Professional Documents

Culture Documents

Failure of Road

Uploaded by

Umesh MishraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Failure of Road

Uploaded by

Umesh MishraCopyright:

Available Formats

1

1. INTRODUCTION

The success of geotechnical works on soft ground relies on

important factors including proper planning, analysis,

design, construction control and supervision. However,

most of the geotechnical failures investigated by the

Authors are usually quite similar in nature and they are

caused by failing to comply with one or a combination of

the factors stated above. Case histories of geotechnical

failures of embankments, foundations and excavations are

presented together with the causes of failures, remedial

works proposed and lessons learned. Finally, some simple

guidelines to prevent failures are also discussed.

2. TYPES OF FAILURE ON SOFT GROUND

Failures of projects on soft ground in this paper can be

broadly classified into two broad categories. The first

category includes those of total or partial collapse of

embankments, excavations, foundations, etc. This category

often needs reconstruction and/or strengthening measures.

The second category of failures is those due to lateral and

vertical movements resulting in severe distortion to

complete or adjacent structures causing loss of

serviceability. The affected structures usually need

expensive repairs or strengthening works.

The following are the case histories discussed in this paper:

(i) Failure of an Embankment

(ii) Failure of Bridge Foundations and Approach

Embankments

(iii) Failure of Approaches to Bridges and Culverts

3. FAILURE OF EMBANKMENTS

Failures of embankments often occur during construction.

A case history of an embankment initially constructed using

vacuum preloading method with prefabricated vertical

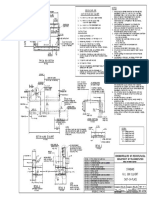

drains was investigated by the Authors. Figure 1 shows the

cross-section of the proposed embankment. After the 1

st

failure, the remedial works involving stone columns were

proposed and constructed. The embankment, with stone

columns, failed when the embankment reached 3.2m of the

planned 5.5m fill height. Figure 2 shows the embankment

after the 2

nd

failure.

As the effectiveness of the vacuum preloading method is

dependent on many factors, close monitoring of the pore

water pressures in the subsoil during filling is vital to

prevent failure. In view of this, instruments such as

piezometers, settlement gauges and vacuum meters have

been installed at site. Prior to embankment failure,

measurements from piezometers indicated that the vacuum

suctions were not functioning properly after finish fill

GEOTECHNICAL ENGINEERING CHALLENGES FOR HIGHWAY DESIGN AND

CONSTRUCTION ON SOFT GROUND

Ir. Dr. Gue, See-Sew, Dr. Wong, Shiao-Yun & Ir. Tan, Yean-Chin

G&P Geotechnics Sdn. Bhd.

gnp-geo@gnpgeoup.com.my

ABSTRACT: The success of geotechnical works on soft ground relies on important factors such as proper planning, analysis, design,

construction control and supervision. However, this is usually easier said than done, and therefore there are still repeated failures of

geotechnical works such as embankments, approaches to bridges and culverts. Most of the failures are quite similar in nature in that they

are caused by failing to comply with one or a combination of the above factors. This paper presents case histories of geotechnical failures

investigated by the Authors. The causes of failures, remedial works proposed and lessons learned are discussed. Finally, some simple

guidelines to prevent failures related to geotechnical works on soft ground are provided.

Keywords: Soft Ground; Failure; Embankment; Culvert; Bridge; Abutment

2

height of 5.5m. This in turn has caused the increase of pore

water pressures in the cohesive subsoil.

The trend of increase in pore water pressures has been

observed for more than one month but no action was taken

to review the monitoring results and prompt for preventive

action. In fact, it is clear that the 1

st

failure of Embankment

could have been avoided if the observational method (Peck,

1969) was employed properly. Details of back-analyses and

methodology of monitoring using the observational method

are presented by Gue et. al. (2001) and Tan & Liew (2000)

respectively.

3.1. Failure Due to General Shear

Our review indicates that the design by the Specialist

Contractor only used Priebes methods (1995) to check on

the stability and settlement of the subsoils treated with

stone columns. Based on the investigation, it is

recommended that when using stone columns in very soft

ground (e.g. s

u

< 15kPa) or as remedial measures for

reconstruction of failed embankments, attention should be

given to probable failure due to general shear instead of

over relying on a single method. For remedial measures, it

is also important to determine the representative

disturbed strength (remoulded and regaining of strength

through thixotropy effects) of the subsoil to be used in the

analyses. In addition, load tests should be carried out on

stone columns to verify the design assumptions as there are

large differences among methods of analysis. However,

many embankments on very soft ground treated with stone

columns have been successfully constructed with the help

of the observational method.

