Professional Documents

Culture Documents

Welding Procedure

Uploaded by

GFDSGSRTGTRHOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure

Uploaded by

GFDSGSRTGTRHCopyright:

Available Formats

Topic No.

: 675-000-000

Materials Manual Effective: March 22, 2012

Steel and Miscellaneous Metal Products

Welding Procedure Specification Review and Approval Process 11-2-1

Chapter 11.2

Volume II

WELDING PROCEDURE SPECIFICATION

REVIEW AND APPROVAL PROCESS

11.2.1 PURPOSE

This procedure provides guidance to the fabricators for the review and approval

of the fabrication facilities welding procedure specifications.

11.2.2 AUTHORITY

Sections 20.23(3)(a) and 334.048(3), Florida Statutes (F.S.)

11.2.3 REFERENCES

American Association of State Highway Transportation Officials/National Steel

Bridge Alliance (AASHTO/NSBA) Steel Bridge Collaboration, Steel Bridge

Fabrication QC/QA Guide Specification S4.1

American Welding Society (AWS) AASHTO/AWS D1.5/D1.5M, Bridge Welding

Code

American Welding Society (AWS) D1.1/D1.1M, Structural Welding Code Steel

American Welding Society (AWS) D1.2/D1.2M,Structural Welding Code-

Aluminum

American Welding Society (AWS) D1.3/D1.3M, Structural Welding Code-Sheet

Steel

American Welding Society (AWS) D1.4/D1.4M, Structural Welding Code-

Reinforcing Steel

American Welding Society (AWS) D1.6/D1.6M, Structural Welding Code-

Stainless Steel

11.2.4 SCOPE

This procedure affects the fabrication facilities, the Florida Department of

Transportations (FDOT or Department) State Materials Office, and the

consultants who are involved in the verification and other quality assurance

Topic No.: 675-000-000

Materials Manual Effective: March 22, 2012

Steel and Miscellaneous Metal Products

Welding Procedure Specification Review and Approval Process 11-2-2

inspection and testing of the steel and miscellaneous metal products.

11.2.5 GENERAL INFORMATION

Each fabrication facility is required to perform welding in accordance with

Department approved Welding Procedure Specifications (WPS). All WPSs shall

be submitted on FDOT forms where those forms are available. Any forms not

available as FDOT forms may be submitted on the fabricators own form. Any

welding performed without Department approved WPSs may be subject to

rejection.

11.2.6 WPS REVIEW AND APPROVAL PROCESS

11.2.6.1 Review of Proposed WPSs

The fabrication facilitys AWS Certified Welding Engineer or AWS Certified

Welding Inspector will review, sign, and stamp the proposed WPSs. Upon

completion of each WPS, submit one stamped electronic copy in PDF format or

hard copy to the Departments responsible verification inspection consultant.

WPSs that require qualification testing shall be submitted with supporting

documentation in accordance with the appropriate code. Contact the State

Materials Office to determine the name of the verification inspection consultant

that is responsible for the review of the proposed Welding Procedure

Specifications.

The responsible verification inspection consultant reviews the submitted WPSs

and any associated Procedure Qualification Records (PQR). The original,

stamped welding procedures will be sent within two weeks of receipt of the

documents to the State Materials Office. The responsible verification inspection

consultant will place the review stamp on the front of each WPS indicating its

disposition. This disposition will be either approved or revise and resubmit.

If additional information is required for the review or if the WPS is rejected, the

responsible verification inspection consultant will contact the fabrication facility in

writing to request clarification, additional information, or resubmission of the

rejected procedure. The two-week review time clock will be reset after the

submittal of the additional information.

11.2.6.2 Maintaining Records of Approved Welding Procedure Specifications

The State Materials Office will store electronic copies of welding procedures

stamped approved on a secured limited access FDOT site maintained by the

State Materials Office.

Topic No.: 675-000-000

Materials Manual Effective: March 22, 2012

Steel and Miscellaneous Metal Products

Welding Procedure Specification Review and Approval Process 11-2-3

11.2.7 UTILIZATION OF THE APPROVED WPSs

The approved WPSs must be used on any applicable Department projects.

