Professional Documents

Culture Documents

Performance and Emissions Characteristics of Diesel Engine Fuelled With Rice Bran Oil

Uploaded by

seventhsensegroup0 ratings0% found this document useful (0 votes)

43 views5 pagesDue to the scarcity of conventional fuels and the crude

oil, the price was going up day to day and there will be no more

conventional fuels in future and also increasing the

environmental pollution by the usage of crude oils, there is a

need for the search of alternative fuel sources for the automobile

applications. Therefore in the present investigation the oil taken

is the rice bran oil which was obtained by the waste rice husk.

The different proportions such as RB25, RB35, RB45, and

RBE25,RBE35, RBE45, to find out the performance parameters

and emissions. This work presents the experimental investigation

carried on four stroke single cylinder diesel engine with Ethanol

and Ethyl Hexyl Nitrate (EHN) as additives to the dieselbiodiesel

blends. Ethanol was added as 10% by volume to the

diesel-biodiesel blends. It was observed that the Brake Thermal

Efficiency (BTE) increases in proportion to the blend percentage.

The CO, HC and NOx emissions are decreased when compared

to neat diesel.

Original Title

Performance And Emissions Characteristics Of Diesel Engine Fuelled With Rice Bran Oil

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDue to the scarcity of conventional fuels and the crude

oil, the price was going up day to day and there will be no more

conventional fuels in future and also increasing the

environmental pollution by the usage of crude oils, there is a

need for the search of alternative fuel sources for the automobile

applications. Therefore in the present investigation the oil taken

is the rice bran oil which was obtained by the waste rice husk.

The different proportions such as RB25, RB35, RB45, and

RBE25,RBE35, RBE45, to find out the performance parameters

and emissions. This work presents the experimental investigation

carried on four stroke single cylinder diesel engine with Ethanol

and Ethyl Hexyl Nitrate (EHN) as additives to the dieselbiodiesel

blends. Ethanol was added as 10% by volume to the

diesel-biodiesel blends. It was observed that the Brake Thermal

Efficiency (BTE) increases in proportion to the blend percentage.

The CO, HC and NOx emissions are decreased when compared

to neat diesel.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

43 views5 pagesPerformance and Emissions Characteristics of Diesel Engine Fuelled With Rice Bran Oil

Uploaded by

seventhsensegroupDue to the scarcity of conventional fuels and the crude

oil, the price was going up day to day and there will be no more

conventional fuels in future and also increasing the

environmental pollution by the usage of crude oils, there is a

need for the search of alternative fuel sources for the automobile

applications. Therefore in the present investigation the oil taken

is the rice bran oil which was obtained by the waste rice husk.

The different proportions such as RB25, RB35, RB45, and

RBE25,RBE35, RBE45, to find out the performance parameters

and emissions. This work presents the experimental investigation

carried on four stroke single cylinder diesel engine with Ethanol

and Ethyl Hexyl Nitrate (EHN) as additives to the dieselbiodiesel

blends. Ethanol was added as 10% by volume to the

diesel-biodiesel blends. It was observed that the Brake Thermal

Efficiency (BTE) increases in proportion to the blend percentage.

The CO, HC and NOx emissions are decreased when compared

to neat diesel.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

International Journal of Engineering Trends and Technology (IJETT) Volume 4 Issue 10 - Oct 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 4574

Performance And Emissions Characteristics Of

Diesel Engine Fuelled With Rice Bran Oil

1

Ch.Narasimha,

2

M.Rajesh

1

M.Tech Student, Mechanical Engineering Department, V.R.Siddhartha Engg.College, Vijayawada

2

Assistant Professor, Mechanical Engineering Department, V.R.Siddhartha Engg.College, Vijayawada

1

Abstract Due to the scarcity of conventional fuels and the crude

oil, the price was going up day to day and there will be no more

conventional fuels in future and also increasing the

environmental pollution by the usage of crude oils, there is a

need for the search of alternative fuel sources for the automobile

applications. Therefore in the present investigation the oil taken

is the rice bran oil which was obtained by the waste rice husk.