Failures of embankments due to design are commonly

caused by the following inadequacies :-

(i) Settlement Analysis

(ii) Stability of Embankment especially general shear

4. FAILURE OF BRIDGE FOUNDATIONS AND

APPROACH EMBANKMENT

Among the many case histories of bridge failures

investigated by the Authors, failure induced by bearing

capacity and stability of the embankment appear to be the

major contributing factors (Gue & Tan, 2003). The layout

of the proposed bridge is shown in Figure 3. Figure 4 shows

an overview of the failed embankment.

The approach embankments were constructed over 25m

thick of soft coastal and riverine alluvium clay underlain by

dense silty Sand and very stiff silty Clay. The approach

embankments were supported by reinforced concrete (RC)

piles and cast with individual pilecaps. The abutments and

piers were supported by spun piles driven to set in the hard

layer at more than 30m depth.

A deep seated slip failure occurred at the approach

embankment with a sheer drop at about 25m behind

Abutment II. Figure 5 shows the sheer drop after removal

of some of the fill behind the abutment. Abutment II tilted

Very Loose Cl ayey SAND

Medi um to Sti ff Si l ty CLAY and Cl ayey SILT

Embankment Fill

(Without Vacuum Preloading)

Embankment Fill (Failed Area)

(Vacuum Preloading with Vertical Drains)

Vertical Drai ns

Liner and Sand Layer

for Vacuum System

Scale (m)

0 5 10

Soft Sandy CLAY

Very Soft Si l ty CLAY

Fig. 1. Cross-section of Embankment A (After Gue et. al.,

2001)

Sheer Drop and Cracks

Fig. 2. Failure of Embankment A treated with Stone Columns (After Gue & Tan, 2004)

Heave Up

3

Fig. 4. Overview failed embankment (After Gue & Tan,

2003)

away from the river, with a magnitude of about 550mm at

the top of the abutment at the time of the site inspection by

the Authors, who were carrying out the geotechnical

investigation of the failure. The tilt translated into excessive

angular distortion affecting the integrity of the spun piles.

Due to the tilt of the Abutment II away from Pier II, a gap

about 300mm wide was observed between the two bridge

decks at the pier. Figure 6 shows the photograph of the tilt

at the Abutment II and the gap between two bridge decks at

Pier II. The failure also caused Pier II to tilt slightly.

Figure 7 shows the schematic diagram of the possible slip

plane relative to the deformed structures.

The above failures were caused by the following factors :-

(i) Inadequacy of geotechnical design for the

approach embankments and abutments.

(ii) Lack of understanding of the subsoil conditions

and awareness of the possible problems/failures

that could happen during construction.

(iii) Lack of construction control and site supervision

by the Consultant.

The following lessons learned are:

(i) Check for lateral soil pressure imposed on piles by

the embankment fill behind an abutment to prevent

failure of the pile group supporting the abutment.

(ii) The design consultant should review the submitted

method statement to avoid slip failure due to

instability of additional loads imposed by

temporary fill. Full-time site supervision by site

engineers having geotechnical experience and an

understanding of design concepts should also be

maintained to ensure compliance of both

temporary and permanent works.

Sheer Drop

Pilecaps

Fig. 5. Sheer Drop at about 25m behind the Tilted Abutment (After Gue & Tan, 2003)

Abutment II

Pier II

Abutment I

Pier I

Fig. 3. Layout of Piers and Abutments (After Gue & Tan,

2003)

4

(iii) The design consultant should ensure the removal

of temporary fill after construction or to design the

piles to accommodate negative skin friction, as

temporary fill would cause the compressible

subsoil to settle with time.

Detailed information on the above case history is

documented in Gue & Tan (2003) and Gue & Tan (2004).

Similar mode of failure was encountered in the case

histories of bridge failures investigated by the Authors, as

documented in Gue (1988).

Fig. 7. Schematic of Slip Failure (After Gue & Tan, 2003)

Fig. 6. Tilted Abutment and Observed Gap between Bridge Decks (After Gue & Tan, 2003)

Opening

between bridge

decks at Pier II

Opening

between bridge

decks at Pier II

Tilt from

Vertical

5

5. FAILURE OF APPROACHES TO BRIDGES

The most common old practice of bridge approach design is

shown in Figure 8. Bridge abutments over soft deposits are

normally supported by piles. The piles for the abutments

are usually driven to set at a firmer layer below. The long

term settlement of the abutments is hence negligible. The

embankment adjacent to the abutments would settle due to

the consolidation settlement of the subsoil under the

embankment load. The time and magnitude of the

consolidation settlement depend on the thickness and the

consolidation properties of the compressible deposits and

the height of embankment. Figure 9 shows the common

problem i.e. settlement of bridge approaches that need

regular resurfacing or topping-up to ensure smooth riding

surface.

Figures 10 and 11 show some of the innovative solutions to

the problems. Figure 10 shows the use of transition piles to

provide a smooth transition to a bridge abutment. The

transition piles are designed to settle, and the piles close to

the unpiled section would have a smaller differential

settlement. This area can further be refined with an

approach slab as indicated. High quality of field tests,

sampling and laboratory tests are needed to obtain reliable

soil parameters for analysis and prediction of the settlement

(Gue, 2000).

