Professional Documents

Culture Documents

Deep Compaction of Granular Soils

Uploaded by

lnanescuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Deep Compaction of Granular Soils

Uploaded by

lnanescuCopyright:

Available Formats

Deep compaction of granular soils

by Dr K. Rainer Massarsch

Chapter 4. DEEP SOIL COMPACTION METHODS

< Previous | Table of contents | Next >

4.1.1 Dynamic compaction

Soil densification by dynamic compaction (DC), also called "heavy tamping" is a well-known

compaction method. The method was "rediscovered" by Menard, who transformed the crude

tamping method into a rational compaction procedure. Soil is compacted by repeated,

systematic application of high energy using a heavy weight (pounder). The imparted energy

is transmitted from the ground surface to the deeper soil layers by propagating shear and

compression waves types, which force the soil particles into a denser state. In order to

assure effective transfer of the applied energy, a 1 to 2 m thick stiff layer usually covers the

ground surface. Pounders can be square or circular in shape and made of steel or concrete.

Their weights normally range from 5 to 25 tons and drop heights of up to 25 m have been

used. Heavier weights and larger drop heights have been used for compaction of deep soil

deposits, but are not very common.

Dynamic compaction is carried out in several passes. During each pass, the weight is

dropped repeatedly in a predetermined grid pattern. The distance between the compaction

points is normally decreased in the subsequent passes and compaction is carried out in-

between the previously compacted points. The final pass, also called "ironing pass", usually

performed with low compaction energy, is carried out with a reduced drop height. The

objective is to densify the superficial soil layers without remoulding the already densified

deeper layers. Mayne (1984) presented a detailed description of the dynamic compaction

method. Choa (1996) has summarised the experience from dynamic compaction work a

major project, the Changi airport in Singapore, fig. 9.

Although the dynamic compaction method appears to be very simple, it requires careful

design of the compaction process. The densification effect is strongly influenced by the

dynamic response characteristics of the soil to be compacted, but also by the underlying soil

layers. Usually, extensive compaction trials are needed to optimise the compaction process

with respect to the required energy for achieving specified densification criteria. A major

limitation of dynamic compaction is the lack of monitoring and quality control during the

production phase. However, for research purposes, the pounder can be equipped with

sensors to monitor the applied energy and to record the dynamic response of the soil layer.

The maximum depth which can be achieved by dynamic compaction depends on several

factors, such as the geotechnical properties of the soil layer to be compacted, the dynamic

soil properties in and below the layer to be compacted (e.g. a soft clay layer below the layer

to be densified can significantly reduce the compaction effect), the ground water level, the

compaction grid, the number of compaction passes and the time interval between passes.

As a general rule, the maximum depth d

max

to which a soil deposit can be estimated from

the following relationship

d

max

=

(18)

where H is the average drop height and M the mass of the pounder. The factor a should be

determined for each site, but varies between 0,3 - 0,5. The typical depth of compaction for

drop height of 15 m and a pounder mass of 15 tons is 7 - 8 m.

Figure 9. Dynamic compaction carried out in the trial area of Changi East Reclamation

Project, Phase 1B (mass 25 tons, drop height 25 m)

Depth and Degree of Improvement

The depth of soil improvement depends on the energy per drop and can be approximated by

Where D = depth of improvement in meters

n = an empirical coefficient that varies from about 0.3 to 1.0, and is primarily dependent

on soil type

W = tamper weight in tons

H = drop height in meters

The degree of soil improvement depends primarily on the total energy applied to the soils, i.e.,

the more energy input into the soil, the greater the degree of improvement. The degree of

improvement is generally expressed in terms of relative density or density as determined by

SPT, CPT, PMT, DMT or some other testing technique.

