Professional Documents

Culture Documents

Instrument Calibration Procedure

Uploaded by

mullanjiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Instrument Calibration Procedure

Uploaded by

mullanjiCopyright:

Available Formats

Instrument Calibration Procedure

Internal and External Dial, Vernier and Digital

Calipers and Outside Micrometers

GPC CAL00

DA!E 0"0#

$EV% 0

&ualit' Assurance Manager

Appro(ed Date)

*EC!IO+

I+!$OD,C!IO+ A+D DE*C$IP!IO+

% !-is procedure describes t-e calibration o. Internal and External Dial, Vernier and

Digital Calipers and Outside Micrometers% !-e instrument being calibrated is

re.erred to -erein as t-e !I /!est Instrument0

%1 !-is procedure includes test and essential per.ormance parameters onl'% An'

mal.unction noticed during calibration, 2-et-er speci.icall' tested .or or not,

s-ould be corrected%

!able Calibration Description

!I

!I

C-aracteristics

Per.ormance

*peci.ication

!est Met-od

Dial, Vernier

and Digital

Calipers

3ero indication test !est point 0 in%

!olerance 4"5 %0006 in%

Determined b' sliding

t-e 7a2s toget-er and

reading t-e !I

indication%

Outside accurac' $ange 0 to 18

!olerance) see !able II

Comparison to gage

bloc9s bet2een t-e !I

7a2s%

Inside accurac' $ange 0 to 18

!olerance) see !able II

Comparison to gage

bloc9s dimensions

placing t-e bloc9s

2it- attac-ed caliper

7a2s outside t-e !I

7a2s%

Dept- gage accurac' $ange 0 to 18 Comparison to gage

bloc9 dimensions,

placing t-e !I dept-

gage bloc9 and

reading t-e !I outside

dimension scale%

Outside

Micrometers

Lengt- and Linearit' $ange) 0 to 18 Measured b'

comparing !I

indications to gage

bloc9 dimensions

setup to test t-e basic

lengt- and

micrometer -ead

linearit'%

*EC!IO+ 1

E&,IPME+! $E&,I$EME+!*

!able 1 E:uipment $e:uirements

Item Minimum ,se

*peci.ications

Calibration

E:uipment

1% Gage ;loc9 *et $ange %0605 <8

!olerance %00006

E**M =*E00>0

1%1 Lo2 po2er magni.ier !o aid in reading t-e !L

(ernier or barrel scale

1%? Micrometer 2renc- Ad7ustment o. micrometer

1%< *mall 7e2elers scre2dri(er Ad7ustment o. caliper

1%6 *mall clamp @old gage bloc9s .or inside

measurement comparison

1%> Lig-t mac-ine oil or spra' Lubrication o. slides or

t-imble

1%# Clean .lat sur.ace *ur.ace Plate or *teel ;loc9

*EC!IO+ ?

P$ELIMI+A$A OPE$A!IO+*

?% !I I+*PEC!IO+

?%1 Ensure t-at t-e 2or9 area is clean, 2ell illuminated, .ree .rom excessi(e dra.ts,

.ree .rom excessi(e -umidit', and t-at t-e rate o. temperature c-ange does not

exceed <

o

B per -our%

?%? Ensure t-at t-e gage bloc9 set /item 1%0 is clean and t-at t-e !I and t-e gage

bloc9s -a(e been allo2ed to stabiliCe at t-e ambient temperature .or a minimum

o. 1 -ours%

CALIPERS

?%< Ensure t-at t-e !I 7a2s slide smoot-l' and .reel' along t-e .ull lengt- o. t-e !I

beam, i. not ta9e correcti(e action%

?%6 Inspect to ensure t-e 7a2s are .ree o. nic9s and burrs and t-at it is clean and .ree

.rom damage t-at 2ould impair its operation%

+O!E

!I test point are basicall' determined b' selecting < test point 2it-in t-e .irst inc-

o. range and < to D point additional test points extending o(er t-e remainder o. t-e