The different proportions such as RB25, RB35, RB45, and

RBE25,RBE35, RBE45, to find out the performance parameters

and emissions. This work presents the experimental investigation

carried on four stroke single cylinder diesel engine with Ethanol

and Ethyl Hexyl Nitrate (EHN) as additives to the diesel-

biodiesel blends. Ethanol was added as 10% by volume to the

diesel-biodiesel blends. It was observed that the Brake Thermal

Efficiency (BTE) increases in proportion to the blend percentage.

The CO, HC and NOx emissions are decreased when compared

to neat diesel.

Keywords Rice bran oil, Ethanol, Ethyl Hexyl Nitrate

(EHN), Emission characteristics.

1. INTRODUCTION

More than 90% worlds rice production coming

from Asia. Rice production first among agricultural

commodity of Indonesia. Rice bran is a brown layer present

between rice and the outer husk of the paddy. Rice bran oil is

an important derivative of rice. Depending on variety of rice

and degree of milling, the bran contains 16-32 wt% of oil.

About 60-70% of the oil produced fromthis bran is non edible

oil, due to the problems attributed to the stability and storage

of the rice bran and the dispersed nature of rice milling . Rice

bran oil (RBO) is considered to be one of the most nutritious

oils due its favourable fatty acid composition and unique

combination of naturally occurring biologically active and

antioxidant compounds [1]. RBO has been difficult to refine

because of the its high content of free fatty acid (FFA),

unsaponifiable matter and dark colour [2] . The results

obtained show a 49% reduction in smoke, 35% reduction in

HC and 37% reduction in CO emissions for the blends

whereas the brake power and BTE are reduced by 2.4% and

3.2% respectively with 4.3% increase in the SFC . Therefore it

is concluded from the present experimental study that the

blends of RBO and Diesel fuel can successfully be used in

Diesel engines as an alternative fuel without any modification

in the engine and it is also environment friendly by the

emission standards. The present research is aimed to

investigate experimentally the performance and exhaust

emission characteristics of a direct injection (DI) diesel engine

when fuelled with conventional diesel fuel, rice bran oil

biodiesel, a blend of diesel and rice bran oil biodiesel and

three blends of diesel-biodiesel-ethanol over the entire range

of load on the engine. The experimental results showed that

the highest brake thermal efficiency was observed with 15%

ethanol in diesel-biodiesel-ethanol blends. The exhaust gas

temperature and the sound intensity fromthe engine reduced

with the increase of ethanol percentage in diesel-biodiesel-

ethanol blends. The Carbon monoxide and smoke emissions

reduced significantly with higher percentage of ethanol in

diesel-biodiesel-ethanol blends. The unused oxygen with 5%

ethanol in diesel-biodiesel-ethanol blend was lower than that

of diesel fuel [3]. .Fromthe literature it is concluded that

alternate fuels can be used as substitute for diesel by

evaluating its properties and blending them with diesel in

small proportions can improved performance parameters and

reduce emissions without modifying the engine design.

2. EXPERIMENTAL PROCEDURE

2.1 Biodiesel Production by Transesterification Method

Rice bran oil and methanol were mixed and poured into the

test reactor. Then base catalyst (CAO) in 1% w/w was added

into the already present mixture in the reactor. The mixture

inside the reactor was heated to a temperature of 65

0

C and

stirred continuously. The mixture in the reactor was allowed

to remain at the same temperature for a period of 3 hrs and

then it was allowed to settle under gravity. After settling two

layers were formed, the upper layer was found to be Rice bran

oil methyl esters (RBO) and the lower layer being glycerol.

2.2 Preparation Of Biodiesel Blends

After production the RBO was blended with neat diesel fuel in

various volume concentrations to prepare biodiesel blends.

These blends were subsequently used in the engine tests. The

level of blending for convenience is referred as RBXX. Where

XX indicates the percentage of biodiesel present in the blend.

For example a RB25 blend is prepared with 25% biodiesel and

75% diesel oil by volume.During the present engine

International Journal of Engineering Trends and Technology (IJETT) Volume 4 Issue 10 - Oct 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 4575

experiments the blends prepared and used were RB25,

RB35, RB45, RBE25, RBE35 and RBE45..

2.3 Properties of biodiesel comparison with diesel

The test fuels used in the engine during the experiments were

RB25,R B35, RB45, RBE25, RBE35, RBE45 and Diesel oil.

