Professional Documents

Culture Documents

MD1 0 V 111 01 00003 B

Uploaded by

tvpham1230%(1)0% found this document useful (1 vote)

123 views5 pagesvendor submission

Original Title

MD1-0-V-111-01-00003-B

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentvendor submission

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0%(1)0% found this document useful (1 vote)

123 views5 pagesMD1 0 V 111 01 00003 B

Uploaded by

tvpham123vendor submission

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

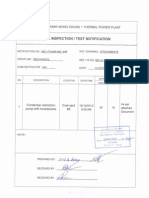

APPROVED A

Approved without exception

APPROVED WITH COMMENTS AC

Approved Subject to Incorporation of comments

RETURNED FOR CORRECTION RT

Insufficient Information/ Detail

Resubmit for Approval

REJECTED RJ

Complete redesign required

RECEIVED FOR INFORMATION I

Returned without comments

RECEIVED FOR INFORMATION IC

Returned with comments

any obligations covered under contract

Engineer:

Discipline:

Date:

Note: Approval or comments does not relieve the Contractor of

Pyry Energy

TWO(2) X 500MW

MONG DUONG 1 THERMAL POWER PLANT

David Langhorne

Senior Mec Engineer

27-Mar-13

Pyry Comment

Two(2) x 500MW Mong Duong 1 Thermal Power Plant Project

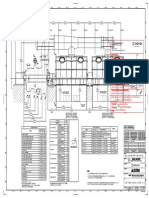

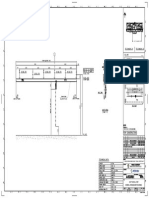

Dwg. / Doc. Title

Arrangement of Steam

Pipes and Valves

Dwg. / Doc. No. MD1-0-V-111-01-00003

HDEC DT No. MD1-HDH-EVN-X-195 Submitted Date 2012-06-15 Rev. A

Pyry TR No. 9A000323-000425 Received Date 2012-06-25

New HDEC DT No. MD1-HDH-EVN-X-2470 Re-Submitted Date 2013.02.25 B

Status Approved with Comments

Page 1 / 4

No. Pyrys Comments Contractors Reply / Action

1 Please show individual details of main steam,

CRH and HRH piping on the drawing.

Poyry comment on Rev. B

Add there drawing numbers to the list of

supplementary drawings.

Refer to the drawing as below;

MD1-1-P-111-24-00001 Piping Isometric

Drawing - Main Steam System (Unit #1)

MD1-1-P-111-24-00011 Piping Isometric

Drawing - Cold Reheat Steam System (Unit #1)

MD1-1-P-111-24-00021 Piping Isometric

Drawing - Hot Reheat Steam System (Unit #1)

2 All valves and piping KKS tag numbers shall

need to be mentioned.

Poyry comment on Rev. B

Closed

Reflected KKS tag numbers in all valves and

piping on this drawing.

3 Confirm that the main steam, CRH and HRH

piping and drain arrangement are in total

compliance with recommendations of ASME

TDP-1 as required per clause 6.9.1 of Book 3 of

11 of EPC Contract.

Poyry comment on Rev. B

There is no drain arrangement indicated on the

main steam P&I D document MD1-0-M-110-21-

00011. This was a comment made against Rev

A. Document MD1-0-V-111-21-00002 indicates

main steam drains but they are in HDEC scope

of supply.

Therefore the HDEC drains should be included

on the HDEC drawing.

Document MD1-0-M-110-21-00013 indicates

drain lines LBB10/20BR401 & 411. Document

MD1-0-V-111-21-00002 indicates hot reheat

drains LBB13/23 in HDEC scope of supply.

Therefore these drains should be included in the

HDEC drawing.

HDEC shall clarify the main steam and hot

reheat system drain arrangements

As you can see MS/CRH/HRH System P&ID

MD1-0-M-110-21-00011~13, Contractor

confirmed that the drain system of major piping

system meet the ASME TDP-1 requirement.

4 It is noted that the drain lines and valves on

those line are not shown on this drawing. Please

refer to the drawings which will show this.