Figure 11 shows the use of Expanded Polystyrene (EPS) to

reduce the weight of the embankment particularly near the

bridge abutment. However, this technique is very sensitive

to the high water table and the design is usually controlled

by floatation (NRRL, 1992).

The other methods are surcharging with or without vertical

drains and stone columns to smoothen the transition. As

the transition is a short section of the alignment, the first

two methods are generally more economical, particularly

the use of transitional embankment piles, as this technique

does not need another set of plant and equipment, thereby

saving on the extra mobilization cost.

Fig. 8. Settlement of a Bridge Approach (After Gue, 2000)

Fig. 11. Expanded Polystyrene (EPS) (After Gue, 2000)

Fig. 9. Hump at Bridge Approach (After Gue, 2000)

Fig. 10. Transition Embankment Piles (After Gue, 2000)

APPROACH SLAB

APPROACH

SLAB

6

6. FAILURE OF APPROACHES TO CULVERTS

Very often, culverts are designed and constructed as shown

in Figure 12 to ensure that the area of flow of the drain

through the embankment remain unchanged with time.

This is achieved by using piles to provide a rigid platform.

The consequence of having rigid platform as shown induces

differential settlement between the rigid piled culvert and

the unpiled embankment. The unpiled embankment over

compressible soil will settle in time, as shown in Figure 13.

The possible solutions to eliminate the differential

settlement are:-

(i) Provide a larger culvert to allow for long term

settlement.

(ii) Provide a transition piles to the approaches to a

culvert.

The first option is shown in Figure 14, which allows the

culvert to settle together with the embankment. Hence, the

size available for flow will reduce with time as the culvert

settles and a section of the culvert will be silted up as

shown. The net flow area after taking into consideration of

settlement and siltation should have a size not smaller than

that required for the volume of flow designed just like the

piled culvert as shown in Figure 12. The second option as

shown in Figure 15 is similar to the transition piles

described earlier (in section 5). This option is generally

more costly.

7. GUIDANCE NOTES ON SUBSOIL

INVESTIGATION, ANALYSIS, DESIGN &

CONSTRUCTION FOR HIGHWAY

CONSTRUCTION

As demonstrated in the above sections, the success of

highway construction on soft ground relies on proper

planning, design, construction control and site supervision

as summarized below:

Fig. 13. Hump over Piled Culvert (After Gue, 2000) Fig. 15. Transition Embankment Piles for Piled Culvert

Fig. 14. Oversized Culvert (After Gue, 2000)

Fig. 12. Piled Culvert (After Gue, 2000)

7

(i) Awareness of the project requirements in terms of

serviceability criteria (deformation tolerances,

bearing capacity, etc.), site constraints, time

(construction time and service period) and costs

(construction and maintenance costs).

(ii) Knowledge of the site and subsoil conditions

through proper desk study, gathering of geological

information and well planned and supervised

subsurface investigation and laboratory tests to

acquire the necessary reliable parameters for

geotechnical designs.

(iii) Proper geotechnical design to address both

stability of the embankment and deformation,

particularly differential settlements.

(i v) Full time proper site supervision for the

construction works by qualified personnel/

engineers.

(v) Careful and proper monitoring on the performance

of the embankment during and after construction

through instrumentation scheme.

7.1. Guidance Notes on Subsoil Investigation

Based on numerous investigations carried out by the

Authors, it has been proven that direct determination of

undrained shear strength for soft marine clayey deposits is

very beneficial in subsequent design and construction

control. This is in addition to collecting undisturbed

samples from conventional boreholes for unconfined

compression and consolidation tests. The use of piezocone

is useful to detect presence of sand lenses and indirect

determination of undrained shear strength. The detection of

sand lenses is particularly important for the assessment of

ground treatment. The selection of surcharge alone or

surcharge with prefabricated vertical drains to accelerate

consolidation depends on this information for economical

design. For example, when intermittent layers of sand

lenses within the clayey marine deposits, vertical drains

may not be necessary.

The spacing of vertical drains is also sensitive to the

permeability or consolidation properties of, the clay.

Hence, SI needs to provide reliable subsoil data for design.

The details on subsoil subject can be obtained from the

papers by Gue & Tan (2000), Gue (1999) and Tan (1999).

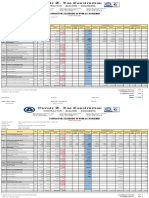

7.2. Localised Weak Zone

Conventional selection of subsoil design parameters are

based on individual judgment and experience, in

particularly on the selection of moderately conservative

design line (MCL), as shown in Figure 16. However,

scattered data that are weaker than the selected MCL is

always unavoidable (see Figure 16). This is also to ensure

practical and economical design being implemented.

