Professional Documents

Culture Documents

04 Milling

Uploaded by

MKPashaPashaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 Milling

Uploaded by

MKPashaPashaCopyright:

Available Formats

CEMENT PROCESS ENGINEERING

VADE-MECUM

4. MILLING

Rev. 2002

CEMENT PROCESS ENGINEERING

VADE-MECUM

SECTION 4 MILLING

Table of Contents

1.

Mill ....................................................................................................... 4.1

1.1 Ball Mill General .......................................................................... 4.1

1.2 Ball Charge and Internals.............................................................. 4.3

1.3 Ball Charge Design (Finish Mill)................................................... 4.6

1.4 Grinding Laws.............................................................................. 4.9

2.

Separator............................................................................................ 4.12

2.1 Circulating Load......................................................................... 4.12

2.2 Tromp Curve.............................................................................. 4.12

2.3 Indicators for Cement Milling and Typical Values ....................... 4.14

2.4 Sturtevant/O'Sepa (Bath #B mill) ................................................ 4.15

2.5 Recommended Steps for Sizing a HES ........................................ 4.16

3.

Heat and Water Balance .................................................................... 4.17

4.

Grinding Aid ...................................................................................... 4.18

5.

Sieve ................................................................................................... 4.19

Index - i

Rev. 2002

CEMENT PROCESS ENGINEERING

VADE-MECUM

SECTION 4 MILLING

1. Mill

1.1 Ball Mill General

a) Mill design

General L/D ratio

Raw mills: 1.5 < L/D < 3.2

Finish / cement mills: 2.8 < L/D < 3.2

Length of first Compartments relative to total mill length

Raw mills: First compartment length equals 35 45% of total mill effective length.

Cement mill: First compartment length equals 30 35% of total mill effective length.

When L/D>1.5, classifying liners might be used.

The lower the L/D, the higher the circulating load needs to be (see below).

b) Percent loading of mill

2

r 2 r sin (h r )

% volume load = 360

r 2

where:

- r is the radius

- h is the free height

hr

- = arccos

r

- in degrees = 3.14

0.9

h/d

0.8

0.7

0.6

0.5 0

10

20

30

40

50%

% volume load

Rules of thumb

% vol. Load = 111.87 123.98 (h/d), 25 50%: error max 0.6%.

It is estimated that material increases the actual ball filling ratio by about 2%.

Another method (quick but not as accurate) consists in counting the number of visible shell liner plates (n) and

to divide by the total number of shell liner plates per circumference (N): Angle = n x 360 / N.

Values of angle h/d ratio in relation to the ball load (% filling degree)

Ball load (%)

20

21

22

23

24

25

26

27

28

29

30

h/d

.7459

.737

.7281

.7193

.7106

.702

.6926

.685

.6765

.6682

.6598

n/N

.667

.653

.639

.625

.611

.601

Ball load (%)

31

32

33

34

35

36

37

38

39

40

41

42

h/d

.6516

.6434

.6352

.627

.6189

.6109

.6028

.5948

.5868

.5789

.5709

.563

n/N

.590

.580

.569

.558

.549

.539

4.1

Rev. 2002

CEMENT PROCESS ENGINEERING

VADE-MECUM

SECTION 4 MILLING

c) Mill Critical Speed

C

m

P

000000000000000000000000000000000000000000000000000000000000000000000000

r

60 2 g

Mill critical speed: nc =

4 2 r

C = m 2 r =

G 2 r

g

where:

- G = Weight of grinding ball in kg

- = angular velocity of mill tube (rad/sec)

- D = inside mill diameter (m)

- n = rev per minute

- C = centrifugal power kg

- D1 = inside mill diameter (ft)

P = G * sin

(P is the resulting force of gravity)

To maintain the ball in this position on the mill wall, it is

necessary that C P.

76.6

42.3

(=

), with D in meters ( D1 in feet)

D1

D

% Critical speed:

Practically, mill speed between 68and 80% of critical speed.

% critical speed is the mill actual speed in RPM divided by nc.

Example:

3.98 meter mill with rotational speed of 15.6 rpm then nc = 21.2, % critical speed = 73.6 %.

d) Retention Time

Rules of thumb:

Retention time:

Open circuits: 12 min

Closed circuits: 5 min

The feed is pushing the material through the mill so that, If mill throughput increases: retention time decreases:

C

8 <

< 12

where: C is the ball charge weight, M is the material weight

M

Fluoresceine test:

2g/t of mill production. Prepare the fluoresceine with 800-ml alcohol and impregnate 2 kg of mill feed

material (in a plastic bag).

Put the material at mill inlet, start the time and sample every 30 s during 30 min. (others use salt).

e) Mill Throughput

Using elevator power and after calibrating we have:

A=

(kW kW0 ). 3600 .

9,81. H

where:

A

kW

kW0

H

-

=

=

=

=

=

Material flow (mtph)

Actual elevator power ( in kW)

Elevator power empty

Elevator efficiency

Inter axis elevator height

4.2

Rev. 2002

CEMENT PROCESS ENGINEERING

VADE-MECUM

SECTION 4 MILLING

f) Required air velocities for mill ventilation

Rules of thumb

Recommended 1.5 m/s above the ball charge:

inside the trunnion: 22-25 m/s.

partitions: 8-14 m/s (<20 m/s).

hood: <5 m/s to prevent dust from being sucked up (dust pick-up is proportional to speed^2).

dropout box: <2 m/s.

0.3-0.5 Nm3/kg ck

0.6-0.8 Nm3/kg raw mix

Wet bulb temperature should be 30oC below the dry bulb temperature.

g) Optimum filling ratio:

U= (volume of powder in the mill)/ (volume of voids in the charge): between 60% and 110%, optimum around

90%.

In practical terms, material level should equal ball level.

1.2 Ball Charge and Internals

a) Biggest Ball

Bond Formula

d KMAX

where:

- d KMAX is the biggest ball diameter (mm)

- d 20 is the sieve dimension () with 20% retained

Quick evaluation

For clinker:

K is a constant (350 for a dry mill open or close circuit,

300 for wet)

is the specific mass of material (g/cm3)

Wi is the Bond work index (kWh/t)

Du is the mill inside diameter (m)

is the ratio between the actual / critical speed (%)

Grinding Ball vs Clinker Size

B = 24 d 80

(Other formula exist that result in value differences

of 5%)

B = ball dimension (mm)

d 80 is the sieve with 80% passing

-

Optimum Ball Diameter (mm)

d

Wi

= 20.17 20 .3

K . Du

100

10

.1

10

100

Clinker Size d80

Rowland Formula

. Wi

d 80

.

