Professional Documents

Culture Documents

Ball Valve Testing Procedure

Uploaded by

Vipul PanchalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ball Valve Testing Procedure

Uploaded by

Vipul PanchalCopyright:

Available Formats

Test

Procedure

for

Floating

ball valves

VTP-01

VOLTECH TEJAS VALVES PVT LTD

VTP-01

Test Procedure for Floating Ball Valves

Prepared : KPR Checked : PMK Approved : IRS

Issue Date : Nov 12,2010 Revision No : 00 Revision Date :

VTVPL/VTP-01 Page 2 of 7

Table of Contents

Sl.No Description Page No

1.0 Scope 01

2.0 Relevant Standard 01

3.0 Test Requirements 01

4.0 Test Fluid 05

5.0 Test Gauges 05

6.0 Test Certification 06

VOLTECH TEJAS VALVES PVT LTD

VTP-01

Test Procedure for Floating Ball Valves

Prepared : KPR Checked : PMK Approved : IRS

Issue Date : Nov 12,2010 Revision No : 00 Revision Date :

VTVPL/VTP-01 Page 3 of 7

1.0 SCOPE

The scope of this document is to define the factory test requirements for floating ball

valves. Standard testing comprises hydrostatic testing of the pressure envelope (body),

and seat tightness testing (hydrostatic and/or pneumatic) as applicable.

2.0 RELEVANT STANDARD

The requirements set out in this document are in accordance with the following national

and international standard:

01. API 598 - Valve Inspection and Testing

02. BS 6755 part1 - Testing of valves

03. BS EN12266 part1 - Industrial valves - Testing

The hydrostatic test pressures expressed in this standard comply with ASME B16.50 for

flanges and fittings and ASME B16.34 for valves and BS EN 17292 for Class 800 valves

3.0 TEST REQUIREMENTS

3.1 General

Surface treatments of pressure containing valve components to prevent

corrosion during storage prior to and during manufacture with a single primer

coat(Minimum 5 microns thickness) or Phosphate/Black oxide coating is

acceptable provided these preservations do not hide any porosity.

3.2 Test Apparatus

Valves which are flanged end connections must not be tested on equipment

which subjects the valve to externally applied loads which may affect the body

joint sealing performance. Single piece bodied valves may be clamped.

VOLTECH TEJAS VALVES PVT LTD

VTP-01

Test Procedure for Floating Ball Valves

Prepared : KPR Checked : PMK Approved : IRS

Issue Date : Nov 12,2010 Revision No : 00 Revision Date :

VTVPL/VTP-01 Page 4 of 7

3.3 HYDROSTATIC SEAT TEST

a) PRINCIPLE :

The seat test assesses the sealing capability of the Valve Seat(s) in the direction

for which the valve is designed. Since ball valve is bi-directional, can be tested in

any direction.

b) PROCEDURE:

Using the clean dry cloth, wipe the Seat(s) clean (Not for Valves where Lubricant

or sealing Compound is the primary means of sealing), if accessible.

Clamp the Valve; fill the Valve including the Body / Cavity, with Test Fluid.

Move the obturator to the closed position, apply and maintain the test pressure

as per standard (Ref. Table 1, 3, 4.) on one side of the valve.

c) CRITERIA FOR ACCEPTANCE:

No visually detectable leakage for the duration of test time as given in the

appropriate valve product standard or test duration mentioned in (Table 2, 5.)

from the vent area.

d) Repeat the same procedure in other stream side and check for leakages.

3.4 HYDROSTATIC SHELL TEST

a) PRINCIPLE:

The shell test assesses the pressure containing capability of the Valve Shell.

b) PROCEDURE

Keep the assembled Valve in partially opened position and clamp the Valve on the Test

Rig.

Fill the cavity with the Test Liquid (Water), vent off the air from the cavity and blank off

the ends of the Valve.

Apply the Test Pressure as per Standards (Ref. Table 1.) and maintain the Test

Pressure to a period specified as per Standard (Ref. Table 2.).