Therefore, special attention should then be paid to localized

weak zones where more intensive ground improvement

procedure should be adopted. If there are no attempts to

solve those localized areas, embankment failures are likely

to occur in areas with these localized weak zones.

For a linear infrastructure project carried out by the

Authors, the selected MCL for a regional undrained shear

Fig. 16. Generalised MCL across 1400m

Fig. 17. MCL for localised weak zone

Material Weaker

than MCL

0 10 20 30 40 50 60 70 80 90 100

12

11

10

9

8

7

6

5

4

3

2

1

0

D

e

p

t

h

(

m

)

0 10 20 30 40 50 60 70 80 90 100

Undrai ned Shear Strength Profile

(Interpretation from Mackintosh Probe Results) 91.3km to 92.0km

12

11

10

9

8

7

6

5

4

3

2

1

0

Su = 10kPa

Su = 25kPa

Su = 40kPa

Su = 15kPa

MCL

0 10 20 30 40 50 60 70 80 90 100

6

5

4

3

2

1

0

D

e

p

t

h

(

m

)

0 10 20 30 40 50 60 70 80 90 100

Undrained Shear Strength Profile

(Interpretation from Mackintosh Probe Results)

91.3km to 92.0km (Further Zoning)

6

5

4

3

2

1

0

Su = 3kPa

Su = 11kPa

Localized

MCL

8

strength (Figure 16) has been further zoomed in to identify

the local weak zone for special ground treatment design

(see Figure 17). Such zoning has enable the usage of

ground surcharge with Prefabricated Vertical Drains as a

general ground treatment across the regional while adopting

Piled Embankment at localized weak zones. This should be

further verified by additional in-situ Vane Shear Tests,

Piezocones and Mackintosh Probes carried out after site

clearance for mapping out of local weak zones.

7.3. Guidance Notes on Embankment Design over

Soft Ground

Embankment design of roads needs to satisfy two important

requirements among others; the stability and settlement.

The short term stability for embankment over soft clay is

always more critical than long term simply because the

subsoil consolidates with time under loading and the

strength increases. In design, it is very important to check

for the stability of the embankment with consideration for

different potential failure surfaces namely circular and non-

circular. Non-circular failure is often more critical.

It is also necessary to evaluate both the magnitude and rate

of settlement of the subsoil supporting the embankment

when designing the embankment so that the settlement in

the long term will not influence the serviceability and safety

of the embankment. The details of the embankment design

can be obtained from Tan & Gue (2000).

A quick preliminary check on the stability of the

embankment is possible using simplified bearing capacity

equation below (Gue & Tan, 2004):

FOS

N s

q

c u

allow

= (1)

where :

q

allow

=allowable bearing pressure (kN/m

2

)

=(

fill

.H +10)

fill

=bulk unit weight of the compacted fill (kN/m

3

)

H =allowable height of embankment (m)

s

u

=undrained shear strength of the subsoil (kPa)

N

c

= 5 (suggested by Authors for ease of hand

calculation)

FOS =Factor of Safety (e.g. minimum of 1.2 for short

term using moderately conservative s

u

)

Note : The 10kPa allowance in the q

allow

is to cater for

the minimum vehicle load.

Of course more detailed analyses are required when more

refined soil layers and properties are obtained.

8. CONCLUSION & RECOMMENDATIONS

The geotechnical challenges presented in the paper are

aimed to reduce or if possible avoid the occurrence of

global and serviceability failures of highways due to design

and construction errors. As such, necessary precautionary

measures should be taken along the entire process of project

implementation, from planning, analysis, design to

construction.

Among others, the following are some of the simple and yet

effective methods recommended for all design consultants:

(i) Always emphasise on engineering assessment of

bearing capacity at least by crude check prior to

detailed analyses. This can be done by exercising

the following suggestions:

a) Do not abuse geotechnical design, detailed

analysis is a must.

b) Do not overlook localised weak zones where

special ground treatment techniques should be

incorporated.

c) Do not overlook the importance of structural

detailing (e.g. to replace approach slabs by

transition slabs)

(ii) A systematic check and review process should be

implemented for all designs. Reviews in particular

must be done by engineers experienced in soft

ground design.

(iii) Structured training programmes should be

scheduled for practitioner of all levels to enhance

the technical understanding and to provide a

platform for the sharing of lessons learned.

ACKNOWLEDGEMENTS

The Authors would like to express appreciation to Mr. Tan

Tau Chuien for his contribution in preparing the necessary

subsoil information for the compilation of this paper.

REFERENCES

Gue, S.S. (1988). An Investigation into Geotechnical

Failures of a Bridge Project. IEM/RRIM Joint

Engineering Symposium, 20th Aug 1988, J ohor Bahru,

Malaysia.