K 100 . . 3.281 Du

B = 25.4

d 80 is the sieve with 80% passing

4.3

Rev. 2002

CEMENT PROCESS ENGINEERING

VADE-MECUM

SECTION 4 MILLING

Material bulk density and Bond index

kWh/st

(g/cm3)

Wi

Clinker:

Limestone

Shale

Slag

Sand stone

Silica sand

Coal

Clay

Gypsum

Kiln feed

13.49

10.18

16.40

15.76

11.53

16.46

11.37

7.10

8.16

10.57

Bulk density

Sand

Sand

Iron

Bauxite

Brick

Gypsum

Fluid coke

Limestone (crushed)

Silica fume

Bottom Ash

Cement T I-II

T 10

T III

Clinker

Clinker

(underburnt)

Raw mix

3.09

2.68

2.58

2.93

2.68

2.65

1.63

2.23

2.69

2.67

g/l or kg/m3

1387

1679

2629

1980

1502

1677

926

1803

1024

1241

1234

1207

1054

1575

1400

lb/ft3

86.6

104.9

164.2

123.6

93.8

104.7

57.8

112.6

63.9

77.5

77.1

75.4

65.8

98.4

87.4

1041

65.0

b) Grinding Balls Data

Grinding Ball dimensions

Weight

Surface

Diameter

(g)

(cm2)

mm

inch

4,001.153

314.159

100.00

4"

2,916.841

254.469

90.00

3"

2,048.590

201.062

80.00

1,826.658

186.265

77.00

3"

1,372.396

153.938

70.00

1,048.878

128.680

64.00

2"

864.249

113.097

60.00

500.144

78.540

50.00

2"

256.074

50.265

40.00

219.551

45.365

38.00

1"

171.549

38.485

35.00

128.061

31.669

31.75

1"

108.031

28.274

30.00

62.518

19.635

25.00

1"

48.682

16.619

23.00

43.895

15.511

22.22

=7/8"

32.009

12.566

20.00

3/4"

19.658

9.079

17.00

5.8"

(Unit weight and specific surface of MAGOTTEAUX grinding media)

Quick calculation:

Ball diameter (mm) =

250 P

Specific surface of balls of diameter =

Number of balls per

metric tons

Weight of 1 m3 of

balls (kg)

Specific surface

(m2 / mt)

250

343

488

548

729

954

1,157

2,000

3,905

4,555

5,830

7,809

9,257

15,996

20,542

22,782

31,242

50,870

4560

4590

4620

7.854

8.728

9.812

10.207

11.222

12.276

13.085

15,708

19.628

20.664

22.437

24.730

26.173

31.408

34.139

35.337

39.259

46.185

4640

4660

4708

4760

4850

4894

4948

4989

(P = weight in g)

785 2

m / mt

d

(d = diameter in mm)

4.4

Rev. 2002

CEMENT PROCESS ENGINEERING

VADE-MECUM

Wear rates:

Ball diameter mm

100

90

80

70

60

50

40

30

25

20

17

SECTION 4 MILLING

Wear GT ball

g/h.T

Wear / Ball

g/100h

Wear diam

mm/100h

12.9

14.4

16.7

19.3

23.1

28.9

38

46.5

58.5

68.2

38.6

30.4

23.6

17.2

11.9

7.6

4.22

2.98

1.92

1.38

0.4

0.4

0.4

0.4

0.4

0.4

0.4

0.4

0.4

0.4

Bulk density for ball load

(coarse to medium ball size distribution):

In first compartment; 4.3 4.5 metric tonnes per tonne of balls (3.0 to 2.0 inch balls would be fine).

In second compartment; 4.5 4.65 metric tonnes per tonne of balls (2.0 to 0.75 inch balls would be considered

medium to fine).

In single compartment: 4.5 4.55 metric tonnes per tonne of balls.

c) Others internals

Partitions

Total slot area: 10 to 20 cm2/tph production:

Slot Size

Central Part

Discharge Part

FM

9 mm 1 mm

7 mm 1 mm

Max: min ball size

RM

12 mm 1 mm

10 mm 1 mm

Liners

Liners must be changed when 60% of their effective lifting height has worn away:

-8 to 10 % production

reference points to measure lifting height are the lowest point on the liner to the highest release point

(contact points between grinding ball and liner plate)

American Lorrain pattern: diameter (ft)*2=# bolt holes/row, 18.8 center to center.

DIN pattern: diameter (m)*10== # bolt holes/row, 31.4 cm center to center.

Classifying liners if L/D>1.5 and volume load<35%.

Without classifying liners, keep a maximum of 3-4 ball sizes.

4.5

Rev. 2002

CEMENT PROCESS ENGINEERING

VADE-MECUM

SECTION 4 MILLING

d) Mill Internal Inspection Sheet

Ball Charge Remarks

Ball Coating Remarks

Ball Classification Remarks

Discharge Grate Slot Size-Average

Discharge Grate Slot Size-Maxim.

Discharge Grate Metal Thickness

Discharge Grate Percent Blinded

Discharge Center Screen Percent Blinded

Material Position in Mill

Points to audit

Shell Liner Thickness

Shell Liner Lifter Thickness

Shell Liner Remarks

Inlet Head Liner Thickness

Inlet Head Liner Remarks

Inlet Opening Remarks

Height Liner, to Balls - Average

Width Across Balls - Average

Calculated Percent Fill

1.3 Ball Charge Design (Finish Mill)

a) Recommended volume loading

(see BP Ball Charge Management)

Recommended Volume Loading

1 Compartment

2nd Compartment

3rd Compartment

Minimum kWh/t1

26 28%

28 30%

28 30%

Maximum Production

32 34 %

34 36%

34 36%

(Ball level in the trunion should not be higher than 2 to 3 inches.)

st

b) Polysius Design

As a rule of thumb, it suits raw mills and especially monochambers very well, especially if no classifying

liners are used.

D

ln

9.6

D = 9.6 e013.x x =

0.13

where:

D = ball (cm)

x = effective mill length (m)

Process step-by-step, calculating each effective length starting from the input and with the largest ball:

1. Calculate effective lengths and the ball sizes you plan to use.

2. Double the first effective length which is both the first interval width and the first cumulative length.

3. Calculate each succeeding interval width by taking the effective length and substract the preceding

cumulative length and doubling it. Add this value to the previous cumulative length to get the new one.