Refer to MD1-0-V-111-01-00038 PIPING

ARRAGEMENT OF STEAM SEAL PIPING

(1/6) (It will be submitted after fixing the

arrangement of piping)

Page 2 / 4

No. Pyrys Comments Contractors Reply / Action

Poyry comment on Rev. B

Document received however it does not show

the required detail.

5 Please show the location of drain lines upstream

of turbine stop valve in line with ASME TDP-1

recommendations. These drain are required to

have minimum 1 inch inside diameter. Which

drawings depict these?

Poyry comment on Rev. B

See response to item 3. Also the request is for

the location of the drains in relation to the

turbine main steam and hot reheat stop valves.

As you can see MS/CRH/HRH System P&ID

MD1-0-M-110-21-00011~13, the drain system of

major piping system meet the ASME TDP-1

requirement. DN 50mm piping is adopted at all

drain line in major piping system.

6 Please show the location of Turbine stop valves

before and after seat drain connection in line

with ASME TDP-1 recommendation.

Poyry comment on Rev. B

Closed

For the location of MSV before and after seat

drain / MSV leak-off, refer to interface point

SD111, SD121, SD211, SD221 / SS511, SS521

on the drawing : OUTLINE-MAIN

STOP&CONTROL VALVE_MD1-0-V-111-10-

00001~2.

It seems that Owner comments the document

based on the old version of ASME TDP-1. We

confirmed that the turbine drain system meet the

latest version of ASME TDP-1.

7 Please show the location of Turbine control

valves before and after seat drain connection in

line with ASME TDP-1 recommendation

Poyry comment on Rev. B

Closed

For the location of CV leak-off, refer to interface

point SS530 ~ SS537 on the drawing :

OUTLINE-MAIN STOP&CONTROL

VALVE_MD1-0-V-111-10-00001~2.

It seems that Owner comments the document

based on the old version of ASME TDP-1. We

confirmed that the turbine drain system meet the

latest version of ASME TDP-1.

8 Please confirm that the drains on each loop

piping at downstream of control valves are of

inch minimum inside diameter as per ASME

TDP-1 recommendations. This does not seem

possible with 1 inch socket welded drain

connections as shown currently.

Poyry comment on Rev. B

Closed

Drain point on each loop piping at downstream

of control valve is satisfied with ASME TDP-

1(3/4 minimum inside dia.).

NPS 1 is larger than 3/4 I.D.

It seems that Owner comments the document

based on the old version of ASME TDP-1. We

confirmed that the turbine drain system meet the

latest version of ASME TDP-1.

9 Please explain the purpose of the ventilator

valve mentioned on the drawing. Please refer to

the P&ID which shows this valve along with

valve KKS tag number.

When the turbine trip, the HP section may

overheat due to windage losses. It is a result of

the buckets spinning in the high pressure and

temperature steam that is bottled up between

the main stop valve and the RSV. When this

occurs, windage losses quickly raise the temp.

of the spinning buckets. At high temp. the

Page 3 / 4

No. Pyrys Comments Contractors Reply / Action

Poyry comment on Rev. B

The highlighted part of the comment has not

been addressed.

bucket material strength is reduced and damage

may result. When turbine start-up, need to

cooling HP section due to reverse flow

operating. To avoid this problem, a ventilator

valve is placed on the steam main steam pipe.

10 Please explain the purpose of the blowdown

valve mentioned on the drawing. Please refer to

the P&ID which shows this valve along with

valve KKS tag number.

Poyry comment on Rev. B

The highlighted part of the comment has not

been addressed.

BDV is closed in normal operation. However

when turbine trip, this valve opens, and any

steam that would have leaked from the HP to

the IP turbine goes instead to the condenser.

11 Which drawing shows the orientation of the CRH

connections? Confirm the provision of minimum

6 inch drain pot as close to the turbine as

practical and at any additional low point for CRH

line, and minimum 2 inch drain connection from

each such drain pot for CRH line. Each drain pot

shall have 2 level sensing devices, for automatic

actuation of the drain valves. These are required

per ASME TDP-1 recommendations. Other

recommendations of TDP1 also apply. Which

drawing will show these?