Gue, S.S. (1999). Selection of Geotechnical Parameters for

Design. Short Course on Soil Investigation and Design

for Slope (SCOFG99), 11 & 12th May, 1999, Kuala

Lumpur.

Gue, S.S. (2000). Innovative Geotechnical Input for

Approaches To Bridges And Culverts Over Compressible

Soils. 4

th

Malaysian Road Conference Towards Better

Highway Environment, Malaysia.

9

Gue, S. S. & Tan, Y. C. (2003). Prevention of Failure of

Bridge Foundation and Approach Embankment on Soft

Ground. Lead Speaker, 2

nd

International Conference on

Soft Soil Engineering and Technology, July 2003,

Putrajaya, Selangor.

Gue, S.S. and Tan, Y.C. (2004). Prevention of Failures

Related to Geotechnical Works on Soft Ground. Special

Lecture, Malaysian Geotechnical Conference, 16 - 18

March, Sheraton Subang, Petaling J aya, Malaysia.

Gue, S. S., Tan, Y. C. & Liew, S. S. & Ng, H. B. (2001).

Failure of an Embankment Treated with Vacuum

Preloading Method. Proceedings of the XV

th

International

Conference on Soil Mechanics and Geotechnical

Engineering, Istanbul, Turkey, 3: 1749 1751.

Norwegian Road Research Laboratory (1992). Expanded

Polystyrene used in Road Embankment Design,

Construction and Quality Assurance. Norwegian

Directorate of Public Roads, Oslo/Norway.

Peck, R.B. (1969). Advantages and limitations of the

observational method in applied soil mechanics.

Geotechnique. 19(2): 171-187.

Priebe, H.J. (1995). The Design of Vibro Replacement.

Ground Engineering, December , 31-37.

Tan, Y.C. (1999) Piezocone Tests and Interpretation. Short

Course on Soil Investigation and Design for Slope

(SCOFG99), 11

th

& 12

th

May, 1999, Kuala Lumpur,

Malaysia.

Tan, Y.C. and Gue, S.S. (2000). Embankment over Soft

Clay Design and Construction Control. Seminar on

Geotechnical Engineering, 22

nd

& 23

rd

September 2000,

Penang.

Tan, Y. C. and Liew, S. S. (2000). Observational Method

to Prevent Failure of Embankment Treated with Vaccum

Preloading. Seminar on Failures Related to Geotechnical

Works, IEM, Kuala Lumpur.

You might also like

- Construction Challenges in Hilly AreasDocument24 pagesConstruction Challenges in Hilly AreasGhanashyam PuttaNo ratings yet

- Bituminous Mixtures - Material Specifications: BSI Standards PublicationDocument9 pagesBituminous Mixtures - Material Specifications: BSI Standards PublicationCristián JiménezNo ratings yet

- Chilean Performance Indicator by Region Rev FinalDocument8 pagesChilean Performance Indicator by Region Rev FinalLeonardo AcunaNo ratings yet

- Transporta Tion EngineeringDocument15 pagesTransporta Tion Engineeringshogun2517No ratings yet

- Classification of AggregateDocument6 pagesClassification of Aggregatewpt civilNo ratings yet

- Weathering Steel For Highway StructuresDocument20 pagesWeathering Steel For Highway StructuresNat Thana AnanNo ratings yet

- (BS EN 14487-2 - 2006) - Sprayed Concrete. ExecutionDocument20 pages(BS EN 14487-2 - 2006) - Sprayed Concrete. ExecutionAGNIVO RAY0% (1)

- Guidelines On NRM 2: Detailed Measurement of Building Works: 1st EditionDocument22 pagesGuidelines On NRM 2: Detailed Measurement of Building Works: 1st EditionhutuguoNo ratings yet

- Application of Infrared Thermography Technique in Uilding Finish EvaluationDocument9 pagesApplication of Infrared Thermography Technique in Uilding Finish EvaluationNicolas De NadaiNo ratings yet

- 9th International Bridge Management Conference OrlandoDocument440 pages9th International Bridge Management Conference OrlandoLaurentiu PavelescuNo ratings yet

- The Impact of Changes in Construction and SchedulesDocument29 pagesThe Impact of Changes in Construction and SchedulesAlexandra Camila Alvarez BurgosNo ratings yet

- Design and Analysis of Flyover Bridge Using SAPDocument7 pagesDesign and Analysis of Flyover Bridge Using SAPInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Road Construction Structure WorksDocument86 pagesRoad Construction Structure Worksadnriod100% (1)

- Construction Technology On SKYPARKDocument17 pagesConstruction Technology On SKYPARKDarrenTofuNo ratings yet

- Modular Construction Seminar ReportDocument15 pagesModular Construction Seminar ReportPratikNo ratings yet

- 7th Conference on Cold In-Place RecyclingDocument13 pages7th Conference on Cold In-Place RecyclingMatei PopaNo ratings yet