4. If an interval overlaps with the partition divide the interval at the point of overlap. The excess is carried

over to the next compartment. At the end of the mill, the interval is truncated at the point of overlap.

5. Once the intervals have been adjusted for compartment lengths as described in step (4), divide the adjusted

interval by compartment length and multiply by 100. This is the percent weight for each size to be used in

the compartment.

c) Slegten Model

1

The recommended volume loading for minimum kWh/t is based on an acceptable compromise with production. For minimum kWh/t

the volume loading can be as low as 22%.

4.6

Rev. 2002

CEMENT PROCESS ENGINEERING

VADE-MECUM

SECTION 4 MILLING

Compatible mostly with classifying linings in the second compartment.

4.7

Rev. 2002

CEMENT PROCESS ENGINEERING

VADE-MECUM

SECTION 4 MILLING

First Compartment Crushing

Same number (n) of balls in each size range.80, 70 and 60 mm and then add some 90 mm to deal with

oversize clinker. This equilibrium charge will not change as you add 90 mm make-up balls to maintain

volume load.

Ball (mm)

% of Weight (x)

% of Weight

90

100-5x

20.0

80

2-4x

38.4

70

1.6x

25.6

60

x

16.0

- x = is taken to be the number of balls in the last size.

Number/ 10 t of Charge

670

1820

1820

1820

In recent years, Slegten has favored a 3-ball size distribution in first compartments over a 4- ball size as shown

in table above.

Transition Zone

This is at the beginning of the second compartment and basically its job is to clean up anything which

penetrated the partition that is oversize for the second compartment charge to fracture.

The design for this area is to use "n" balls of 50 and 40 mm.

Ball (mm)

50

40

Number/ 10 t of Charge

1820

1820

The transition zone is made of the largest ball size used in this transition zone is sometimes identical to the

smallest ball size used in the first compartment.

Second Compartment Fine Grinding

The envelope curve for the balls smaller than 40 mm follows the following formula:

where:

D = 3.3e 010.x

D = ball (cm)

x = distance from transition zone finish (m)

The 30 mm balls start at the completion of the transition zone and the exponential curve follows.

Rule of thumb:

The smallest ball size should, as a minimum, be at least twice the width of the slots in the grates (ex. 16 mm

balls if slots are 8 mm wide). For this reason, it is generally recommended to use (19 mm) balls as the

smallest size in Finish mills. 5/8 balls are fine when the grates are new but often become problematic as the

grate slots enlarge.

d) Example: Comparison Slegten/ Polysius

1st compartment useful length = 3.81 m, 2nd compartment useful length = 7.66 m

Using an average ball weight of 1.65 kg per ball and 3 ball sizes in the first compartment for the Slegten model.

1st compartment

2nd compartment

Ball size and % compartment load

3

3

2

2

1

1

1

5/8

Polysius design

31.0%

31.2%

37.8%

2.31%

23.73%

34.05%

2.57%

37.34%

-

Slegten design

32.1%

43.1%

24.8 %

7.67%

2.94%

10.08%

48.18%

31.13%

(Some)1

Transition

zone

4.8

Rev. 2002

CEMENT PROCESS ENGINEERING

VADE-MECUM

SECTION 4 MILLING

A limited amount of 5/8 balls should theoretically be added but the designer decided to use as the smallest ball size.

e) Fineness in Finish Mills:

In the first compartment before intermediate diaphragm

95% passing of 2.365 mm (2360 or 8 mesh) for the material leaving the first compartment 33% of energy.

Particle size distribution recommended on other sieves:

- 86 92 % passing 1.0 mm (1000 m or 18 mesh)

- 80 90 % passing 0.6 mm (595 m or 30 mesh)

- 75 85 % passing 0.5 mm (500 m or 35 mesh)

In the second compartment before discharge diaphragm

95% passing 0.5 mm (500 m or 35 mesh)

70- 80 % passing 0.2 mm (212 m or 70 mesh)

1.4 Grinding Laws

a) Absorbed Power of a Mill

Only 5-10 % of the energy is used for grinding, 90% is wasted into heat, wear

With similar ball charge gradation and similar liners' lifting effect, the absorbed power is related to:

Tonnage of balls

Mill rpm

% volume load

Mill diameter

Slegten formula

P =W*

rpm

V cr

1.27

W=

and

* K j * K Fr

* Fr 2 * L * J * d

where:

P : the motor absorbed power (kW)

J : the ratio between the apparent ball

W : the weight of the load (T)

volume and the internal volume

- rpm: is mill speed (rpm)

Fr : internal diameter (inside liners) (m)

d is the apparent density of load (t/m3)

#1 comp :

d = 4.5

#2 comp :

d = 4.65, if fine ball size distribution (say with average ball weight < 40 g)

d = 4.6, if coarser ball size distribution (average ball weight > 40 g)

Average :

d = 4.6

Vcr is the critical speed inside liners=

42.3

Fr

, L : the useful length of mill (m)

K j = 1.36 1.2 J , K Fr = C .Fr

K Fr is the influence of the location of the center of gravity for the moving ball charge vs. the mill center

(C is a constant depending on the material and the liners).

C=

11.262 for Clinker mill closed circuit with Slegten equipment

10.7 for clinker + slag, 12.16 for raw mix, 10.1 for slurry

0.379

4.9

Rev. 2002

CEMENT PROCESS ENGINEERING

VADE-MECUM

P = L*

rpm

Vcr

1.27

* J*K j*

SECTION 4 MILLING

* Fr2.379 * d * C

Simplified formula

P =T *

Fr

RPM 100

*Kj *

* 9.5

*

Vcr

75

1.366

Kj Function of Volume Load

Volume load

Kj

40%

0.9

30%

1

20%

1.1

Rules of Thumb

One metric ton of balls increases the mill power draw by 10kW.

Usually, 8 to 12 kWh/t is absorbed in the first compartment for clinker grinding.

b) Grinding Laws

General Law: Charles

dW = cx n dx

- If W = Comminution work,

particles (initial, final)

Value of n

Energy Law

Rittinger

Kick

Bond

Value of n:

2

1

1.5

x = Size of

Applies well over range of:

10 1000 m

Normalized Blaine fineness equation

Fineness equation, generally accepted within Lafarge Corp:

Blaine 1

W2 = W1

Blaine 2

n = 1.4 for high efficiency separator (HES) circuit, n = 1.6 for Sturtevant separators, bearing in mind

that 16 and 18 Sturtevant separators are more efficient than the larger 20 and 22 Sturtevant.

