Professional Documents

Culture Documents

Ed M 700 Install Manual

Uploaded by

Anonymous JR1LSmN0sOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ed M 700 Install Manual

Uploaded by

Anonymous JR1LSmN0sCopyright:

Available Formats

INSTALLINGTHEEGT701SCANNER PAGE1OF 22

REVB

J.P.INSTRUMENTS POBox7033 HuntingtonBeach,CA92615

FAAAPPROVEDINSTALLATIONMANUALFORTHEEGT701#103

ApplicabletoEGT701andEDM750.

THEOWNEROFTHISEGT701 MUST KEEPTHISMANUAL

1) INSTALLATIONOVERVIEW 3

2) INITIALBENCHCHECK 3

3) INSTALLINGTHEINSTRUMENT 3

4) EXHAUSTGASTEMPERATURE(EGT)PROBE 4

5) TURBINEINLETTEMPERATURE(TIT)PROBE 5

6) CYLINDERHEADTEMPERATURE(CHT)PROBE,BAYONET 5

7) CYLINDERHEADTEMPERATURE(CHT)PROBE,SPARKPLUGGASKET 5

8) OILTEMPERATURE(OIL)PROBE 5

9) OUTSIDEAIRTEMPERATURE(OAT)PROBE 6

10) INDUCTIONAIRTEMPERATURE(IAT),COMPRESSORDISCHARGE(CDT)AND

CARBURETOR(CRB)PROBES 7

11) RADIALENGINES 7

12) FUELFLOWOPTIONMOUNTINGPROCEDURE 7

13) WIRINGTHEINSTRUMENTCONNECTORS 9

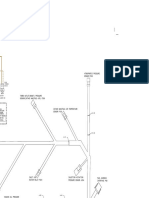

14) ROUTINGTHEWIRINGHARNESSES 11

15) EGT,CHTANDOTHERTEMPERATUREPROBEWIRING 12

16) FUELFLOWTRANSDUCERWIRING 12

17) INITIALCHECKOUT 13

18) SYSTEMDESCRIPTION 13

19) INSTALLATIONRECORD 14

20) OPERATION 14

21) SPECIFICATIONSANDLIMITATIONS 14

22) ENGINEOPERATION 16

23) PARTSLISTFOREGTPROBEPN128,TITPROBEPN120,IATPROBEPN130 16

24) PARTSLISTFORCHTPROBEPN126 16

25) PARTSLISTFOROILPROBEPN124 16

26) PARTSLISTFOROATPROBEPN122 16

27) PARTSLISTFORFUELFLOWTRANSDUCERPN700900 16

28) PARTSLISTFORSINGLEENGINEEGTANDCHT 16

29) WEIGHTANDBALANCEDATA 16

30) CALIBRATINGTHEEGT701FORTHEFACTORYORIGINALTITPROBE 17

31) SETTINGTHEKFACTOR(FUELFLOWOPTION) 17

32) SETTINGTHEDATARECORDINGOPTIONPARAMETERS 17

33) SETTINGTHEALARMLIMITS 19

34) TROUBLESHOOTING 21

INSTALLINGTHEEGT701SCANNER PAGE2OF 22

REVB

READTHISFIRST

Thefollowingnotesapplytoanewinstallation.Readthissectionbeforeproceeding.

a) TheJPIwarrantyfoundinthebackofthepilotsguideclearlystatesthatJPIwillreplacedefective

partsunderwarranty,butdoesNOTcoverlabortoremoveorinstallanyparts.

b) Topreventdamagetothedisplayitisessentialthatthefourmountingscrewsnotpenetratethe

instrumentmorethan0.12inches.Damagecausedbyscrewpenetrationisnotcoveredunder

warranty.

c) YoumustbeanFAAcertifiedaircraftmechanictoinstallthisinstrument.

d) CheckthatanynecessaryFAAapprovals(STCs,etc)areavailablefortheaircraftbeforebeginning

theinstallation.

e) Powerupandtesttheinstrumentbeforeinstallingintheinstrumentpanel.

f) Themostcommoncauseofprobeproblemsispoorterminalcrimps.Crimpringterminalswith

AMPpart45518crimptoolorequivalent.Foldbackthewiredoublebeforecrimpingterminals.

1/4" 11/2"

Foldbackwire

doublebefore

crimpingterminals

21/4"

Thermocouplewireharness

red

yellow

g) Thisinstallationwillrequiresomepartsuniquetoyouraircraftthatarenotsuppliedwiththekit,

(includingbutnotlimitedtotiewraps,hosesandfittings).Acquireallthenecessarypartspriorto

beginningtheinstallation.

h) DonotusealuminumfittingswiththeFXT201orFXT231fuelflowtransducer.

i) WritedowntheKfactorengravedonthesideofthefuelflowtransducerhere_______.Oncethe

transducerisinstalledandcoveredwiththefiresleeve,youwillnotbeabletoaccessthisKfactor.

j) Determinethelocationsofallholesbeforedrillingtoensurethatnothinginterfereswiththeprobe,

clamp,clampscreworwire.

k) Provideserviceloopsattheinstrument.

l) Thermocouplewirelengthisnotcritical.Trimtorequiredlength,allowingforserviceloopsatthe

enginesothatprobescanbeswappedwithprobesonadjacentcylindersfortroubleshooting

purposes.

m)Dressallwiresawayfromhightemperaturecomponentssuchasexhauststacks.

n) Neversplicethermocouplewireusingcopperwire.UseonlyKtypethermocouplewire.Solder

usingzincchloridefluxsuchasNokorodebrandrosinfluxalonewontwork.

o) Observecorrectpolarityonallprobewires.Connectlikecolorstogether(redtored,yellowto

yellow).

p) Theinstrumentmustbegroundedattheengine,notattheavionicsground.

q) Ifasparkpluggasketprobeisused,expecttheCHTreadingonthatcylindertobesomewhathigher

thanonthecylinderswithbayonetprobes.Atadditionalcostanadapterprobe(bayonetorscrewin)

isavailablethatpermitsthefactoryCHTprobeandtheJPIprobetobeplacedinthesamebayonet

location.

INSTALLINGTHEEGT701SCANNER PAGE3OF 22

REVB

r)

1) InstallationOverview

Theoverallinstallationprocedureisasfollows:

1. Powertheinstrumentonthebenchtoverifyitwasreceivedinworkingorder.

2. Installtheinstrumentintheinstrumentpanel.

3. Installtheprobes,sensors,andtransducersintheenginecompartment.

4. Connecttheconnectorstotheinstrument.

5. Mountthedataportconnectorandoptionalfuelflowtoggleswitchtotheinstrumentpanel.

6. Runtheharnessfromtheinstrumentintheinstrumentpanelthroughthefirewalltotheengine

compartment.Dressthewirestotheprobes,sensors,andtransducers.

7. Cuttheexcesslengthofftheharnesswiresandconnecttotheprobes,sensors,andtransducers.

8. Verifysystemoperation.

9. Setthealarmlimitsandothercalibrationconstants.

2) InitialBenchCheck

ConnecttheP1connectortotherearoftheEGT701andconnecttheredwireto+12Vor+24Vandtheblack

wiretoground.VerifythatthedisplayshowsDEMOfollowedby EDM700,andthateachcolumnisselftested

insequence.

3) InstallingtheInstrument

Topreventdamagetothedisplayitisessentialthatthefourmountingscrewsnot

penetratetheinstrumentmorethan0.12inches.Damagecausedbyscrew

penetrationisnotcoveredunderwarranty.

InstallationshouldbeinaccordancewithAdvisorCircularAC43.131A.Identifythelocationfortheinstrument

ontheinstrumentpanelthathasa2.25inchinstrumentholeand8.5inchesclearancebehindtheinstrument

panel.Checktherearclearancewiththeconnectorsattachedtotheinstrument.AGEMupgrademayrequire

extraclearancebelowtherearoftheinstrument.

1.39

45typ

2.25

0.312"diahole

DataPort(standard)

Locatenearinstrument

onleftside

2.63 0.147"diahole

6plcs

1.60min.

1.45min.