- Prefabricated ConstructionDocument9 pagesPrefabricated ConstructionKennith NgNo ratings yet

- Pile SpecificationsDocument16 pagesPile SpecificationsHarshini Reddy B.100% (1)

- ECM 366: PFI and PMC Project ManagementDocument24 pagesECM 366: PFI and PMC Project ManagementAlma AinaNo ratings yet

- A New Test Method For Porosity Measurements of PortlandDocument6 pagesA New Test Method For Porosity Measurements of PortlandElias Antunes SantosNo ratings yet

- Pe Exam For ContractorDocument8 pagesPe Exam For ContractorMELCHOR JR ESPILOYNo ratings yet

- Durability CharacteristicsDocument4 pagesDurability CharacteristicsSathish KumarNo ratings yet

- Godrej Platinum - Architactural - BOQ 1Document11 pagesGodrej Platinum - Architactural - BOQ 1Vishwas GadreNo ratings yet

- Road User Cost Models and Safety AnalysisDocument118 pagesRoad User Cost Models and Safety AnalysisMwawiNo ratings yet

- Specification For Highway Works UK - SERIES 1900Document78 pagesSpecification For Highway Works UK - SERIES 1900Kévin JacobNo ratings yet

- 2010-Pervious Concrete Overview-Article-K.Obla PDFDocument10 pages2010-Pervious Concrete Overview-Article-K.Obla PDFSaul Lopez MejiaNo ratings yet

- Structural Steel Design 1Document22 pagesStructural Steel Design 1Chamil MahagamageNo ratings yet

- Week 7 Concrete Quality Control & AdmixturesDocument46 pagesWeek 7 Concrete Quality Control & AdmixturesKreem AlfaNo ratings yet

- Arup Future of Project Management2Document68 pagesArup Future of Project Management2LaurentiuNo ratings yet

- Construction Tech 1: Excavation & BasementDocument40 pagesConstruction Tech 1: Excavation & BasementJayaniNo ratings yet

- Lecture 6-Project Delivery MethodsDocument37 pagesLecture 6-Project Delivery MethodsKinfe MehariNo ratings yet

- Runway Length Requirements for Airport DesignDocument42 pagesRunway Length Requirements for Airport Designbadarmunir23No ratings yet

- Lecture 4 ConcreteDocument134 pagesLecture 4 ConcreteMegaNo ratings yet

- Highway Material 1Document33 pagesHighway Material 1Pijah AhmadNo ratings yet

- International Practices For Connecting One Pass Precast Segmental Tunnel LiningsDocument7 pagesInternational Practices For Connecting One Pass Precast Segmental Tunnel LiningsMehdi BakhshiNo ratings yet

- CENGR 2230 - Construction Materials & TestingDocument60 pagesCENGR 2230 - Construction Materials & TestingNico100% (1)

- Subsurface Exploration (Site Investigation) PDFDocument92 pagesSubsurface Exploration (Site Investigation) PDFrenrenzNo ratings yet

- Sustainability in Construction & Civil EngineeringDocument4 pagesSustainability in Construction & Civil EngineeringSyed Mohd MehdiNo ratings yet

- Construction Project Claim ManagementDocument10 pagesConstruction Project Claim ManagementDilpreet SinghNo ratings yet

- Bituminous Mixtures in Road ConstructionDocument42 pagesBituminous Mixtures in Road ConstructionThamiresGuerraNo ratings yet

- Cost Management Practices in ConstructionDocument3 pagesCost Management Practices in ConstructionbjNo ratings yet

- Foundations: Types, Functions and Design FactorsDocument139 pagesFoundations: Types, Functions and Design Factorssayqa100% (6)

- PPV PresentationDocument66 pagesPPV PresentationIvan BogdanNo ratings yet

- The Effects of Poor Drainage System On Road Pavement: A ReviewDocument8 pagesThe Effects of Poor Drainage System On Road Pavement: A ReviewEditor IJIRMF50% (2)

- Sidewalk Design Construction and Maintenance enDocument48 pagesSidewalk Design Construction and Maintenance enMuhammad ZakiNo ratings yet

- The SCL Delay and Disruption ProtocolDocument7 pagesThe SCL Delay and Disruption ProtocolJailanee ImakNo ratings yet

- Urban Planning Nairobi Zones 3,4,5Document228 pagesUrban Planning Nairobi Zones 3,4,5musiomi2005No ratings yet

- CIDA Guidelines For Construction SitesDocument14 pagesCIDA Guidelines For Construction SitesAudithya KahawattaNo ratings yet

- Steel vs. Concrete MaterialDocument3 pagesSteel vs. Concrete MaterialGerald YasonNo ratings yet

- Construction Reports (Appendices)Document21 pagesConstruction Reports (Appendices)Haneef MohamedNo ratings yet

- Introduction To Transportation Engineering and Planning - Term PaperDocument54 pagesIntroduction To Transportation Engineering and Planning - Term PaperMJ Dela Cruz100% (1)