W: communition work, W is proportional to production rates.

Proposed by Polysius: C2 = C1 * e0.43( Blaine 1 Blaine 2 ) / 1000

where C2 and C1 are production capacities

Renes Study: +1% passing at 10m: +10.8 SSB

Rules of thumb

Raw material: 10-16 kWh/t (target fineness: passing 200m>99%, passing 100m>90%)

4.10

Rev. 2002

CEMENT PROCESS ENGINEERING

VADE-MECUM

SECTION 4 MILLING

Clinker: 45 15 kWh/t at 3500 SSB

4.11

Rev. 2002

CEMENT PROCESS ENGINEERING

VADE-MECUM

SECTION 4 MILLING

2. Separator

2.1 Circulating Load

a) Junction with Three Streams

A, R, F are the feed, reject and fine of the separator

A

- ai , ri , f i are the cumulated % passing at a defined sieve(i).

- da, dr, df are the % retained corresponding to the sieve interval dx.

A=

A da

With:

R+F

=

Rdr + Fdf

da = ai + 1 ai ,

b) Drawing

Plot ( f i a ) vs ( f i ri )

If the mill circuit is steady, the graph has to be a

straight line:

( f a) = + ( f r )

- should be close to 0

R

- is the most probable value of

A

R

- The circulating load is defined as:

=

F 1

R df da

=

,

A df dr

F dr da

=

A dr df

c) CL calculation

Using the least square line calculations,

with = 0

d) Quick CL calculation

With one set of results of sieving:

R f a

=

F ar

2.2 Tromp Curve

a) Tromp Curve

On the Gausso-logarithmic paper, let's plot the probability for a given particle of a certain size entering the

dr( x )* R

with:

separator to go to the rejects =

da( x )* A

n

( f i ai )( f i ri )

R i =0

=

n

A

i =0

( f i ri ) 2

The Tromp curve can be divided into two straight lines:

The right one (higher sieves) has a slope which is representative of the separator efficiency (a perfect one

would be vertical).

The left one (smaller sieves) is flat.

4.12

Rev. 2002

CEMENT PROCESS ENGINEERING

VADE-MECUM

b) Imperfection

I = d75 d 25

2 * d 50

SECTION 4 MILLING

where:

- d25 is the size of the particle which has 25 % chance of going to rejects

- d50 is the size of the particle which has 50 % chance of going to rejects

- d75 is the size of the particle which has 75 % chance of going to rejects

I=

0.4 -0.5 for a high efficiency separator

0.6 - 0.7 for a Sturtevant

0.45 - 0.6 for a Raymond separator

Imperfection vs Circulation Load

0.44

Imperfection

0.42

0.40

0.38

0.36

0

100

200

300

Circ. load (%)

400

c) Acuity Limit

AL is the abscissa of the intersection of the two Tromp curve lines.

Its the size at which selection is initiated

Rule of thumb

Cement mill = Acuity limit: 20-30 m, Raw mill = Acuity limit: 30-60 m

d) Bypass

Definition:

By-pass is the ordinate of the intersection of the two Tromp curve lines.

The bypass is the lowest percentage of feed that will go to the separator rejects.

60

40

20

0

50

100

150

200

250

Feedrate to Separator (t/h)

300

80

70

60

Bypass (%)

Bypass (%)

80

00000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000

000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000

100

Bypass vs. feed rate OSepa/Sturtevant

50

40

30

20

10

0

0000000000000000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000

00000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000

Bypass vs. feed rate Sturtevant

The following graph shows the Bypass of an

18Sturtevant versus its feed rate.

Sturtevant

O-Sepa

1.0

1.5

2.0

2.5

3.0

Qf/Qa (kg feed/m3 separator sweep)

3.5

4.13

Rev. 2002

CEMENT PROCESS ENGINEERING

VADE-MECUM

SECTION 4 MILLING

Bypass (%)

20

10

Bypass = 1 + e

- f1: coefficient for the separator

2

3

Qf/Qa (kg/m3)

RRnumber vs. Feed to Air Ratio

1.20

Rosin-Ramler Number (n)

e) Rosin Rammler Number

The steeper the size distribution (RR# high) the

more efficient the grinding and separating

process.

Cement Mill RR#

Open Circuit 0.75 0.85

Raymond Sturtevant 0.85 1.00

2nd general HW 1.00 1.20

High Efficiency Separator 1.10 1.40

1.15

1.10

1.05

1.00

0 0 0 0 0

0000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000

0000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000

0000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000

0 0 0 0 0

Qf

Qa

f1

30

0 00 00

00 0000 0000

00000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000

000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000

000000000000000000000000000000000000000000000000000000000000000000000000000000000000

00 0000 0000

40

QF/Qa vs. bypass

If Qf is the separator feed rate (kg/h) and Qa the

separator ventilation (m3/h),

Qf/Qa is an important ratio for the separator

efficiency.

1.0

1.5

2.0

2.5

3.0

3.5

4.0

Qf/Qa (kg/m3)

Raw mix RR# are usually lower

Separation Performance

Rate of recuperation in the fines of particles smaller than a given dimension.

F f

r= *

A a

2.3 Indicators for Cement Milling and Typical Values

IMLt

IMLm:

100/c:

100/c C1:

100/c C2:

NRR fines:

% recovery, 45 m:

Acuity:

Imperfection:

Bypass:

Circulating load:

HES Qf/Qa:

% Passing 45 m:

> 37 (laser / sieve)

in the 17 19 range

63 91 % range

60 85 % range

80 110 % range

1.1 1.4 for HES

0.85 1.0 for 1st generation separators (Sturtevant, Raymond)

1.2 for second generation separators

55% for HES

20 30 m

0.4 0.5 for HES

0.45 0.6 for Raymond separators

0.6 0.7 for Sturtevant separators

5 10% range for HES

150 200 % with HES

1.5 2.0 range

93% minimum (45 m = 325 mesh)

4.14

Rev. 2002

CEMENT PROCESS ENGINEERING

VADE-MECUM

SECTION 4 MILLING

2.4 Sturtevant/O'Sepa (Bath #B mill)

Data before (22' Sturtevant)-after (O'Sepa)

T10

Before

Prod(T/H)

81

kWh/t

total

42.6

Mill+elev+sep

42.1

Mill

38.3

Blaine

380

45

89

Strength

3d (MPa)

24.3

7d (MPa)

28.4

28d (MPa)

34.5

Water dem

(% for NC)