Submittals of WPSs on a per project basis are not necessary, unless the project

requires additional information that is not available in the current WPSs. WPSs

may be given an expiration date based on their PQRs or in accordance with the

appropriate AWS code. Approved WPSs may be used by the submitting

fabrication facility until they expire.

A list of the approved WPSs that the fabricator proposes for use on the project

must be provided with the submittal of shop drawings. The same list must also

be provided during the prefabrication meetings. At the completion of the project

the list of the Welding Procedure Specifications must be revised and resubmitted

to include the actual WPSs that were used.

If additional welding procedures are required for a particular project, or as

existing procedures expire, additional or new WPSs must be submitted to the

responsible verification inspection consultant for review as stated in Section

11.2.6.1.

The fabricator shall provide a stamped copy of each approved WPS when

requested by a Department representative. Copies of approved WPSs must be

posted in the fabrication shop for reference by shop personnel performing

welding.

11.2.8 PRODUCERS WITH ACCEPTED QUALITY CONTROL PLANS

All fabricators working on FDOT projects involving welding shall have applicable

WPSs approved by the Department prior to the commencement of welding,

whether or not the materials and welds are subject to inspection by the

Department..

11.2.9 TRAINING

No training is required for the implementation of this document.

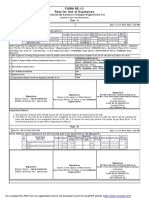

11.2.10 FORMS

The fabricator is responsible to make sure that they are using the most current

version of the following FDOT forms:

Fillet Weld Soundness Test D1.1/D1.1M-D1.5/D1.5M (Form 675-070-01)

Weld Procedure Qualification Record D1.2/D1.2M (Form 675-07-04)

Topic No.: 675-000-000

Materials Manual Effective: March 22, 2012

Steel and Miscellaneous Metal Products

Welding Procedure Specification Review and Approval Process 11-2-4

Weld Procedure Qualification Record D1.5/D1.5M (Form 675-07-03)

Welding Procedure Specification D1.1/D1.1M (Form 675-070-05)

Welding Procedure Specification D1.2/D1.2M (Form 675-070-06)

Welding Procedure Specification D1.5 (Form 675-070-02)

Topic No.: 675-000-000

Materials Manual Effective: March 22, 2012

Steel and Miscellaneous Metal Products

Welding Procedure Specification Review and Approval Process 11-2-5

APPENDIX A

FDOT FORM SAMPLES

Topic No.: 675-000-000

Materials Manual Effective: March 22, 2012

Steel and Miscellaneous Metal Products

Welding Procedure Specification Review and Approval Process 11-2-6

Topic No.: 675-000-000

Materials Manual Effective: March 22, 2012

Steel and Miscellaneous Metal Products

Welding Procedure Specification Review and Approval Process 11-2-7

Topic No.: 675-000-000

Materials Manual Effective: March 22, 2012

Steel and Miscellaneous Metal Products

Welding Procedure Specification Review and Approval Process 11-2-8

Topic No.: 675-000-000

Materials Manual Effective: March 22, 2012

Steel and Miscellaneous Metal Products

Welding Procedure Specification Review and Approval Process 11-2-9

Topic No.: 675-000-000

Materials Manual Effective: March 22, 2012

Steel and Miscellaneous Metal Products

Welding Procedure Specification Review and Approval Process 11-2-10

Topic No.: 675-000-000

Materials Manual Effective: March 22, 2012

Steel and Miscellaneous Metal Products

Welding Procedure Specification Review and Approval Process 11-2-11

You might also like

- Welding Quality Contral ChecklistDocument18 pagesWelding Quality Contral ChecklistRamzi BEN AHMED100% (1)

- 03-Procedure For WeldingDocument8 pages03-Procedure For WeldingAyush AgarwalNo ratings yet

- SP-2202 Specification For Electric Overhead Traveling CranesDocument15 pagesSP-2202 Specification For Electric Overhead Traveling CranesHaitham Mohammad100% (1)