Before application on the engine, various physico-chemical

properties of all the above test fuels were determined and

compared to each other.

Properties Rice bran oil Pure diesel

Density at15

0

c

(gm/cc)

0.92 0.82

Viscosity at

40

0

c (Centi

stokes)

6.29 5

Cloud point

(

0

C)

7 -6

Pour point

(

0

C)

-3 3

Carbon Residue

(%)

0.48 0.1

Calorific value

( KJ/kg)

37900.8 42,500

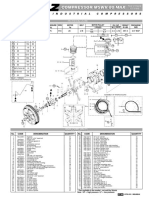

3. EXPERIMENTAL SETUP

The experimental setup shown in figure is a single cylinder

four stroke naturally aspirated diesel engine.

Figure 4.1: Engine Test Rig

The setup is provided with necessary instruments like Rope

brake dynamometer, Smoke meter(Netels-NPM-DSM),Gas

analyzer(Netels-NPM-MGA-2),etc.,for performance and

emission analysis. The Specifications of the test engine is

shown in given below.

3.1. Specifications Of the Engine:

Type of Engine Four stroke single cylinder

vertical air cooled diesel engine

Rated power 4.4kw

Rated speed 1500 rpm

Bore dia 87.5 mm

Stroke length 100 mm

Compression ratio 17.5

4.RESULTS AND DISCUSSION

The performance and emission characteristics of a high speed

diesel engine at various loads fromno load to full load fueled

with rice bran oil and its diesel blends with additives like

ethanol and ethyl hexyl nitrate are discussed below as per the

results obtained.

4.1 Specific Fuel Consumption (SFC):

The variation of brake specific fuel consumption with brake

power is shown in fig.1.the plot it is reveals that as the the

load increases the fuel consumption decreases. At full load

condition the BSFC obtained are 0.34kg/kw-hr, 0.36 kg/kw-

hr,0. 36kg/kw-hr ,0.36kg/kw-hr ,035kg/kw-hr,0.33kg/kw hr

and0.36kg/kw-hr of fuels of diesel RB25,RB35,RB45,RBE25,

RBE35,RBE45 respectively. The BSFC of rice bran oil blend

RBE45 decreased when compared to the diesel at full load

condition.

Fig:4.1. Variation of specific Fuel Consumption with

brake power

4.2Brake Thermal Efficiency(BTE):

The variation of brake thermal efficiency with brake power is

shown in fig. 2.fromthe the plot it is observed that as the the

load increases the brake thermal efficiency increases. At full

International Journal of Engineering Trends and Technology (IJETT) Volume 4 Issue 10 - Oct 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 4576

load condition the brake thermal efficiency obtained are

25.96%,24.72%, 25.83%,26.45%,27.47%,29.87%,and 23.7%

for fuels of RB25,RB35,RB45,RBE25,RBE35,RBE45and

diesel respectively. The brake thermal efficiency of rice bran

oil blend RBE35 increased when compared to the diesel at

full load condition.

4.3. Indicated Power(IP):

The variation of indicated power with brake power

is shown in fig.3.the plot it is reveals that as the the load

increases the indicated power decreases. At full load

condition the indicated power obtained are 6.3kw,6.2kw 6.6

klw,4.7 kw 4.6 kw,4.3 kw, and 7.7 kw for fuels of

RB25,RB35,RB45,RBE25,RBE35,RBE45 and diesel

respectively. The indicated power of rice bran oil blend RB25

decreased when compared to the diesel at full load condition.

Fig:4.3. Variation of Indicated Power with brake power

4.4. Mechanical Efficiency:

The variation of mechanical efficiency with brake

power is shown in fig.4.the plot it is reveals that as the the

load increases the mechanical efficiency increases. At full

load condition the mechanical efficiency obtained are

70.11%,71.48%,73.34%,69.66%,67.43%,79.76%and 57.09%.

For fuels of RB25,RB35,RB45,RBE25,RBE35,RBE45and

diesel, respectively. The mechanical efficiency of rice bran

oil blend RBE35 increased when compared to the diesel at full

load condition.