You might also like

- Ground ImprovementDocument16 pagesGround Improvement9897856218No ratings yet

- Ground Improvement Case Histories: Embankments with Special Reference to Consolidation and Other Physical MethodsFrom EverandGround Improvement Case Histories: Embankments with Special Reference to Consolidation and Other Physical MethodsNo ratings yet

- Ground Improvement TechniqueDocument3 pagesGround Improvement TechniqueAlex Crispim Fortunato0% (1)

- Microsoft Word - 20080820 Overview of Vibro Compaction and Dynamic Compaction - 3Document9 pagesMicrosoft Word - 20080820 Overview of Vibro Compaction and Dynamic Compaction - 3nn-85614No ratings yet

- PVDDS ManualDocument7 pagesPVDDS ManualPTchongNo ratings yet

- State of The Practice of Rigid Inclusions - 3-17-2021Document11 pagesState of The Practice of Rigid Inclusions - 3-17-2021Tanju Tahir Ökten100% (1)

- Vibroreplacement PDFDocument9 pagesVibroreplacement PDFthadikkaranNo ratings yet

- Geosynthetic Reinforced Embankments on Soft Clay Foundations Strengthened by LimeDocument21 pagesGeosynthetic Reinforced Embankments on Soft Clay Foundations Strengthened by Limei7mpNo ratings yet

- 5 Innovative Slurry Trench MethodsDocument9 pages5 Innovative Slurry Trench MethodsMalik BilalNo ratings yet

- Chapter11 Coduto CompressibilityAndSettlementDocument160 pagesChapter11 Coduto CompressibilityAndSettlementTuğçe TürkanNo ratings yet

- S3 Dynamic Compaction 2018-19Document8 pagesS3 Dynamic Compaction 2018-19flashtronNo ratings yet

- Empirical CPT 2003Document12 pagesEmpirical CPT 2003Mümin ŞenNo ratings yet

- Advances in Vertical Drains and Vacuum PreloadingDocument53 pagesAdvances in Vertical Drains and Vacuum PreloadingNicole CarrilloNo ratings yet

- Wick Drain LectureDocument21 pagesWick Drain LectureChrisWaltzNo ratings yet

- Rapid DrawdownDocument50 pagesRapid Drawdowngaurave999No ratings yet

- Types of Earth Retaining Systems For Deep ExcavationsDocument16 pagesTypes of Earth Retaining Systems For Deep ExcavationsRajesh KhadkaNo ratings yet

- Wick DrainsDocument2 pagesWick Drainsdarkobogd75No ratings yet

- Liquefaction of SoilDocument10 pagesLiquefaction of SoilSanthosh SantosNo ratings yet

- Terzaghi's Bearing Capacity TheoryDocument9 pagesTerzaghi's Bearing Capacity TheoryBe civil Sixth batchNo ratings yet

- Basic Soil MechanicsDocument104 pagesBasic Soil MechanicsJorisGirdzijauskasNo ratings yet

- The Earth Pressure ProblemDocument28 pagesThe Earth Pressure ProblemAliMuhammedTekinNo ratings yet

- Stone Column 123Document34 pagesStone Column 123Nilesh0% (1)

- AASHTO - GeoTechnical Design of PileDocument6 pagesAASHTO - GeoTechnical Design of PileAlfredo A LopezNo ratings yet

- Magnetic Extensometer Monitoring Record Sheet: Response Level MM Alert Action AlarmDocument4 pagesMagnetic Extensometer Monitoring Record Sheet: Response Level MM Alert Action AlarmHamza NadeemNo ratings yet

- Pile Foundations: Experimental Investigations, Analysis and DesignDocument38 pagesPile Foundations: Experimental Investigations, Analysis and Designниикита100% (1)

- Determination of Soil StrengthDocument10 pagesDetermination of Soil StrengthFoo Saik KhengNo ratings yet

- Computers and Geotechnics: Sari W. Abusharar, Jun-Jie Zheng, Bao-Guo ChenDocument10 pagesComputers and Geotechnics: Sari W. Abusharar, Jun-Jie Zheng, Bao-Guo ChenIrvin AlbertoNo ratings yet

- Bearing Capacity of Geopier® Supported FoundationsDocument16 pagesBearing Capacity of Geopier® Supported FoundationsRodrigo Rojas CortésNo ratings yet

- Comparison of Bearing Capacity of A Strip Footing On Sand With Geocell and With Planar Forms of Geotextile ReinforcementDocument13 pagesComparison of Bearing Capacity of A Strip Footing On Sand With Geocell and With Planar Forms of Geotextile Reinforcementhamed karimpoorNo ratings yet

- Execution & Engineering Principles of Control Modulus Column (CMC)Document6 pagesExecution & Engineering Principles of Control Modulus Column (CMC)faisaltmNo ratings yet