- Welding Procedure PreparationDocument122 pagesWelding Procedure Preparationthe_badass1234100% (21)

- MS For Welding Consumable ControlDocument10 pagesMS For Welding Consumable Controlmansih457100% (1)

- Fabrication ProcedureDocument17 pagesFabrication ProcedureThi Pham100% (9)

- WELDING CONTROL PROCEDURE ASF-QC-WCP-001Document7 pagesWELDING CONTROL PROCEDURE ASF-QC-WCP-001el_sharkawy2011100% (1)

- WPS & PQRDocument84 pagesWPS & PQRjoseph.maquez24100% (4)

- Welding Procedure Specification GuideDocument23 pagesWelding Procedure Specification Guidearnoldbatista55100% (2)

- Welding control system method statementDocument14 pagesWelding control system method statementmansih457100% (1)

- C6 RS6 Engine Wiring DiagramsDocument30 pagesC6 RS6 Engine Wiring DiagramsArtur Arturowski100% (3)

- 6 Welding ProcedureDocument74 pages6 Welding Procedureadel100% (5)

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985From EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985No ratings yet

- Saep-1160 (NDT - Tracking and Reporting of Welding, NDT and Pressure Testing For Capital ProjectsDocument12 pagesSaep-1160 (NDT - Tracking and Reporting of Welding, NDT and Pressure Testing For Capital ProjectsShajin Mohammed Shamsudhin89% (9)

- Saep 324Document13 pagesSaep 324Hansel Francis100% (4)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- General Welding Fabrication and TestingDocument24 pagesGeneral Welding Fabrication and TestingAhmed FathyNo ratings yet

- Fabrication Inspection of Structural Steel Final 1.28.15Document12 pagesFabrication Inspection of Structural Steel Final 1.28.15Vinod Kumar Verma100% (1)

- TOTAL Welding Control Procedure Rev.2 PDFDocument116 pagesTOTAL Welding Control Procedure Rev.2 PDFWenney N Pali100% (1)

- Welder Quality ManualDocument36 pagesWelder Quality ManualJonNo ratings yet

- Method of Statment For Welding of Carbon Steel Pipes Dks-mst-c11-001 Rev 1Document17 pagesMethod of Statment For Welding of Carbon Steel Pipes Dks-mst-c11-001 Rev 1Sherief Abd El Baky83% (12)

- Welding Procedure SpecificationDocument101 pagesWelding Procedure SpecificationOsman Gone Rana63% (8)

- Materials Inspection ManualDocument280 pagesMaterials Inspection ManualSreedhar Patnaik.MNo ratings yet

- Hand Book For Steel Structure Quality Control on SiteFrom EverandHand Book For Steel Structure Quality Control on SiteNo ratings yet

- Welding Repair Procedure for Diesel Fuel TankDocument4 pagesWelding Repair Procedure for Diesel Fuel Tankgstketut100% (2)

- Welding Procedure SpecificationDocument21 pagesWelding Procedure Specificationboypardede100% (7)

- Welding Procedure Specification Review and Approval ProcessDocument4 pagesWelding Procedure Specification Review and Approval ProcessfallalovaldesNo ratings yet

- Engineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureDocument11 pagesEngineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureJaveed A. Khan100% (1)

- Welding Consumables ProcedureDocument7 pagesWelding Consumables ProcedureSenthil Kumaran100% (1)

- Welding Procedure Specification WPSDocument31 pagesWelding Procedure Specification WPSCui Xiao89% (9)

- Welding ConsumablesDocument128 pagesWelding ConsumablesAsad Bin Ala Qatari100% (1)

- Forensic Science From The Crime Scene To The Crime Lab 2nd Edition Richard Saferstein Test BankDocument36 pagesForensic Science From The Crime Scene To The Crime Lab 2nd Edition Richard Saferstein Test Bankhilaryazariaqtoec4100% (25)