0.250dia

fuelflowswitch(optional)

locateclosetothelower

rightsideofthe

instrument

EGT

ALL

FF

INSTALLINGTHEEGT701SCANNER PAGE4OF 22

REVB

Usethesteeltemplatesuppliedwiththeinstallationkitasaguidefordrillingthetwobuttonholesinthe

instrumentpanel.Drilltwo0.125inchpilotholes.Removethetemplateandverifytheinstrumentalignment.

Thendrillfinal0.147inchholes.Drilla0.312diameterholeforthedataportatleast1.60fromthevertical

centerlineoftheinstrumentface.Drilla0.250diameterholefortheoptionalfuelflowselectswitchatleast

1.45fromtheverticalcenterlineoftheinstrumentface.Theinstrumentmountsinastandard2.25inch

instrumenthole.

Theinstrumentconfiguresitselfautomaticallyforthenumberofcylindersandthesupplyvoltage(12or24

volt).Theinstrumentis7.5inchesdeep,lessconnectors,andis2.6inchessquare.

4) ExhaustGasTemperature(EGT)Probe

Determinethelocationsofallholesbeforedrillingto ensurethatnothinginterfereswiththeprobe,

clamp,clampscreworwire.DonotmountEGTprobesinslipjoints. ThemodelM111EGTprobewillfit

anyenginehavingexistingholesintheexhauststackofbetween0.125and0.250.Ifnoholeexists,drilla

0.125holeandreamtofit.Itisimportantthateachprobebemountedauniform distancefromtheexhaust

stackflange.Anominaldistanceof2to4inchesfromtheexhaustflangeisrecommended.Iftherecommended

distanceisimpracticalduetoobstructions,slipjointsorbendsintheexhaustsystem,thenpositiontheprobesa

uniformdistancefromtheflangeasspacepermits.Carefulmatchingofprobepositionwillprovidethebest

temperaturereadings.

2"to4"(50to100mm)

EGTprobe

Drillno.40pilothole,thenno.30hole.

(P210usecylinder6probeasreference.

Place4.5"downfromflange)

CHTprobe

e

x

h

a

u

s

t

s

t

a

c

k

Inserttheprobeintheexhauststackholesuchthatthetipoftheprobeisinthecenteroftheexhauststream.

Tightenthestainlesssteelclampandtorqueto45in/Lbs.Cutoffexcessstrapclosetothescrew.Theprobe

warrantyisvoidiftheprobeismountedinanytypeofaslipjoint.

Positionprobe

inapproximate

centerof

exhaust

Probe

Clamp

Thimble

noteorientation

ofslot

SealWasher

INSTALLINGTHEEGT701SCANNER PAGE5OF 22

REVB

5) TurbineInletTemperature(TIT)Probe

ThestandardTITprobePNM111Twitha#48clampisplacedintheexhauststackaccumulatortoa

maximum depthof1/2inchandapproximately4inchesfromtheturbineinletifpossible,onthewastegateside

oftheturbine.TITwillappearastherightmostcolumnlabeledTandthedigitaldisplaywillshowI650TIT

(forexample)whentheindexingdotisundertheT.TheEGT701inputisahighimpedanceandiscompatible

withtheaircraftfactoryinstalledTITprobe.TheEGT701TITcablemaybeconnectedinparallel(piggyback)

attheTITprobe(preferred),orattheaircraftTITgage.Besuretomatchtheredandyellowwirecolorcodes.If

youraircraftisusingthefactoryoriginalTITprobeandgage,youwillberequiredtocalibratetheEGT701for

thatprobe.Followtheproceduredescribelaterinthismanual(insection 30).

6) CylinderHeadTemperature(CHT)Probe,Bayonet

Thebayonetprobe5050Thasacaptive3/824bossthatisscrewedintothebaseofthecylinder(seefigurein

section 4).Theprobehasascrewdriverslottofacilitatetightening.

NOTE:RequiredoriginalequipmentthathasaRedLinemaynotbereplacedbytheEGT701TITor

CHTinstallation.Thisincludesbutisnotlimitedtoallaircraftwithadjustablecowlflapsandonaircraft

withplacardsontheinstrumentpanelshowingaclimbairspeed,forcooling,differentfromthebestrate

ofclimbairspeed.

Ifapreviously installedTIT,CHTorEGTislistedontheaircraftequipmentlistasoptionalequipmentornot

listedatall,itmaybereplacedbytheEGT701.

7) CylinderHeadTemperature(CHT)Probe,SparkPlugGasket

Mostfactoryinstalledcylinderheadtemperaturegagesutilizeabayonetorscrewinresistancetypeprobethat

occupiesasocketinoneofthecylinders.Thisprobeisnotcompatiblewiththethermocoupleprobesrequired

fortheEGT701.

Thesparkpluggasketprobe,PNM113,replacesthestandardcoppersparkpluggasketononesparkplug.

Choosetheupperorlowersparkplug,theonethatprovidesthebestcorrelationwiththeothertemperature

probes.Theprobeisusuallyplacedontheplugthatreceivesthemostdirectcoolingair.Duetothespark

pluglocation,thegasketprobemayread20

o

Fhigherorlowerthanthefactoryprobe.Ifthediscrepancyis

greater,besurethesparkpluggasketprobeismountedonthetopsparkplug.Anadapterprobeisavailableto

occupythesamesocketasthefactoryoriginalprobe.ContactJ.P.Instruments.

8) Oiltemperature(OIL)Probe

TheOilTemperatureProbePN400505Cor400505Lisinstalledasasupplementaloiltemperatureindicator.

LycomingEngines:TheLpartnumberisforallLycomingdirectdriveenginesandisinstalledintheright

(passengerside)frontoilgalleybyremovingtheexisting1/8NPTplugonthepassengersideoftheengineand

insertingtheoptionalJPIoilprobesuppliedwiththekit.

INSTALLINGTHEEGT701SCANNER PAGE6OF 22

REVB

OilProbeLocation AlternateOilProbe

Location

LycomingEngines

frontview

ContinentalEngines: TheCpartnumberisforallContinentaldirectdriveenginesandisinstalledintheleft

(pilotside)frontoilgalleybyremovingtheexisting3/8or1/8inchNPTplug(seefigurebelow)locatedonthe

front,pilotssideoftheengine.InserttheoptionalJPIoilprobesuppliedinthekit.For3/8inchNPT

installations,usethesuppliedbrassadapter.Analternatelocationisonthetop,frontoftheengineonthepilots

side,wheretheprobeisinsertedvertically.Therearetwo1/8NPTplugsclosetogether.Installtheprobeinthe

positionthatisaboveandtotherearofthenearbyposition.

Oiltemperaturewillbeshowninthedigitalpartofthedisplayas,forexample230OILandwillbe

displayedIntherightmostcolumnifnoTITprobeisinstalled.Theoriginaloiltemperaturegageandsensor

mustremaininstalledintheaircraft.Checkforoilleaksbeforefirstflight.

AlternateOilProbe

Location

OilProbeLocation

ContinentalEngines

AlternateOilProbe

Location

frontview

Anotherlocationfortheoilprobemaybetheoilcooler.Checktoseeiftheoilcoolerhasanunoccupiedplug,

typicallyonthetop.

9) OutsideAirTemperature(OAT)Probe

InstalltheOATprobe,PN400510intheairframemanufacturersrecommendedlocation.Ifthisisnotpossible,

placetheOATprobeincleanairflowsuchasinacabinairscooporontheundersideofthewingawayfrom

engineheatorexhaust.Remember,theengineisoperatingwithtemperaturesinexcessof1500F.Justalittle

hotairorconductivityfromtheenginecancausetheindicatedOATtoincreaseby10to20.Itisrecommended

thattheinstallationbedonesimilartotheantennainstallationinstructionsofAC43.122aAcceptable

Methods,TechniquesandPractices.

INSTALLINGTHEEGT701SCANNER PAGE7OF 22

REVB

washer

aircraftsheetmetal

washer

probe

shieldtube

usedtosecure

probe

Theoutsidealuminumshieldtubeisusedtobothholdtheprobeinplace,protectitfromdamage,andshieldit

fromradiatedheat.OATwillbeshowninthedigitalpartofthedisplayas,forexample,75OAT.When

testingtheOAT,shieldthesensorfromdirectsunlightandengineheat,whiletheengineisoperating.

10) InductionAirTemperature(IAT),CompressorDischarge(CDT)and

Carburetor(CRB)Probes

TheInductionAirTemperatureprobe,(IAT),isinstalledjustaftertheintercoolerOUT,andtheCompressor

DischargeTemperature(CDT)justbeforetheintercoolerIN.TheIATandCDTprobesarethesameasEGT

probesandareinstalledsimilarlytoEGTprobes.Alargeclampissuppliedtofitaroundtheairportleavingthe

intercooler.Alternatelya1/8NPTfittingisavailable.IATwillbeshowninthedigitalportionofthedisplay

as,forexampleI25IAT.Onnonturboenginesinstallthecarburetorprobeinthethreadedholeonthe

enginesideofthebutterflyvalve.Thecarburetortemperatureisdisplayedas,forexample,34CRB.

11) RadialEngines

RadialengineexhaustsrequirealargerEGTclamp(supplied)tofitthe2.5inchexhaustpipe.TheEGTprobeis

installedusingthesametechniqueasonaLycomingorContinentalengineandshouldbeplacedbetweenthe

exhaustpipeflangeandtheaccumulatoratadistanceof2to3inchesfromtheengineexhaustflange.Cylinder

headtemperaturesaremeasuredwithasparkpluggaskettypeprobeplacedunderthefrontsparkplugs.Referto

theenginemanufacturersredlineandsettheEGT701redlineaccordingly.Frontsparkplugswillread15to

20degreescoolerthantherearplugs.DonotroutetheEGT/CHTharnessadjacenttoorintheignitionharness.

Donotextendthermocouplewireswithcopperwire.

12) FuelFlowOptionMountingProcedure

TheKfactorisengravedonthesideofthetransducer.WritedowntheKfactorhereforfuturereference

__________.Youwillneeditlaterinthisprocedure.

Acompleteandthoroughfamiliarizationandunderstandingofthesystemisnecessarybeforecommencingthe

installation.AllworkmustconformtoAC43.131A,chap11,section2.3.7requirements.

TheEGT701canbeconnectedtoanypreviouslyinstalleddigitalflowmeasuringdevicesuchasaFloScan

transducer.WhenwiringtheEGT701toapreexistingtransducerthatisalsoconnectedtoanotherfuelflow

instrument,connectonlythesignal(whitewire)andground(blackwire).Donotconnectthepowerlead(red

wire).IfthepreviouslyinstalledinstrumentisaAerosonic,thefuelflowconnectorontheEDM701mustbe

labeledAerosonic.Otherwise,returntheEDM701toJPIformodification.

Beforeconnectinganyhosestothetransducer,thoroughlycleanthemandinsuretheyarefreeofany

loosematerial.Neverpasshighpressureairthroughorblowthroughthetransducerdamage

mayoccur.Removethetransducercapplugsonlywhenreadytoinstallthehoses.Notethedirection

offuelflowmarkedonthetransducer.Fuelmustflowinthisdirection.Mountthetransducerwiththe

INSTALLINGTHEEGT701SCANNER PAGE8OF 22

REVB

threewirespointingup.Torquethefittingsnomorethan15ftlb=180inlbs.,ortwofullturnspast

handtight.

Donotusealuminumfittingswheninstallingthefuelflowtransducer.

AeroquipFireSleeve

AE102/6224

Aeroquip

900591BClamp

IN

OUT

8inchesmaximumfrom

support

tocarburetor,flow

divider,orfuel

injector

fromfueltank,

throttlebodyor

enginedrivenfuel

pump.

MS21919

Clampasrequired

Fittings1/4NPT.DoNOT

usealuminumfittings

Aeroquip

303hose

Transducer

Cutslitinfiresleeve

up

TheEGT701receivessignalfromanyinstalledFloscantransducerwithanyofthesepartnumbersembossed

ontothetopofthetransducer(FloscanInstruments,SeattleWA98106) orequivalentShadin:Floscan201A,

Floscan201B(equivalenttoShadin680501/680600),Floscan201C,orFlowscan231(equivalenttoShadin

680503).

Selecttheappropriateinstallationconfigurationfromthethreefollowingfuelsystemcategories:

qForgravityfeedsystemswithoutafuelpump usetransducerFXT231(yellowplastictop).Connect

thetransducerbetweenthefueltankandcarburetor.

qForpumpfeedorfuelinjectedsystemswithout

vaporreturnlines

usetransducerFXT201(blackplastictop).Connect

thetransducerbetweentheenginedrivenpumpand

servo/throttlebodyorcarburetor.

qForall fuelinjectedengineswithvaporreturn

linesto thefueltankbeforetheservo/throttle.

usetransducerFXT201(blackplastictop).Connect

thetransducerbetweenthethrottlebodyandthefuel

flowdivider.

Thetransduceroutputportshouldbemountedlowerorlevelwiththecarburetorinletport(orfuelservoona

fuelinjectedengine).Ifthisisnotpossible,anantisiphonloopshouldbeputinthefuellinebetweenthefuel

flowtransducerandthecarburetororfuel

servo.

Findaconvenientlocationwithin8inches

ofahosesupportorfittingtosuspendthe

fuelflowtransducer.Mountitawayfrom

anyhotexhaustpipes.Thehosesupportor

fittingmaybeontheinputoroutputlineof

thefuelflowtransducer.Securetheendof

thetransducertoanyconvenientpointon

theenginewithMS21919clampsor

equivalent.Donotplaceanangled

elbowjointimmediatelypriortotheinputportofthefuelflowtransducer.Thereshouldbesix

inchesofstraightflowimmediatelybeforethetransducerinputport.

Foracarburetedengine:removethefuelhosewhichconnectsthecarburetortothefueltank.Purchasetwo

newhosesonetoconnectthecarburetortothefuelflowtransducer,andtheothertoconnectthefuelflow

transducertothefueltank.Beforeconnectingthefuelhosetothecarburetor,verifythattheboostpumpdelivers

atleast125percentoftakeofffuelflowatminimumfuelpressureasmarkedonthefuelpressuregage.

IN

OUT

carburetor

orservo

transducer

Ifthetransducerishigherthanthe

carburetororfuelservo,putaloop

betweenthetransducerandcarburetor

orservo

SIDEVIEW

INSTALLINGTHEEGT701SCANNER PAGE9OF 22

REVB

Fora pumpfedcarburetedorfuelinjectedenginewithoutvaporreturnlines:removethefuelhosewhich

connectstheenginedrivenpumpandtheservo/throttlebodyorthecarburetor.Purchasetwonewhosesoneto

connecttheenginedrivenpumptothefuelflowtransducer,andtheothertoconnectthefuelflowtransducerto

theservo/throttlebodyorthecarburetor.

Forafuelinjectedenginewithvaporreturnlinesbeforetheservo/throttle:removethefuelhosewhich

connectsthethrottlebodyandtheflowdivider.Purchasetwonewhosesonetoconnectthethrottlebodytothe

fuelflowtransducer,andtheothertoconnectthefuelflowtransducertotheflowdivider.ForContinentalfuel

injectedenginesadjustthefuelpressuretoaccountforthepressuredropacrossthetransducerperContinental

ServiceBulletinM8910.

Theremustbeflexiblehoseintoandoutofthefuelflowtransducer.ThehosesmustmeetTSOC53atypeCor

DFAAspecification.Thenewhosesmustbethesamesizeasthecurrenthoseintheaircraft.Thefuelflow

transducermustbewrappedwithfiresleeving.Cuta1inchslitinthecenterofthefiresleeveandpassthe

transducerconnectorandcablethroughit.SealwithhightemperaturesiliconeRTVsealant.

TheplacardDonotrelyonfuelflowinstrumenttodeterminefuellevelsintanksmustbemountedonthe

aircraftinstrumentpanelneartheEGT701.Iftheaircraftisequippedwithaprimaryfuelflowinstrument,the

followingplacardmustbemountedontheaircraftinstrumentpanelneartheEGT701Refertooriginalfuel

flowinstrumentationforprimaryinformation.

13) WiringtheInstrumentConnectors

P2BottomConnector(hastheyellowCHTandEGTwires)

TheP2connectorplugsintothebottomjackonthebackoftheinstrumentandcontainsthefirstsixEGTand

CHTchannels.Theplugshouldbeprewiredwithaharness.