24.8

Flow@

48%W/C

113

Gypsum

dehydrant(%)

65%

Setting time

VIS(min)

120

VFS(min)

218

Blaine vs

325

40.6

Circuit characteristics

Mill

Diameter:

#1 comp length:

#2 comp length:

Power Connect:

Lining #1 comp:

Lining #2 comp:

Partition slots:

Discharge slots:

After

93.3

40.3

36

34.9

358

91.6

24.8

28.9

34.4

25.8

107

25

120

225

39.0

T1

Before

71

48.6

48.0

43.7

380

90

25.2

29.7

35.2

25.3

121

65

117

218

After

79.4

47.1

42.4

41.0

361

94.7

24.7

29.2

35.2

26.4

113

25

124

231

Separator

O'Sepa N-2000

Airflow design:

Pressure drop:

Rotor speed:

Feed capacity:

Power:

3.96 m

5.04 m eff

9.72 m eff

3581 kW

Lifting

Classifying

8mm-1

8mm+1

2000 m3/mi

8"

100-230 rpm

420 tph

200 HP AC var. freq

Ball charge (B mill)

comp

Volume load

comp

Volume load

Power kw

3"1/2

3"

2"1/2

2"1/2

2"

1"1/2

1"1/4

1"

3/4"

Before

20%

60%

20%

33%

7%

4%

8%

9%

12%

60%

34%

3100

After

20%

60%

20%

33%

3%

6%

9%

9%

22%

51%

36%

3260

Mill sweep

Separator

Primary

Aux

Secondary

Tertiary

TOTAL

Outlet fan

Temp

C

78.3

Press

"WG

-11

Flow

m3/h

34101

Flow

Nm/h

25781

15

66487

15

15

0

0

24079

13814

61

143381

63024

1301

22825

13095

100245

117156

4.15

Rev. 2002

CEMENT PROCESS ENGINEERING

VADE-MECUM

Separator sp =

Mill feed =

Mill #1 sound =

Mill #2 sound =

Tromp curve (A mill)

R/A) mean

CL

Acuity limit

174 RPM

79.2 t/h

78.2

62.5

Mill out temp =

Elevator =

Mill =

Type 10

= 0.656

= 191%

= 12 m

SECTION 4 MILLING

84 C

34 kW

3101 kW

Bypass

Imperfection

Rosin-Rammler(fine)

=8%

= 0.39

= 1.15

2.5 Recommended Steps for Sizing a HES

a)

Estimate new production rate

Assume a specific power consumption for an optimized ball mill with HES (37 kWh/t TI @3700 Blaine)

Back calculate the production rate based on the available motor power

Use the standard Blaine adjustment formula (Prod1/Prod2 = [Blaine2/Blaine1]^1.4).

b) Fix the Qf/Qa target with the circulating load

Decreasing Qf/Qa (kg feed per Am3 of air) increases the separator efficiency but also increases the capital and

the operating costs.

The CTS process target is Qf/Qa = 1.6 @ CL (R/F) = 150%; Qa @ 65C; 3800 Blaine.

The CTS upper limit is Qf/Qa = 2.0. Lower than this only marginally improve the separator Imperfection and

Bypass of 2-5% and therefore has no effect on production or product quality

Other suppliers rules of thumb:

Fuller typically sizes at a Qf/Qa = 2.0-2.5 @ CL = 180%.

Christian Pfeiffer

- Finish mill:

Qf/Qa = 1.8 @ CL = 200%; Qa @ 90C; 3500 Blaine; Qp/Qa (kg fines per m3 of air)

3000 Blaine

0.75-0.80 kg/Am3

4000

0.55-0.60

5000

< 0.50

- Raw mix:

Qf/Qa = 2.2 @ CL = 200%; Qa @ 90C; 12-14%R 90 m., Qp/Qa: 0.55 kg/m3.

- Slag: Christian Pfeiffer sizes slightly larger for slag circuits due to lower density and higher CL, as does

Polysius.

c)

Fan and Bag House Sizing

Use the new production rate (T/h), Qf/Qa (kg/ Am3) and circulating load (%) to specify the air flow.

Most separators can operate at +/- 20% of nominal.

Only a margin of 5 - 8% above the separator airflow is recommended for the BH.

Margin of 5-10% is recommended on top of the BH for the fan.

Correctly specifying the static pressure:

- Pressure drop can be estimated by the dP of the separator (8-12"), D/C (4-8"), ducting. (3-6") and if

present, silencer (1-2").

- The recommendation is 26 in WG with a minimum of 24 in WG.

Include in the circuit design, the possibility to recirculate from 0-80% of the separator airflow.

4.16

Rev. 2002

CEMENT PROCESS ENGINEERING

VADE-MECUM

SECTION 4 MILLING

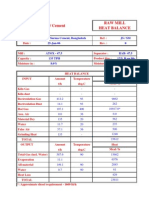

3. Heat and Water Balance

a) Water

Gypsum dehydration

Water generated = 0.156977*M*K*D

where:

- M = kg/h of SO3 source excluding clinker,

- K = % pure CaSO4(2H2O)

- D = % dehydration (from DSC)

Spray cooling with water

Water flow(kg/h) = Q*Cp*(Tf-Ti)/((100-Tw)+538.9*f)

where:

- Tf and Ti are the temperatures of material or gas before and after cooling (in C)

- Cp (kcal/kg) is the specific heat of material or gas and Q its flow rate (kg/h)

- Tw is the water temperature (C) and f is the % water evaporated.

Rule of thumb

Usually, water flow ranges from 0 to 3 % of the mill production

b) Heat balance

Mill heat generation

Kcal/h = kWh (power measured)*factor*860

Factor = 0.75 for vertical mill and 0.9 for ball mill

Furnace wall losses

About 5kcal/kg fuel

c) Mill heat balance sheet

Mill Product Rate (STPH)

Feed Temperature ___________ Percent H2O

%

Mill Diameter_ Ft. Mill Length____ Ft. Mill Motor HP

Mill Liner Thickness ________in Ball Charge

%

Separator Ventilator

Volume

ACFM

Temperature

F

Pressure

in.H2O

Mill Ventilator

Volume

ACFM

Temperature

F

Pressure

in.H2O

Baghouse Ventilator

Volume

ACFM

Temperature

F

Pressure

in.H2O

Auxiliary Ventilator

Volume

ACFM

Temperature

F

Pressure

in.H2O

Percent H2O in

Separator Rejects

Product

Mill Discharge

Percent Recirculating Load

%

Percent Leakage Into Separator (CFM)

Maximum Separator Inlet Temperature

Ambient Temperature

F

Percent Relative Humidity

%

Plant Altitude

FT

Fuel Type

Heat

Value

Separator Rejects Temperature F

Product Temperature

F

Baghouse Cloth Area

FT2

Number of Compartments

Number of Compartments Cleaning Together

4.17

Rev. 2002

%

%

%

%

F

CEMENT PROCESS ENGINEERING

VADE-MECUM

SECTION 4 MILLING

4. Grinding Aid

Type of Products

Surface active agents tend to saturate the free valence and inhibit the pack-set. Typical surface-active agents

are:

- ligno-sulphonates

- polyoils

- amines

- organic acids

Polar compounds (water, ammonia) are known to have some action on such bonds through their polar moment.

