Professional Documents

Culture Documents

03 - TDS - Standard For Making and Curing Cubes

Uploaded by

Patricia Jackson0 ratings0% found this document useful (0 votes)

295 views5 pagesStandards for making and curing concrete cube samples

Original Title

03 - TDS -Standard for Making and Curing Cubes

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentStandards for making and curing concrete cube samples

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

295 views5 pages03 - TDS - Standard For Making and Curing Cubes

Uploaded by

Patricia JacksonStandards for making and curing concrete cube samples

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

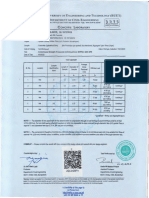

Standard method for making and curing

cubes made from pre-bagged grouts and

polymer modified mortars

General

The method described below is based on

practical experience of making and curing mortar

and grout cubes in the laboratory and on site.

BASF offers the methods stated in good faith

and endeavours to ensure that any advice given

is accurate, however, the method, although

using ASTM C-109 and C-942 as a guideline,

should not be construed as relating to any

International standard.

The method statement relates to BASF products

only. Other materials falling into the above

categories may be mixed successfully using this

method, but BASF cannot be held responsible

for failures caused by not following

manufacturers recommendations or stated

procedures.

Philosophy

The basic philosophy behind testing should be to

assess the material quality following a standard

procedure. The results of these tests should,

initially, be used to determine the suitability of

the product for use, and later to check the

consistency of the supply. Tests may also be

carried out to check the quality of the product

being used in a critical area. This type of

testing, however, should be more a check on the

mixing quality rather than the product itself.

The manufacture and testing of cubes made

from grout or polymer modified cementitious

mortars can pose many problems to the

Engineer. The materials are based on cement,

and yet there may be conflicting requirements as

to how to do the 3 'C's (cast, cure and crush).

Maybe, because the material is cementitious in

nature, and all technicians and Engineers know

BS 1881, it is often easy to treat these types of

product as "concrete". However, this does not

take into account the type of products or the

product's reaction to different curing regimes.

With so many Standards, different cube sizes

and various curing methods, it is possible for the

Engineer to become confused.

This guideline hopes to cover some of these

points and set out what is believed to be a

reasonable method, easily reproduced on site or

in the laboratory, and able to provide consistent

results.

Cube size

Detailed below are some of the various cube

sizes found in grout and repair specifications

used world-wide.

BS 1881 Methods for testing concrete 100mm

BS 4551 Methods for testing mortars 100 or

70.7mm

BS 4550 Methods for testing cement 100 or

70.7mm

BS 6319 Methods for testing resin

compositions

40mm

ASTM C-109 Compressive strength of

grouts

50mm

Cube size used is to an extent irrelevant. The

main points to consider are:

I. The correct type and quality of testing

equipment must be specified and maintained

at a fit for use level. (Planeness, levelness,

quality of internal surfaces, cleanliness etc.)

II. The testing should be comparative

throughout. Cubes of 40, 50 and 70mm will

give similar results however, there may be a

big difference between 50 and 100mm

cubes, which could amount to 4 - 5 N/mm.

III. The testing should be carried out by trained

personnel and procedures should be followed

strictly and under supervision.

Curing regimes should be used to check the

potential strength of the product. Regimes

designed to simulate "site conditions", e.g.

cubes stripped at 1 day and allowed to air dry

until test, will result in lower strengths. These

should not be compared to data sheet values,

which have been determined using maximum

curing regimes. Cube strengths are directly

related to the manufacturing technique (given all

other values equal) and to the curing regime

employed. Full immersion curing may be

suitable for some products and detrimental for

others. The curing method specified allows for

Standard method for making and curing

cubes made from pre-bagged grouts and

polymer modified mortars

full curing without over-wetting or over-drying of

the sample. Small cubes are more prone to

rapid drying out due to their size /volume ratio.

For high strength materials, e.g. grouts, once

that water has escaped no amount of immersion

in water will recover the lost strength. Full curing

is particularly important over the first 3 days.

The one aspect not able to be covered by this

method is temperature of cure. All standards

specify a curing temperature. In a static

laboratory this is usually available, but may be

impossible to achieve in a site laboratory.

Curing tanks stored outside and not temperature

controlled may suffer from solar gain in the day

and rapid cooling at night. Temperatures and

standard temperatures vary from region to

region.

The general rule which should be followed,

where ever possible, is to maintain the

temperature within the range of:

20 1C for temperate climates

27 1C for tropical and sub-tropical climates.