P1TopConnector(containstheredpowerandblackgroundwiresandthedataloggingportconnector)

TheP1connectorplugsintothetopjackonthebackoftheinstrumentandcontainstheoptionprobechannels,

EGTandCHTchannels7,8and9,alarmsignal,dataloggingportandpowerandground.TheEGT701

automaticallyaccommodatesboth14and28voltelectricalsystems.Connectthepowerlead(red)toaseparate

2ampcircuitbreakerorinlinefuseconnectedtotheavionicspowerbus.Theavionicsmasterswitchwillthen

beusedtoturnofftheinstrumentduringenginestartup.Ifthepanellacksanavionicsmasterswitchitis

recommendedthatonebeinstalledoracircuitbreakerswitchbeprovidedtoturnofftheEGT701during

enginestartup.

TheEGT701mustbegroundedtotheengineblock,notatagroundpointundertheinstrumentpanel.No

connectiontotheaircraftdimmersystemisrequiredorpermittedbecausetheinstrumentdimsautomatically

withreductionsinambientlight.

Installthedataportconnectorin theinstrumentpanel.Thisisthe2.5mmID,5.5mmODon

thetwistedwhiteandblackwiresonJ1.SeeInstallingtheInstrumentsectionearlierinthis

manual.

InyouareinstallinganytemperatureoptionssuchasOIL,TIT,CRB,orOAT,inserttheoptionfemalepinsinto

theP1connectoraccordingtothetablebelow.

INSTALLINGTHEEGT701SCANNER PAGE10OF 22

REVB

P2Connector(bottom) P1Connector(top)

Yel Red probe Yel Red 4or6cylinder 7,8,or9cylinder

1 2 CHT1 1 2 OIL OIL

3 4 CHT2 3 4 IAT CRB

5 6 CHT3 5 6 CDTorCRB CHT7

7 8 CHT4 7 8 CHT8

9 10 CHT5 9 10 CHT9

11 12 CHT6 14 15 OAT OAT

14 15 EGT1 16 17 TIT1 TIT

16 17 EGT2 18 19 TIT2 EGT7

18 19 EGT3 20 21 EGT8

20 21 EGT4 22 23 EGT9

22 23 EGT5 11 (wht) Miketip(optional)

24 23 EGT6 12 (gry) Remotealarm(optional)

13 (red) +power+14/28voltsfuse2a

25 (blk) GroundTOENGINEBLOCK

24 DataportRS232(withconn.)

FuelflowConnector(hasthefuelflowtransducer,RS232inandout,andthetoggleswitch)

Iftheinstallationincludesthefuelflowoption,InstalltheEGTALLFFdisplayselectorswitchandlegend

labelinthepanel.Connectwirestothefuelflowoptionconnectorasshownbelow.Thefuelflowconnectoris

thejackthatisontheshortwirebundleoutoftherearoftheinstrument.Routethewiresalongtheexisting

wiringbundle,lacingeveryfoot.

Cutredleadif

transduceris

alsoconnected

toanotherfuel

flowinstrument

IN

OUT

WHT

BLK

RED

WHT

BLK

RED

fuelflowoption

connector

1

1

1

5

FF

COM

EGT

+12/24avionicbus

GPS

RS232inputtoEDM700

GPSoutput

GPSinput

(someKLNseriesonly)

RS232

outputfrom

EDM700

8

7

6

5

4

3

2

1

FuelFlowTransducer

FloScan201A,B,C,or231

Alarmlamporenunciator

(customersuppliedoption)

11

9

panel

mounted

switch

(alarmwirenotsupplied)

EGT

ALL

FF

Thefuelflowconnectorisattachedtotheinstrumentbyashortcable.Theplugshouldbeprewiredwitha

harness.Fuelflowoptionconnectorpinassignmentsareasfollows:

INSTALLINGTHEEGT701SCANNER PAGE11OF 22

REVB

Pin Signal Pin signal

1 RS232out(toGPS) 7 EGT/FFswitchcommon

2 RS232in(fromGPS) 8 EGT/FFswitchEGT

3 9 EGT/FFswitchFF

4 Fuelflowsignal(wht) 10

5 Fuelflowground(blk) 11 Remotealarm(optional)

6 Fuelflowpower(red) 12

TheEGT701withfuelflowoptionmaybeconnectedtoaGPS.MostGPSreceivershaveanoutputportfrom

whichtheEGT701willacceptdata.SomeGPSreceiverscanacceptdatafromtheEGT701.

Theremotealarmwireonthefuelflowconnector,pin11,isanopencollectorcapableofsinkingupto150ma.

Thissignalmaybeconnectedtoauniquealarmlightorbuzzer,oritmaybeconnectedtotheEGT70125pin

Dconnector,P112,inawiredORtoacommonalarmlightorbuzzer.Ifitisnotused,leavethelineopen

andtiewrapthewiresothatitdoesnotobstructthefreedomofcontroltravel.

14) RoutingtheWiringHarnesses

TheEGT701issuppliedwithspecialTefloninsulatedChromel

Alumelfactoryassembledwiringharnessesconfiguredforthecorrect

numberofcylindersandoptionspurchased.Thewireharnessis

markedE1forEGT1,C1forCHT1,etc.TforTIT,Ofor

OILandAforOAT.ForupgradesfromtheEGT100Classic

ScannerornonJPIbargraph instruments,whereonlytheindicators

arebeingexchanged,theexistingharnesswiresmusthavepins

crimpedon(AMPPN665049pins)andfittedintotheDsub

connector(AMPPN2052071)withhoodorconnecteddirectlyusing

anadapterconnectoriftheexistinginstallationhasconnectors.

Leaveadequateserviceloopsattheinstrument.Bundlealltheprobe,

sensorandtransducerwirestogetherwiththegroundwireandroute

theharnesswiresfromtheinstrumentthroughthefirewallusing

fireproofrubbergrommetsandflameretardingsilicone.Usean

existingholeifpossible.Allwiresmustberouted awayfromhigh

temperatureareas(exhauststacks,turbochargers,etc.).Secure

probe,sensorandtransducerleadstoaconvenientlocationontheengineapproximately8to12inchesfromthe

probe,sensorortransducer,beingsurethereissufficientslacktoabsorbenginetorque.Itisessentialinrouting

theprobe,sensorortransducerwirethatthiswirenotbeallowedtotouchmetalpartsoftheairframeorengine

sinceabrasionwilldestroythewire.

Thetemperature(thermocouple)probewiringschematicisshownbelow:

7.10

P1

P2

Engine

block

ground

#1

Oilprobe

#2

#3 #5

#4 #6

TITprobe

EGT

CHT

EGT EGT EGT

EGT EGT

CHT CHT CHT

CHT CHT

Tocircuit

breakerorinline

fuse14to28

volts

firewall

Carbprobe

OATprobe

Dataportconnector

engine

block

ground

instrumentpanel

firewall

topower

EDM700

dataport

connector

INSTALLINGTHEEGT701SCANNER PAGE12OF 22

REVB

15) EGT,CHTandOtherTemperatureProbeWiring

Beforeyoubegin,notethatthemostcommoncauseofprobeproblemsispoorterminalcrimps.

Whencuttingeachpairofleadsinthewiringharnesstotheproperlengthtoconnecttotheprobes,leave

enoughslackintheharnesssothatprobesfromadjacentcylindersmaybeinterchangedifnecessaryfor

troubleshootingandservicing.Thermocouplewirelengthisnotcriticalandshouldbetrimmedtoanylengthas

requiredforacleaninstallation.

TheTemperatureprobesmustbewiredwiththecorrectpolarity.Eachwireismarkedwiththecylindernumber.

TheEGTandCHTprobesconnecttothetemperatureindicatorwithyellowjacketTeflonChromelAlumelwire

supplied.Stripthewiresasshownbelow,observingcolorcodes.Important:foldbackthewiredouble

beforecrimpingterminals.

1/4" 11/2"

Foldbackwire

doublebefore

crimpingterminals

21/4"

Thermocouplewireharness

red

yellow

Terminateeachwirewithacrimponringterminal,provided.Theringterminalsmaybecrimpedwitha

servicetypetool,howeverAMPpartnumber48518crimptoolisrecommended.Verifythequalityofeach

crimpwithasharptugonthewire.Theterminalshouldbeimpossibletopulloffwhencrimpedcorrectly.

shrinktubing

shrinktubing

ringterminal

Placeax4inchsleeveovereachpairofwiresintheharness.Connecttheharnessringterminaltotheprobe

ringterminalusingthesuppliednumber4screwsandnuts,placingthestarwasherbetweentheringterminals,

notagainstthenut.