In the mean time inspect the Valve Shell (Body) thoroughly.

VOLTECH TEJAS VALVES PVT LTD

VTP-01

Test Procedure for Floating Ball Valves

Prepared : KPR Checked : PMK Approved : IRS

Issue Date : Nov 12,2010 Revision No : 00 Revision Date :

VTVPL/VTP-01 Page 5 of 7

c) CRITERIA FOR ACCEPTANCE:

Visually detectable leakage / wetting through the pressure Boundary Walls is not

acceptable. Stem Seal Leakage during the Shell test shall not be the cause for rejection,

provided that the stem seals when the internal test pressure is reduced to the maximum

permissible working pressure at 20 C.

3.5) PNEUMATIC SEAT TEST

a) PROCEDURE:

Clamp the Valve, and move the obturator to close position.

Apply the Pneumatic Test Pressure on the upstream side of the closed Valve and

maintain the pressure as per standard.

b) CRITERIA FOR ACCEPTANCE:

No visually detectable leakage for the duration of test time as given in the appropriate

valve product standard or test duration mentioned in Table 2.

Repeat the same procedure in other stream side and check for leakages.

4.0 Test Fluid

4.1 Test Liquid

Hydrostatic tests shall be carried out with water at ambient temperatures, within

the range of 41 F (5 C) and 122 F (50 C),unless the use of another liquid is agreed

between the purchaser and the manufacturer. If water is used, it will contain

water-soluble oil or rust inhibitor. Potable water used for pressure test of

austenitic stainless steel valves shall have chloride content less than 30ppm and

for carbon steel valves shall be less than 200ppm.

4.2 Cleaning

Austenitic and duplex stainless steel valves and valves made of 9% nickel alloy

shall be flushed with demineralized water (chloride content of 1ppm maximum)

immediately after the hydrostatic test.

VOLTECH TEJAS VALVES PVT LTD

VTP-01

Test Procedure for Floating Ball Valves

Prepared : KPR Checked : PMK Approved : IRS

Issue Date : Nov 12,2010 Revision No : 00 Revision Date :

VTVPL/VTP-01 Page 6 of 7

4.3 Drying

After Hydrostatic testing, the valves should be blown through using dry

compressed air, followed by a visual inspection for dryness. If moisture is still

found, the above process shall be repeated until visually dry.

5.0 Test Gauges

Test bay gauges shall be calibrated at intervals not exceeding three months.

6.0 Test Certification

When specified by the purchaser, the manufacturer shall issue a BS EN10204

Type 3.1 test certificate confirming that the valves have been tested in

accordance with the requirements of this specification.

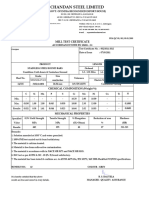

Table 1: Test Pressure

(ASME B 16.34 & BS EN 17292 for Class 800 valves)

Sl.No Valve Class Hydro Shell Hydro seat

Kg/cm2 psig Kg/cm2 psig

01 150 32 450 22 315

02 300 79 1125 58 815

04 800 105 1500 77 1100

03 600 157 2225 115 1630

05 900 236 3350 172 2445

06 1500 396 5575 287 4080

07 2500 649 9280 475 6790

VOLTECH TEJAS VALVES PVT LTD

VTP-01

Test Procedure for Floating Ball Valves

Prepared : KPR Checked : PMK Approved : IRS

Issue Date : Nov 12,2010 Revision No : 00 Revision Date :

VTVPL/VTP-01 Page 7 of 7

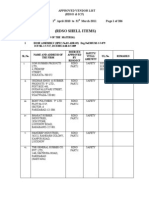

Table 2: Test Duration

Nominal Size (NPS) Minimum Test Duration (seconds)

Hydro shell test Back seat test Hydro seat

test

Air seat

test

< 2 15 15 15 15

2 6 60 60 60 60

8 12 120 60 120 120

>14 300 60 120 120

Note: The test duration is the period of inspection after the valve is fully prepared and is

under full pressure.