- Welding InspectionDocument9 pagesWelding InspectionJackNo ratings yet

- Qualification of Welding Procedure Specification FCDocument14 pagesQualification of Welding Procedure Specification FCmister pogi100% (4)

- Welding Welding Procedure Qualification PDFDocument38 pagesWelding Welding Procedure Qualification PDFpratap biswas100% (1)

- Welding InspectionDocument16 pagesWelding Inspectionraguraman4u100% (3)

- 6 Welding Procedure Qualification & Welder QualificationDocument15 pages6 Welding Procedure Qualification & Welder QualificationSampath KumarNo ratings yet

- Welding Consumable and Storage ProcedureDocument10 pagesWelding Consumable and Storage Procedurehasan_676489616100% (1)

- PR-1272 Standard Welding PQRs For On-Plot PipingDocument10 pagesPR-1272 Standard Welding PQRs For On-Plot Pipinghappale2002No ratings yet

- Fit-Up Preparation and Acceptance Criteria As Per Project RequirementsDocument6 pagesFit-Up Preparation and Acceptance Criteria As Per Project RequirementsAbdülHak ÖZkaraNo ratings yet

- 04-SAMSS-035 ARAMCO General Reuirement For ValvesDocument18 pages04-SAMSS-035 ARAMCO General Reuirement For ValvesAhmed100% (4)

- Maverick Brochure SMLDocument16 pagesMaverick Brochure SMLmalaoui44No ratings yet

- Control of Welding Consumables ProcedureDocument16 pagesControl of Welding Consumables Procedureimran100% (1)

- Welding Procedure SpecificationDocument30 pagesWelding Procedure Specificationrahman196011100% (1)

- Welding ProcedureDocument38 pagesWelding ProcedureRicardo Ceballos100% (1)

- Field Welding Inspection GuideDocument15 pagesField Welding Inspection Guideranjit.rajappa19709872100% (19)

- 1 Qualified Welding Procedure Specifications: GeneralDocument15 pages1 Qualified Welding Procedure Specifications: GeneralAlaaNo ratings yet

- Case Study Hotel The OrchidDocument5 pagesCase Study Hotel The Orchidkkarankapoor100% (4)

- The Welding Inspection Services Are Define in Three Stages As BelowDocument9 pagesThe Welding Inspection Services Are Define in Three Stages As BelowdeliNo ratings yet

- Welding ProcedureDocument7 pagesWelding Proceduredương_thành_28No ratings yet

- Bs130 CSPG Guidelines 24062021 PDFDocument38 pagesBs130 CSPG Guidelines 24062021 PDFRamesh GuptaNo ratings yet

- 10080-1-SS-MT-007Document34 pages10080-1-SS-MT-007SURAJ PRSADNo ratings yet

- 141667-FAF-SPE-EOH-000007 OEE Galvanised Structural Steel Specifications PDFDocument12 pages141667-FAF-SPE-EOH-000007 OEE Galvanised Structural Steel Specifications PDFmarigusatuNo ratings yet

- Engineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 3, Welding Procedure SpecificationDocument5 pagesEngineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 3, Welding Procedure SpecificationHadi BarakNo ratings yet

- Guideline - Review - of - Supplier - Welding - Docs (18.08)Document32 pagesGuideline - Review - of - Supplier - Welding - Docs (18.08)Jodan AsiborNo ratings yet

- GWS 1 02 Procedure R7Document11 pagesGWS 1 02 Procedure R7Vuong BuiNo ratings yet

- MDOT Welder Certification Program OverviewDocument4 pagesMDOT Welder Certification Program OverviewedwinNo ratings yet

- Material Acceptance Is Documentation That Provides An Adequate Level of Quality Assurance For The Material Being AppliedDocument3 pagesMaterial Acceptance Is Documentation That Provides An Adequate Level of Quality Assurance For The Material Being AppliedmovilaNo ratings yet

- 5.1.4 Fire Fighting Appliance Construction StandardsDocument7 pages5.1.4 Fire Fighting Appliance Construction StandardsAdi DarmawanNo ratings yet