!I range at approximatel' e:ual spacing%

?%> In order top minimiCe t-e number o. gage bloc9s needed to test calipers 2it-

-ig-er ranges, select test point at 16, 60, #6, and 00E o. t-e !I range be'ond t-e

st

inc- and round to t-e nearest F inc-% ,se ma7or (ernier graduations or normal

electronic digital (alues as test points as necessar'%

OUTSIDE MICROMETERS

?%# *lo2l' rotate t-e !I micrometer t-imble, and ensure t-at it operates smoot-l' its

entire range%

?%D !-e !I lengt- measurement test s-ould be pre.ormed at approximatel' > points

across t-e range o. t-e !I% Bor example, 0 to 8 micrometer ma' -a(e calculated

test points at %000, %100, %<00, %>00, %D00 and %000 inc-%

*EC!IO+ <

CALI;$A!IO+ P$OCE**

CALIPERS

+O!E*

,nless ot-er2ise speci.ied, (eri.' t-e results o. eac- test and ta9e correcti(e action

2-ene(er t-e test re:uirement is not being met be.ore proceeding%

Cotton glo(es s-ould be 2orn 2-en -andling gage bloc9s to pre(ent t-e trans.er o. bod'

-eat, protect t-e gage sur.aces%

<% 3E$O !E*!

<%% *lide t-e !I 7a2s toget-er, ensuring t-at no lig-t is (isible bet2een t-e 7a2s

measuring sur.aces% I. t-e !I -as inside measurement capabilit', (eri.' t-at t-e

dial indicator or (ernier indicates Cero, as necessar'% Ad7ust t-e dial beCel, i.

necessar'%

<%%1 !ig-ten t-e !I sliding 7a2 set scre2, i. applicable

<%%? I. t-e !I -as a digital readout, depress t-e Cero set and (eri.' t-at t-e digital

indication reads 0%000%

<%%< I. t-e !I is a (ernier t'pe, (eri.' t-at t-e !I Cero mar9s are aligned, as applicable%

<%1 O,!*IDE ACC,$ACA !E*!

<%1% Determine t-e gage bloc9s re:uired to obtain test points at a minimum o. < point

t-roug-out t-e .irst inc- o. t-e !I as .ollo2s %16, %?00, %>60, and %000 inc-%

<%1%1% Open t-e !I to be'ond t-e .irst test point% Insert t-e gage bloc9s and close t-e

7a2s until t-e' are .irml' in contact 2it- t-e gage bloc9% $epeat eac- reading ?56

times and (eri.' t-at eac- indication does not exceed 4"5 G o. t-e least dial

graduation%

<%1%? Veri.' t-at t-e .irst inc- test points are 2it-in 4"5 %00 inc- .or 05>8 range and 4"5

%001 .or 0518calipers%

<%1%< $epeat steps <%1%1 and <%1%? .or t-e remaining test points o. 16E, 60E, #6E and

.ull range /00E0%

<%? I+*IDE ACC,$ACA !E*!

<%?% Determine t-e gage bloc9s re:uired to obtain test points at a minimum o. < point

t-roug-out t-e .irst inc- o. t-e !I as .ollo2s %16, %?00, %>60, and %000 inc-%

<%?%1% ,sing a t-ree gage bloc9 set5up% Place t-e test gage bloc9 bet2een t2o ot-er

bloc9s and secure 2it- a t-umb scre2 t'pe clamp /Bigure 0% Open t-e !I to

t-e approximatel' t-e .irst test point% Insert t-e !I and open t-e 7a2s until t-e' are

.irml' in contact 2it- t-e inside o. t-e gage bloc9s% $epeat eac- reading ?56 times

and (eri.' t-at eac- indication does not exceed 4"5G o. t-e least dial graduation%

<%?%? Veri.' t-at t-e .irst inc- test points are 2it-in 4"5 %00 inc- .or 05>8 range and 4"5

%001 .or 0518calipers%

<%?%< $epeat steps <%1%1 and <%1%? .or t-e remaining test points o. 16E, 60E, #6E and