Poyry comment on Rev. B

The highlighted part of the comment has not

been addressed.

Drain pot size closed

The drawing identifying the location of the CRH

drain pots has not been identified.

As you can see MS/CRH/HRH System P&ID

MD1-0-M-110-21-00011~13, the drain system of

major piping system meet the ASME TDP-1

requirement. DN 250mm and DN300mm drain

pot with DN 50mm drain piping is adopted at all

drain line in major piping system.

12 Confirm the drain provisions on the HRH pipe

and Combined Reheater stop and control valve,

and illustrate how ASME TDP-1

recommendations are complied.

Poyry comment on Rev. B

The comment has not been addressed. The

answer is a response to the previous question.

As you can see MS/CRH/HRH System P&ID

MD1-0-M-110-21-00011~13, the drain system of

major piping system meet the ASME TDP-1

requirement. DN 250mm and DN300mm drain

pot with DN 50mm drain piping is adopted at all

drain line in major piping system.

13. Complete all information shown as LATER on

the drawing

Poyry comment on Rev. B

Noted.

Reflected on drawing. (Q-2), (Q-7)

In case movements table, it will be filled out after

detail analysis are finalized.

14. Coordinate with EPC Contractor and confirm

which notes apply specifically to this project, as

they seem to be generic in nature at this stage.

Notes in this drawing are specially applied to

MongDuong1 project.

Page 4 / 4

No. Pyrys Comments Contractors Reply / Action

Poyry comment on Rev. B

Noted. See comment 1.

15 Poyry comment on Rev. B

The identification of the main steam control

valve differs from P&I Diagram MD1-0-V-111-

21-00002. The error would appear to be on the

P&I Diagram which only has two KKS identifiers

for four valves.

16 Poyry comment on Rev. B

The KKS identification of the loop pipes from the

main steam control valves differs from the P&I

Diagram. On the P&I Diagram CV3 is

connected to line BR003. This drawing

indicates it connected to BR004.

Consequently the connection from CV4 is also

incorrect.

You might also like

- LP Turbine Exhaust Loss CurveDocument1 pageLP Turbine Exhaust Loss CurveShameer MajeedNo ratings yet

- VGB R-167 e ContentDocument6 pagesVGB R-167 e ContentFayaz ShaikNo ratings yet

- OM Document For Seawater Booster Pump For FGDDocument109 pagesOM Document For Seawater Booster Pump For FGDAnh CatNo ratings yet

- File - 20220523 - 210015 - Pid FGDDocument11 pagesFile - 20220523 - 210015 - Pid FGDThắng NguyễnNo ratings yet

- ThrustBearing Orion PDFDocument13 pagesThrustBearing Orion PDFFarzadNo ratings yet

- T219AB-384A9554 Rev E Deaerating Condenser Functional SpecificationDocument6 pagesT219AB-384A9554 Rev E Deaerating Condenser Functional SpecificationvankayalasuryaNo ratings yet

- Turbine Bypass System - HORADocument11 pagesTurbine Bypass System - HORAhozipekNo ratings yet

- Convert Thermal Energy to ElectricityDocument3 pagesConvert Thermal Energy to ElectricityHaris RanaNo ratings yet

- KOSO Turbine Bypass Systems - (Sales Training, March 10 2011) - Rev ADocument78 pagesKOSO Turbine Bypass Systems - (Sales Training, March 10 2011) - Rev Atriplbingazi100% (2)

- VT4-YT01-P1LAC-120004 - RE - Technical Data Sheet For Main BFP& BFBPDocument7 pagesVT4-YT01-P1LAC-120004 - RE - Technical Data Sheet For Main BFP& BFBPNguyễn Hữu LượngNo ratings yet

- WH Vacuum in Steam TurbineDocument2 pagesWH Vacuum in Steam Turbinemiths_0087No ratings yet