You might also like

- QCP-12 Valve Leak Test Procedure PDFDocument21 pagesQCP-12 Valve Leak Test Procedure PDFIbrahim100% (3)

- MST Valve TestingDocument7 pagesMST Valve TestingSiva RamNo ratings yet

- Control Valve Test ProcedureDocument5 pagesControl Valve Test ProcedureMark Haizlip100% (2)

- Hydro Test ProceduresDocument10 pagesHydro Test Proceduresazimr157100% (1)

- Factory Acceptance Test & Inspection Test Report Pneumatic Ball Valve KSB Document No: PMT-INS-FIPBV-001 Rev: DDocument6 pagesFactory Acceptance Test & Inspection Test Report Pneumatic Ball Valve KSB Document No: PMT-INS-FIPBV-001 Rev: Dbayu dewantoNo ratings yet

- RELIEF VALVE TEST PROCEDUREDocument30 pagesRELIEF VALVE TEST PROCEDUREAnonymous ffje1rpa100% (1)

- Testing Procedure For Ball Valve MAPDocument16 pagesTesting Procedure For Ball Valve MAPbasuki100% (3)

- Hydrostatic Shell TestDocument5 pagesHydrostatic Shell TestsojeckNo ratings yet

- Testing Procedure of Ball ValveDocument2 pagesTesting Procedure of Ball Valverajesh100% (2)

- Ball Valve HandbookDocument13 pagesBall Valve HandbookGanesh Yadav100% (5)

- Valve Testing ProceduresDocument9 pagesValve Testing ProceduresFaiz Zainudin83% (6)

- Installing and Operating a Thermal Relief ValveDocument12 pagesInstalling and Operating a Thermal Relief ValveHiren Panchal100% (1)

- Hydrotest & Pneumatic TestDocument3 pagesHydrotest & Pneumatic TestjokishNo ratings yet

- API6D Ball Valves Inspection and Test ProceduresDocument5 pagesAPI6D Ball Valves Inspection and Test ProceduresChi Cha100% (2)

- Neles Seat Leakage SpecDocument9 pagesNeles Seat Leakage SpecIkhsan Ly100% (1)

- Flangemanagementpresentation 160911122834Document83 pagesFlangemanagementpresentation 160911122834Yusuf Alfathony100% (2)

- Ball Valve Overhaul ProcedureDocument7 pagesBall Valve Overhaul Procedurerocket789No ratings yet

- Hydro Test Procedure for Berri Development Onshore PipelinesDocument14 pagesHydro Test Procedure for Berri Development Onshore PipelinesARJUN100% (4)

- Api 598Document2 pagesApi 598Nitin Aggarwal78% (9)

- Design wellhead control panel specification under 40 charsDocument3 pagesDesign wellhead control panel specification under 40 charsaminmuminiNo ratings yet

- Valve Testing ProcedureDocument10 pagesValve Testing Proceduremoytabura96100% (5)

- Leakage of Valves - Testing API 598, ANSI FCI 70-2, MSS-SP-61 and ISO Standard 5208Document14 pagesLeakage of Valves - Testing API 598, ANSI FCI 70-2, MSS-SP-61 and ISO Standard 5208anon_9896895680% (1)

- Api-598-En-12266-1 Seat LeakDocument2 pagesApi-598-En-12266-1 Seat Leakelumalai24100% (10)

- PIPING PNEUMATIC TEST PROCEDUREDocument2 pagesPIPING PNEUMATIC TEST PROCEDUREruzla67% (3)

- Double Piston and Single Piston Effect in Ball ValvesDocument5 pagesDouble Piston and Single Piston Effect in Ball ValvesPipeline Engineer100% (6)

- STFFD-P1-004003-P05-0001 Rev C FAT Procedure For Complete SkidDocument50 pagesSTFFD-P1-004003-P05-0001 Rev C FAT Procedure For Complete SkidTuyen Pham100% (2)

- Inspection and Testing of ValveDocument5 pagesInspection and Testing of ValveCandy Kendee100% (2)

- Air Leak TestingDocument5 pagesAir Leak TestingsarikaNo ratings yet

- Hydrostatic Testing Procedure Pressure TestDocument4 pagesHydrostatic Testing Procedure Pressure Testmahi1437No ratings yet

- Pressure Test ProcedureDocument11 pagesPressure Test ProcedureRolando Nicanor0% (1)

- Pneumatic Testing Procedure For PipelinesDocument3 pagesPneumatic Testing Procedure For PipelinesKu Masayu Ku HusinNo ratings yet

- Hydro Test ProcedureDocument9 pagesHydro Test ProcedureAdeel QaiserNo ratings yet

- Tn-38 Bolt Torque Flanged JointsDocument37 pagesTn-38 Bolt Torque Flanged Jointsprabu prasadNo ratings yet

- Pipe Bending Procedure for Sulphuric Acid LineDocument7 pagesPipe Bending Procedure for Sulphuric Acid Linemohd as shahiddin jafri100% (1)

- Testing Procedure of Dual Plate Check ValveDocument2 pagesTesting Procedure of Dual Plate Check Valverajesh100% (2)

- PNEUMATIC TESTDocument2 pagesPNEUMATIC TESTdyke_engg50% (2)

- Control Valves ExplainedDocument58 pagesControl Valves ExplainedNIKHIL SHINDENo ratings yet

- Piping Hydrotest Procedure GuideDocument3 pagesPiping Hydrotest Procedure GuideFrank100% (6)

- Inspection and Test Plan For Line Pipe PDFDocument4 pagesInspection and Test Plan For Line Pipe PDFsherviny100% (1)

- Control Valves &safety ValvesDocument83 pagesControl Valves &safety ValvesGopi Krish100% (2)

- Valve Type Acceptance Testing ExperiencesDocument22 pagesValve Type Acceptance Testing ExperiencesJames ChaiNo ratings yet

- Boiler Hydrostatic TestingDocument2 pagesBoiler Hydrostatic Testingbonginkosi mathunjwaNo ratings yet

- Testing StandardDocument7 pagesTesting StandardDiego Fernando Pedroza UribeNo ratings yet

- 9501-PP-QA-009 Piping Leak Test Procedure R-0Document27 pages9501-PP-QA-009 Piping Leak Test Procedure R-0Josh RuddyNo ratings yet

- IENCSEPRO0007-2 - General Leak Test Procedure PDFDocument9 pagesIENCSEPRO0007-2 - General Leak Test Procedure PDFCatalinNo ratings yet

- API 527 - Seal Tightness of Pressure Relief Valves 3rd Ed.Document13 pagesAPI 527 - Seal Tightness of Pressure Relief Valves 3rd Ed.Melvin EbronNo ratings yet

- Procedure Manual: Ball Valve Hydro TestDocument5 pagesProcedure Manual: Ball Valve Hydro Testnima_h10No ratings yet

- ROCEDURE - INSPECTION & TEST ValvesDocument10 pagesROCEDURE - INSPECTION & TEST Valvessabes26No ratings yet

- C22-Yb60-F-4765 - 0 Sa3-Ps2, Butterfly Valve, Test ProceduresDocument8 pagesC22-Yb60-F-4765 - 0 Sa3-Ps2, Butterfly Valve, Test ProceduressartajNo ratings yet

- Shop Inspection & Test procedure-GVK-1Document7 pagesShop Inspection & Test procedure-GVK-1Sungil ChoiNo ratings yet

- Procedure Manual: Cast Valve ProductionDocument10 pagesProcedure Manual: Cast Valve ProductionParveen Kohli0% (1)

- 4008-Pi-Pro-001 - 0 - Piping Hydrotest Procedure-1Document8 pages4008-Pi-Pro-001 - 0 - Piping Hydrotest Procedure-1Randu WatangNo ratings yet

- Valves Valve LeakageDocument5 pagesValves Valve Leakagearson5646100% (1)