Normal weight grout and repair mortar cubes

(Density > 1900 kg/m)

Due to the density of the products, curing in the

traditional way, (full immersion in water) does

not pose any problems. However, often curing

tanks on site are not maintained and the cubes

need to be transported from site to a testing

house. This is also an area where ill treatment

of cubes can occur.

Light weight repair mortars (Density <1900

kg/m)

The strengths of these types of product are

greatly influenced by the curing regime.

Insufficient curing will show low strengths due to

rapid de-hydration of the specimen. Conversely,

total immersion in water can also show a loss in

strength. The full reasons for this are unclear at

the present time but one theory has it that,

because the porosity is slightly higher, the pores

fill with water and the water exerts an internal

hydrostatic force during the crushing process,

which weakens the material.

By employing the method stated below, cubes

manufactured on site can be assured full cure

without the need to take from tanks and risk

dehydration during transport or, over soaking.

IV. The method of tamping the material into the

moulds is also important. Grout cubes need

only light tapping of the mould to release any

entrapped air. Lightweight repair mortars need

careful handling to ensure full compaction.

Summary

Normal site testing should only be carried out to

check the consistency of supply using some or

all of the tests employed to confirm initial

acceptance, unless other testing regimes have

been agreed.

Only trained technicians should be used for the

preparation and testing of materials, as without

doubt, the majority of product failures come from

poor curing and testing technique.

Curing should be properly employed to ensure

cementitious materials gain their full potential

strength. Any other technique is open to

variation unless fully controlled and monitored.

Making and curing cubes made from

cementitious grouts and normal weight / light

weight repair mortars

General

The method described below, if carried out by

trained staff, should ensure consistency of

manufacture and hence consistency of results.

Equipment

Cube moulds

The size to be used should not exceed 70mm

and certainly not be more than 100mm for grout

products. Only one size of cube should be used.

Combinations of mould sizes will give

inconsistent cube strengths.

Standard method for making and curing

cubes made from pre-bagged grouts and

polymer modified mortars

The cube moulds should be precision moulds,

specifically designed as cube moulds, made

from metal with matched parts marked with

unique numbers or characters on the opposite

sides of the top flange to facilitate correct

assembly.

The internal faces of the moulds shall be

machined. All angles will be at right angles (90)

to adjacent faces. The depth of the mould and

the distance between either pair of opposite

internal faces based on the average of four

measurements should be the nominal size

0.15mm.

The joint between the mould sections and the

bottom plate should be watertight. The mould's

internal and external surfaces and joints should

be kept clean from build up of cement and loose

rust by wire brushing, or other suitable

technique, and lightly oiled with a proprietary

mould release agent.

Note: Mould oil should not be allowed to pool in

the mould and any excess oil should removed

prior to use. The correct application can be

checked by wiping a dry finger across the mould

surface. If the mould oil is ridged either side of

the finger mark an excess of oil is present. If the

finger is still oil free then insufficient oil is on the

surface. New moulds should have the travelling

grease removed before use.

All fasteners should be tightened using the

correct tools such that the mould sections are

rigid and will not loosen under compaction or

movement. Avoid over tightening that can

distort the sections.

Where the cubes are made from products that

have partial or complete expansion or are to be

restrained in application, the moulds shall be

provided with a covering plate which shall be

firmly fixed ensure that the top of the grout is not

allowed to expand freely.

Cleaning equipment

Wire brush

Rags or similar cleaning materials

25mm paintbrush

Mould release oil

Dust pan and brush

Spanners or hexagonal screw keys

Scrapers

Rubber hammer

Screwdriver

Tamping bar

A normal concrete tamping bar (25mm square)

is too heavy and not suitable. A hard wood, or

hard rubber or plastic rod of cross- section

approximately - of the nominal dimensions

of the mould should be used. The rod should be

150 - 200mm in length. (If wood is used the

wood should be prepared by saturating in a light

mineral oil. This prevents water from being

absorbed during tamping. Note: remove all

excess oil before use.)

Steel float for levelling

Absorbent cloth or heavy duty tissue to wrap

the cubes after stripping

Heavy gauge polythene bags and 50mm wide

plastic packing tape

Permanent marker pens and self adhesive

labels

Small scoop for filling

Procedure

Prepare an area to manufacture and store the

cubes. The area should be dry and the cubes

should be made on a flat, solid base free from

vibration and the effects of weather. The area

should be shaded and if possible inside an

enclosed room.