However, their practical use as surface agents is limited by their other impacts on the cement properties.

Other agents, particularly coal dust, have been used in the past.

Commercial products available as grinding aids are essentially (60-800 g/t ck):

- Triethanolamine

- Polypropyleneglycols and polyethylene

HEA2, DDA& and other products cause a definite reduction of pack-set but do not prevent agglomeration or

lump-formation problems that are caused by:

- Alkalis ( K 2 SO4 )

- Moisture

The effect of grinding aid on milling process:

- Enhances the flowability and prevents agglomeration

- Prevents coating on liners and grinding media- Decreases the "Blaine: Passing 325" ratio

- Is lLowers effect on coarser product (below 320 m2/kg)

- Reduces contraction

Example Bath

HEA2 on the feeding belt, Range: 0.1-0.2 kg/t of kk

Specific gravity: 1.195 kg/l, % active agent: 70%

0.15

* 1.31 = 0.234 $/t kk

Price: 1.31 $/l, Cost:

0.7 * 1.195

At kWh/t cte, 200g/t of glycol: +80 SSB

Production increase and pack set decrease. Mixed with water (3/1) and injected in #1 comp

HEA2 (Grace)

0.025% weight per weight of kk

2.02$/kg

6% production increase

reduce cracks

HEA2/rm (Grace)

0.078% weight per weight of kk

1.48$/kg

for a higher setting time (20 min)

4.18

Rev. 2002

CEMENT PROCESS ENGINEERING

VADE-MECUM

SECTION 4 MILLING

5. Sieve

Sieve Screen

#400

#325

#270

#230

#200

#170

#140

#120

#100

#80

#70

#60

#50

#45

#40

#35

#30

#25

#20

#18

#16

Micron

37

44

53

63

74

88

105

125

149

177

210

250

297

354

420

500

595

707

1000

Iso alter

38

45

53

63

75

90

106

125

150

180

212

250

300

355

425

500

600

710

850

1000

1180

Screen

#14

#12

#10

#8

#7

#6

#5

#4

#3.5

1/4"

5/16"

3/8"

7/16"

1/2"

5/8"

3/4"

7/8"

1"

1"1/4

1"1/2

2"

Micron

2000

6350

8000

9510

11200

12700

16000

19000

22600

25400

32000

38100

50800

Iso alter

1400

1700

2000

2360

2800

3350

4000

4750

5600

6300

8000

9500

11200

12500

16000

19000

22400

25000

31500

38100

50000

4.19

Rev. 2002

You might also like

- Lucie MillDocument50 pagesLucie MillJoko DewotoNo ratings yet

- Blaine Vs OutputDocument2 pagesBlaine Vs OutputAaron HortonNo ratings yet

- Cement Mill Ball Mill TestingDocument30 pagesCement Mill Ball Mill Testingzementhead100% (2)

- Tromp Curve Calculations and ResultsDocument3 pagesTromp Curve Calculations and Resultsrecai100% (2)

- .Improvement in Performance of Ball Mill in Cement GrindingDocument4 pages.Improvement in Performance of Ball Mill in Cement Grindingdeni jakaNo ratings yet

- Cement Milling I Blue Circle PDFDocument24 pagesCement Milling I Blue Circle PDFIrshad HussainNo ratings yet

- HOCM MAR Fez CoolerHeatBalanceDocument1 pageHOCM MAR Fez CoolerHeatBalanceOUSSAMA LAKHILI100% (2)

- Cement Chapter 4Document11 pagesCement Chapter 4shani5573100% (2)

- Rotary Kiln-1910 PDFDocument96 pagesRotary Kiln-1910 PDFSunday Paul100% (1)

- Fan Flow CalculationDocument1 pageFan Flow CalculationvvijaybhanNo ratings yet

- Grinding Media Pattern & Charge CalcDocument1 pageGrinding Media Pattern & Charge CalcJayaram SudhakarNo ratings yet

- Pyro ProcessingDocument29 pagesPyro ProcessingMKPashaPasha100% (2)

- Odudimu Certification ScenerioDocument50 pagesOdudimu Certification Scenerioabosede2012No ratings yet

- Optimum efficiency range for separator performanceDocument3 pagesOptimum efficiency range for separator performanceShakil AhmadNo ratings yet

- Cement Mill Calculation DesaignDocument1 pageCement Mill Calculation DesaignHilmy MuhammadNo ratings yet

- A Better Kiln CoatingDocument2 pagesA Better Kiln Coatingamir100% (4)

- 06 SeparatorDocument91 pages06 SeparatorVăn Vinh100% (2)

- B Level Audit For Ball MillDocument27 pagesB Level Audit For Ball MillTin Nguyen100% (1)

- Heat Balance of Kilns and Coolers and Related Topics PDFDocument62 pagesHeat Balance of Kilns and Coolers and Related Topics PDFAli HüthütNo ratings yet

- Grinding With Tube MillDocument43 pagesGrinding With Tube MillGorissNo ratings yet

- R A R F U: % Passing Size, M Feed Coarse FinesDocument3 pagesR A R F U: % Passing Size, M Feed Coarse FinesAli HüthütNo ratings yet

- Mill Ventilation MeasurementDocument5 pagesMill Ventilation MeasurementBùi Hắc HảiNo ratings yet

- Raw Mill Heat BalanceDocument1 pageRaw Mill Heat BalanceElwathig Bakhiet100% (1)

- Lafarge Process Engg ManualsDocument132 pagesLafarge Process Engg ManualsYhane100% (1)

- 273Document75 pages273LabroufiAbdelouahedNo ratings yet

- Red RiverDocument16 pagesRed RiverNael100% (1)

- Decarbonisation Cement IndustryDocument96 pagesDecarbonisation Cement IndustryKevin AdiwidjajaNo ratings yet