- Establishing Proper Pressure Drop For Feedwater Flow Control ValvesDocument5 pagesEstablishing Proper Pressure Drop For Feedwater Flow Control ValvesAkshay SetlurNo ratings yet

- PDFDocument49 pagesPDFshameer_febiNo ratings yet

- Startup Purge Credit Benefits Combined Cycle OperationsDocument13 pagesStartup Purge Credit Benefits Combined Cycle OperationsVaibhav SarinNo ratings yet

- Gea32885 Bouchain Whitepaper Final Aug 2016 PDFDocument8 pagesGea32885 Bouchain Whitepaper Final Aug 2016 PDFMd. Humayun Kabir ChowdhuryNo ratings yet

- Catalogue - ElysisPUREDocument20 pagesCatalogue - ElysisPURETAREK ALMAHDYNo ratings yet

- DuctIsolationSystems DiverterDampersDocument12 pagesDuctIsolationSystems DiverterDampersefte_14100% (1)

- Suction Strainer Boxes: Standard Specification ForDocument5 pagesSuction Strainer Boxes: Standard Specification ForEduardoNo ratings yet

- Practical Guidelines For Determining Electrical Area ClassificationDocument17 pagesPractical Guidelines For Determining Electrical Area ClassificationOmar AzzainNo ratings yet

- For Information: Doosan Heavy Industries & ConstructionDocument9 pagesFor Information: Doosan Heavy Industries & ConstructionĐể MaiNo ratings yet

- Condensate System Functional DescriptionDocument20 pagesCondensate System Functional Descriptionanbesivam87100% (1)

- Steam Turbines For Waste To EnergyDocument4 pagesSteam Turbines For Waste To EnergyJennifer GomezNo ratings yet

- Thyristor Control Heater Panel GuideDocument63 pagesThyristor Control Heater Panel Guidevaithy1990No ratings yet

- BB73-8.7m2 LP TurbineDocument2 pagesBB73-8.7m2 LP TurbineMan HumanNo ratings yet

- Operation and Maintenance Manual for Cooling TowerDocument39 pagesOperation and Maintenance Manual for Cooling TowerfaisalnadimNo ratings yet

- 15MW Steam Turbine Installation and Operation ManualDocument83 pages15MW Steam Turbine Installation and Operation ManualMohammed MuzzamilNo ratings yet

- KOGAS Natural Gas Ball Valve SpecificationDocument25 pagesKOGAS Natural Gas Ball Valve Specification윤병택No ratings yet

- HRSG High Pressure Evaporator Sampling For Internal DepositDocument26 pagesHRSG High Pressure Evaporator Sampling For Internal Depositak_thimiriNo ratings yet

- 3082-ET-A-005 - Diverter Damper System ManufacturingDocument137 pages3082-ET-A-005 - Diverter Damper System Manufacturingmanh hung leNo ratings yet

- HRSGDocument13 pagesHRSGMohit Tyagi100% (1)

- Technical Spec Control Valve 660 MWDocument136 pagesTechnical Spec Control Valve 660 MWSHIVAJI CHOUDHURY100% (1)

- 28990-Turbinebypass Prds PDFDocument12 pages28990-Turbinebypass Prds PDFbuddhivasu100% (2)

- 10069a 9 V06 Musg 00093Document4 pages10069a 9 V06 Musg 00093ahs beinNo ratings yet

- ASME PTC 7.1 Displacement PumpsDocument22 pagesASME PTC 7.1 Displacement PumpsLorenzo Antonio CordovaNo ratings yet

- Seawater Flue Gas DesulphurisationDocument2 pagesSeawater Flue Gas DesulphurisationNestramiNo ratings yet

- ACC - Offer 000984 Rev PDFDocument31 pagesACC - Offer 000984 Rev PDFMohamed SaaDNo ratings yet

- Product Specification: Forbes-Bryan Low Corrosion Tray Type Deaerator - 5Mw To 400MwDocument3 pagesProduct Specification: Forbes-Bryan Low Corrosion Tray Type Deaerator - 5Mw To 400MwCarlos ACNo ratings yet