Ensure that the moulds are clean and ready for

use, and all equipment required to complete the

task is at hand. (i.e. rags, plastic bags, heavy

duty cloth etc.)

Standard method for making and curing

cubes made from pre-bagged grouts and

polymer modified mortars

Follow the mixing method outlined in the

appropriate technical datasheet to mix the

material. Use only full bags of product.

On completion of mixing make the cubes

immediately. Do not wait until the pour is

complete and then cast the moulds.

It is recommended to make at least 2 cubes for

each age of test and curing regime.

Recommended standard ages for test are 1,3, 7

and 28 days although other ages can be cast at

the Engineer's discretion, provided sufficient

moulds are available.

Scoop a quantity of the mortar or grout and half

fill each of the moulds to be cast. Ensure that a

representative sample is taken. This is

particularly important for grout products.

Compact in the following manner for:

Grouts

Using the rubber hammer, tap the four corner of

each section of the mould until no air bubbles

are seen to rise and the grout is level. The

corners should be completely filled. The more

fluid the product, the less taps are required.

Repeat the process, slightly overfilling the

mould. Strike off level with the trowel using a

sawing motion. When all sections of the mould

are filled immediately attach the top plate and

tighten it down. Cover the whole with a plastic

sheet. Alternatively the moulds can be sealed

inside a plastic bag.

Repair mortars

Using the square section tamper, rod with firm

even pressure over the entire surface of the

mould 25 times. Do not strike through the

mortar as this can have the effect of leaving

holes behind after filling the second layer. At the

end of the tamping, lift and drop the mould

through 10mm 5 times. This will ensure that any

bubbles are forced out.

Repeat the process, again slightly overfilling the

mould. Strike off level with the top surface of the

mould. Immediately fit the top restraining plate

and cover the whole with a plastic sheet.

Alternatively the moulds can be sealed inside a

plastic bag.

Clearly mark the moulds with the identification

assigned to that batch of cubes.

After 24 hours carefully strip the cubes from the

moulds. Set the mould sections aside in groups

for easy cleaning and re-assembly. Examine the

cubes for any defects. Reject any that do not

look normal (e.g. have an excess of surface

voids or are not complete) and inform the

Laboratory Supervisor or Engineer. Mark on the

surface of each cube with the permanent

marker, its' full identification and the age for test.

Do not scratch details onto the cube.

Immediately wrap each set of cubes in the heavy

duty tissue or absorbent cloth pre - soaked in

water and seal inside the polythene bag. Fold

over the open end and seal it with packing tape,

such that a water tight and air tight seal is

formed. Repeat the identification marks on a

self-adhesive label for sticking on the polythene

bag. Store the bag containing the cubes

carefully ,ensuring that it has no punctures and

cannot be punctured, away from sunlight or

other operations until ready for testing.

Grout and normal weight cubes may

alternatively be stored directly in water until

ready for test. Follow the identification

procedures as above prior to immersion. Ensure

the marking medium is water proof. It is

recommended that if the cubes need to be

transported to a testing house, they are wrapped

as described above for the journey.

Clean up

Carefully clean the mould sections with the wire

brush and lightly oil the sections before re-

assembly. Ensure all joints and internal faces

are clean and there are no steps between

pieces.

Standard method for making and curing

cubes made from pre-bagged grouts and

polymer modified mortars

BASF_CC-UAE/STd_Grouts_11_94/v1/12_13

STATEMENT OF

RESPONSIBILITY

The technical information and application advice given in this BASF publication are based on the present state of

our best scientific and practical knowledge. As the information herein is of a general nature, no assumption can be

made as to a product's suitability for a particular use or application and no warranty as to its accuracy, reliability or

completeness either expressed or implied is given other than those required by law. The user is responsible for

checking the suitability of products for their intended use.

NOTE

Field service where provided does not constitute supervisory responsibility. Suggestions made by

BASF either orally or in writing may be followed, modified or rejected by the owner, engineer or contractor since

they, and not BASF, are responsible for carrying out procedures appropriate to a specific application.

BASF Construction Chemicals UAE LLC

P.O. Box 37127, Dubai, UAE

Tel: +971 4 8090800 Fax: +971 4 8851002

www.basf-cc.ae

Ensure all fasteners are tightened correctly and

the corresponding matching sections are in their

proper position.

Stack the moulds in a covered area away from

the influence of weather, dirt and other

operations. Periodically check the internal faces

and joints

dimensions for excessive wear. Do not join non-

matched sections,

Reporting

For each set of cubes made the following

minimum information should be available.