- 14 528Lecture6-GroupandLateralAnalysesDocument47 pages14 528Lecture6-GroupandLateralAnalysesSuhas JoshiNo ratings yet

- Geotextile Encased Columns (GEC) : Load Capacity & Geotextile SelectionDocument10 pagesGeotextile Encased Columns (GEC) : Load Capacity & Geotextile SelectionGustavo Andres Mayorga RehbeinNo ratings yet

- Role of CPTuDocument10 pagesRole of CPTuPiotr ZielińskiNo ratings yet

- COEFFICIENT OF CONSOLIDATION BY INFLECTION POINT METHODDocument5 pagesCOEFFICIENT OF CONSOLIDATION BY INFLECTION POINT METHODMike MikeNo ratings yet

- Etd 1267Document190 pagesEtd 1267Lê Anh KhoaNo ratings yet

- Moment Load in WallapDocument3 pagesMoment Load in WallapSajjad AnwarNo ratings yet

- Geosynthetics in Coastal Engineering Protection and Placement IssuesDocument15 pagesGeosynthetics in Coastal Engineering Protection and Placement Issues蓉蓉No ratings yet

- Lecture 7 - Pre LoadingDocument9 pagesLecture 7 - Pre LoadingGorkem AktasNo ratings yet

- 17 Priebe 1998 Vibro Replacement To Prevent LiquefactionDocument4 pages17 Priebe 1998 Vibro Replacement To Prevent LiquefactionGerman RodriguezNo ratings yet

- Secondary Creek in Soft SoilsDocument9 pagesSecondary Creek in Soft Soilsgeo_unoNo ratings yet

- Using Pindan Sand-Clay in Pavement Structural LayersDocument15 pagesUsing Pindan Sand-Clay in Pavement Structural Layersganguly147147No ratings yet

- CE 441 Foundation Engineering 05 07 2019Document216 pagesCE 441 Foundation Engineering 05 07 2019Md. Azizul Hakim100% (1)

- Elements of rock mechanics, identification and treatment of rock defectsDocument68 pagesElements of rock mechanics, identification and treatment of rock defectsAshebir AsratNo ratings yet

- 08 - Footings On SandDocument16 pages08 - Footings On SandHoshear Bakr100% (1)

- Sheet Pile Wall IntroductionDocument19 pagesSheet Pile Wall IntroductionSâu HeoNo ratings yet

- Plaxis Common MistakeDocument22 pagesPlaxis Common MistakeBenjamin HasecicNo ratings yet

- History: Prefabricated Vertical Drains (PVDS) or Wick Drains' Are Composed of A PlasticDocument19 pagesHistory: Prefabricated Vertical Drains (PVDS) or Wick Drains' Are Composed of A PlasticSyeda Sabina YashminNo ratings yet

- Failure of An Embankment Treated With Vacuum Preloading MethodDocument4 pagesFailure of An Embankment Treated With Vacuum Preloading MethodtangkokhongNo ratings yet

- Piles IntroductionDocument39 pagesPiles IntroductionKhushboo PriyaNo ratings yet

- Recent Evolutions in Deep Foundation TechnologiesDocument38 pagesRecent Evolutions in Deep Foundation TechnologiesAnand JadoenathmisierNo ratings yet

- Prevabricated Vertical Drain (PVD)Document47 pagesPrevabricated Vertical Drain (PVD)aider indonesiaNo ratings yet

- Soil Consolidation (Vertical Drains)Document20 pagesSoil Consolidation (Vertical Drains)E Hammam El MissiryNo ratings yet

- Use of Geogrids in Railroad ApplicationsDocument12 pagesUse of Geogrids in Railroad Applicationsthadikkaran100% (1)

- Properties of Soils AppendixDocument5 pagesProperties of Soils Appendixpinkuru100% (1)

- Group Reduction Factors For Analysis of Laterally Loaded Pile GroupsDocument12 pagesGroup Reduction Factors For Analysis of Laterally Loaded Pile Groupsmsafa63No ratings yet

- Ground Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980From EverandGround Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980No ratings yet

- Loading and Design of Box Culverts To EurocodesDocument35 pagesLoading and Design of Box Culverts To Eurocodeslnanescu83% (6)