Fig:4.4. Variation of Mechanical Efficiency with

brake power

4.5. Carbon Monoxide (CO):

The variation of CO emission with brake power is

shown in fig.5.the plot it is reveals that as the the load

increases the CO emission decreases. At full load condition

the CO emissions obtained are 0.45%,0.61%,0.77%,0.67%,

0.59%,and 0.07% for fuels of RB25,RB35,RB45,RBE25,RBE

35,RBE45 and diesel respectively. The Co emission of rice

bran oil blend RBE35 decreased when compared to the other

diesel at full load condition.

International Journal of Engineering Trends and Technology (IJETT) Volume 4 Issue 10 - Oct 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 4577

Fig:4.5. Variation of Carbon Monoxide with brake power

4.6.Unburned Hydrocarbon (HC):

The variation of HC emission with brake power is shown in

fig.6.the plot it is reveals that as the the load increases the HC

emission decreases. At full load condition the HC emissions

obtained are 40,42,38,39,37,19 and 47ppm for fuels of

RB25,RB35,RB45,RBE25,RBE35,RBE45 and diesel

respectively. The HC emission of rice bran oil blend RB20

decreased when compared to the other diesel at full load

condition.

Fig:4.6. Variation of Unburned Hydrocarbon withbrake

power

4.7. Co2 Emission(CO2):

The variation of CO2 emission with brake power is

shown in fig.6.the plot it is reveals that as the the load

increases theCO2 emission decreases. At full load condition

theCO2emissionsobtainedare:7.8%,7.7%,7.5%,7.2%,6.9%,5.3

%,and7.9%,forfuelsofRB25,RB35,RB45,RBE25,RBE35,RBE

45 and diesel respectively. The CO2 emission of rice bran oil

blend RBE35decreased when compared to the diesel at full

load condition.

Fig:4.7. Variation of carbon dioxide with brake power

4.8. OXIDES OF NITROGEN(NOx):

The variation of NOx emission with brake power is shown in

fig.6.the plot it is reveals that as the the load increases theNOx

emission decreases. At full load condition the NOx emissions

obtainedare:592ppm,579ppm,541ppm,875ppm,783ppm,530pp

m,and971ppm, for fuels of RB25,RB35,RB45,RBE25,RBE35,

RBE45 and diesel respectively.The NOx emission of tyre oil

blend RBE35 decreased when compared to the other blends at

full load condition.

Fig: 4.8.Variation of oxides of nitrogen with brake power

5 CONCLUSIONS

The conclusions derived from present experimental

investigations to evaluate performance and emission

International Journal of Engineering Trends and Technology (IJETT) Volume 4 Issue 10 - Oct 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 4578

characteristics on four stroke single cylinder diesel engine

fueled with diesel RBOblends with Ethanol and EHN as

additives are summarized as follows.

1. Brake thermal efficiency increased with all blends

when compared to the conventional diesel fuel.

2. The Brake specific fuel consumption is decreased

with the blends when compared to diesel.

3. CO,CO2 and HC emissions are decreased

significantly with the blends when compared with

diesel.

From the above analysis the blend RBE35 shows the better

performance compared to other blends(RB25,RB35, RB45,

RBE25,RBE45) and diesel

REFERENCES

[1]. RamPrakash, S.P.Pandey,S.Chatterji, S.N. Singh,

Emission Analysis of CI Engine Using Rice Bran Oil

and their Esters. JERS/Vol.II/ Issue I/2011, pp.173-

178.

[2]. B.K.Venkanna, C. Venkataramana Reddy, Swati B

Wadawadagi, Performance, Emission and

Combustion Characteristics of Direct Injection

Diesel Engine Running on Rice Bran Oil / Diesel

Fuel Blend. International Journal of Chemical and

Bio molecular Engineering vol 2, No.3, 2009.

[3]. Chandan Kumar, Gajendra Babu MK, Das LM.

Experimental investigations on a Karanja oil ester

fueled DI diesel engine. SAE Paper No. 2006-01-

0238; 2006. p.11724.

[4]. Ramadhas AS, Muraleedharan C, Jayaraj S.

Performance and emission evaluation of a diesel

engine fueled with methyl esters of rubber seed oil.

Renewable Energy 2005;30:1789800.

[5]. Rukmini, C., and T.C. Raghuram, J. Am. Coll. Nutr.

10: 593-597 (1991). Bhattacharyya, D.K., M.M.

Chakrabarty, R.S. Vaidyanathan, A.C Bhatachryya,

J. Am. Oil Chem. Soc,60: 467-471 (1983).

[6]. Goffman, F.D., S. Pinson, and C. Bergman, Genetic

diversity for Lipid Content and Fatty Acid Profilein

Rice Bran, J. Am. Oil Chem. Soc. 80: 485-490

(2003).

[7]. Rogers, E.J., S.M. Rice, R.J. Nicolosi, D.R. Carpenter,

C.A. Mc Clelland, and L. J. Romanczyk, J.Am. Oil

Chem. Soc. 70: 301-305 (1993).

[8]. Puhan Sukumar, Vedaraman N, Sankaranarayanan G,

Bharat Ram Boppana V. Performance and emission

study of Mahua oil (Madhuca indica oil) ethyl ester

in a 4-stroke natural aspirated direct injection diesel

engine. Renewable Energy 2005;30:126978.

[9]. Hargrove, K.L., Processing and Utilization of Rice

Bran in the United States, in Rice Science

andTechnology, edited by W.E. Marshall and J.I.

Wadsworth, Marcel Dekker, New York, 1993,

pp.381-404.

You might also like

- Comparison of The Effects of Monochloramine and Glutaraldehyde (Biocides) Against Biofilm Microorganisms in Produced WaterDocument8 pagesComparison of The Effects of Monochloramine and Glutaraldehyde (Biocides) Against Biofilm Microorganisms in Produced WaterseventhsensegroupNo ratings yet

- Experimental Investigation On Performance, Combustion Characteristics of Diesel Engine by Using Cotton Seed OilDocument7 pagesExperimental Investigation On Performance, Combustion Characteristics of Diesel Engine by Using Cotton Seed OilseventhsensegroupNo ratings yet

- Fabrication of High Speed Indication and Automatic Pneumatic Braking SystemDocument7 pagesFabrication of High Speed Indication and Automatic Pneumatic Braking Systemseventhsensegroup0% (1)

- An Efficient Model of Detection and Filtering Technique Over Malicious and Spam E-MailsDocument4 pagesAn Efficient Model of Detection and Filtering Technique Over Malicious and Spam E-MailsseventhsensegroupNo ratings yet

- Ijett V5N1P103Document4 pagesIjett V5N1P103Yosy NanaNo ratings yet

- Design, Development and Performance Evaluation of Solar Dryer With Mirror Booster For Red Chilli (Capsicum Annum)Document7 pagesDesign, Development and Performance Evaluation of Solar Dryer With Mirror Booster For Red Chilli (Capsicum Annum)seventhsensegroupNo ratings yet

- Application of Sparse Matrix Converter For Microturbine-Permanent Magnet Synchronous Generator Output Voltage Quality EnhancementDocument8 pagesApplication of Sparse Matrix Converter For Microturbine-Permanent Magnet Synchronous Generator Output Voltage Quality EnhancementseventhsensegroupNo ratings yet

- Optimal Search Results Over Cloud With A Novel Ranking ApproachDocument5 pagesOptimal Search Results Over Cloud With A Novel Ranking ApproachseventhsensegroupNo ratings yet

- Extended Kalman Filter Based State Estimation of Wind TurbineDocument5 pagesExtended Kalman Filter Based State Estimation of Wind TurbineseventhsensegroupNo ratings yet

- Comparison of The Regression Equations in Different Places Using Total StationDocument4 pagesComparison of The Regression Equations in Different Places Using Total StationseventhsensegroupNo ratings yet

- The Utilization of Underbalanced Drilling Technology May Minimize Tight Gas Reservoir Formation Damage: A Review StudyDocument3 pagesThe Utilization of Underbalanced Drilling Technology May Minimize Tight Gas Reservoir Formation Damage: A Review StudyseventhsensegroupNo ratings yet

- FPGA Based Design and Implementation of Image Edge Detection Using Xilinx System GeneratorDocument4 pagesFPGA Based Design and Implementation of Image Edge Detection Using Xilinx System GeneratorseventhsensegroupNo ratings yet

- Color Constancy For Light SourcesDocument6 pagesColor Constancy For Light SourcesseventhsensegroupNo ratings yet

- Implementation of Single Stage Three Level Power Factor Correction AC-DC Converter With Phase Shift ModulationDocument6 pagesImplementation of Single Stage Three Level Power Factor Correction AC-DC Converter With Phase Shift ModulationseventhsensegroupNo ratings yet

- A Multi-Level Storage Tank Gauging and Monitoring System Using A Nanosecond PulseDocument8 pagesA Multi-Level Storage Tank Gauging and Monitoring System Using A Nanosecond PulseseventhsensegroupNo ratings yet

- An Efficient and Empirical Model of Distributed ClusteringDocument5 pagesAn Efficient and Empirical Model of Distributed ClusteringseventhsensegroupNo ratings yet

- An Efficient Expert System For Diabetes by Naïve Bayesian ClassifierDocument6 pagesAn Efficient Expert System For Diabetes by Naïve Bayesian ClassifierseventhsensegroupNo ratings yet

- High Speed Architecture Design of Viterbi Decoder Using Verilog HDLDocument7 pagesHigh Speed Architecture Design of Viterbi Decoder Using Verilog HDLseventhsensegroupNo ratings yet

- An Efficient Encrypted Data Searching Over Out Sourced DataDocument5 pagesAn Efficient Encrypted Data Searching Over Out Sourced DataseventhsensegroupNo ratings yet

- Separation Of, , & Activities in EEG To Measure The Depth of Sleep and Mental StatusDocument6 pagesSeparation Of, , & Activities in EEG To Measure The Depth of Sleep and Mental StatusseventhsensegroupNo ratings yet

- Design and Implementation of Height Adjustable Sine (Has) Window-Based Fir Filter For Removing Powerline Noise in ECG SignalDocument5 pagesDesign and Implementation of Height Adjustable Sine (Has) Window-Based Fir Filter For Removing Powerline Noise in ECG SignalseventhsensegroupNo ratings yet

- Non-Linear Static Analysis of Multi-Storied BuildingDocument5 pagesNon-Linear Static Analysis of Multi-Storied Buildingseventhsensegroup100% (1)

- Review On Different Types of Router Architecture and Flow ControlDocument4 pagesReview On Different Types of Router Architecture and Flow ControlseventhsensegroupNo ratings yet

- Study On Fly Ash Based Geo-Polymer Concrete Using AdmixturesDocument4 pagesStudy On Fly Ash Based Geo-Polymer Concrete Using AdmixturesseventhsensegroupNo ratings yet

- A Comparative Study of Impulse Noise Reduction in Digital Images For Classical and Fuzzy FiltersDocument6 pagesA Comparative Study of Impulse Noise Reduction in Digital Images For Classical and Fuzzy FiltersseventhsensegroupNo ratings yet

- Free Vibration Characteristics of Edge Cracked Functionally Graded Beams by Using Finite Element MethodDocument8 pagesFree Vibration Characteristics of Edge Cracked Functionally Graded Beams by Using Finite Element MethodseventhsensegroupNo ratings yet

- Key Drivers For Building Quality in Design PhaseDocument6 pagesKey Drivers For Building Quality in Design PhaseseventhsensegroupNo ratings yet

- Ijett V4i10p158Document6 pagesIjett V4i10p158pradeepjoshi007No ratings yet

- A Review On Energy Efficient Secure Routing For Data Aggregation in Wireless Sensor NetworksDocument5 pagesA Review On Energy Efficient Secure Routing For Data Aggregation in Wireless Sensor NetworksseventhsensegroupNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Planning For Chevy VoltDocument26 pagesPlanning For Chevy Voltljain989100% (1)

- Fix Displacement MotorDocument28 pagesFix Displacement MotorIan MuhammadNo ratings yet

- Ee1252 - Power Plant Engineering: Question Bank Unit I - Thermal Power Plants PART A (2 Marks)Document4 pagesEe1252 - Power Plant Engineering: Question Bank Unit I - Thermal Power Plants PART A (2 Marks)Vivek BendreNo ratings yet

- Engine Control (MR) FunctionDocument2 pagesEngine Control (MR) FunctionBogar PinedaNo ratings yet

- Rotating SystemDocument18 pagesRotating Systemevillalobos00067% (3)

- Simulation and CFD Analysis of Various Combustion Chamber Geometry of A C.I Engine Using CFXDocument8 pagesSimulation and CFD Analysis of Various Combustion Chamber Geometry of A C.I Engine Using CFXZineddine AlicheNo ratings yet

- Drag Chain Conveyor BrochureDocument8 pagesDrag Chain Conveyor BrochureAnonymous Cxriyx9HIXNo ratings yet

- COMPRESSOR MSWV 80 MAX TWO STAGE 175 PSIG TECHNICAL DATADocument2 pagesCOMPRESSOR MSWV 80 MAX TWO STAGE 175 PSIG TECHNICAL DATAebebvetbNo ratings yet

- 40kW 50kVA Generator Set HT-50 CDDocument1 page40kW 50kVA Generator Set HT-50 CDAnsoriNo ratings yet

- TG 73-200 - en PDFDocument7 pagesTG 73-200 - en PDFSheril ChandraboseNo ratings yet

- Deutz WP6C/WP4C Marine Diesel Engine ManualDocument37 pagesDeutz WP6C/WP4C Marine Diesel Engine ManualSergio DezzuttoNo ratings yet

- PM 3 (1000 HOUR Interval) : ChecklistDocument3 pagesPM 3 (1000 HOUR Interval) : ChecklistPutera Bumi NusantaraNo ratings yet

- PIM130B1 - Turbomeca Makila TI Archived NOV PDFDocument5 pagesPIM130B1 - Turbomeca Makila TI Archived NOV PDFValBMSNo ratings yet

- Fire Pump FAQDocument2 pagesFire Pump FAQK SubramaniNo ratings yet

- Aker Arc 106Document2 pagesAker Arc 106ronny-suNo ratings yet

- SYLLABUS - M TECH Mechanical - Engineering - JNUDocument22 pagesSYLLABUS - M TECH Mechanical - Engineering - JNUVinayak GhatageNo ratings yet

- Proxima Z 6421-8441 GBDocument222 pagesProxima Z 6421-8441 GBAnonymous Pk3VzhXUGB100% (1)

- DT466-530 Service Manual (B)Document96 pagesDT466-530 Service Manual (B)jeffrey pelletier100% (7)

- PENEX PROCESS TECHNOLOGY OVERVIEWDocument34 pagesPENEX PROCESS TECHNOLOGY OVERVIEWSALAM ALINo ratings yet

- Gasoline Generator 800WDocument12 pagesGasoline Generator 800WRIcardo SotoNo ratings yet

- BHEL Was Founded in 1950s. BHEL orDocument27 pagesBHEL Was Founded in 1950s. BHEL orashish_coolboyNo ratings yet

- Chap Chap Chap Chap Chapttttter One Er One Er One Er One Er OneDocument18 pagesChap Chap Chap Chap Chapttttter One Er One Er One Er One Er Oneabash_u1No ratings yet

- SNAME T&R Bulletin No 3-39 - Guide For Shop & Installation Tests - 1985Document84 pagesSNAME T&R Bulletin No 3-39 - Guide For Shop & Installation Tests - 1985kman548No ratings yet

- AVL White Paper Reducing GDI Engine Soot Emission by Minimizing Nozzle Tip WettingDocument11 pagesAVL White Paper Reducing GDI Engine Soot Emission by Minimizing Nozzle Tip Wettingabdulremanehagyc calaneNo ratings yet

- Ford GT 2004 - 2004-01-1252Document20 pagesFord GT 2004 - 2004-01-1252jorgeerrazquinNo ratings yet

- En SDG PDFDocument8 pagesEn SDG PDFDuy KhaNo ratings yet

- High Concentration Ash Slurry Disposal SystemsDocument4 pagesHigh Concentration Ash Slurry Disposal SystemsMiloš RadovanovićNo ratings yet

- Husqvarna - Manual - 137 - 142Document16 pagesHusqvarna - Manual - 137 - 142Nistor FlorinNo ratings yet

- Caterpillar 3512BDocument2 pagesCaterpillar 3512BMauricio Gomes de Barros100% (1)

- HSL Final ReportDocument52 pagesHSL Final Reportkarthik raju100% (1)