- The KilnDocument43 pagesThe Kilnraja ghoshNo ratings yet

- Sepax SeperatorDocument6 pagesSepax Seperatoradanis01100% (1)

- Cooler Design and Operation CriteriaDocument19 pagesCooler Design and Operation Criteriatricky777100% (1)

- Grinding Mills Optimisation: Magotteaux / Slegten / Sturtevant SolutionsDocument44 pagesGrinding Mills Optimisation: Magotteaux / Slegten / Sturtevant Solutionsshani5573100% (1)

- Cooler Air Flow Vs Kiln FeedDocument2 pagesCooler Air Flow Vs Kiln FeedBùi Hắc HảiNo ratings yet

- Loesche Round Table VICATDocument20 pagesLoesche Round Table VICATFirdaus Azizan86% (7)

- BM TrompcurveDocument1 pageBM Trompcurveniladri.jagatyNo ratings yet

- Rotary Kiln Operation .Kiln Feed Vs Kiln Speed CalculationDocument1 pageRotary Kiln Operation .Kiln Feed Vs Kiln Speed CalculationVijay Bhan80% (5)

- Precalciner Kilns Systems & OperationDocument58 pagesPrecalciner Kilns Systems & OperationYhaneNo ratings yet

- Ball - Mill - Finish Mill Ball Charge CalculationDocument3 pagesBall - Mill - Finish Mill Ball Charge CalculationVijay Bhan50% (2)

- Measuring False Air in Pyroprocessing SystemsDocument3 pagesMeasuring False Air in Pyroprocessing SystemsharyantoaditNo ratings yet

- Refractory Thickness in Rotary KilnDocument3 pagesRefractory Thickness in Rotary KilnDileepSaragadamNo ratings yet

- Optimizing Raw Mills PerformanceDocument9 pagesOptimizing Raw Mills PerformanceIrshad HussainNo ratings yet

- Improvement of Productivity Using Tromp Curve MeasDocument11 pagesImprovement of Productivity Using Tromp Curve MeasRachit Bansal BJ20099No ratings yet

- Days 1+2 - Learning Objectives: at The End of The 2 Days The Trainee Shall Be Able ToDocument24 pagesDays 1+2 - Learning Objectives: at The End of The 2 Days The Trainee Shall Be Able ToeeekkkgggNo ratings yet

- FormulaeDocument163 pagesFormulaeilvspeedNo ratings yet

- Kiln Golden RulesDocument19 pagesKiln Golden RulesWisnu Indriyanto50% (2)

- V5 Process Technology 3Document441 pagesV5 Process Technology 3Pavel ParfenovNo ratings yet

- Grinding and Classifying Technology For Slag: Replacement Factors DryingDocument6 pagesGrinding and Classifying Technology For Slag: Replacement Factors DryingGerman Gabriel Anaya Vega100% (1)

- Kiln AuditDocument13 pagesKiln AuditAdnan Nawaz100% (2)

- Pre-Homogenization Factor PDFDocument6 pagesPre-Homogenization Factor PDFAfqan B-v0% (1)

- Precalciner Systems Cement IndustryDocument22 pagesPrecalciner Systems Cement IndustryfaheemqcNo ratings yet

- Mill Testing Optimisation and TargetingDocument134 pagesMill Testing Optimisation and TargetingArtemMirra90% (10)

- Finish Grinding by Roller PressDocument3 pagesFinish Grinding by Roller PressManish Verma100% (3)

- Rotary Kilns: Transport Phenomena and Transport ProcessesFrom EverandRotary Kilns: Transport Phenomena and Transport ProcessesRating: 4.5 out of 5 stars4.5/5 (4)

- Ball Mill OptimizationDocument82 pagesBall Mill OptimizationRashek_119588% (16)

- Cement Mill NotebookDocument32 pagesCement Mill NotebookNael92% (50)

- Cement Separator & Ball Mill OptimizationDocument29 pagesCement Separator & Ball Mill OptimizationAdelezzat OmranNo ratings yet

- Cement Mill NotebookDocument32 pagesCement Mill Notebookhamedmustafa093100% (1)

- Ball Mill Testingjune99Document29 pagesBall Mill Testingjune99Shakil Ahmad83% (6)

- Rotor Spinning Mill PlanDocument35 pagesRotor Spinning Mill Planstylish eagleNo ratings yet

- Cyclone Sizing Selection GuideDocument18 pagesCyclone Sizing Selection GuideLuis VelasquezNo ratings yet

- Cooling BedDocument47 pagesCooling BedSubrata ChakrabortyNo ratings yet

- Req 4 422108 0 enDocument2 pagesReq 4 422108 0 enMKPashaPashaNo ratings yet

- Filtration: Fiber FilterDocument20 pagesFiltration: Fiber FilterTamer Farouk KhalifaNo ratings yet

- Mechanical Properties For Steel FastenersDocument7 pagesMechanical Properties For Steel FastenersepriyonoNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- POwise Monthly Trend-153Document1 pagePOwise Monthly Trend-153MKPashaPashaNo ratings yet

- POwise Monthly Trend-812Document1 pagePOwise Monthly Trend-812MKPashaPashaNo ratings yet

- Lucky Cement Raw Mill Budget vs Actual July-August 2012Document1 pageLucky Cement Raw Mill Budget vs Actual July-August 2012MKPashaPashaNo ratings yet

- POwise Monthly Trend-102Document1 pagePOwise Monthly Trend-102MKPashaPashaNo ratings yet

- Creating A BudgetDocument131 pagesCreating A BudgetMKPashaPashaNo ratings yet

- Summerized Form of Budget - PO WISEDocument6 pagesSummerized Form of Budget - PO WISEMKPashaPashaNo ratings yet

- POwise Monthly Trend-812Document1 pagePOwise Monthly Trend-812MKPashaPashaNo ratings yet

- POwise Monthly Trend-205206207Document1 pagePOwise Monthly Trend-205206207MKPashaPashaNo ratings yet

- POwise Monthly Trend-405406407Document1 pagePOwise Monthly Trend-405406407MKPashaPashaNo ratings yet

- POwise Monthly Trend-405406407Document1 pagePOwise Monthly Trend-405406407MKPashaPashaNo ratings yet

- POwise Monthly Trend-102Document1 pagePOwise Monthly Trend-102MKPashaPashaNo ratings yet

- AIS-Mechanical Maintenance ModuleDocument3 pagesAIS-Mechanical Maintenance ModuleMKPashaPashaNo ratings yet