Name of product and manufacturer.

Manufacturer's batch identification.

Appearance of the powder (e.g. free flowing,

lump free etc.)

Quantity of mixing water per bag of product

used for mixing. (and temperatures where

required)

Cube identification marks and number made

for each age of test. (These must be unique

to each set of cubes)

Time of casting the cubes.

Temperature at time of manufacture.

Temperature and conditions under which the

cubes were stored.

Address of testing house.

Comment on appearance of cubes at

stripping.

Position reference where product was used

and quantity represented by the cube test.

Name, signature and position of the person

making the cubes.

Name, signature and position of the

Supervisor.

Cube crushing

The cubes should be transported to the testing

house if this is not at the site of the cube

manufacture, at least 1 day prior to the crushing

time. Grout cubes and normal weight mortar

cubes should be stripped from the paper and

plastic wrapping and stored in water until ready

for crushing.

For reference cubes should be crushed within

the following time limits after casting.

1 day 23.5 - 24.5 hours

3 days 71.0 - 73.0 hours

7 days 7 days 3 hours

28 days 28 days 4 hours

The cubes should be crushed in accordance

with BS 1881, Part 116 ASTM C109 or DIN

standards using a compression test machine

with ranges suitable for the maximum strength

and cube size of the material under test.

Reporting

Cube identification and age of test.

Cube dimensions in three directions to the

nearest 0.5mm.

Cube weight.

Density (either from cube weight or weight in

air and water).

Crushing load in kN.

Compressive strength in N/mm.

Type of failure observed.

Name, position and signature of technician

carrying out the testing.

Name, position and signature of Supervisor.

You might also like

- DIY Cabin Building Plans PDFDocument6 pagesDIY Cabin Building Plans PDFRoberto Landa100% (5)

- Aashto T 119Document6 pagesAashto T 119Regen BasiñoNo ratings yet

- Mould Maintenance A.kumarDocument40 pagesMould Maintenance A.kumarShankar Hindgavkar100% (2)

- Road Works Method Statements GuideDocument37 pagesRoad Works Method Statements GuidePatricia JacksonNo ratings yet

- Handbook of Adhesive Bonded Structural RepairFrom EverandHandbook of Adhesive Bonded Structural RepairRating: 5 out of 5 stars5/5 (1)

- Sampling and Testing Grout: Standard Test Method ForDocument6 pagesSampling and Testing Grout: Standard Test Method Formirwais100% (1)

- Isostatic PressingDocument39 pagesIsostatic PressingBala SundaramNo ratings yet

- Masonry Testing 101 - 2018 04 12Document57 pagesMasonry Testing 101 - 2018 04 12Jeff LongoriaNo ratings yet

- MS For Electrical InstallationDocument31 pagesMS For Electrical InstallationPatricia Jackson100% (1)

- MS For Electrical InstallationDocument31 pagesMS For Electrical InstallationPatricia Jackson100% (1)

- ASTM C1019 GroutingDocument5 pagesASTM C1019 Groutingalexago75% (4)

- Astm C 156-17Document5 pagesAstm C 156-17reniNo ratings yet

- BASF Standard Method For Making and Curing Grout Cubes v1Document4 pagesBASF Standard Method For Making and Curing Grout Cubes v1robin rezkNo ratings yet

- Internal Audits OpDocument30 pagesInternal Audits OpPatricia JacksonNo ratings yet

- Standard Method For Making and Curing Cubes Made From Pre-Bagged Grouts and Polymer Modified Mortars PDFDocument7 pagesStandard Method For Making and Curing Cubes Made From Pre-Bagged Grouts and Polymer Modified Mortars PDFVCNo ratings yet

- The Fabrication of Materials: Materials TechnologyFrom EverandThe Fabrication of Materials: Materials TechnologyRating: 5 out of 5 stars5/5 (1)

- Monolithic Isolating Joint DatasheetDocument3 pagesMonolithic Isolating Joint DatasheetEpwe100% (1)

- Astm C143Document4 pagesAstm C143Audrey Schwartz100% (2)

- As 1478.2-2005 Chemical Admixtures For Concrete Mortar and Grout Methods of Sampling and Testing Admixtures FDocument9 pagesAs 1478.2-2005 Chemical Admixtures For Concrete Mortar and Grout Methods of Sampling and Testing Admixtures FSAI Global - APACNo ratings yet

- Meat & Potatoes of Plastic Injection Moulding, Explanation & Guides TroubleshootingFrom EverandMeat & Potatoes of Plastic Injection Moulding, Explanation & Guides TroubleshootingNo ratings yet