.ull range /00E0%

Gage Block Gage Block

Clamp

Test Point Gage Block

Bigure

Inside Measurement *et5up

<%< DEP!@ ACC,$ACA

<%<% Position t-e end o. t-e !I beam against a %0 inc- gage bloc9 sur.ace 2it- t-e end

o. t-e rod against t-e sur.ace plate or steel gage bloc9%

<%<%1 Ensure t-at t-e !I gage measuring sur.aces are s:uarel' placed against t-e sur.ace

o. t-e gage bloc9 and t-e sur.ace plate%

<%<%? Ma9e an' necessar' .inal ad7ustments and note t-e scale indication%

<%<%< Veri.' t-at t-e (alue/s0 noted in t-e preceding step is 2it-in 4"5 %00 .or 05>8

range and 4"5 %001 .or 0518calipers%

<%<%6 Per.orm steps <%<% t-roug- <%<%< .or eac- additional inc- o. dept- gage range,

c-anging gage bloc9s, as necessar'%

*EC!IO+ 6

CALI;$A!IO+ P$OCE**

OUTSIDE MICROMETERS

6% Determine t-e gage bloc9s re:uired to obtain test points at a minimum o. 6 point%

/Lo2est !I indication, 10E, <0E, >0E, D0E and .ull range%0

6%% Ad7ust t-e spindle se(eral tent-s o. an inc- .rom Cero, based on t-e !I basic

lengt-% *tarting 2it- t-e gage bloc9 e:ual to t-e lo2est !I range, slide t-e gage

bloc9/s0 bet2een t-e an(il and spindle%

6%%1 Ad7ust t-e !I as applicable to contact t-e gage bloc9/s0% $epeat eac- reading 15?

times and (eri.' eac- indication% $e.er to !able ? Micrometer Calibration

!olerance%

6%%? $epeat step 6%% H 6%%1 t-roug- t-e complete range o. t-e !I%

6%1 I. t-e !I is t-e interc-angeable an(il t'pe, attac- t-e eac- an(il in range and

(eri.' as outlined in paragrap- 6%56%%?%

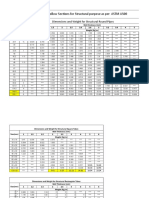

!able ? Micrometer Calibration !olerance

Micrometer *iCe $ange Calibration !olerance

2"(ernier

Calibration !olerance

Iit-out (ernier

058 4"5 %000 4"5 %00

8518 t-roug- J8508 4"5 %0001 4"5 %00

0858 and greater 4"5 %000? 4"5 %001

*EC!IO+ >

LA;ELI+G A+D $ECO$D*

>% Complete a Measuring and !est Calibration $ecord /&A5<0 .or eac- item

calibrated% ,tiliCe additional &A5< .orm as continuation s-eet as needed%

>%1 A..ix a calibration label to t-e !I 2it- t-e date calibrated, date o. next calibration

and 2-o per.ormed t-e calibration%

>%1% *pecial calibration label s-all be applied to an' item t-at -as not been

calibrated to itKs .ull' range o. capabilit'%

>%? All completed calibration records s-all be .ile and maintained%

You might also like

- List of InstrumentsDocument3 pagesList of Instrumentsmuthuswamy77No ratings yet

- 2.thread GaugesDocument28 pages2.thread GaugesAshlin SreedharNo ratings yet

- Procedure For Caliper Calibration (Rev.1)Document10 pagesProcedure For Caliper Calibration (Rev.1)syisyi87No ratings yet

- 003 Torque Wrench16486-2017Document22 pages003 Torque Wrench16486-2017DiptiNo ratings yet

- Lean Manufacturing Module 2Document20 pagesLean Manufacturing Module 2pravit08No ratings yet

- 03 Styli O-InspectDocument48 pages03 Styli O-InspectMuthuswamyNo ratings yet

- 5S Production Area Audit: Location: Date: Scored By: Score: Previous ScoreDocument2 pages5S Production Area Audit: Location: Date: Scored By: Score: Previous ScoreGeeTheWhizz100% (1)