- Hydrotesting of VALVE AND REFURBISHMENT PROCEDUREDocument16 pagesHydrotesting of VALVE AND REFURBISHMENT PROCEDUREISAACNo ratings yet

- Boiler Hydrotest Procedure Boiler BDFB 350-1004Document10 pagesBoiler Hydrotest Procedure Boiler BDFB 350-1004Gunung A E SinamnbelaNo ratings yet

- Valve) - 2. End Fittings For ClosureDocument10 pagesValve) - 2. End Fittings For ClosureNaveen Vel100% (1)

- Hydo Test ProcedureDocument2 pagesHydo Test ProcedureAbdulMajidYousoffNo ratings yet

- Spe 77 - 307Document5 pagesSpe 77 - 307Dunamis Joe100% (1)

- Pneumatic Test ProcedureDocument10 pagesPneumatic Test ProcedureahmadNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- 5 WhyDocument26 pages5 Whybipin.chouguleNo ratings yet

- Sample Test Cert. 07.09.2011 - 02Document1 pageSample Test Cert. 07.09.2011 - 02Vipul PanchalNo ratings yet

- Engineering Bulletin: Rev. 10/07 Page 1 of 4Document5 pagesEngineering Bulletin: Rev. 10/07 Page 1 of 4Iván López PavezNo ratings yet

- Price of ErmetoDocument5 pagesPrice of ErmetoVipul PanchalNo ratings yet

- G & M CodeDocument4 pagesG & M CodeVipul PanchalNo ratings yet

- DEP 30.55.03.30-Gen. - 4Document19 pagesDEP 30.55.03.30-Gen. - 4Vipul PanchalNo ratings yet

- BD Series Ball ValveDocument2 pagesBD Series Ball ValveVipul PanchalNo ratings yet

- HAVI Takes Utmost Care While Producing A Product From Material Sourcing Till On-Site InstallationDocument1 pageHAVI Takes Utmost Care While Producing A Product From Material Sourcing Till On-Site InstallationVipul PanchalNo ratings yet

- A3925Document1 pageA3925Vipul PanchalNo ratings yet

- Tube Pressure RatingDocument1 pageTube Pressure RatingVipul PanchalNo ratings yet

- HAVI BrochureDocument4 pagesHAVI BrochureVipul PanchalNo ratings yet

- Business ProjectionDocument1 pageBusiness ProjectionVipul PanchalNo ratings yet

- System Process FlowDocument1 pageSystem Process FlowVipul PanchalNo ratings yet

- Sample Form For VisaDocument2 pagesSample Form For VisaVipul Panchal100% (1)

- 07 Master List of Test EquipmentsDocument1 page07 Master List of Test EquipmentsVipul PanchalNo ratings yet

- NCR-CC 001 12-13Document1 pageNCR-CC 001 12-13Vipul Panchal100% (1)

- SIL Made SimpleDocument12 pagesSIL Made SimpleandhrimnirNo ratings yet

- Gvba 8SW150 8N S6L CLDocument1 pageGvba 8SW150 8N S6L CLVipul PanchalNo ratings yet

- 02 Master List of Machine & EquipmentsDocument1 page02 Master List of Machine & EquipmentsVipul Panchal50% (2)

- Gvba 8N 16MGT S6L CLDocument1 pageGvba 8N 16MGT S6L CLVipul PanchalNo ratings yet

- Icf & Rdso Vendor ListDocument206 pagesIcf & Rdso Vendor ListVipul PanchalNo ratings yet

- Brief Company IntroductionDocument22 pagesBrief Company IntroductionVipul PanchalNo ratings yet

- Sin1111500 13 3 25Document95 pagesSin1111500 13 3 25asyrafmuhddNo ratings yet

- River Training and Protection WorksDocument8 pagesRiver Training and Protection Worksnandi_scrNo ratings yet

- Hardware Auto & MachineryDocument86 pagesHardware Auto & MachineryHenry ChanNo ratings yet

- Project steel section check summary for combo and stationDocument1 pageProject steel section check summary for combo and stationMoon AhaeNo ratings yet

- Journal of Rock Mechanics and Geotechnical Engineering: CorrigendumDocument2 pagesJournal of Rock Mechanics and Geotechnical Engineering: CorrigendumRadhi WahyuziNo ratings yet

- Skripsi Tanpa Bab PembahasanDocument64 pagesSkripsi Tanpa Bab PembahasanMuhammad Azhar100% (1)

- BOQ For Repair Work of 40'X20' Building at A/Selesthimaduwa VidyalayaDocument9 pagesBOQ For Repair Work of 40'X20' Building at A/Selesthimaduwa VidyalayaAnuranga SahampathNo ratings yet

- Experimental and Numerical Investigations On Seismic Responses of Reinforced Concrete Structures Considering Strain Rate EffectDocument15 pagesExperimental and Numerical Investigations On Seismic Responses of Reinforced Concrete Structures Considering Strain Rate EffectIon SococolNo ratings yet

- Domestic Gas PipingDocument2 pagesDomestic Gas Pipingvalentinlupascu33No ratings yet

- 4.3 Jahangir Shahjahan PDFDocument48 pages4.3 Jahangir Shahjahan PDFnaima jaleelNo ratings yet

- 5geb20c2 PB 31107 016Document6 pages5geb20c2 PB 31107 016lei songNo ratings yet

- ITP - Fire Extinguisher InstallationDocument7 pagesITP - Fire Extinguisher InstallationGultom Juliana LiliesNo ratings yet

- Hardie Reveal Panel Installation Instructions 1597005Document29 pagesHardie Reveal Panel Installation Instructions 1597005David TorskeNo ratings yet

- AlhambraDocument10 pagesAlhambraapi-377767762No ratings yet

- The Haryana Building CodeDocument130 pagesThe Haryana Building CodeArjun MiddhaNo ratings yet

- 6000 5 Inox LCDDocument17 pages6000 5 Inox LCDpotoculNo ratings yet

- Pipe Expansion and Support Methods ExplainedDocument23 pagesPipe Expansion and Support Methods ExplainedGodwinNo ratings yet

- TDS HIPERSITE W2000 (Black)Document1 pageTDS HIPERSITE W2000 (Black)It WittayaNo ratings yet

- CompanyListG LDocument198 pagesCompanyListG LMahasar SiddiquiNo ratings yet

- St Kevin's College Music Centre by Baldasso Cortese ArchitectsDocument24 pagesSt Kevin's College Music Centre by Baldasso Cortese ArchitectsArjun MiddhaNo ratings yet

- Worthington D1022 Pump DataSheet P-701Document10 pagesWorthington D1022 Pump DataSheet P-701Andrey Pulido Barrera100% (1)

- S Rinkler D I Az NG Protection of Exterior: AbstruetDocument23 pagesS Rinkler D I Az NG Protection of Exterior: AbstruetShashikant ChaturvediNo ratings yet

- Tree Cutting MethodDocument14 pagesTree Cutting MethodBienSabadoNo ratings yet

- Spilways Unit - IVDocument49 pagesSpilways Unit - IVvixivi6780100% (1)

- Catálogo EC200DDocument912 pagesCatálogo EC200DCasa da Madeira100% (1)

- Tape & Glue Process 2Document6 pagesTape & Glue Process 2ocolibriNo ratings yet

- Turner's IOR Key to Risk ManagementDocument9 pagesTurner's IOR Key to Risk Managementremya_392830015No ratings yet

- 3 Way Ball ValvesDocument17 pages3 Way Ball ValvesSagar Bhosale100% (1)

- Optimum Design of Castellated Beams Effect of Comp PDFDocument24 pagesOptimum Design of Castellated Beams Effect of Comp PDFAnika dixitNo ratings yet

- Max-3 Plus (420-2700) Technical Information & Assembly Instructions Manual PDFDocument60 pagesMax-3 Plus (420-2700) Technical Information & Assembly Instructions Manual PDFFlorentina SanduNo ratings yet