- EPRI's Phosphate Continuum and Caustic Treatment GuidelineDocument59 pagesEPRI's Phosphate Continuum and Caustic Treatment GuidelineDian PiresNo ratings yet

- 20.12 - GEK72281f Steam Purity Recommendations For Steam TurbinesDocument14 pages20.12 - GEK72281f Steam Purity Recommendations For Steam TurbinesLIUNo ratings yet

- Api 610Document1 pageApi 610Angel CipagautaNo ratings yet

- Tubine Bypass SystemDocument12 pagesTubine Bypass Systemkalyanm203515No ratings yet

- Gas TurbineDocument18 pagesGas TurbinenivasssvNo ratings yet

- Supercritical Benson BoilerDocument18 pagesSupercritical Benson BoilerJerry Mateo100% (2)

- Job No: 6812A: NTPC - Lara Super Thermal Power Project Stage 1 (2X800 MW)Document6 pagesJob No: 6812A: NTPC - Lara Super Thermal Power Project Stage 1 (2X800 MW)A N MadhavanNo ratings yet

- HRSG OPERATION AND STARTUPDocument7 pagesHRSG OPERATION AND STARTUPM Moarraf Naeem100% (1)

- Waste Water TreatmentDocument91 pagesWaste Water TreatmentHariajahNo ratings yet

- Tech Paper - Reheat Steam Temperature Control Concept in Once-Through Boilers - A ReviewDocument5 pagesTech Paper - Reheat Steam Temperature Control Concept in Once-Through Boilers - A ReviewQen Zyg EizernNo ratings yet

- Power Air Preheater Ljungstrom Air Preheaters PDFDocument16 pagesPower Air Preheater Ljungstrom Air Preheaters PDFNaveen ChodagiriNo ratings yet

- FAC ToolDocument6 pagesFAC Toolsksrinivas_inNo ratings yet

- Air, Steam Vent Silencer - Enquiry Data SheetDocument1 pageAir, Steam Vent Silencer - Enquiry Data Sheetkishore1214No ratings yet

- Kawasaki's Presentation on FGD and SCR SystemsDocument20 pagesKawasaki's Presentation on FGD and SCR Systemsjitendrashukla10836No ratings yet

- SAMA Drawings ExamplesDocument9 pagesSAMA Drawings ExamplesJean De Armas SánchezNo ratings yet

- Explosion e Implosion CalderasDocument2 pagesExplosion e Implosion CalderasAntonio RamonNo ratings yet

- Steam DumpingDocument9 pagesSteam DumpingsrinivasanNo ratings yet

- O&Msec2 Heat & Material BalanceDocument8 pagesO&Msec2 Heat & Material Balanceugun87No ratings yet

- Estimating Condensate During HRSG PurgingDocument15 pagesEstimating Condensate During HRSG PurgingCoalhouse Walker JuniorNo ratings yet

- Approved: Pöyry EnergyDocument5 pagesApproved: Pöyry Energytvpham123No ratings yet

- Approved: Pöyry EnergyDocument3 pagesApproved: Pöyry Energytvpham123No ratings yet

- Approved: Pöyry EnergyDocument3 pagesApproved: Pöyry Energytvpham123No ratings yet

- MD1 0 V 113 01 00001 ADocument2 pagesMD1 0 V 113 01 00001 Atvpham123No ratings yet

- NLVNPF 0369 01Document49 pagesNLVNPF 0369 01tvpham123No ratings yet

- CV Pham Van TrinhDocument6 pagesCV Pham Van Trinhtvpham123No ratings yet

- Mong Duong 1 Thermal Plant Fire Layout Underground PipingDocument1 pageMong Duong 1 Thermal Plant Fire Layout Underground Pipingtvpham123No ratings yet

- Technical ScheduleDocument54 pagesTechnical Scheduletvpham123No ratings yet

- MD1 0 V 113 01 00001 ADocument2 pagesMD1 0 V 113 01 00001 Atvpham123No ratings yet

- MD1 0 F 750 23 00015 - R0Document1 pageMD1 0 F 750 23 00015 - R0tvpham123No ratings yet

- MD1 0 F 750 23 00016 - R0Document1 pageMD1 0 F 750 23 00016 - R0tvpham123No ratings yet

- Calculation of Ball Mill PowerDocument10 pagesCalculation of Ball Mill PowerMarey MorsyNo ratings yet

- MD1 0 F 750 23 00017 - R0Document1 pageMD1 0 F 750 23 00017 - R0tvpham123No ratings yet

- MD1 0 F 750 23 00018 - R0Document1 pageMD1 0 F 750 23 00018 - R0tvpham123No ratings yet

- Ball MillDocument14 pagesBall MillISLAM I. Fekry95% (20)

- CONVEYOR CALCULATION SHEET DraftDocument37 pagesCONVEYOR CALCULATION SHEET Drafttvpham12350% (6)

- ADB MD1 0 C D 0001 A, Geotechnical Soil Investigation Plan DrawingDocument2 pagesADB MD1 0 C D 0001 A, Geotechnical Soil Investigation Plan Drawingtvpham123No ratings yet

- Power Plant Drawing Reviewed with CommentsDocument2 pagesPower Plant Drawing Reviewed with Commentstvpham123No ratings yet

- 01-08-2013 Issue For InformationDocument5 pages01-08-2013 Issue For Informationtvpham123No ratings yet

- Md1 Itn MR Me 087 Condensor (VM 279)Document16 pagesMd1 Itn MR Me 087 Condensor (VM 279)tvpham123No ratings yet

- MD1 0 V 121 01 00001Document2 pagesMD1 0 V 121 01 00001tvpham123100% (1)

- Calculation for Generator Transformer SizingDocument19 pagesCalculation for Generator Transformer Sizingtvpham123No ratings yet

- MD1-ITN-MR-ME-136, Loose Part For LP #1A, LP#1B HeaterDocument5 pagesMD1-ITN-MR-ME-136, Loose Part For LP #1A, LP#1B Heatertvpham123No ratings yet

- MD1 0 e 182 06 00001 0Document6 pagesMD1 0 e 182 06 00001 0tvpham123No ratings yet

- Vmon 0030M Dji Irc 001Document83 pagesVmon 0030M Dji Irc 001tvpham123No ratings yet

- MD1-0-E-505!06!00001 Generator Transformer Sizing CalculationDocument19 pagesMD1-0-E-505!06!00001 Generator Transformer Sizing Calculationtvpham12350% (2)

- Md1-0-V-191!01!10207-0, Acwp Manual Hoist General Arrangement DrawingsDocument1 pageMd1-0-V-191!01!10207-0, Acwp Manual Hoist General Arrangement Drawingstvpham123No ratings yet

- MD1 Itn MR Me 088Document87 pagesMD1 Itn MR Me 088tvpham123No ratings yet

- MD1-0-V-191!11!10601-A, Detail Drawings For Compressed Air System HoistDocument2 pagesMD1-0-V-191!11!10601-A, Detail Drawings For Compressed Air System Hoisttvpham123No ratings yet

- MD1 ITN MR ME 122 - General Service PumpDocument7 pagesMD1 ITN MR ME 122 - General Service Pumptvpham123No ratings yet

- MD1-0-V-191!11!14701-A, Detail Drawings For ACWP Manual HoistDocument2 pagesMD1-0-V-191!11!14701-A, Detail Drawings For ACWP Manual Hoisttvpham123No ratings yet

- MD1 ITN MR ME 155 - Air Compressors W Other Equip. (VM 294)Document16 pagesMD1 ITN MR ME 155 - Air Compressors W Other Equip. (VM 294)tvpham123No ratings yet

- MD1 Itn MR Me 109Document61 pagesMD1 Itn MR Me 109tvpham123No ratings yet

- Md1 Itn MR Me 119 Compressed AirDocument25 pagesMd1 Itn MR Me 119 Compressed Airtvpham123No ratings yet

- Apex NTLM Authentication WPDocument14 pagesApex NTLM Authentication WPramaniqbal123100% (1)

- New wave theories of cognition criticismDocument40 pagesNew wave theories of cognition criticismJCNo ratings yet

- SI 60E 6H - DatasheetDocument1 pageSI 60E 6H - DatasheetAbhinashNo ratings yet

- Dereka Associates Profile 050510Document24 pagesDereka Associates Profile 050510David NGNo ratings yet

- Euler BucklingDocument6 pagesEuler Bucklingsuniljha121No ratings yet

- MTC RFP for Converged BSS/OSS SolutionDocument27 pagesMTC RFP for Converged BSS/OSS SolutionLaluMohan KcNo ratings yet

- Daily site report progressDocument9 pagesDaily site report progressVikrant KoulNo ratings yet

- 005-Sample Method Statement CivilDocument2 pages005-Sample Method Statement CivilS.C.Satish Chander100% (1)

- Magelis XBTGTDocument25 pagesMagelis XBTGTArturo FuentesNo ratings yet

- WS-I Basic Profile ComparisonDocument3 pagesWS-I Basic Profile Comparison88throwawayNo ratings yet

- Inno Monitor Q&ADocument3 pagesInno Monitor Q&Ajose navarroNo ratings yet

- Computer Network by Kanodia PublicationDocument30 pagesComputer Network by Kanodia PublicationNeha BhavsarNo ratings yet

- In Plane Response of Wide Spaced Reinforced Masonry Shear WallsDocument323 pagesIn Plane Response of Wide Spaced Reinforced Masonry Shear Wallstbrotea100% (1)

- Portrait Artists - BadgerDocument94 pagesPortrait Artists - BadgerThe 18th Century Material Culture Resource Center100% (1)

- 1 Haunted Perron ManorDocument185 pages1 Haunted Perron Manormiguel ghanemNo ratings yet

- Duct Presentation MaineDocument22 pagesDuct Presentation MaineCharmaine ManliguezNo ratings yet

- SE506 Auto Ic - China SE506 Auto Ic Products PDFDocument2 pagesSE506 Auto Ic - China SE506 Auto Ic Products PDFDhany SiregarNo ratings yet

- Column Shortening Effects and Prediction MethodsDocument28 pagesColumn Shortening Effects and Prediction MethodsKhaled Ali AladwarNo ratings yet

- Technical PDFDocument634 pagesTechnical PDFUlianov SinforosoNo ratings yet

- Marconi SMA/MSH - Carritech TelecommunicationsDocument2 pagesMarconi SMA/MSH - Carritech TelecommunicationsCarritech TelecommunicationsNo ratings yet

- Work Break Down StructureDocument2 pagesWork Break Down StructuretambaNo ratings yet

- US548160Document3 pagesUS548160Rohan KulkarniNo ratings yet

- Interior Design Freshmen Parents Program OrientationDocument73 pagesInterior Design Freshmen Parents Program OrientationCrisencio M. PanerNo ratings yet

- Telecommunications TechnicianDocument4 pagesTelecommunications Technicianapi-78381064No ratings yet

- Integration EVS AvidTM V4.3 PDFDocument113 pagesIntegration EVS AvidTM V4.3 PDFLaurentiu IacobNo ratings yet

- Boris Groys - Self Design and Public SpaceDocument6 pagesBoris Groys - Self Design and Public SpaceMartaNo ratings yet

- Sanghvi Estella BycullaDocument6 pagesSanghvi Estella BycullaMandar KadamNo ratings yet

- Architect List PunjabDocument11 pagesArchitect List Punjabkapil100% (2)

- SAP HANA Security Introduction: Key Concepts & FeaturesDocument34 pagesSAP HANA Security Introduction: Key Concepts & FeaturesSachin Deo100% (1)

- IPL Logic FlowDocument40 pagesIPL Logic Flowapi-3828592100% (1)