- 1 UlmiDocument3 pages1 UlmilnanescuNo ratings yet

- Centura Sebes Dn1 Dn7 ProfileleDocument1 pageCentura Sebes Dn1 Dn7 ProfilelelnanescuNo ratings yet

- Hot Rolled Sheet PileDocument52 pagesHot Rolled Sheet Pileswarup_datta03100% (1)

- RoadsDocument20 pagesRoadslnanescuNo ratings yet

- 2 Inel Stalp 15n Detaliu Sect 2 2 ModelDocument1 page2 Inel Stalp 15n Detaliu Sect 2 2 ModellnanescuNo ratings yet

- Import Geotechnical DataDocument10 pagesImport Geotechnical DatalnanescuNo ratings yet

- Hot Rolled Sheet PileDocument52 pagesHot Rolled Sheet Pileswarup_datta03100% (1)

- Analysis Using Finite Element MethodDocument10 pagesAnalysis Using Finite Element MethodlnanescuNo ratings yet

- Ecological Reconstruction of Popina II Fishpond: ArticleDocument10 pagesEcological Reconstruction of Popina II Fishpond: ArticlelnanescuNo ratings yet

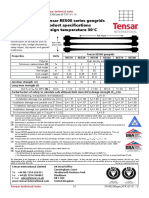

- RE500 30oc SpecDocument1 pageRE500 30oc SpeclnanescuNo ratings yet

- Gate HouseDocument6 pagesGate HouselnanescuNo ratings yet

- ContentDocument1 pageContentlnanescuNo ratings yet

- RTGDocument8 pagesRTGlnanescuNo ratings yet

- DrainageDocument5 pagesDrainagelnanescuNo ratings yet

- Grai TecDocument1 pageGrai TeclnanescuNo ratings yet

- Container BeamsDocument7 pagesContainer BeamslnanescuNo ratings yet

- RTGDocument8 pagesRTGlnanescuNo ratings yet

- Borderou Planuri PutDocument2 pagesBorderou Planuri PutlnanescuNo ratings yet

- Constantza Sewerage and WWTP Rehabilitation Pumping Stations and SewerageDocument1 pageConstantza Sewerage and WWTP Rehabilitation Pumping Stations and SeweragelnanescuNo ratings yet

- ContentDocument1 pageContentlnanescuNo ratings yet

- RMGDocument6 pagesRMGlnanescuNo ratings yet

- MD 90Document116 pagesMD 90lnanescuNo ratings yet

- Maurice Nicoll The Mark PDFDocument4 pagesMaurice Nicoll The Mark PDFErwin KroonNo ratings yet

- Systems BOX Wall Retaining Keystone Aluminum Contech Culverts Plate Structural & ArchesDocument1 pageSystems BOX Wall Retaining Keystone Aluminum Contech Culverts Plate Structural & ArcheslnanescuNo ratings yet

- Calculo de Canal Abierto Con ManningDocument2 pagesCalculo de Canal Abierto Con ManningJuan BobedaNo ratings yet

- ApplicationsDocument12 pagesApplicationspuretone711100% (1)

- Calculo de Canal Abierto Con ManningDocument2 pagesCalculo de Canal Abierto Con ManningJuan BobedaNo ratings yet

- Grai TecDocument1 pageGrai TeclnanescuNo ratings yet

- FHWA-NHI-00-043 - Mechanically Stabilized Earth Walls and Reinforced Soil Slopes Design and Construction GuidelinesDocument418 pagesFHWA-NHI-00-043 - Mechanically Stabilized Earth Walls and Reinforced Soil Slopes Design and Construction Guidelinestenkken1504100% (2)

- 4563Document58 pages4563nikosNo ratings yet

- Module 7Document2 pagesModule 7prof_ktNo ratings yet

- Opentbs Demo: Merge Data With A ChartDocument4 pagesOpentbs Demo: Merge Data With A Charteduarditom1No ratings yet

- Grade6 Integers Multiple Additions Subtractions PDFDocument9 pagesGrade6 Integers Multiple Additions Subtractions PDFEduGainNo ratings yet

- Gram-Charlier para Aproximar DensidadesDocument10 pagesGram-Charlier para Aproximar DensidadesAlejandro LopezNo ratings yet