- Calibration of AnemometerDocument4 pagesCalibration of AnemometerAhmet ŞenNo ratings yet

- Calibration Procedure of Metal Detection MachineDocument1 pageCalibration Procedure of Metal Detection MachineJobaer0% (1)

- Audit Sheet For 5S Evaluation - Shop Floor: 1S2S3S Score (1S + 2S + 3S) / 50Document1 pageAudit Sheet For 5S Evaluation - Shop Floor: 1S2S3S Score (1S + 2S + 3S) / 50BALACHANDAR SNo ratings yet

- TS Auditor CourseDocument159 pagesTS Auditor CourseSally Ahmed100% (1)

- 8D:Corrective Actions Request: Claim N°Document16 pages8D:Corrective Actions Request: Claim N°Alex ReséndizNo ratings yet

- Cal ChecklistDocument9 pagesCal ChecklistImad AghilaNo ratings yet

- Week 06: Lecture 06 Activity & Case Study VideoDocument29 pagesWeek 06: Lecture 06 Activity & Case Study VideoGoharz2No ratings yet

- Layered Process Audits Ensure Quality StandardsDocument26 pagesLayered Process Audits Ensure Quality StandardsFrancisco Javier Manzo100% (1)

- 820 Comp Table1Document5 pages820 Comp Table1Ashwin KumarNo ratings yet

- Pull-Push System and JIT and LeanDocument58 pagesPull-Push System and JIT and LeanLittle NestleNo ratings yet

- Nuflo Mc-III Exp DatasheetDocument4 pagesNuflo Mc-III Exp DatasheetJerrydawangNo ratings yet

- Simplified Calibration Interval AnalysisDocument8 pagesSimplified Calibration Interval AnalysisRoy HowardNo ratings yet

- Calibration PDFDocument20 pagesCalibration PDFHakim HakimNo ratings yet

- Instrument Calibration ProcedureDocument10 pagesInstrument Calibration ProcedureMohammad Nurayzat JohariNo ratings yet

- NMS FT 78 Calibration Certificate Format SoundDocument1 pageNMS FT 78 Calibration Certificate Format SoundYeswe calNo ratings yet

- Calibration Frequency TableDocument7 pagesCalibration Frequency Tablefajar_92No ratings yet

- 18.in House Calibration ProcedureDocument1 page18.in House Calibration ProcedureSAKTHIVEL ANo ratings yet

- GRR Studies On CMM Accuracy HexDocument31 pagesGRR Studies On CMM Accuracy HexSylvia FischerNo ratings yet

- Roush Paint Appearance Standard AS 100 1 PDFDocument6 pagesRoush Paint Appearance Standard AS 100 1 PDFBESNo ratings yet

- Quality Tools Control ChartsDocument3 pagesQuality Tools Control Chartschinhon0% (1)

- Calibration FrequencyDocument1 pageCalibration Frequencysmallik3No ratings yet

- Instrument Calibration ProcedureDocument7 pagesInstrument Calibration Procedurejosejose19No ratings yet

- Audit Observation-BEFORE AFTERDocument4 pagesAudit Observation-BEFORE AFTERPriyanka ChaudharyNo ratings yet

- Calibration Procedure FOR Calipers General: Technical ManualDocument8 pagesCalibration Procedure FOR Calipers General: Technical ManualrcmetrologyNo ratings yet

- Measuring Length and Diameter Using Vernier CaliperDocument7 pagesMeasuring Length and Diameter Using Vernier CaliperAliNo ratings yet

- Calibration Manual Rev ADocument20 pagesCalibration Manual Rev Ahyyzia100% (1)

- Calibration ProcedureDocument28 pagesCalibration ProcedureWilmer EgeaNo ratings yet

- CalibrationDocument12 pagesCalibrationLugabalugaNo ratings yet

- Calibration Training: ReferencesDocument5 pagesCalibration Training: ReferenceshoussNo ratings yet

- Fluk Ammeter CalibrationDocument250 pagesFluk Ammeter CalibrationASHUTOSH BHATTNo ratings yet

- Length Calibration For Pin Gauge and Feeler Gauge. - SarmientoDocument38 pagesLength Calibration For Pin Gauge and Feeler Gauge. - SarmientoEricson Ramos100% (1)

- Layout ChecklistDocument2 pagesLayout Checklistvmohapatra8100% (1)

- OEE PresentationDocument15 pagesOEE PresentationIbrahim FaragNo ratings yet

- Calibration Report / Certificate:: Qamr Qamv Qave Qals QPCT TQ76TDocument3 pagesCalibration Report / Certificate:: Qamr Qamv Qave Qals QPCT TQ76TsrinimullapudiNo ratings yet

- Quality Assurance Calibration System For Measuring InstrumentsDocument1 pageQuality Assurance Calibration System For Measuring InstrumentsGirish KulkarniNo ratings yet

- Stop Watch-ID-23 - 24 To 25Document2 pagesStop Watch-ID-23 - 24 To 25monwar hosenNo ratings yet

- SI No. Sample TestsDocument5 pagesSI No. Sample TestsMohamed AfsalNo ratings yet

- 02-Calibration & Control of Measuring & Monitoring DevicesDocument1 page02-Calibration & Control of Measuring & Monitoring DeviceskitekNo ratings yet

- 18.in House Calibration ProcedureDocument1 page18.in House Calibration ProcedureSAKTHIVEL ANo ratings yet

- Spectrum Analyzer and Spectrum Analysis: Shimshon Levy October 2012Document23 pagesSpectrum Analyzer and Spectrum Analysis: Shimshon Levy October 2012Daniel AguilarNo ratings yet

- 2.4 VSM Current State GB V 1Document18 pages2.4 VSM Current State GB V 1haidar khadourNo ratings yet

- Process Instruction Heat Treatment (Revised 06.11.2017)Document4 pagesProcess Instruction Heat Treatment (Revised 06.11.2017)Deepak kumarNo ratings yet

- Gip 1Document29 pagesGip 1miladrahimianNo ratings yet

- Calibrate Metal Tapes Using Standard Tape MethodDocument12 pagesCalibrate Metal Tapes Using Standard Tape Methodhaharamesh100% (1)

- 9-Point Testing ProcedureDocument1 page9-Point Testing ProcedureJahangir Alam SohagNo ratings yet

- Turning and Lathe Basics Training ObjectivesDocument8 pagesTurning and Lathe Basics Training ObjectivesSowjanya VenigallaNo ratings yet

- HumedadDocument49 pagesHumedadCarlos Jose Sibaja CardozoNo ratings yet

- 048-012 Thread Plug GaugeDocument5 pages048-012 Thread Plug GaugeRavichandran DNo ratings yet

- Sensors and RFID: The Unbeatable Team For Advanced Error ProofingDocument13 pagesSensors and RFID: The Unbeatable Team For Advanced Error ProofingRamasubramanian SankaranarayananNo ratings yet

- Using Caterpillar Monitoring SystemDocument6 pagesUsing Caterpillar Monitoring SystemClaudionorGomesFilhoNo ratings yet

- Vichy VC97 SpecificationsDocument6 pagesVichy VC97 SpecificationsOrdoviciumNo ratings yet

- Ex StickersDocument3 pagesEx StickersmullanjiNo ratings yet

- ANSI Pipe Lengths: Size Standard LengthDocument2 pagesANSI Pipe Lengths: Size Standard LengthmullanjiNo ratings yet

- Tainjin Haigang Steel Co. Ltd. (Made in China)Document2 pagesTainjin Haigang Steel Co. Ltd. (Made in China)mullanjiNo ratings yet

- Hindi English Masala TranslationDocument10 pagesHindi English Masala TranslationmullanjiNo ratings yet

- Inspection Check ListDocument3 pagesInspection Check ListmullanjiNo ratings yet

- Product Details ASTM A53Document4 pagesProduct Details ASTM A53mullanjiNo ratings yet

- Pre-Galvanized (Round Pipes) NPS Wall Thickness (MM) 1.5 1.8 2 3 3.2 Weight (KG/M) Outside DiameterDocument1 pagePre-Galvanized (Round Pipes) NPS Wall Thickness (MM) 1.5 1.8 2 3 3.2 Weight (KG/M) Outside DiametermullanjiNo ratings yet

- Product Specification Levels for PipesDocument14 pagesProduct Specification Levels for PipesmullanjiNo ratings yet

- Astm 500Document4 pagesAstm 500mullanjiNo ratings yet

- Zinc MTC PDFDocument1 pageZinc MTC PDFmullanjiNo ratings yet

- NPT Thread DetailsDocument1 pageNPT Thread DetailsmullanjiNo ratings yet

- API 5l Details From My SideDocument14 pagesAPI 5l Details From My SidemullanjiNo ratings yet

- BPV Stencil MarkingDocument2 pagesBPV Stencil MarkingmullanjiNo ratings yet

- ANSI Coupling Weight Chart by SizeDocument1 pageANSI Coupling Weight Chart by SizemullanjiNo ratings yet

- Inspection Check ListDocument3 pagesInspection Check ListmullanjiNo ratings yet

- Employee training recordsDocument10 pagesEmployee training recordsmullanjiNo ratings yet

- Al-Jazera Steel Factories API 5L Pipe SpecificationsDocument22 pagesAl-Jazera Steel Factories API 5L Pipe Specificationsmullanji50% (2)

- CSWIP-WI-6-92 14th Edition April 2017Document17 pagesCSWIP-WI-6-92 14th Edition April 2017mullanjiNo ratings yet

- Standard Analysis UpdatedDocument15 pagesStandard Analysis UpdatedmullanjiNo ratings yet

- Zinc MTCDocument1 pageZinc MTCmullanjiNo ratings yet

- NoiceDocument2 pagesNoicemullanjiNo ratings yet

- Supplier List: Supplier Name & Address Vendor Code Product / Services StatusDocument2 pagesSupplier List: Supplier Name & Address Vendor Code Product / Services StatusmullanjiNo ratings yet

- Hydro Test Pressure As Per UL 852 (Sprinkler Pipes) IsDocument1 pageHydro Test Pressure As Per UL 852 (Sprinkler Pipes) IsmullanjiNo ratings yet

- Performance of Galvanized Steel ProductsDocument16 pagesPerformance of Galvanized Steel ProductsAndy ChongNo ratings yet

- 46 RegionalMaterialsDocument8 pages46 RegionalMaterialsmullanjiNo ratings yet

- Pipe ThreadsDocument11 pagesPipe Threadsanac_mathNo ratings yet

- Oznake ČelikaDocument8 pagesOznake ČelikaSamra DukićNo ratings yet

- BS 1387/1985 Standard for Black and Galvanized Steel TubesDocument2 pagesBS 1387/1985 Standard for Black and Galvanized Steel TubesmullanjiNo ratings yet

- Work at Height Safety GuideDocument1 pageWork at Height Safety GuidemullanjiNo ratings yet

- M1 - 2 Welding Symbols and DrawingsDocument13 pagesM1 - 2 Welding Symbols and DrawingsmullanjiNo ratings yet

- Employee Engagement A Case Study at IVRCL-1Document7 pagesEmployee Engagement A Case Study at IVRCL-1Anonymous dozzql7znKNo ratings yet

- Emerson Park Master Plan 2015 DraftDocument93 pagesEmerson Park Master Plan 2015 DraftRyan DeffenbaughNo ratings yet

- Post Marketing SurveillanceDocument19 pagesPost Marketing SurveillanceRamanjeet SinghNo ratings yet

- Suband Coding in MatlabDocument5 pagesSuband Coding in MatlabZoro Roronoa0% (1)