Important:placestarwasterbetweentworing

terminalsandtightennutandboltas

necessary toinstrument

toprobe

Slidethesleeveoverthejointandsecurewiththreetiewraps.

1/4x4"sleeve

tiewrap3places

Themostcommoninstallationproblemsarepoorqualityterminations.

16) FuelFlowTransducerWiring

Cutthefuelflowtransducerleadstolengthatthefuelflowtransducer.Provideadequateserviceloop.Attach

thesupplied3pinconnectorbystrippingandcrimpingapinoneachwire,andtheninsertingeachpinintothe

plasticconnectorhousing.Observepinnumberingandwirecolors.

INSTALLINGTHEEGT701SCANNER PAGE13OF 22

REVB

FUEL

FLOW

RED

BLK

WHT

PIN5

PIN6

PIN4

CONNECTOR3PIN

FUELFLOWTRANSDUCER

1

fuelflowoption

connector

17) InitialCheckout

Turnontheaircraftmasterswitchandavionicsmaster,withtheengineoff.TheEGT701willperformaself

testwhereinallsegmentswilllightupandeachcylindercolumnwillcyclevertically.

WithFuelFlowOption(skiptonextsubsectioniffuelflowoptionisnotinstalled)

ThedisplayshouldshowFILL?N.TapSTEP.SettheinstrumenttoggleswitchtoFF(Fuelflow).TapSTEP

until 0GPHisdisplayed.Turnontheboostpumpforafewsecondsandverifythedisplayshowsbetween

3and8GPH.

Turnofftheboostpumpandverifythefuelflowreadingreturnsto00GPH.Adisplayof GPH indicates

nofuelflowtransducersignalsaredetected.ChecktheconnectionsbetweentheEGT701andthefuelflow

transducer.

Checktheflowreadingwiththeenginerunning.Afterrunningtheengine,checkthefuelhoses,transducerand

fittingsforleaks.

SettheinstrumenttoggleswitchtoEGTandcontinuethecheckoutatthefollowingstep.

WithoutFuelFlowOption.

TaptheSTEPbuttonandverifythattheoptionsinstalledaredisplayedinsequence.Withtheenginenot

running,verifythatallthetemperaturesarereadingambientwithinoneortwodegrees.

Ifthereareanyproblems,seetheTroubleshootingsectionattheendofthismanual.

18) SystemDescription

TheEGT701temperatureindicatordisplaystemperaturedigitallyandinanalogformat.TheTITasdisplayed

canreadupto100Fhigherthanany EGT.Thisisduetomixingandreburningofunburnedgasesatthe

turbine.TheTITprobewillnotnecessarilybeinagreementwiththeprimaryTITprobebutcanreadhigher.

ThereforetheEGT701maynotindicatethesameastheaircraftprimaryinstruments.Theanalogdisplayisan

electronicbargraphofEGTandTITtemperaturespresentedasapercentageof1650Fwithdefaultfactory

limits.BelowtheverticalcolumnsthespecificvalueforEGTandCHTaredisplayeddigitally.TheEGTonthe

leftandCHTontheright.Thedotoverthecolumnindicateswhichcylindersdigitaltemperaturesarecurrently

displayed.ThemissingbarinthegraphrepresentstheCHTtrend,showingwhichcylinderishotterorcooler,

whichcanbeverifieddigitally.ThelastcolumnwilldisplayOILtemperatureifthatoptionisinstalledandthe

TIToptionisnotinstalled.

HoldingtheLFandSTEPbuttonssimultaneouslyenterstheprogrammodewheretheindexingdwellcanbe

adjusted.TaptheLFbuttonuntilthedesiredindexingdwelltimeisdisplayed.1through9secondsdwellcanbe

selected.ExittheprogrammodebytapingtheSTEPbutton.

INSTALLINGTHEEGT701SCANNER PAGE14OF 22

REVB

IftheEGT701buttonsarenotactivatedfortenminutesthesystemwillbeginindexingautomatically.Tapping

theSTEPbuttonwillstoptheautomaticindexingandsubsequenttapsoftheSTEPbuttonwillstepthroughall

availablefunctions.Duringcruise,iftheLFbuttonisheldforthreesecondsallEGTbargraphswillnormalize

atmidlevel.Eachbarrepresents10FandnowactsasanEGTandTITtrendmonitor,showingamagnified

viewoftemperaturechange.HoldingLFbuttonforthreesecondsreturnsthedisplaytopercentview.Noother

functionsareeffected.

OptionsofTIT,OAT,IAT(inductionair),OIL,andstandardBAT(voltage)andCLD(rateofchangeofCHT

indegreesperminute)aredisplayedonlydigitallywithlegendsfollowingthenumericalvalue,suchas230

OIL.AlargevalueofCLDindicatespotentialshockcoolingwhichhasadetrimentaleffectontheengineandis

usually associatedwithrapiddescentsatlowpower.Thoseoptionswhicharenotinstalledwillnotbe

displayed.

Thefuelflowoption,whenconnectedtoapreviouslyinstalledflowtransducersuchastheFloscanInc.

transducer,displaysfuelflowingallons,liters,kilograms,orpoundsperhourandtracksthequantityoffuel

burned.Athreepositiontoggleswitchlocatednearthedisplaycanbeusedtoselectfordisplayfuelflow

parameters,temperatures,orboth.

19) InstallationRecord

TheindicatorisFAATSOapproved,asatemperatureindicatorunderTSOC43b.Recordtheinstallation

oftheEGT701per STC#SA2586NM.Makeanappropriateentryintheaircraftlogbook.FAAform337may

berequired.

20) Operation

Airplaneflightmanuallimitationsbasedonprimaryinstrumentindicationtakeprecedenceoverthoseofthe

EGT701.CAUTION:Complywithmanufacturer'sairplane/rotorcraftflightmanualleaningprocedure.

Donotexceedapplicableengineoraircraftlimitations.

21) SpecificationsandLimitations

FAAApproved:

IndicatorSTCSA2586NM

FuelFlowOptionSTCSA00432SE

Environmental:

PassedTSOC43candDO178a(softwarelevel3)

Power:

10to35voltsDC,2amps

OperatingTemperatureRange:

40to195

F

DisplaySize:

2inpanelmount

2.6in.sq.,7.1in.deep

CommonModeRange:

+4v,rejection>80db

Digitalinputchannels:

1Fuelflow(GPH)

Analoginputchannels:

6ExhaustGasTemperature(EGT)

6CylinderHeadTemperature(CHT)

2TurbineInletTemperature(TIT)

1Oiltemperature(OIL)

1CarburetorTemperature(CRB)

1InductionAirTemperature(IAT)

1Compress.DischargeTemp.(CDT)

1OutsideAirTemperature(OAT)

1SystemBusVoltage(BAT)onpowerlead

AnalogThermocouples:

Responsecurve:AllLinearized.

Resolution:1.0F

Accuracy:+1.0F

Calibration:JorK

INSTALLINGTHEEGT701SCANNER PAGE15OF 22

REVB

ResolutionandDisplayRange(FuelFlowOption)

display maximumdisplayvalue resolution

Kfactorrange: 5,000 99,990 10

Fuelflow: Accuracy(8to60GPH) >2%(TSOC44a)

140.0GPHatKfactor85,000 0.1GPH

410.0GPHatKfactor29,000 0.1GPH

820PPHatKfactor85,000 1PPH

2400PPHatKfactor29,000 1PPH

560LPHatKfactor85,000 1LPH

1640LPHatKfactor29,000 1LPH

372KPHatKfactor85,000 1KPH

1088KPHatKfactor29,000 1KPH

FuelRemaining: 999.9Gal 0.1Gal

999Lbs.,L,orKg 1Lb.,L,orKg

FuelUsed: 999.9Gal. 0.1Gal

9999Lbs.,L,orKg 1Lb.,L,orKg

TimetoEmpty: 50hours 1minute

FuelflowTransducer Standardfuelpump(FXT201) Gravity(FXT231)

Range 0.6to60GPH 3to90GPH

Linearity 1%(8to60GPH) 1%(8to60GPH)

KFactor Approximately29,000 Approximately19,500

Pressuredrop 1.2psiat30GPH,4.8psiat60GPH 0.31psiat30GPH,2.8psiat90GPH

Workingpressure 200psi 200psi

Minimumburstpressure 2000psi 2000psi

Temperaturerange 65Cto125C 65Cto125C

Fuelports FemaleNPT FemaleNPT

OutputDisplayFunctions(AllOptions): FactoryDefaultAlarmLimits

EGT(ExhaustGasTemp.,K,Max.limit2500

o

F) 1650

o

F

CHT(CylinderHeadTemp.,J/KMax.limit600

o

F) 450

o

F

TIT (TurbineInletTemperature,K,Max.limit2500

o

F) 1650

o

F

OIL(Oiltemperature,K,Max.limit600

o

F) (Hi/Lo)230/90

o

F

OAT(OutsideAirTemp.,K,Limit 40to300

o

F)

IAT(InductionAirTemp.,K,Max.Limit600

o

F.)