- Road Maintenance Planning: Indevelopment: John Van RijnDocument64 pagesRoad Maintenance Planning: Indevelopment: John Van RijnJair JaraNo ratings yet

- Protecting Steep Slopes and WaterwaysDocument8 pagesProtecting Steep Slopes and WaterwaysVinod TiwariNo ratings yet

- SS900-General Tunnel Construction - 161026Document5 pagesSS900-General Tunnel Construction - 161026jologscresenciaNo ratings yet

- Unit (2) Construction TechnologyDocument31 pagesUnit (2) Construction TechnologyNyein Chan Aung100% (1)

- Condition Assessment and Rating of A Building Using Condition Survey Protocol (CSP) 1 MatrixDocument6 pagesCondition Assessment and Rating of A Building Using Condition Survey Protocol (CSP) 1 MatrixGRD JournalsNo ratings yet

- Quantity Surveying Services - Pure CompetitionDocument2 pagesQuantity Surveying Services - Pure CompetitionteeyuanNo ratings yet

- Construction On Soft GroundDocument9 pagesConstruction On Soft GroundyantieschumiNo ratings yet

- Fs Falla de Fondo Kohsaka & IshizukaDocument15 pagesFs Falla de Fondo Kohsaka & IshizukaJosé Francisco Martínez GutiérrezNo ratings yet

- Mitigation of Risks Associated With Deep ExcavationsDocument18 pagesMitigation of Risks Associated With Deep ExcavationsSayed ElarabyNo ratings yet

- Brick wall cost analysisDocument2 pagesBrick wall cost analysisGopal SudhirNo ratings yet

- Air Conditioner Outdoor Unit: Installation Manual Manuel D'Installation Manual de InstalaciónDocument16 pagesAir Conditioner Outdoor Unit: Installation Manual Manuel D'Installation Manual de InstalaciónUmesh MishraNo ratings yet

- Delhi Analysis of Rates 2014 Vol-1 PDFDocument696 pagesDelhi Analysis of Rates 2014 Vol-1 PDFJaisree Balu Pydi95% (22)

- Technical Writing Tutorial: Purpose: Importance: The Main Modes of Communication Are Written, Verbal, and Visual. As ADocument8 pagesTechnical Writing Tutorial: Purpose: Importance: The Main Modes of Communication Are Written, Verbal, and Visual. As ACash SlyNo ratings yet

- PSC ResultDocument10 pagesPSC ResultUmesh MishraNo ratings yet

- Green Schools Virtual Learning Program ProgressDocument26 pagesGreen Schools Virtual Learning Program ProgressUmesh MishraNo ratings yet

- GPS Map 62stc ManualDocument60 pagesGPS Map 62stc ManualUmesh MishraNo ratings yet

- PSC ResultDocument10 pagesPSC ResultUmesh MishraNo ratings yet

- 5 9128 969Document4 pages5 9128 969Umesh MishraNo ratings yet

- 8 WritingYourNeedsAssessmentReportDocument6 pages8 WritingYourNeedsAssessmentReportUmesh MishraNo ratings yet

- Copy Text From Excel To NotepadDocument1 pageCopy Text From Excel To NotepadUmesh MishraNo ratings yet

- Design of One Way SlabDocument31 pagesDesign of One Way SlabRam Ingalkar90% (10)

- Bridge AbutmentsDocument11 pagesBridge AbutmentsIulian SeverinNo ratings yet

- Technical Writing Tutorial: Purpose: Importance: The Main Modes of Communication Are Written, Verbal, and Visual. As ADocument8 pagesTechnical Writing Tutorial: Purpose: Importance: The Main Modes of Communication Are Written, Verbal, and Visual. As ACash SlyNo ratings yet

- Grade 2Document1 pageGrade 2Umesh MishraNo ratings yet

- Rich Text Editor FileDocument1 pageRich Text Editor FileUmesh MishraNo ratings yet

- Rich TUmeshext Editor FileDocument1 pageRich TUmeshext Editor FileUmesh MishraNo ratings yet

- Design of One Way SlabDocument31 pagesDesign of One Way SlabRam Ingalkar90% (10)

- Rich Text Editor FileUMeshDocument1 pageRich Text Editor FileUMeshUmesh MishraNo ratings yet

- Rich Text Umesheditor FileDocument1 pageRich Text Umesheditor FileUmesh MishraNo ratings yet

- RE05267Document38 pagesRE05267Umesh MishraNo ratings yet

- Rural Road NepDocument2 pagesRural Road NepUmesh MishraNo ratings yet

- Design of One Way SlabDocument31 pagesDesign of One Way SlabRam Ingalkar90% (10)