- 1390-Twi 552 Elec Rev.3 Sep 5Document11 pages1390-Twi 552 Elec Rev.3 Sep 5Joel AlcantaraNo ratings yet

- DIN Flange Dimensions PDFDocument1 pageDIN Flange Dimensions PDFrasel.sheikh5000158No ratings yet

- Oxford Digital Marketing Programme ProspectusDocument12 pagesOxford Digital Marketing Programme ProspectusLeonard AbellaNo ratings yet

- Dole-Oshc Tower Crane Inspection ReportDocument6 pagesDole-Oshc Tower Crane Inspection ReportDaryl HernandezNo ratings yet

- Prenatal and Post Natal Growth of MandibleDocument5 pagesPrenatal and Post Natal Growth of MandiblehabeebNo ratings yet

- Electronics Ecommerce Website: 1) Background/ Problem StatementDocument7 pagesElectronics Ecommerce Website: 1) Background/ Problem StatementdesalegnNo ratings yet

- The European Journal of Applied Economics - Vol. 16 #2Document180 pagesThe European Journal of Applied Economics - Vol. 16 #2Aleksandar MihajlovićNo ratings yet

- Petty Cash Vouchers:: Accountability Accounted ForDocument3 pagesPetty Cash Vouchers:: Accountability Accounted ForCrizhae OconNo ratings yet

- Journal Entries & Ledgers ExplainedDocument14 pagesJournal Entries & Ledgers ExplainedColleen GuimbalNo ratings yet

- PESO Online Explosives-Returns SystemDocument1 pagePESO Online Explosives-Returns Systemgirinandini0% (1)

- Phys101 CS Mid Sem 16 - 17Document1 pagePhys101 CS Mid Sem 16 - 17Nicole EchezonaNo ratings yet

- System: Boehringer Mannheim/Hitachi AnalysisDocument20 pagesSystem: Boehringer Mannheim/Hitachi Analysismaran.suguNo ratings yet

- The Ultimate Advanced Family PDFDocument39 pagesThe Ultimate Advanced Family PDFWandersonNo ratings yet

- Accomplishment Report 2021-2022Document45 pagesAccomplishment Report 2021-2022Emmanuel Ivan GarganeraNo ratings yet

- India: Kerala Sustainable Urban Development Project (KSUDP)Document28 pagesIndia: Kerala Sustainable Urban Development Project (KSUDP)ADBGADNo ratings yet

- CMC Ready ReckonerxlsxDocument3 pagesCMC Ready ReckonerxlsxShalaniNo ratings yet

- Evolution of Bluetooth PDFDocument2 pagesEvolution of Bluetooth PDFJuzerNo ratings yet

- Orc & Goblins VII - 2000pts - New ABDocument1 pageOrc & Goblins VII - 2000pts - New ABDave KnattNo ratings yet

- Inventory Control Review of LiteratureDocument8 pagesInventory Control Review of Literatureaehupavkg100% (1)

- всё необходимое для изучения английского языкаDocument9 pagesвсё необходимое для изучения английского языкаNikita Chernyak100% (1)

- CR Vs MarubeniDocument15 pagesCR Vs MarubeniSudan TambiacNo ratings yet

- MODULE+4+ +Continuous+Probability+Distributions+2022+Document41 pagesMODULE+4+ +Continuous+Probability+Distributions+2022+Hemis ResdNo ratings yet

- Android software download guideDocument60 pagesAndroid software download guideRizky PradaniNo ratings yet

- Guiding Childrens Social Development and Learning 8th Edition Kostelnik Test BankDocument16 pagesGuiding Childrens Social Development and Learning 8th Edition Kostelnik Test Bankoglepogy5kobgk100% (27)

- STAT455 Assignment 1 - Part ADocument2 pagesSTAT455 Assignment 1 - Part AAndyNo ratings yet

- UAPPDocument91 pagesUAPPMassimiliano de StellaNo ratings yet

- Sewage Pumping StationDocument35 pagesSewage Pumping StationOrchie DavidNo ratings yet