- TruShot Product Sheet-05-18 PDFDocument2 pagesTruShot Product Sheet-05-18 PDFAgostina MiniNo ratings yet

- Secure Password-Driven Fingerprint Biometrics AuthenticationDocument5 pagesSecure Password-Driven Fingerprint Biometrics AuthenticationDorothy ManriqueNo ratings yet

- 71cryptocurrencies Have Become One of The Hottest Topics in The Financial WorldDocument2 pages71cryptocurrencies Have Become One of The Hottest Topics in The Financial WorldicantakeyouupNo ratings yet

- @airbus: Component Maintenance Manual With Illustrated Part ListDocument458 pages@airbus: Component Maintenance Manual With Illustrated Part Listjoker hotNo ratings yet

- Brushed Axial Fans: VA85-A101-96A Performance DiagramDocument3 pagesBrushed Axial Fans: VA85-A101-96A Performance DiagramJaskaran SinghNo ratings yet

- Material SelectionDocument99 pagesMaterial SelectionRaj Bindas100% (8)

- Spouses Aggabao v. Parulan, Jr. and ParulanDocument5 pagesSpouses Aggabao v. Parulan, Jr. and ParulanGeenea VidalNo ratings yet

- Noam Chomsky Propaganda Modela Critical EvaluationDocument24 pagesNoam Chomsky Propaganda Modela Critical Evaluationsatyanarayana vuyyapuNo ratings yet

- Converting WSFU To GPMDocument6 pagesConverting WSFU To GPMDjoko SuprabowoNo ratings yet

- VRIL-Compendium-Vol-7-Dendritic Ground Systems-1992 PDFDocument204 pagesVRIL-Compendium-Vol-7-Dendritic Ground Systems-1992 PDFAnton Dremlyuga100% (3)

- Delhi Metro Rail Corporation LTD Jr. Engineer Results PDFDocument3 pagesDelhi Metro Rail Corporation LTD Jr. Engineer Results PDFedujobnewsNo ratings yet

- SMB GistDocument7 pagesSMB GistN. R. BhartiNo ratings yet

- Djiwandono, Indonesian Financial Crisis After Ten Years: Some Notes On Lessons Learned and ProspectsDocument12 pagesDjiwandono, Indonesian Financial Crisis After Ten Years: Some Notes On Lessons Learned and ProspectsMuhammad Arief Billah100% (1)

- CH 5 Audit-Planning MCQDocument3 pagesCH 5 Audit-Planning MCQEhab hoba0% (1)

- FLO-2D Storm Drain Manual - Build 17Document148 pagesFLO-2D Storm Drain Manual - Build 17royerarangoasisNo ratings yet

- Image Processing Toolbox - FunctionsDocument16 pagesImage Processing Toolbox - Functionsabcd efghNo ratings yet

- Masonry Design and DetailingDocument21 pagesMasonry Design and DetailingKIMBERLY ARGEÑALNo ratings yet

- Office of The Integrity Commissioner - Investigation Report Regarding The Conduct of Councillor Mark Grimes (July 05, 2016)Document44 pagesOffice of The Integrity Commissioner - Investigation Report Regarding The Conduct of Councillor Mark Grimes (July 05, 2016)T.O. Nature & DevelopmentNo ratings yet

- Cladding & Hardfacing ProcessesDocument16 pagesCladding & Hardfacing ProcessesMuhammed SulfeekNo ratings yet

- Ds Gigavue FM Fabric ManagerDocument9 pagesDs Gigavue FM Fabric ManagerMARCELOTRIVELATTONo ratings yet

- Bus 102 QuestionsDocument4 pagesBus 102 Questionsali2aliyuNo ratings yet

- QSK60 G6 PDFDocument2 pagesQSK60 G6 PDFShahzad Ali100% (2)

- Banking DictionaryDocument499 pagesBanking DictionaryVanessa Jenkins100% (4)

- Saurabh Pandey - Management Trainee - Recruitment - 5 Yrs 10 MonthsDocument2 pagesSaurabh Pandey - Management Trainee - Recruitment - 5 Yrs 10 MonthsDevraj GurjjarNo ratings yet

- Shear Stress ProblemsDocument5 pagesShear Stress ProblemsNoven VillaberNo ratings yet