfor EventslisaconnollyNo ratings yet

- Chapter 1a - OSHA Electricity SafetyDocument60 pagesChapter 1a - OSHA Electricity SafetyGopinath SubramaniNo ratings yet

- Safety Everyday Safety Pep - Talk: Wrigley BangaloreDocument34 pagesSafety Everyday Safety Pep - Talk: Wrigley Bangaloreramkumardotg_5807772No ratings yet

- Business Procedure: Welding SafetyDocument10 pagesBusiness Procedure: Welding Safetylucky414No ratings yet

- Heavy Equipment SafetyDocument19 pagesHeavy Equipment SafetyQhsef Karmaveer Jyoteendra Vaishnav100% (1)

- Fire Safety Training Tata Power 19-09-2016Document26 pagesFire Safety Training Tata Power 19-09-2016Praful E. PawarNo ratings yet

- Fall-Protection Guide: Department of The NavyDocument157 pagesFall-Protection Guide: Department of The Navyspiderlance100% (2)

- While You're Here: P Lease Turn-Off Your Cell Phone, or Place On Mute / VibrateDocument50 pagesWhile You're Here: P Lease Turn-Off Your Cell Phone, or Place On Mute / VibrateFabogadie Scaffolding100% (2)

- Essence of Good HousekeepingDocument26 pagesEssence of Good HousekeepingPritta VioletaNo ratings yet

- EHSS Risk Management System - DraftDocument17 pagesEHSS Risk Management System - DraftMd Rafat ArefinNo ratings yet

- 042 Osha Stairways LaddersDocument45 pages042 Osha Stairways LaddersgonzaloaqpNo ratings yet

- Fall Protection ChecklistDocument2 pagesFall Protection ChecklistKevin Yudhistira PribadiNo ratings yet

- HSE Professionals - Lifting SafetyDocument15 pagesHSE Professionals - Lifting Safetychinne046No ratings yet

- Overhead Crane SafetyDocument42 pagesOverhead Crane SafetyRizky Ananda PutriNo ratings yet

- The Real Product Safety Guide: Reducing the Risk of Product Safety Alerts and RecallsFrom EverandThe Real Product Safety Guide: Reducing the Risk of Product Safety Alerts and RecallsNo ratings yet

- Flight DetailsDocument2 pagesFlight DetailsSiddharthNo ratings yet

- ABDN P G Prospectus 2016 OnlineDocument57 pagesABDN P G Prospectus 2016 OnlineSiddharthNo ratings yet

- Untitled 1Document1 pageUntitled 1SiddharthNo ratings yet

- HEATEXDocument34 pagesHEATEXSiddharthNo ratings yet

- Indg 214Document6 pagesIndg 214Columbia GomezNo ratings yet

- Heat TransferDocument0 pagesHeat TransferfarshidianNo ratings yet

- Siod AssignmentDocument5 pagesSiod AssignmentSiddharthNo ratings yet

- Maurice Nicoll The Mark PDFDocument4 pagesMaurice Nicoll The Mark PDFErwin KroonNo ratings yet

- Condition Monitoring of Transformers SAILDocument17 pagesCondition Monitoring of Transformers SAILavadiraja100% (1)

- GC3 - Exam TemplateDocument10 pagesGC3 - Exam TemplateSiddharthNo ratings yet

- Rope Rescue ManualDocument43 pagesRope Rescue ManualTheDoctorFeelGood100% (7)

- The Factories Act, 1948 INDIADocument71 pagesThe Factories Act, 1948 INDIAArun KumarNo ratings yet

- SIOD Assignment Roll No 43Document10 pagesSIOD Assignment Roll No 43SiddharthNo ratings yet

- Leading Health Safety Work: and atDocument12 pagesLeading Health Safety Work: and atfordleeNo ratings yet

- Faults/Defects in Mechanical Workshop: Presented By: 39,40,42,43,44Document15 pagesFaults/Defects in Mechanical Workshop: Presented By: 39,40,42,43,44SiddharthNo ratings yet

- Commissioning Process Plant ProceduresDocument4 pagesCommissioning Process Plant ProceduresSiddharth0% (1)

- AcDocument20 pagesAcSiddharthNo ratings yet

- Assignment 1Document40 pagesAssignment 1SiddharthNo ratings yet

- AcDocument20 pagesAcSiddharthNo ratings yet

- QuestionnaireDocument4 pagesQuestionnaireSiddharthNo ratings yet

- Hot Work PermitDocument2 pagesHot Work PermitSiddharthNo ratings yet

- Permit To Work FormDocument1 pagePermit To Work FormSiddharthNo ratings yet

- NEBOSH IGC3 Practical Application Risk AssessmentDocument12 pagesNEBOSH IGC3 Practical Application Risk Assessmentnaidu952282% (55)

- Newreprt 120903072614 Phpapp02Document55 pagesNewreprt 120903072614 Phpapp02saruNo ratings yet

- Legendbr PDFDocument1 pageLegendbr PDFviswamanojNo ratings yet

- Dissertation FormatDocument1 pageDissertation FormatSiddharthNo ratings yet

- MR - Chozhapandi.G, 13/15A, Sixth Street, Sengunthapuram (Po), Jayankondam (Via), Udayar Palayam (TK), Ariyalur. Pin: 621802Document3 pagesMR - Chozhapandi.G, 13/15A, Sixth Street, Sengunthapuram (Po), Jayankondam (Via), Udayar Palayam (TK), Ariyalur. Pin: 621802SiddharthNo ratings yet

- Conversion Factors for Units of Pressure ChartDocument2 pagesConversion Factors for Units of Pressure Chart@nshu_theachieverNo ratings yet

- The Role of Safety OfficerDocument10 pagesThe Role of Safety OfficerSiddharth100% (1)

- Lsp401 Writing OutlineDocument2 pagesLsp401 Writing OutlineasfarinaNo ratings yet

- Six-Week Walk ChallengeDocument4 pagesSix-Week Walk ChallengeHazelNo ratings yet

- School Form 8 SF8 Grade 6 2022-2023Document3 pagesSchool Form 8 SF8 Grade 6 2022-2023DORINA RODRIGUEZNo ratings yet

- Ayoola Oluwaseun Bosede - ESHAN PaperDocument45 pagesAyoola Oluwaseun Bosede - ESHAN PaperAyoola Seun-GoldNo ratings yet

- HEALTH 9 1 First QuarterDocument13 pagesHEALTH 9 1 First QuarterJal keth AbuevaNo ratings yet

- Effects of Banning Cigarette Production and SaleDocument3 pagesEffects of Banning Cigarette Production and SaleOmer OzdenNo ratings yet

- Effects of Smoking On Family LifeDocument3 pagesEffects of Smoking On Family LifeDeepNo ratings yet

- AIRTH AC Air Purifier - KitDocument10 pagesAIRTH AC Air Purifier - KitAirth SupportNo ratings yet

- Air Pollution in North CyprusDocument6 pagesAir Pollution in North CypruslebronvskobeNo ratings yet

- Cancer Risk AssessmentDocument18 pagesCancer Risk AssessmentBIJAY GAUTAMNo ratings yet

- Teori 7 Pilar Dasar IKMDocument41 pagesTeori 7 Pilar Dasar IKMIntan Putri Wirahana ShantyNo ratings yet

- UNIT II Written Work 3Document2 pagesUNIT II Written Work 3ItzKenMC INo ratings yet

- Environmental Quality Report 2017 PDFDocument154 pagesEnvironmental Quality Report 2017 PDFJoyce Wm WongNo ratings yet

- Plume AQI: An Air Quality Index Aligned With Health RecommendationsDocument11 pagesPlume AQI: An Air Quality Index Aligned With Health Recommendationsmothman22No ratings yet

- AQI Bulletin 20201126Document10 pagesAQI Bulletin 20201126Kartik PrabhakarNo ratings yet

- AraDocument55 pagesAramourad arroujNo ratings yet

- Intermediate Reading Comprehension Test 01Document4 pagesIntermediate Reading Comprehension Test 01khanNo ratings yet

- Soal Ukk Bahasa Inggris Kelas 10Document8 pagesSoal Ukk Bahasa Inggris Kelas 10Ridwan TaufikNo ratings yet

- 00-V027 Environment Heath Safety Manual - English Procedure Rev290311Document21 pages00-V027 Environment Heath Safety Manual - English Procedure Rev290311Tuong NguyenNo ratings yet

- Nutritional Status SF8 by Teacher TechDocument8 pagesNutritional Status SF8 by Teacher TechJONATHAN GARGANERANo ratings yet

- Task 3 - CSS - NG Kok Hong - 2021212310034Document13 pagesTask 3 - CSS - NG Kok Hong - 2021212310034PISMPTESLB0622 Ng Kok HongNo ratings yet

- Electronic Cigarettes-Users Profile, Utilization, Satisfaction and Perceived EfficiacyDocument12 pagesElectronic Cigarettes-Users Profile, Utilization, Satisfaction and Perceived Efficiacyanalog_100% (1)

- JHSPH Prospectus 11 12Document80 pagesJHSPH Prospectus 11 12franz_sitepuNo ratings yet

- AJMedP-3-1 SRD EDA V1 E 2547 PDFDocument84 pagesAJMedP-3-1 SRD EDA V1 E 2547 PDFSergNo ratings yet

- Flaws of Ra 8749Document1 pageFlaws of Ra 8749Arturo Ramos AlvezoNo ratings yet

- Environmental Modeling and Health Risk AnalysisESTEDocument478 pagesEnvironmental Modeling and Health Risk AnalysisESTESantiago Cardona GalloNo ratings yet

- Environmental HealthDocument2 pagesEnvironmental Healthjosang11No ratings yet

- Project ReportDocument16 pagesProject Reportshaqib71% (7)

- Week 2 PPT HEALTH 9Document27 pagesWeek 2 PPT HEALTH 9REYES, MARK VINCENT M.No ratings yet

- APLIKASI MODEL PENYEBARAN POLUTAN UDARADocument12 pagesAPLIKASI MODEL PENYEBARAN POLUTAN UDARANurul MuhibbahNo ratings yet