- Process Guidelines for Cement Production OptimizationDocument20 pagesProcess Guidelines for Cement Production OptimizationMKPashaPasha100% (4)

- CEMENT PROCESS ENGINEERING VADE-MECUM SECTION 7 - NOX, SOX, DUST, CO2 EMISSION GUIDEDocument14 pagesCEMENT PROCESS ENGINEERING VADE-MECUM SECTION 7 - NOX, SOX, DUST, CO2 EMISSION GUIDEMKPashaPashaNo ratings yet

- 01 - IP SOW Template v3.0Document26 pages01 - IP SOW Template v3.0MKPashaPashaNo ratings yet

- GCCL ManualDocument26 pagesGCCL ManualMKPashaPashaNo ratings yet

- Trainer Profile Detailed Course ContentsDocument12 pagesTrainer Profile Detailed Course ContentsMKPashaPashaNo ratings yet

- XClass - BrochureDocument25 pagesXClass - BrochureMKPashaPashaNo ratings yet

- PDDDocument77 pagesPDDMKPashaPashaNo ratings yet

- 117 - DWP Difficult Solid Fuel Burning 191207 - RDB&YJBDocument10 pages117 - DWP Difficult Solid Fuel Burning 191207 - RDB&YJBMKPashaPashaNo ratings yet

- Testing and Repairing Festo and Numatics Valve StacksDocument13 pagesTesting and Repairing Festo and Numatics Valve StacksMKPashaPashaNo ratings yet

- Design Manual WHADocument18 pagesDesign Manual WHAMKPashaPashaNo ratings yet

- Pyro ProcessingDocument29 pagesPyro ProcessingMKPashaPasha100% (2)

- The Marketing Environment and Competitor Analysis: - SWOT Analysis - PEST Analysis - Five Forces AnalysisDocument10 pagesThe Marketing Environment and Competitor Analysis: - SWOT Analysis - PEST Analysis - Five Forces AnalysisMKPashaPashaNo ratings yet

- GCCL ManualDocument26 pagesGCCL ManualMKPashaPashaNo ratings yet

- Pyro ProcessingDocument29 pagesPyro ProcessingMKPashaPasha100% (2)

- 1 KinematicsDocument65 pages1 KinematicsMohd ShaanNo ratings yet

- Fluid Bed DryerDocument3 pagesFluid Bed DryerPartha MukherjeeNo ratings yet

- Scilab Code for Fox and McDonald's Introduction to Fluid MechanicsDocument116 pagesScilab Code for Fox and McDonald's Introduction to Fluid MechanicsSneha SolankiNo ratings yet

- 02 BMFG 1213 - Atomic Structure and Bonding PDFDocument48 pages02 BMFG 1213 - Atomic Structure and Bonding PDFHalizah RamthanNo ratings yet

- 03 Electrical NotesDocument27 pages03 Electrical NotesizzazackNo ratings yet

- Hydrogen-Like Atoms: Energy LevelDocument13 pagesHydrogen-Like Atoms: Energy LevelJohn DoeNo ratings yet

- Complex PotentialDocument2 pagesComplex PotentialAshvin Grace100% (1)

- Analysis of Laterally Loaded Drilled Shafts and Piles Using LpileDocument51 pagesAnalysis of Laterally Loaded Drilled Shafts and Piles Using LpileSudharsananPRSNo ratings yet

- HGJHGHJDocument1 pageHGJHGHJVenom GamingNo ratings yet

- And Alu SiteDocument55 pagesAnd Alu SiteSimon Aristoteles BlessiaNo ratings yet

- 9 3polarDocument9 pages9 3polarZazliana IzattiNo ratings yet

- Merchant's Circle NotsDocument5 pagesMerchant's Circle NotsSaravanan MathiNo ratings yet

- Topic 3 - Periodicity: Quick QuestionsDocument3 pagesTopic 3 - Periodicity: Quick QuestionsRafael Burgos CabanillaNo ratings yet

- 1 - Presentation Genencor 2011 05 25Document120 pages1 - Presentation Genencor 2011 05 25Kannan RanganathanNo ratings yet

- Agar Cubes (Diffusion)Document5 pagesAgar Cubes (Diffusion)shaharhr10% (1)

- Assignment 4 5Document4 pagesAssignment 4 5maluNo ratings yet

- Epoxy-OAT Composites Improve Mechanical PropertiesDocument9 pagesEpoxy-OAT Composites Improve Mechanical PropertiesSanket AntreNo ratings yet

- Birth and DeathDocument3 pagesBirth and DeathPralin Ponnanakal PremachandranNo ratings yet

- Introduction To Mechanical Vibrations EnotesDocument14 pagesIntroduction To Mechanical Vibrations Enotesaayushmech18100% (2)

- Crystal Violet Kinetics College Board Investigation 11 Student LabDocument10 pagesCrystal Violet Kinetics College Board Investigation 11 Student LabBrianaNo ratings yet

- Heat Trans - 2022 - Hussain - Significance of Solar Radiation and Magnetic Dipole Impact On Micropolar Ferromagnetic FluidDocument18 pagesHeat Trans - 2022 - Hussain - Significance of Solar Radiation and Magnetic Dipole Impact On Micropolar Ferromagnetic FluidMuazzamNo ratings yet

- Physics PaperDocument16 pagesPhysics Paperonitha812sellerNo ratings yet

- Geophysical Methods For Petroleum ExplorationDocument28 pagesGeophysical Methods For Petroleum ExplorationAbie Badhurahman100% (5)

- FFCR, Japan Monograph - Beet RedDocument2 pagesFFCR, Japan Monograph - Beet RedNur Hanisah MohtarNo ratings yet

- Flyer Misalignment Switch SLS EX - en PDFDocument4 pagesFlyer Misalignment Switch SLS EX - en PDFLazar MihailNo ratings yet

- CernDocument119 pagesCernCarlos Gustavo MoraesNo ratings yet

- Chapter 15 NotesDocument5 pagesChapter 15 NotesNicole BercegeayNo ratings yet

- 6 Interference FitsDocument42 pages6 Interference FitsMadhu Mitha50% (2)

- Metal Casting: Compiled By: Norliana Mohd AbbasDocument34 pagesMetal Casting: Compiled By: Norliana Mohd AbbasAziful AimanNo ratings yet

- Asco Series Nt320 Nuclear CatalogDocument4 pagesAsco Series Nt320 Nuclear CatalogJota JotaNo ratings yet