- 5505 SW 138th CT, Miami, FL 33175 ZillowDocument1 page5505 SW 138th CT, Miami, FL 33175 Zillowlisalinda29398378No ratings yet

- Programming Manual Magic 308/616-CLI Quick ReferenceDocument16 pagesProgramming Manual Magic 308/616-CLI Quick ReferencekrishnamarajublrNo ratings yet

- Second Law of EntrophyDocument22 pagesSecond Law of EntrophyMia Betia BalmacedaNo ratings yet

- 14 15 XII Chem Organic ChaptDocument2 pages14 15 XII Chem Organic ChaptsubiNo ratings yet

- Microsoft Word 2000 IntroductionDocument72 pagesMicrosoft Word 2000 IntroductionYsmech SalazarNo ratings yet

- Machine Spindle Noses: 6 Bison - Bial S. ADocument2 pagesMachine Spindle Noses: 6 Bison - Bial S. AshanehatfieldNo ratings yet

- Operation Manual: Auto Lensmeter Plm-8000Document39 pagesOperation Manual: Auto Lensmeter Plm-8000Wilson CepedaNo ratings yet

- Drafting TechnologyDocument80 pagesDrafting Technologyong0625No ratings yet

- Lecture 4Document25 pagesLecture 4ptnyagortey91No ratings yet

- NPV Irr ArrDocument16 pagesNPV Irr ArrAnjaliNo ratings yet

- CL 5313 17021-1 Requirements Matrix-1458-5Document6 pagesCL 5313 17021-1 Requirements Matrix-1458-5Ana AnaNo ratings yet

- Impact of Bap and Iaa in Various Media Concentrations and Growth Analysis of Eucalyptus CamaldulensisDocument5 pagesImpact of Bap and Iaa in Various Media Concentrations and Growth Analysis of Eucalyptus CamaldulensisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Domingo V People (Estafa)Document16 pagesDomingo V People (Estafa)Kim EscosiaNo ratings yet

- NameDocument5 pagesNameMaine DagoyNo ratings yet

- Basf Masterseal 725hc TdsDocument2 pagesBasf Masterseal 725hc TdsshashiNo ratings yet

- Common Size Analys3esDocument5 pagesCommon Size Analys3esSaw Mee LowNo ratings yet

- Obligations and Contracts Bar Questions and Answers PhilippinesDocument3 pagesObligations and Contracts Bar Questions and Answers PhilippinesPearl Aude33% (3)

- EASA TCDS E.007 (IM) General Electric CF6 80E1 Series Engines 02 25102011Document9 pagesEASA TCDS E.007 (IM) General Electric CF6 80E1 Series Engines 02 25102011Graham WaterfieldNo ratings yet

- PW CDocument4 pagesPW CAnonymous DduElf20ONo ratings yet

- Colour Ring Labels for Wireless BTS IdentificationDocument3 pagesColour Ring Labels for Wireless BTS Identificationehab-engNo ratings yet

- Irctc Tour May 2023Document6 pagesIrctc Tour May 2023Mysa ChakrapaniNo ratings yet

- FALL PROTECTION ON SCISSOR LIFTS PDF 2 PDFDocument3 pagesFALL PROTECTION ON SCISSOR LIFTS PDF 2 PDFJISHNU TKNo ratings yet

- Sekolah Menengah Kebangsaan Ss17 JALAN SS17/1, Subang Jaya English Scheme of Work Form 3Document11 pagesSekolah Menengah Kebangsaan Ss17 JALAN SS17/1, Subang Jaya English Scheme of Work Form 3Rohana YahyaNo ratings yet

- NetsimDocument18 pagesNetsimArpitha HsNo ratings yet

- LON-Company-ENG 07 11 16Document28 pagesLON-Company-ENG 07 11 16Zarko DramicaninNo ratings yet

- Ca. Rajani Mathur: 09718286332, EmailDocument2 pagesCa. Rajani Mathur: 09718286332, EmailSanket KohliNo ratings yet