- METHODS of monta Klebebandwerk GmbHDocument12 pagesMETHODS of monta Klebebandwerk GmbHJayant Kumar JhaNo ratings yet

- Astm A574Document8 pagesAstm A574nmclaughNo ratings yet

- ASTM C172 EnglishDocument5 pagesASTM C172 EnglishJorge Lewis Rodriguez Santos0% (1)

- Sample Quality ManualDocument15 pagesSample Quality ManualPatricia JacksonNo ratings yet

- TN 39 - Testing For Engineered Brick Masonry-Brick and Mortar - 2001 PDFDocument8 pagesTN 39 - Testing For Engineered Brick Masonry-Brick and Mortar - 2001 PDFAnonymous PjmE9RJcghNo ratings yet

- Design Against CreepDocument112 pagesDesign Against CreepRishabh TripathiNo ratings yet

- C882Document4 pagesC882Jorge Luis Arevalo LopezNo ratings yet

- C1403 15Document5 pagesC1403 15Lorena JimenezNo ratings yet

- Types & Procedures: Internal Tank Linings & CoatingsDocument22 pagesTypes & Procedures: Internal Tank Linings & CoatingsAhmed100% (1)

- Measuring Changes in Height of Cylindrical Specimens of Hydraulic-Cement GroutDocument5 pagesMeasuring Changes in Height of Cylindrical Specimens of Hydraulic-Cement GroutEvert RiveraNo ratings yet

- Economiser & DrumDocument75 pagesEconomiser & DrumGaurav ChauhanNo ratings yet

- Installation, Assembly and Test Procedure: Kamos Patented Kammprofil GasketDocument16 pagesInstallation, Assembly and Test Procedure: Kamos Patented Kammprofil Gasketjayhuacat7743No ratings yet

- Norma ASTM C156Document5 pagesNorma ASTM C156Jony GutiérrezNo ratings yet

- Astm - C1579Document7 pagesAstm - C1579Diego Bonadiman100% (1)

- Making and curing cementitious grout andrepair mortar cubesDocument4 pagesMaking and curing cementitious grout andrepair mortar cubesVenkata RaoNo ratings yet

- Crushing Strength of ConcreteDocument11 pagesCrushing Strength of ConcreteKevin TangNo ratings yet

- Department of Transportation: California Test 551 August 2012Document21 pagesDepartment of Transportation: California Test 551 August 2012Mohsen TennichNo ratings yet

- M-L/NE ACCESSORIES Student Instruction Bulletin Strain Gage InstallationsDocument10 pagesM-L/NE ACCESSORIES Student Instruction Bulletin Strain Gage InstallationsJoanna SimmonsNo ratings yet

- Compressive StrengthDocument14 pagesCompressive StrengthApril Lyn SantosNo ratings yet

- ASTM C-156 Water Retention by Concrete Curing MaterialsDocument5 pagesASTM C-156 Water Retention by Concrete Curing MaterialsfahadNo ratings yet

- Water Retention by Liquid Membrane-Forming Curing Compounds For ConcreteDocument5 pagesWater Retention by Liquid Membrane-Forming Curing Compounds For ConcreteSebastian EspitiaNo ratings yet

- 672CDocument3 pages672CJGD123No ratings yet

- Water Retention by Concrete Curing Materials: Standard Test Method ForDocument5 pagesWater Retention by Concrete Curing Materials: Standard Test Method ForTemur LomidzeNo ratings yet

- Astm D6934 22Document3 pagesAstm D6934 22akmalzainal.onlineNo ratings yet

- 12 Astm D 6928Document7 pages12 Astm D 6928Joel BecerraNo ratings yet

- Durability Test PaintDocument9 pagesDurability Test PaintMohamed NouzerNo ratings yet

- Cemfil Sprayguide WW 12 2008 Rev1Document32 pagesCemfil Sprayguide WW 12 2008 Rev1freidorNo ratings yet

- Grouts GroutingDocument4 pagesGrouts GroutingBalaiya ParthibanNo ratings yet

- High Performance Epoxy GroutDocument2 pagesHigh Performance Epoxy Groutpravi3434No ratings yet

- Grouts Grouting PDFDocument4 pagesGrouts Grouting PDFG. SASIDHARA KURUPNo ratings yet

- Measuring Concrete Strength and Developing a Vibration SensorDocument7 pagesMeasuring Concrete Strength and Developing a Vibration SensorAmirul Zolkhairi100% (1)