- UMESHDocument1 pageUMESHUmesh MishraNo ratings yet

- Di CalciumDocument5 pagesDi CalciumUmesh MishraNo ratings yet

- Combating Corruption in Public Works in NepalDocument87 pagesCombating Corruption in Public Works in NepalUmesh MishraNo ratings yet

- CDN CalendarDocument1 pageCDN CalendarUmesh MishraNo ratings yet

- CDN CalendarDocument1 pageCDN CalendarUmesh MishraNo ratings yet

- Box Culvert Design DetailsDocument5 pagesBox Culvert Design DetailsFauzankalibata100% (1)

- Project Drainage Report: Design Manual Chapter 2 - Stormwater 2A - General InformationDocument10 pagesProject Drainage Report: Design Manual Chapter 2 - Stormwater 2A - General InformationUmarNo ratings yet

- LiveLoad Beakley-AASHTO 2017Document89 pagesLiveLoad Beakley-AASHTO 2017Huy BaoNo ratings yet

- DM Section 4 Drainage Design 3-18-14Document161 pagesDM Section 4 Drainage Design 3-18-14Shoayful islamNo ratings yet

- CD 522 Drainage of Runoff From Natural Catchments-WebDocument18 pagesCD 522 Drainage of Runoff From Natural Catchments-WebBalaji NaikNo ratings yet

- General Specification Road and Bridges Rv-2016Document228 pagesGeneral Specification Road and Bridges Rv-2016china james100% (1)

- Low-Volume Roads EngineeringDocument183 pagesLow-Volume Roads Engineeringeng_osman_mukhtar100% (1)

- Surface Water DrainageDocument5 pagesSurface Water DrainagecakijieyNo ratings yet

- Summary of Cost EstimateDocument18 pagesSummary of Cost EstimatehitcvlNo ratings yet

- Manual Prático de Estradas PDFDocument69 pagesManual Prático de Estradas PDFMarcelo LiraNo ratings yet

- Culverts Installation GuideDocument91 pagesCulverts Installation GuiderodcgonNo ratings yet

- W'/vv". / VDocument369 pagesW'/vv". / VlehlabileNo ratings yet

- Chapter Four: Water Conveyance Structures: CanalDocument11 pagesChapter Four: Water Conveyance Structures: Canaljebril yusufNo ratings yet

- Road Maintenance PDFDocument112 pagesRoad Maintenance PDFakhilkuwarNo ratings yet

- Standard Design Parameters for Stormwater Pipes and PitsDocument5 pagesStandard Design Parameters for Stormwater Pipes and PitsxtianNo ratings yet

- Canal Str1Document25 pagesCanal Str1Joseph PayatNo ratings yet

- T HR Ci 12020 STXXXXDocument99 pagesT HR Ci 12020 STXXXXfastwritenameNo ratings yet

- Construction Specifications en (Momora)Document557 pagesConstruction Specifications en (Momora)altuwaijri100% (1)

- Design reinforcement for cast-in-place box culvertDocument13 pagesDesign reinforcement for cast-in-place box culvertPRAKASHNo ratings yet

- HY8 TestsDocument8 pagesHY8 Testsjosue.angelo9459No ratings yet

- Slab Bridge Final KPJDocument73 pagesSlab Bridge Final KPJvinoraamNo ratings yet

- Design and Cost Estimate of A Twin-Cell Reinforced Concrete Culvert in Yawiri, Oyo StateDocument71 pagesDesign and Cost Estimate of A Twin-Cell Reinforced Concrete Culvert in Yawiri, Oyo StateSolomon ElumaNo ratings yet

- Vanuatu Resilient Roads Manual Draft PWD Rev 1Document415 pagesVanuatu Resilient Roads Manual Draft PWD Rev 1CK-LAO TEENo ratings yet

- Revised Data Roadsbridges1Document404 pagesRevised Data Roadsbridges1Krishna SinghNo ratings yet

- Analysis of A RCC Underpass Box-Bridge: Surabhi Tiwari, A.M.Gharad, P.D.PachporDocument4 pagesAnalysis of A RCC Underpass Box-Bridge: Surabhi Tiwari, A.M.Gharad, P.D.PachporBilal Ahmed BarbhuiyaNo ratings yet

- Asset Inspection Procedures PDFDocument100 pagesAsset Inspection Procedures PDFwessamalexNo ratings yet

- Task 2 Final Assignment Oumh1303 English For Oral CommunicationDocument4 pagesTask 2 Final Assignment Oumh1303 English For Oral Communicationernie sham100% (2)

- Swa Oct 15 22KJ0068Document6 pagesSwa Oct 15 22KJ0068Jed CobongNo ratings yet

- OSIM FieldGuide (Apr 2008)Document50 pagesOSIM FieldGuide (Apr 2008)mtor86No ratings yet

- 1.0 Description: Specifications For Supplying and Placing BackfillDocument7 pages1.0 Description: Specifications For Supplying and Placing BackfillbilalNo ratings yet