CLD(RateofchangeofCHT) 60

o

/minute

DIF(MaximumEGTdifferential) 500

o

F

LFM(LeanFindMode,detectsfirstEGTpeak)

BAT(Voltage,0to40volts.)NotFAAApprovedunderTSOC43b 15.5/11.0or

Allalarmlimitsareadjustablebyaqualifiedmechanic.

TheconditionsandtestrequiredforTSOapprovalofthisarticleareminimumperformancestandards.Itisthe

responsibility of those desiring to install this article either on or within a specific type or class of aircraft to

determinethattheaircraftinstallationconditionsarewithintheTSOstandards.

Analarmcausesthedigitalfunctiontoflashwhentheparticularlimitisexceeded.Factorysetdefaultalarm

limitsforCHT(450

o

F)andOIL(230

o

F)arelowerthantheactualaircraftlimits.Thevaluesmaybeadjustedto

suitindividualpreferencebypressingtheresetbutton.Otherfactorysetalarmlimitsare:BATVoltage

15.5/11.0or31.0/22.0Hi/LoasappropriateDIF(differentialHi/LoEGT)500

o

FTIT1650

o

FHiOIL

Lo90

o

FCLD(Rateofchangeofcylinderheadtemperatureindegreesperminute)60degrees/minute.Fuel

flowwarnings:LowFuelRemainingorLowTimetoEmpty.

Thepilotshouldbeawareofthesettingofeachalarmforhisparticularaircraft.Analarmisdisarmedforthe

remainderoftheflightbyholdingthestepbuttoninfor5secondsandobservingthewordOFF.Onlythat

particularalarmisdisarmed.Disarmedalarmsarenotarmedagainuntilthepowerhasbeenremovedand

reappliedtotheEGT701.Theentiredisplaydimsautomaticallydependingontheambientlighting.

INSTALLINGTHEEGT701SCANNER PAGE16OF 22

REVB

22) EngineOperation

Operateandleantheengineinaccordancewiththemanufacturers'recommendationsfordifferentpower

settings. Lycoming recommends running peak EGT only at 75% power or less. Continental recommends

runningpeakEGTat65%powerorless.

23) PartsListforEGTProbePN128,TITProbePN120,IATProbePN130

1ThermocoupleprobePNM111

1StainlessSteelClampThimble

1StainlessSteelExhaustSealWasher

1StainlessSteelScrewTypeClamp

2RingTerminals

2Screwsandnuts632X1/4

1Fiberglasstube1/2X4

24) PartsListforCHTProbePN126

1BayonetProbeSpringloadedPN5050

1GasketthermocoupleprobePNM113

2RingTerminals

2ScrewsandNuts632X1/4

1Fiberglasstube1/2X4

25) PartsListforOILProbePN124

1PN400505 Cor L,OILprobe

2RingTerminals

2ScrewsandNuts632X1/4

1Fiberglasstube1/2X4

26) PartsListforOATProbePN122

1PN400509,OATprobe

2RingTerminals

2ScrewsandNuts632X1/4

1Fiberglasstube1/2X4

27) PartsListforFuelflowTransducerPN700900

1FuelflowTransducerPNFXT201or 231

3AMPFemaleTerminals

1AMPFemaleConnectorhousing

1FireSleeve

3AMPFemaleTerminals 1AMPFemaleConnectorhousing

28) PartsListforSingleEngineEGTandCHT

Part 4C 6C 7C 8C 9C

TemperatureIndicatorEGT701 1 1 1 1 1

EGTprobekitPN128 4 6 7 8 9

CHTprobekitPN126 3 5 7 7 9

CHTGasketprobekitPN126 1 1 1

OilprobewithoptionOkitPN124 1 1 1 1 1

TITprobewithoptionTkitPN120 1 1 1 1

OATprobewithoptionAkitPN122 1 1 1 1 1

IATprobewithoptionIkitPN130 1 1 1 1 1

29) WeightandBalanceData

Weightsbelowdonotincludecustomersuppliedfittings,hoses,andotherhardware.

TSOC43b,TemperatureIndicatorEGT701 14.5oz./0.9lbs.

Fuelflowoption Add2.0oz./0.125lbs.toinstrument

EGTprobeM111,CRB,IAT,TIT,OAT 2.0oz.each/0.125lbs.each

CHTprobe5050 1.5oz.each/0.094lb.each

Fuelflowoptiontransducer 3.0oz./0.186lbs.

WireHarnessPN7007008,8ft. 14.0oz.each/0.88lbs.

INSTALLINGTHEEGT701SCANNER PAGE17OF 22

REVB

30) CalibratingtheEGT701fortheFactoryOriginalTITprobe

IftheaircraftisusingthefactoryoriginalTITprobeandgage,youwillberequiredtocalibratetheEGT701for

thatprobe.ThefactoryoriginalTITprobemustbeatypeKandtheleadsmustbewiredredtoredand

yellowtoyellow.BoththeEGT701andfactoryoriginalgagemaybeusedconcurrently.Duetothehighinput

impedanceoftheEGT701instrument,itwillnotaffecttheaccuracyofthefactoryinstalledprobeorgage.

Innormalcruiseflight,recordthedifferencebetweenthefactoryinstalledTITgageandtheEGT701TIT

reading.TITgage________EDM________.

TurnontheEGT701andafterselftest,pressSTEPuntiltheinstrumentiscyclingnormally.Start thePilot

ProgrammingProcedure,bysimultaneouslyholdingtheSTEPandLFbuttonsforfiveseconds.

STEP

sequencesto

thenext

item

TaptheLFbuttonto

sequencethroughthese

values Comments

PROGRAM

Staysonfortwoseconds.

RATE4 RATE4

holdbothSTEPandLFforfivesecondstobeginthenextsequence.

ORIG

TIT

ORIGTN

ORIGTY

YYes selectsfactoryoriginalTITprobeandproceedstothenextstep.

CAL

TIT

TIT + 0 TIT

5

TITI0

...TIT 975

TIT +975

970

tapLFtolowerthecorrectionhold:LFtoraisethecorrection.

Forexample,iftheEGT701reads100lessthantheaircraftsTITgage,setthedisplay

toread TIT +I00.

STEPexitstheprocedure.

31) SettingtheKfactor(FuelFlowOption)

YoumustsettheKfactorbeforeusingtheEGT701withfuelflow.NotetheKfactorthatwasengravedonthe

fuelflowtransducer.

1. TurnontheEGT701andafterselftest,pressSTEPuntiltheinstrumentiscyclingnormally.

2. PlacetheselecttoggleswitchintheFFposition.

3. StartthePilotProgrammingProcedurebysimultaneouslyholdingtheSTEPandLFbuttonsforfiveseconds.Youwill

seetheword PROGRAM fortwoseconds.

4. TaptheSTEPbuttonrepeatedlyuntilyousee KFSET.

5. HoldSTEPandLFforfiveseconds.Firstdigitblinks:29.00

6. TaporHoldLFtochangeflashingdigit(forexample): I9.00

7. TapSTEPfornextdigit: I9.00

8. TaporHoldLFtochangeflashingdigit: I8.00

9. TapSTEPfornextdigit: I8.00

10. Repeatsteps7and8fortheremainingtwodigits.

11. VerifytheKfactorthatwasengravedonthefuelflowtransducerisnowdisplayed.

12. HoldSTEPandLFforfivesecondstoexit.

13. TapSTEP

32) SettingtheDataRecordingOptionParameters

(DataRecordingOptiononly)

INSTALLINGTHEEGT701SCANNER PAGE18OF 22

REVB

Ifyouhaventalreadydoneso,startthepilotprogrammingprocedure,simultaneouslyholdtheSTEPandLF

buttonsforfiveseconds.Youwillseetheword PROGRAMfortwoseconds.Tochangethedate,timeanduserid

fortheDataRecordingOption,taptheSTEPbuttonuntilthedisplayshowsDUMP?N.Next,simultaneously

holdtheSTEPandLFbuttonsforfiveseconds.Thensetthedateandtimeasshowbelow

INSTALLINGTHEEGT701SCANNER PAGE19OF 22

REVB

TapSTEP to

nextitem

LF sequences

throughthesevalues Comments

MNTH

I I2

Month

DAY

I 3I

Day

YEAR

80 79

1980through2079

HOUR

OO 23

24hourtime.WesuggestyousetZulutime.

MIN

OO 59

Tappingthestepwillalsozerotheseconds(notshown)

USERID NI2345 HoldbothSTEPandLFbuttonssimultaneouslyuntilthefirstcharacterflashes.

UseLFtoselectthefirstcharacter.STEPmovestothenextcharacter.

HoldbothSTEPandLFtoexit.

33) SettingtheAlarmLimits

TurnontheEGT701andafterselftest,pressSTEPuntiltheinstrumentiscyclingnormally.

TostarttheAlarmLimitProcedure,withtheEGT701poweredup,dothefollowing:

Holdboth

buttonsfor5

secondsuntil

thewords

FACLIM

TapSTEP

buttonuntil

thewords

ENDY

Holdboth

buttonsfor5

secondsuntil

theword

PROGRAM

TaptheSTEPbuttontoadvancetothenextiteminthelist.TaptheLFbuttontoselectalternatevaluesofthat

item.HoldtheLFbuttontorapidlybackup.Promptslistedinthefirstcolumnaredisplayedforonly two

seconds.

ChangingtheAlarmLimits:

STEPto

nextitem

LFsequencesthroughthesevalues

Description

FAC

LIM

FactoryLimits.

FAC?N FAC?Y

Restorefactorydefaults

REV

X.XX

Firmwarerev.number.

TYPEK

TYPEK TYPEJ

HoldSTEPandLFforfivesecondstotoggle

TypeKorTypeJCHTprobes.USETHISWITHCAUTION.*

EGTCHT

ENGF ENGC

SelectForCdegreesforallenginetemps.

BATTERY

I0.0HBAT 35.0HBAT

Batteryhighvoltagelimit,setin0.5voltincrements.

8.5LBAT 30.0LBAT

Batterylowvoltagelimit.

EGT

DIF

30DIF 990DIF

EGTdifferencelimit,setin10increments.

CHTHI

90HCHT 500HCHT

CHThighlimit,setin5increments.

COOL

5CLD 200CLD

Coolinglimit,setin5/min.increments.

INSTALLINGTHEEGT701SCANNER PAGE20OF 22

REVB

CHT

TITHI

650TIT 2000TIT

BothEGTandTIThilimitsarethesame.

OIL

TEMP

40HOIL 500HOIL

Oiltemperaturehighlimit,setin5increments.

I0LOIL 250LOIL

Oiltemperaturelowlimitsetin5increments

FUEL

FLW

FUELGALFUELKGSFUEL

LTRFUELLBS

Selectstheunitsinall parameterswherefuelquantityor

fuelrateisdisplayed

MAINTK

MAIN=50

Maintankcapacity,inunitsselected

AUXTNK

AUX?NAUX?Y

YYes aircrafthasauxiliarytanks

AUX=0

Auxiliarytankcapacity

LOTIME

MIN =45

Alarmlimitinminutesforlowtimeintanks

LOFUEL

REM =I0

Alarmlimitforlowfuelquantityintanks,inunitsselected

CARB?N CARB?Y

YYes:carburetedengine

RECRD?

RECRD?YRECRD?N

DataRecordingOptionYonlydatarecording.N onlyrealtime

dataoutput.

ENDY ENDN

Y YestoexitN Notoreviewlistagain

*CHTwillreadincorrectlyifthewrongprobetypeisselected.TypeKprobesgenerallyhaveredandyellow

wirestypeJprobeshaveblackandwhitewires.

FuelFlowUnits(FuelFlowOption)

Selectstheunitsin allparameterswherefuelquantityorfuelrateisdisplayed.Ifyouchangethisparameter,it

doesnotchangethenumericalvalueofthefueltankcapacity.Youmustdothismanually.Forexampleifyou

changefromGal.toLbs.,thetankcapacitywillbeinterpretedas50Lbs.ratherthan50gallonstheEGT701

willnotconvert50Galtoequivalentpounds.

MainTankCapacity(FuelFlowOption)

Enterthetotalcapacityofthemaintanksinthefuelflowunitsselected.Ifyouhavetanktabs(butnoauxiliary

tanks)andsometimesfillonlytothetabs,setthemaintankcapacitytothecapacityuptothetabs.

AuxiliaryTanks(FuelFlowOption)

Ifyoudonothaveauxiliarytanksortanktabs,answerNo.Ifyouansweryes,youwillbeaskedtoinputthe

capacityoftheauxiliarytanksinthefuelflowunitsselected.Ifyouhavetanktabsandsometimesfillonlyto

thetabs,settheauxiliarytankcapacitytothedifferencebetweenfulltankcapacityandtabcapacity.

LowTimeAlarmLimit(FuelFlowOption)

Selectthevalueofthetimeremaining,inminutes,thattriggersthealarm.Timeremainingiscalculatedatthe

currentfuelflowrate.

LowFuelAlarmLimit(FuelFlowOption)

Selectthevalueofthefuelremaining,intheselectedfuel flowunits,thattriggersthealarm.Fuelremainingis

calculatedatthecurrentfuelflowrate.

Carburetor?(FuelFlowOption)

Differentresponsefiltersareuseddependingonwhetheryourengineiscarburetedorfuelinjected.Thefilter

foracarburetedenginehasaslowerresponsetimetoreducesuddenfluctuationsinreadings.

INSTALLINGTHEEGT701SCANNER PAGE21OF 22

REVB

34) Troubleshooting

a) Amissingcolumninthedisplayonstartupindicatesthatthediagnosticroutinehasfoundanopenwire

orprobewithapoorconnection.Theerrormessagewillindicatewhichchanneltoexamine.

b) Amissingcolumninthedisplayduringflightindicatesawidelyvaryingorerroneoustemperaturevalue.

Theprobeisdeletedfromtheindexingtopreventfalsealarms.

c) StartupOPENPRBmessage.Ifoneofthetemperature probecircuitsisopen,thedisplayindicatesOPEN

PRBfollowedbyoneofthesemessages:EGT1,EGT2,EGT3,EGT4,EGT5,EGT6,EGT

7,EGT8,EGT9,CHT1,CHT2,CHT3,CHT4,CHT5,CHT6,CHT7,CHT

8,CHT9,OIL,IND,OAT,TIT. Checktheconnectorattheinstrumentandverifythatafemale

pinisnotrecessedintheconnector.Checkthecrimpswheretheprobeisconnectedtothewiringharness.

d) Displaysallsixcolumnsindemomode.Probesarenotconnected.Plugprobeharnessontotherearofthe

instrument.

e) Anegativereading(infrontofthenumber)indicatesreversepolarityontheredandyellowthermocouple

wiretoprobe.

f) Ohmmetercheck.Removetheconnectorfromtherearoftheinstrumentandmeasuretheresistanceofthe

probeleadpairs.Thereadingshouldbeabout10ohms.Attheconnectionsbetweentheprobeandthe

wiringharnessintheenginecompartment,theresistanceshouldreadabout2ohms.

g) Allreadingsvaryingrapidly.VerifythattheInstrumentisgroundedattheengineblockforsingle

engineinstallations.Ifanadapterprobeisbeingusedinsurethatitisscrewedintightly.Removethefactory

originalprobethatisintheadapterandnoteifproblemisresolved.Ifsoanohmicgroundexistsbetween

theengineandtheadapterprobe.

h) OneCHTreadshigherorlowerthantheothers.Itismostlikelythatthisisthecylinderthathasthe

sparkpluggasketprobeinstalled.Choosetheupperorlowersparkplug,theonethatprovidesthebest

correlationwiththeothertemperatureprobes.Duetothesparkpluglocation,thegasketprobemayread

higherorlowerthanthefactoryprobe.Placetheprobeontheplugthatreceivesthemostdirectcoolingair

i) Onecylinderseemstoreaderroneously.Physicallyswapthesuspectedprobewithaprobefroma

correctlyreadingcylinder.Iftheproblemmovestothecorrectlyreadingcylinder(staysinthesamecolumn

ontheinstrument)checkthecrimpsbetweentheprobeandthewiringharness.Checkthepinsonthe

connectorthatplugsintotheinstrument.Ifthosecheckokay,thentheprobeshouldbereplaced.Ifthe

problemmovestotheotherprobescolumnontheinstrument,thetemperaturereadingsarecorrectand

thereisprobablyaproblemwiththeoriginalcylinder.

j) LargeEGTspan.Normallyaspirated(carburetor)enginesatnormalcruisedisplayaDIFof125to175

o

F

spreadbetweencylinders.InjectedenginesatnormalcruisedisplayaDIF50to90

o

Fspreadbetween

cylinders.Allcylindersaremeasuredbycommoncircuitry.Itisunlikelythatthecalibrationisinerroron

onlyonechannel.

k) Temperaturereadingvariesmorethan500Finonesecond.Checkforapoorqualitycrimpbetweenthe

probeandharness.

l) AllEGTorCHTreadingsseemtoohighorloworunsteady.VerifythattheInstrumentisgroundedat

theengineblockforsingleengineinstallations.UseaDVM(digitalvoltmeter)tomeasurethedifference

betweeninstrumentgroundandtheengineblockground.Ifthedifferenceisgreaterthan0.5voltswiththe

alternatorcharging,thegroundtotheinstrumentisfaulty.

m) AllEGTandCHTreadingsseemtoolow.Theinstrumentmaybesettodisplayenginetemperaturesin

CelsiuswhenyouareusedtoseeingFahrenheit.SeePilotsGuideunderPilotProgramming.

INSTALLINGTHEEGT701SCANNER PAGE22OF 22

REVB

n) OATreadingsinerrormorethan10, butoilandCHTreadingsareokay.Lookfor copperwirespliced

inlinetotheOATprobe.TheOATreadingcanbeadjusted 10.SeePilotsGuideunderPilot

Programming.

o) Gemconversion,allCHTsreadhigh EGT701notcalibratedforGeminstallationJcalibration.Change

toKcalibrationusingtheproceduretosetalarmlimitsdescribedearlier.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- SsangYong Action Service ManualDocument2,172 pagesSsangYong Action Service ManualHector Garin91% (103)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Corolla L 2014 2zr FaeDocument526 pagesCorolla L 2014 2zr Faeelizardo macias condoriNo ratings yet

- 1.2 63 77 KW TSI EngineDocument257 pages1.2 63 77 KW TSI Engineteodor1974100% (3)

- 3736a g9t Common Rail SystemDocument180 pages3736a g9t Common Rail SystemKornelija Balandė50% (2)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- BASSnet 2.7 OnBoard Manual v5 PDFDocument119 pagesBASSnet 2.7 OnBoard Manual v5 PDFante100% (1)

- Tim LC, Tim LF, Tim LP GpsDocument158 pagesTim LC, Tim LF, Tim LP GpsAnonymous JR1LSmN0sNo ratings yet

- Shema Napajanje MonitorDocument2 pagesShema Napajanje MonitorCedomir AcimovicNo ratings yet

- G-303, G-808, GR-300 Service NotesDocument12 pagesG-303, G-808, GR-300 Service NotesAnonymous JR1LSmN0sNo ratings yet

- Brigs StratonDocument20 pagesBrigs StratonAnonymous JR1LSmN0sNo ratings yet

- Zero Voltage Switch Circuit GuideDocument11 pagesZero Voltage Switch Circuit GuideAnonymous JR1LSmN0sNo ratings yet

- SKKT 92, SKKH 92, SKKT 92B: Semipack 1Document4 pagesSKKT 92, SKKH 92, SKKT 92B: Semipack 1Anonymous JR1LSmN0sNo ratings yet

- 80C32Document20 pages80C32Anonymous JR1LSmN0sNo ratings yet

- 320 D A8fDocument2 pages320 D A8fRudolph Prieto M100% (4)

- Doosan Common Rail Diesel Engine OverviewDocument34 pagesDoosan Common Rail Diesel Engine Overviewvarthot0% (1)

- Renr7948renr7948 01 P PDFDocument12 pagesRenr7948renr7948 01 P PDFTbgrhvNo ratings yet

- Bollard Pull TestingDocument25 pagesBollard Pull TestingججللبببننيونرتؤتPicatcho PicaچNo ratings yet

- In-CylinderFlameDevelopment DieselEngineThesisRusly13Document126 pagesIn-CylinderFlameDevelopment DieselEngineThesisRusly13enjpetNo ratings yet

- Common Rail PengabdianDocument77 pagesCommon Rail PengabdianRio SetiadiNo ratings yet

- 12 COROLLA / AURIS CVT and Shift Indicator and Engine ControlDocument7 pages12 COROLLA / AURIS CVT and Shift Indicator and Engine ControlISAAC SIDIBENo ratings yet

- Diesel Engine - Wikipedia PDFDocument32 pagesDiesel Engine - Wikipedia PDFS M NaveedNo ratings yet

- 16074102-Triumph Daytona 675 R 2013-2016 Workshop Service ManualDocument697 pages16074102-Triumph Daytona 675 R 2013-2016 Workshop Service ManualAlfredo VillamorNo ratings yet

- KAYO EFI Instructions: 1 Operating PrincipleDocument16 pagesKAYO EFI Instructions: 1 Operating Principlekenny nieuwenwegNo ratings yet

- Bosch Diesel Injector Pump Tuning On Land RoverDocument7 pagesBosch Diesel Injector Pump Tuning On Land RoverJelena KalcNo ratings yet

- Kirloskar SpecDocument1 pageKirloskar Specstephen prosserNo ratings yet

- Too Much Smoke, Low Power FixDocument3 pagesToo Much Smoke, Low Power FixKhincho ayeNo ratings yet

- Ilovepdf MergedDocument15 pagesIlovepdf MergedDeb Sankar MukhopadhyayNo ratings yet

- In-Use Compliance and Deterioration of Vehicle Emissions: July 2015Document38 pagesIn-Use Compliance and Deterioration of Vehicle Emissions: July 2015andrelennonNo ratings yet

- motor-EEM3Troubleshoot v2 5Document180 pagesmotor-EEM3Troubleshoot v2 5Nicoleta Costea100% (1)

- MED 9.2.1 Engine Management System OverviewDocument81 pagesMED 9.2.1 Engine Management System OverviewSalisbur100% (1)

- JRP CaterpillarDocument4 pagesJRP CaterpillarWillington Augusto ArizaNo ratings yet

- Piper Service Manual 761-590 PDFDocument675 pagesPiper Service Manual 761-590 PDFjhoneto007No ratings yet

- 2011 09 EquipAutoENlowDocument16 pages2011 09 EquipAutoENlowPhạm Thủy CươngNo ratings yet

- 003-013 Rocker Lever HousingDocument7 pages003-013 Rocker Lever HousingYè WințNo ratings yet

- ME 7th SemDocument6 pagesME 7th SemShaleen SharmaNo ratings yet

- Zenit Pro 1.32 Software Mazenit - Pro - 1.32 - Softwarenual EngDocument32 pagesZenit Pro 1.32 Software Mazenit - Pro - 1.32 - Softwarenual EngАдрианЛюбитЛариса100% (1)

- MB SL55 AMG - pdf-1635604883Document182 pagesMB SL55 AMG - pdf-1635604883Mohamed AhmedNo ratings yet

- Digrama de Moto Cat 3126aDocument2 pagesDigrama de Moto Cat 3126aDaniel LopezNo ratings yet