- TDS - Masterflow 648CPDocument3 pagesTDS - Masterflow 648CPVenkata RaoNo ratings yet

- Chapter Three 3.0 Methodology: 3.2.1 Aggregates of Requirement in EssentialDocument11 pagesChapter Three 3.0 Methodology: 3.2.1 Aggregates of Requirement in EssentialAsghar Hussain Shah S/o Zubair Shah MS Engg. Management (Swat Campus)No ratings yet

- 5 Racking: Issues To Consider in The Design & Care of Parts RacksDocument2 pages5 Racking: Issues To Consider in The Design & Care of Parts RacksDaniela MateiNo ratings yet

- Compressive Strength of Chemical-Resistant Mortars, Grouts, Monolithic Surfacings, and Polymer ConcretesDocument4 pagesCompressive Strength of Chemical-Resistant Mortars, Grouts, Monolithic Surfacings, and Polymer ConcretesigorcidNo ratings yet

- Bitumastic 300MDocument2 pagesBitumastic 300Mtharman749781No ratings yet

- Abrasion Testing of Cementitious Floors - Technical Note 2Document4 pagesAbrasion Testing of Cementitious Floors - Technical Note 2BamsiamNo ratings yet

- Compressive Strength of Chemical-Resistant Mortars, Grouts, Monolithic Surfacings, and Polymer ConcretesDocument4 pagesCompressive Strength of Chemical-Resistant Mortars, Grouts, Monolithic Surfacings, and Polymer ConcretesPedro SánchezNo ratings yet

- Mortar Strength TestDocument47 pagesMortar Strength TestVikas SharmaNo ratings yet

- EMCEKRETE 90 DS - Updated-Dec 2022Document3 pagesEMCEKRETE 90 DS - Updated-Dec 2022Suvajit BisaiNo ratings yet

- CRD c260 PDFDocument8 pagesCRD c260 PDFJersey Mae PerlasNo ratings yet

- CRD c260 PDFDocument8 pagesCRD c260 PDFJersey Mae PerlasNo ratings yet

- AstmDocument4 pagesAstmHilal kan uyarNo ratings yet

- Sample Preparation for Metallographic ExaminationDocument83 pagesSample Preparation for Metallographic ExaminationErdi Sofyandra AdikriNo ratings yet

- C397Document2 pagesC397Rufo CascoNo ratings yet

- Care Maintenance LiningsDocument7 pagesCare Maintenance LiningsEdgarDavidDiazCamposNo ratings yet

- MASTERTOP 100 Dry Shake Floor Hardener Test ResultsDocument3 pagesMASTERTOP 100 Dry Shake Floor Hardener Test ResultsVenkata RaoNo ratings yet

- Potential Expansion of Portland-Cement Mortars Exposed To SulfateDocument3 pagesPotential Expansion of Portland-Cement Mortars Exposed To SulfatezhunsheanNo ratings yet

- Quality Control of Material ConstructionDocument7 pagesQuality Control of Material ConstructionMustafa TalibNo ratings yet

- Project ManagerDocument5 pagesProject ManagerPatricia JacksonNo ratings yet

- ACI Mix DesignDocument9 pagesACI Mix DesignAbdul Hamid BhattiNo ratings yet

- Project Logo Audit Report SummaryDocument2 pagesProject Logo Audit Report SummaryPatricia JacksonNo ratings yet

- Health Safety OffDocument1 pageHealth Safety OffOmar FarukNo ratings yet

- Final - CFR CqappDocument134 pagesFinal - CFR CqappPatricia JacksonNo ratings yet

- Final - CFR CqappDocument134 pagesFinal - CFR CqappPatricia JacksonNo ratings yet

- Non Metallic MaterialsDocument16 pagesNon Metallic MaterialsthisisjineshNo ratings yet

- Finite Element Modeling of RC Beams Strengthened in Flexure Using FRP MaterialDocument12 pagesFinite Element Modeling of RC Beams Strengthened in Flexure Using FRP MaterialCu ToànNo ratings yet

- My Projects:: Your NameDocument2 pagesMy Projects:: Your NameDragos Ionel CiobanicaNo ratings yet

- RTHDDocument32 pagesRTHDizmaya72660No ratings yet

- Lap. Splice in Beam Staggering of Lap. Splice: S.No Items MMDocument1 pageLap. Splice in Beam Staggering of Lap. Splice: S.No Items MMpavan kumarNo ratings yet

- Unit IV - