Professional Documents

Culture Documents

RET670 Technical Reference Manual

Uploaded by

Arijit MajumdarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RET670 Technical Reference Manual

Uploaded by

Arijit MajumdarCopyright:

Available Formats

Copyright 2006 ABB. All rights reserved.

Technical reference manual

Transformer protection IED

RET670

About this manual

Document No: 1MRK 504 048-UEN

Issued: J anuary 2006

Revision: A

COPYRIGHT

WE RESERVE ALL RIGHTS TO THIS DOCUMENT, EVEN IN THE EVENT THAT A PATENT IS

ISSUED AND A DIFFERENT COMMERCIAL PROPRIETARY RIGHT IS REGISTERED. IMPROPER

USE, IN PARTICULAR REPRODUCTION AND DISSEMINATION TO THIRD PARTIES, IS NOT

PERMITTED.

THIS DOCUMENT HAS BEEN CAREFULLY CHECKED. HOWEVER, IN CASE ANY ERRORS ARE

DETECTED, THE READER IS KINDLY REQUESTED TO NOTIFY THE MANUFACTURER AT THE

ADDRESS BELOW.

THE DATA CONTAINED IN THIS MANUAL IS INTENDED SOLELY FOR THE CONCEPT OR

PRODUCT DESCRIPTION AND IS NOT TO BE DEEMED TO BE A STATEMENT OF GUARAN-

TEED PROPERTIES. IN THE INTERESTS OF OUR CUSTOMERS, WE CONSTANTLY SEEK TO

ENSURE THAT OUR PRODUCTS ARE DEVELOPED TO THE LATEST TECHNOLOGICAL STAN-

DARDS. AS A RESULT, IT IS POSSIBLE THAT THERE MAY BE SOME DIFFERENCES BETWEEN

THE HW/SW PRODUCT AND THIS INFORMATION PRODUCT.

Manufacturer:

ABB Power Technologies AB

Substation Automation Products

SE-721 59 Vsters

Sweden

Telephone: +46 (0) 21 34 20 00

Facsimile: +46 (0) 21 14 69 18

www.abb.com/substationautomation

Contents

Page Chapter

Chapter 1 Introduction ..................................................................... 1

Introduction to the technical reference manual.................................... 2

About the complete set of manuals for an IED............................... 2

About the technical reference manual ............................................ 2

Design of the Technical reference manual (TRM).......................... 3

Intended audience.......................................................................... 8

Related documents......................................................................... 9

Revision notes.............................................................................. 10

Chapter 2 Local human-machine interface .................................. 11

Human machine interface.................................................................. 12

Small size graphic HMI ...................................................................... 14

Introduction................................................................................... 14

Design .......................................................................................... 14

Medium size graphic HMI .................................................................. 16

Introduction................................................................................... 16

Design .......................................................................................... 16

Keypad............................................................................................... 18

LED.................................................................................................... 20

Introduction................................................................................... 20

Status indication LEDs ................................................................. 20

Indication LEDs ............................................................................ 20

LHMI related functions....................................................................... 22

Introduction................................................................................... 22

General setting parameters.......................................................... 22

Status indication LEDs ................................................................. 22

Design..................................................................................... 22

Function block......................................................................... 23

Input and output signals .......................................................... 23

Indication LEDs ............................................................................ 23

Introduction.............................................................................. 23

Design..................................................................................... 23

Function block......................................................................... 31

Input and output signals .......................................................... 31

Setting parameters .................................................................. 32

Chapter 3 Basic IED functions ...................................................... 35

Analog inputs..................................................................................... 36

Introduction................................................................................... 36

Principle of operation.................................................................... 36

Function block .............................................................................. 37

Output signals............................................................................... 39

Contents

Setting parameters ....................................................................... 41

Self supervision with internal event list.............................................. 48

Introduction................................................................................... 48

Principle of operation.................................................................... 48

Function block............................................................................... 53

Output signals............................................................................... 53

Setting parameters ....................................................................... 53

Technical data .............................................................................. 53

Time synchronization......................................................................... 54

Introduction................................................................................... 54

Principle of operation.................................................................... 54

Function block............................................................................... 58

Output signals............................................................................... 58

Setting parameters ....................................................................... 58

Technical data .............................................................................. 61

Parameter setting groups .................................................................. 62

Introduction................................................................................... 62

Principle of operation.................................................................... 62

Function block............................................................................... 63

Input and output signals................................................................ 64

Setting parameters ....................................................................... 64

Test mode functionality...................................................................... 66

Introduction................................................................................... 66

Principle of operation.................................................................... 66

Function block............................................................................... 67

Input and output signals................................................................ 68

Setting parameters ....................................................................... 68

IED identifiers .................................................................................... 69

Introduction................................................................................... 69

Setting parameters ....................................................................... 69

Signal matrix for binary inputs (SMBI) ............................................... 70

Introduction................................................................................... 70

Principle of operation.................................................................... 70

Function block............................................................................... 70

Input and output signals................................................................ 70

Signal matrix for binary outputs (SMBO) ........................................... 72

Introduction................................................................................... 72

Principle of operation.................................................................... 72

Function block............................................................................... 72

Input and output signals................................................................ 72

Signal matrix for mA inputs (SMMI) ................................................... 74

Introduction................................................................................... 74

Principle of operation.................................................................... 74

Function block............................................................................... 74

Input and output signals................................................................ 74

Signal matrix for analog inputs (SMAI) .............................................. 76

Introduction................................................................................... 76

Principle of operation.................................................................... 76

Function block............................................................................... 76

Input and output signals................................................................ 77

Setting parameters ....................................................................... 79

Summation block 3 phase (SUM3Ph)................................................ 81

Introduction................................................................................... 81

Contents

Principle of operation.................................................................... 81

Function block .............................................................................. 81

Input and output signals ............................................................... 81

Setting parameters ....................................................................... 82

Chapter 4 Differential protection................................................... 83

Transformer differential protection (PDIF, 87T)................................. 84

Introduction................................................................................... 84

Principle of operation.................................................................... 86

Function block ............................................................................ 109

Input and output signals ............................................................. 110

Setting parameters ..................................................................... 114

Technical data............................................................................ 119

Restricted earth fault protection (PDIF, 87N)................................... 120

Introduction................................................................................. 120

Principle of operation.................................................................. 120

Function block ............................................................................ 128

Input and output signals ............................................................. 128

Setting parameters ..................................................................... 129

Technical data............................................................................ 129

High impedance differential protection (PDIF, 87)........................... 130

Introduction................................................................................. 130

Principle of operation.................................................................. 130

Function block ............................................................................ 131

Input and output signals ............................................................. 131

Setting parameters ..................................................................... 132

Technical data............................................................................ 132

Chapter 5 Distance protection..................................................... 133

Distance protection zones (PDIS, 21).............................................. 134

Introduction................................................................................. 134

Principle of operation.................................................................. 134

Function block ............................................................................ 147

Input and output signals ............................................................. 148

Setting parameters ..................................................................... 149

Technical data............................................................................ 150

Phase selection with load encroachment (PDIS, 21)....................... 152

Introduction................................................................................. 152

Principle of operation.................................................................. 152

Function block ............................................................................ 166

Input and output signals ............................................................. 166

Setting parameters ..................................................................... 167

Technical data............................................................................ 168

Power swing detection (RPSB, 78).................................................. 169

Introduction................................................................................. 169

Principle of operation.................................................................. 169

Function block ............................................................................ 175

Input and output signals ............................................................. 175

Contents

Setting parameters ..................................................................... 176

Technical data ............................................................................ 177

Automatic switch onto fault logic (PSOF)......................................... 178

Introduction................................................................................. 178

Principle of operation.................................................................. 178

Function block............................................................................. 180

Input and output signals.............................................................. 180

Setting parameters ..................................................................... 180

Technical data ............................................................................ 181

Chapter 6 Current protection....................................................... 183

Instantaneous phase overcurrent protection (PIOC, 50) ................. 184

Introduction................................................................................. 184

Principle of operation.................................................................. 184

Function block............................................................................. 184

Input and output signals.............................................................. 185

Setting parameters ..................................................................... 185

Technical data ............................................................................ 185

Four step phase overcurrent protection (POCM, 51/67).................. 187

Introduction................................................................................. 187

Principle of operation.................................................................. 187

Function block............................................................................. 191

Input and output signals.............................................................. 192

Setting parameters ..................................................................... 193

Technical data ............................................................................ 199

Instantaneous residual overcurrent protection (PIOC, 50N)............ 201

Introduction................................................................................. 201

Principle of operation.................................................................. 201

Function block............................................................................. 202

Input and output signals.............................................................. 202

Setting parameters ..................................................................... 202

Technical data ............................................................................ 203

Four step residual overcurrent protection (PEFM, 51N/67N)........... 204

Introduction................................................................................. 204

Principle of operation.................................................................. 204

Function block............................................................................. 207

Input and output signals.............................................................. 208

Setting parameters ..................................................................... 209

Technical data ............................................................................ 215

Thermal overload protection, two time constants (PTTR, 49).......... 217

Introduction................................................................................. 217

Principle of operation.................................................................. 217

Function block............................................................................. 221

Input and output signals.............................................................. 221

Setting parameters ..................................................................... 222

Technical data ............................................................................ 223

Breaker failure protection (RBRF, 50BF)......................................... 224

Introduction................................................................................. 224

Principle of operation.................................................................. 224

Function block............................................................................. 227

Contents

Input and output signals ............................................................. 227

Setting parameters ..................................................................... 228

Technical data............................................................................ 229

Pole discordance protection (RPLD, 52PD) .................................... 230

Introduction................................................................................. 230

Principle of operation.................................................................. 230

Function block ............................................................................ 233

Input and output signals ............................................................. 234

Setting parameters ..................................................................... 234

Technical data............................................................................ 235

Chapter 7 Voltage protection....................................................... 237

Two step undervoltage protection (PUVM, 27)................................ 238

Introduction................................................................................. 238

Principle of operation.................................................................. 238

Function block ............................................................................ 247

Input and output signals ............................................................. 247

Setting parameters ..................................................................... 248

Technical data............................................................................ 251

Two step overvoltage protection (POVM, 59).................................. 252

Introduction................................................................................. 252

Principle of operation.................................................................. 252

Function block ............................................................................ 260

Input and output signals ............................................................. 260

Setting parameters ..................................................................... 261

Technical data............................................................................ 263

Two step residual overvoltage protection (POVM, 59N).................. 264

Introduction................................................................................. 264

Principle of operation.................................................................. 264

Function block ............................................................................ 270

Input and output signals ............................................................. 270

Setting parameters ..................................................................... 271

Technical data............................................................................ 273

Overexcitation protection (PVPH, 24).............................................. 274

Introduction................................................................................. 274

Principle of operation.................................................................. 274

Function block ............................................................................ 282

Input and output signals ............................................................. 283

Setting parameters ..................................................................... 283

Technical data............................................................................ 285

Chapter 8 Frequency protection ................................................. 287

Underfrequency protection (PTUF, 81)............................................ 288

Introduction................................................................................. 288

Principle of operation.................................................................. 288

Function block ............................................................................ 294

Input and output signals ............................................................. 295

Setting parameters ..................................................................... 295

Contents

Technical data ............................................................................ 296

Overfrequency protection (PTOF, 81).............................................. 297

Introduction................................................................................. 297

Principle of operation.................................................................. 297

Function block............................................................................. 302

Input and output signals.............................................................. 302

Setting parameters ..................................................................... 302

Technical data ............................................................................ 303

Rate-of-change frequency protection (PFRC, 81) ........................... 304

Introduction................................................................................. 304

Principle of operation.................................................................. 304

Function block............................................................................. 311

Input and output signals.............................................................. 311

Setting parameters ..................................................................... 312

Technical data ............................................................................ 312

Chapter 9 Multipurpose protection ............................................. 313

General current and voltage protection (GAPC).............................. 314

Introduction................................................................................. 314

Principle of operation.................................................................. 314

Function block............................................................................. 328

Input and output signals.............................................................. 329

Setting parameters ..................................................................... 331

Technical data ............................................................................ 340

Chapter 10 Secondary system supervision.................................. 343

Current circuit supervision (RDIF).................................................... 344

Introduction................................................................................. 344

Principle of operation.................................................................. 344

Function block............................................................................. 346

Input and output signals.............................................................. 346

Setting parameters ..................................................................... 347

Technical data ............................................................................ 347

Fuse failure supervision (RFUF)...................................................... 348

Introduction................................................................................. 348

Principle of operation.................................................................. 348

Function block............................................................................. 355

Input and output signals.............................................................. 355

Setting parameters ..................................................................... 356

Technical data ............................................................................ 357

Chapter 11 Control .......................................................................... 359

Synchrocheck and energizing check (RSYN, 25)............................ 360

Introduction................................................................................. 360

Principle of operation.................................................................. 360

Contents

Basic functionality.................................................................. 360

Logic diagrams ...................................................................... 360

Function block ............................................................................ 368

Input and output signals ............................................................. 369

Setting parameters ..................................................................... 371

Technical data............................................................................ 373

Apparatus control (APC).................................................................. 375

Introduction................................................................................. 375

Principle of operation.................................................................. 375

Bay control (QCBAY).................................................................. 376

Introduction............................................................................ 376

Principle of operation............................................................. 376

Function block....................................................................... 377

Input and output signals ........................................................ 378

Setting parameters ................................................................ 378

Local/Remote switch (LocalRemote, LocRemControl)............... 378

Introduction............................................................................ 378

Principle of operation............................................................. 378

Function block....................................................................... 380

Input and output signals ........................................................ 380

Setting parameters ................................................................ 381

Switch controller (SCSWI).......................................................... 382

Introduction............................................................................ 382

Principle of operation............................................................. 382

Function block....................................................................... 388

Input and output signals ........................................................ 388

Setting parameters ................................................................ 389

Circuit breaker (SXCBR)............................................................. 390

Introduction............................................................................ 390

Principle of operation............................................................. 390

Function block....................................................................... 394

Input and output signals ........................................................ 395

Setting parameters ................................................................ 396

Circuit switch (SXSWI)................................................................ 396

Introduction............................................................................ 396

Principle of operation............................................................. 396

Function block....................................................................... 401

Input and output signals ........................................................ 401

Setting parameters ................................................................ 402

Bay reserve (QCRSV) ................................................................ 402

Introduction............................................................................ 402

Principle of operation............................................................. 402

Function block....................................................................... 405

Input and output signals ........................................................ 405

Setting parameters ................................................................ 406

Reservation input (RESIN) ......................................................... 406

Introduction............................................................................ 406

Principle of operation............................................................. 407

Function block....................................................................... 408

Input and output signals ........................................................ 408

Setting parameters ................................................................ 409

Interlocking...................................................................................... 410

Introduction................................................................................. 410

Contents

Principle of operation.................................................................. 410

Logical node for interlocking (SCILO)......................................... 413

Introduction............................................................................ 413

Principle of operation............................................................. 413

Function block ....................................................................... 414

Input and output signals ........................................................ 414

Interlocking for line bay (ABC_LINE).......................................... 415

Introduction............................................................................ 415

Function block ....................................................................... 416

Logic diagram........................................................................ 417

Input and output signals ........................................................ 422

Interlocking for bus-coupler bay (ABC_BC)................................ 424

Introduction............................................................................ 424

Function block ....................................................................... 426

Logic diagram........................................................................ 427

Input and output signals ........................................................ 432

Interlocking for transformer bay (AB_TRAFO)............................ 434

Introduction............................................................................ 434

Function block ....................................................................... 435

Logic diagram........................................................................ 436

Input and output signals ........................................................ 439

Interlocking for bus-section breaker (A1A2_BS)......................... 441

Introduction............................................................................ 441

Function block ....................................................................... 442

Logic diagram........................................................................ 443

Input and output signals ........................................................ 445

Interlocking for bus-section disconnector (A1A2_DC)................ 446

Introduction............................................................................ 446

Function block ....................................................................... 447

Logic diagram........................................................................ 448

Input and output signals ........................................................ 449

Interlocking for busbar earthing switch (BB_ES) ........................ 450

Introduction............................................................................ 450

Function block ....................................................................... 450

Logic diagram........................................................................ 451

Input and output signals ........................................................ 451

Interlocking for double CB bay (DB) ........................................... 451

Introduction............................................................................ 451

Function block ....................................................................... 453

Logic diagrams ...................................................................... 455

Input and output signals ....................................................... 461

Interlocking for 1 1/2 CB diameter (BH)...................................... 464

Introduction............................................................................ 464

Function blocks...................................................................... 466

Logic diagrams ...................................................................... 469

Input and output signals ........................................................ 476

Logic rotating switch for function selection

and LHMI presentation (GGIO)........................................................ 481

Introduction................................................................................. 481

Principle of operation.................................................................. 481

Function block............................................................................. 482

Input and output signals.............................................................. 482

Setting parameters ..................................................................... 484

Contents

Chapter 12 Logic............................................................................. 487

Tripping logic (PTRC, 94) ................................................................ 488

Introduction................................................................................. 488

Principle of operation.................................................................. 488

Function block ............................................................................ 493

Input and output signals ............................................................. 494

Setting parameters ..................................................................... 495

Technical data............................................................................ 495

Trip matrix logic (GGIO, 94X) .......................................................... 496

Introduction................................................................................. 496

Principle of operation.................................................................. 496

Function block ............................................................................ 498

Input and output signals ............................................................. 498

Setting parameters ..................................................................... 500

Configurable logic blocks (LLD)....................................................... 501

Introduction................................................................................. 501

Inverter function block (INV)....................................................... 501

OR function block (OR)............................................................... 501

AND function block (AND).......................................................... 502

Timer function block (Timer)....................................................... 503

Pulse timer function block (PULSE)............................................ 503

Exclusive OR function block (XOR)............................................ 504

Set-reset with memory function block (SRM) ............................. 504

Controllable gate function block (GT)......................................... 505

Settable timer function block (TS)............................................... 506

Technical data............................................................................ 507

Fixed signal function block (FIXD)................................................... 508

Introduction................................................................................. 508

Principle of operation.................................................................. 508

Function block ............................................................................ 508

Input and output signals ............................................................. 508

Setting parameters ..................................................................... 509

Chapter 13 Monitoring.................................................................... 511

Measurements (MMXU, MSQI) ....................................................... 512

Introduction................................................................................. 512

Principle of operation.................................................................. 514

Function block ............................................................................ 524

Input and output signals ............................................................. 526

Setting parameters ..................................................................... 528

Technical data............................................................................ 544

Event counter (GGIO)...................................................................... 545

Introduction................................................................................. 545

Principle of operation.................................................................. 545

Function block ............................................................................ 546

Input signals ............................................................................... 546

Setting parameters ..................................................................... 546

Technical data............................................................................ 546

Event function (EV).......................................................................... 547

Contents

Introduction................................................................................. 547

Principle of operation.................................................................. 547

Function block............................................................................. 548

Input and output signals.............................................................. 549

Setting parameters ..................................................................... 550

Technical data ............................................................................ 552

Measured value expander block...................................................... 553

Introduction................................................................................. 553

Principle of operation.................................................................. 553

Function block............................................................................. 554

Input and output signals.............................................................. 554

Disturbance report (RDRE).............................................................. 555

Introduction................................................................................. 555

Principle of operation.................................................................. 555

Function block............................................................................. 563

Input and output signals.............................................................. 565

Setting parameters ..................................................................... 568

Technical data ............................................................................ 580

Event list (RDRE)............................................................................. 582

Introduction................................................................................. 582

Principle of operation.................................................................. 582

Function block............................................................................. 582

Input signals................................................................................ 582

Technical data ............................................................................ 583

Indications (RDRE).......................................................................... 584

Introduction................................................................................. 584

Principle of operation.................................................................. 584

Function block............................................................................. 585

Input signals................................................................................ 585

Technical data ............................................................................ 585

Event recorder (RDRE).................................................................... 586

Introduction................................................................................. 586

Principle of operation.................................................................. 586

Function block............................................................................. 586

Input signals................................................................................ 586

Technical data ............................................................................ 587

Trip value recorder (RDRE)............................................................. 588

Introduction................................................................................. 588

Principle of operation.................................................................. 588

Function block............................................................................. 588

Input signals................................................................................ 589

Technical data ............................................................................ 589

Disturbance recorder (RDRE).......................................................... 590

Introduction................................................................................. 590

Principle of operation.................................................................. 590

Function block............................................................................. 592

Input and output signals.............................................................. 592

Setting parameters ..................................................................... 593

Technical data ............................................................................ 593

Chapter 14 Metering ....................................................................... 595

Contents

Pulse counter logic (GGIO).............................................................. 596

Introduction................................................................................. 596

Principle of operation.................................................................. 596

Function block ............................................................................ 598

Input and output signals ............................................................. 598

Setting parameters ..................................................................... 599

Technical data............................................................................ 599

Chapter 15 Station communication .............................................. 601

Overview.......................................................................................... 602

IEC 61850-8-1 communication protocol .......................................... 603

Introduction................................................................................. 603

Generic single point function block (SPGGIO) ........................... 603

Introduction............................................................................ 603

Principle of operation............................................................. 603

Function block....................................................................... 603

Input and output signals ........................................................ 603

Setting parameters ................................................................ 603

Generic double point function block (DPGGIO).......................... 604

Introduction............................................................................ 604

Principle of operation............................................................. 604

Function block....................................................................... 604

Input and output signals ........................................................ 604

Setting parameters ................................................................ 604

Generic measured values function block (MVGGIO).................. 605

Introduction............................................................................ 605

Principle of operation............................................................. 605

Function block....................................................................... 605

Input and output signals ........................................................ 605

Setting parameters ................................................................ 606

Technical data............................................................................ 606

LON communication protocol .......................................................... 607

Introduction................................................................................. 607

Principle of operation.................................................................. 607

Setting parameters ..................................................................... 623

Technical data............................................................................ 623

SPA communication protocol........................................................... 624

Introduction................................................................................. 624

Principle of operation.................................................................. 624

Design ........................................................................................ 633

Setting parameters ..................................................................... 633

Technical data............................................................................ 634

IEC 60870-5-103 communication protocol ...................................... 635

Introduction................................................................................. 635

Principle of operation.................................................................. 635

Function block ............................................................................ 645

Input and output signals ............................................................. 648

Setting parameters ..................................................................... 653

Technical data............................................................................ 656

Single command, 16 signals (CD) ................................................... 657

Contents

Introduction................................................................................. 657

Principle of operation.................................................................. 657

Function block............................................................................. 658

Input and output signals.............................................................. 658

Setting parameters ..................................................................... 659

Multiple command (CM) and Multiple transmit (MT)........................ 660

Introduction................................................................................. 660

Principle of operation.................................................................. 660

Design......................................................................................... 660

Function block............................................................................. 661

Input and output signals.............................................................. 661

Setting parameters ..................................................................... 663

Chapter 16 Remote communication.............................................. 665

Binary signal transfer to remote end................................................ 666

Introduction................................................................................. 666

Principle of operation.................................................................. 666

Setting parameters ..................................................................... 667

Chapter 17 Hardware...................................................................... 669

Overview.......................................................................................... 670

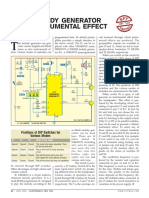

Variants of case- and HMI display size....................................... 670

Case from the rear side.............................................................. 673

Hardware modules........................................................................... 676

Overview..................................................................................... 676

Combined backplane module (CBM).......................................... 677

Introduction............................................................................ 677

Functionality .......................................................................... 677

Design ................................................................................... 677

Universal backplane module (UBM) ........................................... 679

Introduction............................................................................ 679

Functionality .......................................................................... 679

Design ................................................................................... 679

Power supply module (PSM) ...................................................... 682

Introduction............................................................................ 682

Design ................................................................................... 682

Technical data....................................................................... 682

Numeric processing module (NUM)............................................ 683

Introduction............................................................................ 683

Functionality .......................................................................... 683

Block diagram........................................................................ 684

Local human-machine interface (LHMI)...................................... 684

Transformer input module (TRM) ............................................... 685

Introduction............................................................................ 685

Design ................................................................................... 685

Technical data....................................................................... 685

Analog digital conversion module,

with time synchronization (ADM) ............................................. 686

Contents

Introduction............................................................................ 686

Design................................................................................... 686

Binary input module (BIM).......................................................... 688

Introduction............................................................................ 688

Design................................................................................... 688

Technical data....................................................................... 692

Binary output modules (BOM) .................................................... 692

Introduction............................................................................ 692

Design................................................................................... 693

Technical data....................................................................... 695

Binary input/output module (IOM)............................................... 695

Introduction............................................................................ 695

Design................................................................................... 695

Technical data....................................................................... 697

Line data communication module (LDCM) ................................. 698

Introduction............................................................................ 698

Design................................................................................... 698

Technical data....................................................................... 698

Serial SPA/LON/IEC 608705103

communication module (SLM) ................................................ 699

Introduction............................................................................ 699

Design................................................................................... 699

Technical data....................................................................... 700

Optical ethernet module (OEM).................................................. 701

Introduction............................................................................ 701

Functionality.......................................................................... 701

Design................................................................................... 701

Technical data....................................................................... 702

mA input module (MIM) .............................................................. 702

Introduction............................................................................ 702

Design................................................................................... 702

Technical data....................................................................... 704

GPS time synchronization module (GSM).................................. 704

Introduction............................................................................ 704

Design................................................................................... 704

Technical data....................................................................... 706

GPS antenna.............................................................................. 707

Introduction............................................................................ 707

Design................................................................................... 707

Technical data....................................................................... 708

Case dimensions ............................................................................. 709

Case without rear cover.............................................................. 709

Case with rear cover................................................................... 710

Panel cut-outs for single case .................................................... 711

Side-by-side flush mounting dimensions.................................... 712

Wall mounting dimensions.......................................................... 714

Mounting alternatives....................................................................... 716

Flush mounting, single case....................................................... 716

Side-by-side flush mounting details............................................ 717

Wall mounting............................................................................. 717

Wall mounting details ............................................................ 718

Side-by-side................................................................................ 720

Mounting in a 19-inch rack ......................................................... 721

Contents

Technical data ................................................................................. 722

Enclosure.................................................................................... 722

Connection system..................................................................... 722

Influencing factors....................................................................... 723

Type tests according to standard................................................ 724

Chapter 18 Connection diagrams.................................................. 727

Chapter 19 Time inverse characteristics ...................................... 743

Application....................................................................................... 744

Principle of operation....................................................................... 748

Mode of operation....................................................................... 748

Inverse characteristics..................................................................... 754

Chapter 20 Glossary ....................................................................... 767

Glossary........................................................................................... 768

1

About this chapter Chapter 1

Introduction

Chapter 1 Introduction

About this chapter

This chapter explains concepts and conventions used in this manual and provides information

necessary to understand the contents of the manual.

2

Introduction to the technical reference manual Chapter 1

Introduction

1 Introduction to the technical reference manual

1.1 About the complete set of manuals for an IED

The users manual (UM) is a complete set of four different manuals:

The Application Manual (AM) contains application descriptions, setting guidelines and setting

parameters sorted per function. The application manual should be used to find out when and for

what purpose a typical protection function could be used. The manual should also be used when

calculating settings.

The Technical Reference Manual (TRM) contains application and functionality descriptions

and it lists function blocks, logic diagrams, input and output signals, setting parameters and tech-

nical data sorted per function. The technical reference manual should be used as a technical ref-

erence during the engineering phase, installation and commissioning phase, and during normal

service.

The Installation and Commissioning Manual (ICM) contains instructions on how to install

and commission the protection IED. The manual can also be used as a reference during periodic

testing. The manual covers procedures for mechanical and electrical installation, energizing and

checking of external circuitry, setting and configuration as well as verifying settings and per-

forming directional tests. The chapters are organized in the chronological order (indicated by

chapter/section numbers) in which the protection IED should be installed and commissioned.

The Operators Manual (OM) contains instructions on how to operate the protection IED dur-

ing normal service once it has been commissioned. The operators manual can be used to find

out how to handle disturbances or how to view calculated and measured network data in order

to determine the cause of a fault.

1.2 About the technical reference manual

The technical reference manual contains the following chapters:

Thechapter IED Overview describes the IED in general.

The chapter Local human-machine interface describes the control panel on the

IED. Display characteristics, control keys and various local human-machine in-

terface features are explained.

Application

manual

Technical

reference

manual

Installation and

commissioning

manual

Operators

manual

en01000044.vsd

3

Introduction to the technical reference manual Chapter 1

Introduction

The chapter Basic IED functions presents functions that are included in all

IEDs regardless of the type of protection they are designed for. These are func-

tions like Time synchronization, Self supervision with event list, Test mode and

other functions of a general nature.

The chapter Distance protection describes the functions for distance zones

with their quadrilateral characteristics, phase selection with load encroachment,

power swing detection and similar.

The chapter Current protection describes functions such as overcurrent pro-

tection, breaker failure protection and pole discordance.

The chapter Voltage protection describes functions like undervoltage and ov-

ervoltage protection as well as residual overvoltage protection.

The chapter Frequency protection describes functions for overfrequency, un-

derfrequency and rate of change of frequency.

The chapter Multipurpose protection describes the general protection function

for current and voltage.

The chapter Secondary system supervision includes descriptions of functions

like current based Current circuit supervision and Fuse failure supervision.

The chapter Control describes the control functions. These are functions like

the Synchronization and energizing check as well as several others which are

product specific.

The chapter Scheme communication describes among others functions related

to current reversal and weak end infeed logic.

The chapter Logic describes trip logic and related functions.

The chapter Monitoring describes measurement related functions used to pro-

vide data regarding relevant quantities, events, faults and the like.

The chapter Metering describes primarily Pulse counter logic.

The chapter Station communication describes Ethernet based communication

in general including the use of IEC61850, and horizontal communication via

GOOSE.

The chapter Remote communication describes binary and analog signal trans-

fer, and the associated hardware.

The chapter Hardware provides descriptions of the IED and its components.

The chapter Connection diagrams provides terminal wiring diagrams and in-

formation regarding connections to and from the IED.

The chapter Time inverse characteristics describes and explains inverse time

delay, inverse time curves and their effects.

The chapter Glossary is a list of terms, acronyms and abbreviations used in

ABB technical documentation.

1.3 Design of the Technical reference manual (TRM)

The description of each IED related function follows the same structure (where applicable). The

different sections are outlined below.

1.3.1 Introduction

Outlines the implementation of a particular protection function.

4

Introduction to the technical reference manual Chapter 1

Introduction

1.3.2 Principle of operation

Describes how the function works, presents a general background to algorithms and measure-

ment techniques. Logic diagrams are used to illustrate functionality.

Logic diagrams

Logic diagrams describe the signal logic inside the function block and are bordered by dashed

lines.

Signal names

Input and output logic signals consist of two groups of letters separated by two dashes. The first

group consists of up to four letters and presents the abbreviated name for the corresponding

function. The second group presents the functionality of the particular signal. According to this

explanation, the meaning of the signal BLKTR in figure4 is as follows:

BLKTR informs the user that the signal will BLOCK the TRIP command from

the under-voltage function, when its value is a logical one (1).

Input signals are always on the left hand side, and output signals on the right hand side. Settings

are not displayed.

Input and output signals

In a logic diagram, input and output signal paths are shown as a lines that touch the outer border

of the diagram.

Input and output signals can be configured using the CAP531 tool. They can be connected to the

inputs and outputs of other functions and to binary inputs and outputs. Examples of input signals

are BLKTR, BLOCK and VTSU. Examples output signals are TRIP, START, STL1, STL2,

STL3.

Setting parameters

Signals in frames with a shaded area on their right hand side represent setting parameter signals.

These parameters can only be set via the PST or LHMI. Their values are high (1) only when the

corresponding setting parameter is set to the symbolic value specified within the frame. Example

is the signal Block TUV=Yes. Their logical values correspond automatically to the selected set-

ting value.

Internal signals

Internal signals are illustrated graphically and end approximately. 2 mm from the frame edge. If

an internal signal path cannot be drawn with a continuous line, the suffix -int is added to the sig-

nal name to indicate where the signal starts and continues, see figure 3.

5

Introduction to the technical reference manual Chapter 1

Introduction

Figure 1: Logic diagram example with -int signals

External signals

Signal paths that extend beyond the logic diagram and continue in another diagram have the suf-

fix -cont., see figure2 and figure3.

TEST

Block TUV=Yes

STUL1N

STUL2N

STUL3N

&

>1 &

TEST

>1

&

&

&

xx04000375.vsd

t

BLKTR

BLOCK

VTSU

TRIP

START

STL1

STL2

STL3

BLOCK-int.

BLOCK-int.

BLOCK-int.

BLOCK-int.

6

Introduction to the technical reference manual Chapter 1

Introduction

Figure 2: Logic diagram example with an outgoing -cont signal

&

&

&

&

&

&

STCND

STNDL1L2-cont.

STNDL2L3-cont.

STNDL3L1-cont.

STNDL1N-cont.

STNDL2N-cont.

STNDL3N-cont.

STZMPP-cont.

STNDPE-cont.

&

1--BLOCK

1--VTSZ

1--STND

BLK-cont.

>1

>1

>1

>1

xx04000376.vsd

1L1L2

1L2L3

1L3L1

1L1N

1L2N

1L3N

7

Introduction to the technical reference manual Chapter 1

Introduction

Figure 3: Logic diagram example with an incoming -cont signal

1.3.3 Input and output signals

Input and output signals are presented in two separate tables. Each table consists of two columns.

The first column contains the name of the signal and the second column contains the description

of the signal.

1.3.4 Function block

Each function block is illustrated graphically.

Input signals are always on the left hand side, and output signals on the right hand side. Settings

are not displayed. Special kinds of settings are sometimes available. These are supposed to be

connected to constants in the configuration scheme, and are therefore depicted as inputs. Such

signals will be found in the signal list but described in the settings table.

xx04000377.vsd

STNDL1N-cont.

STNDL3N-cont.

STNDL1L2-cont.

STNDL2L3-cont.

STNDL3L1-cont.

>1

>1

>1

>1

&

&

&

&

BLK-cont.

t

15 ms

t

15 ms

t

15 ms

t

15 ms

START

STL3

STL2

STL1

STNDL2N-cont.

8

Introduction to the technical reference manual Chapter 1

Introduction

Figure 4: Example of a function block

1.3.5 Setting parameters

These are presented in tables and include all parameters associated with the function in question.

1.3.6 Technical data

The technical data section provides specific technical information about the function or hard-

ware described.

1.4 Intended audience

1.4.1 General

This manual addresses system engineers, installation and commissioning personnel, who use

technical data during engineering, installation and commissioning, and in normal service.

1.4.2 Requirements

The system engineer must have a thorough knowledge of protection systems, protection equip-

ment, protection functions and the configured functional logics in the protective devices. The

installation and commissioning personnel must have a basic knowledge in the handling electron-

ic equipment.

PH2PUVM

TUV1-

U3P

BLOCK

BLKTR1

BLKST1

BLKTR2

BLKST2

TRIP

TR1

TR1L1

TR1L2

TR1L3

TR2

TR2L1

TR2L2

TR2L3

START

ST1

ST1L1

ST1L2

ST1L3

ST2

ST2L1

ST2L2

ST2L3

en05000330.vsd

IEC 61850 - 8 -1

Logical Node CAP531 Name

Outputs

Inputs

Diagram

Number

9

Introduction to the technical reference manual Chapter 1

Introduction

1.5 Related documents

Documents related to RET670 Identity number

Operators manual 1MRK 504 049-UEN

Installation and commissioning manual 1MRK 504 050-UEN

Technical reference manual 1MRK 504 048-UEN

Application manual 1MRK 504 051-UEN

Buyers guide 1MRK 504 080-BEN

Connection diagram, Two winding trasf. Single breaker arrangements 1MRK 002 801-LA

Connection diagram, Two winding transf. Multi breaker arrangements 1MRK 002 801-HA

Connection diagram, Three winding transf. Single breaker arrangements 1MRK 002 801-KA

Connection diagram, Three winding transf. Multi breaker arrangements 1MRK 002 801-GA

Configuration diagram A, Two winding transf. with single or double busbar but

with a single breaker arr. on both sides

1MRK 004 500-93

Configuration diagram B, Two winding transf. in multi breaker arr. on one or

both sides

1MRK 004 500-94

Configuration diagram C, Three winding transf. with single or double busbar

but with a single breaker arr. on both sides

1MRK 004 500-95

Configuration diagram D, Two winding transf. in multi breaker arr. on one or

both sides

1MRK 004 500-96

Setting example 1, 400/230 kV 500 MVA Transformer, YNyn connected 1MRK 504 083-WEN

Setting example 2, 132/230 kV 40 MVA Transformer, YNd1 connected 1MRK 504 084-WEN

Connection and Installation components 1MRK 013 003-BEN

Test system, COMBITEST 1MRK 512 001-BEN

PCM600, Protection and Control IED Manager 1MRS755552

Getting started guide 1MRK 500 065-UEN

SPA signal list for IED670 1MRK 500 075-WEN

IEC 6185081 signal list for IED670 1MRK 500 077-WEN

Latest versions of the described documentation can be found on www.abb.com/substationautomation

10

Introduction to the technical reference manual Chapter 1

Introduction

1.6 Revision notes

Revision Description

- First release

A First revision, addition of SPA protocol, LON protocol and IEC 60870-5-103 proto-

col.

11

About this chapter Chapter 2

Local human-machine interface

Chapter 2 Local

human-machine

interface

About this chapter

This chapter describes the structure and use of the Local human machine interface (LHMI) or in

other words, the control panel on the IED.

12

Human machine interface Chapter 2

Local human-machine interface

1 Human machine interface

The local human machine interface is available in a small, and a medium sized model. The prin-

ciple difference between the two is the size of the LCD. The small size LCD has a four lines and

the medium size LCD can display the single line diagram with up to 15 objects.

The local human machine interface is equipped with an LCD that can display the single line di-

agram with up to 15 objects.

The local human-machine interface is simple and easy to understand the whole front plate is

divided into zones, each of them with a well-defined functionality:

Status indication LEDs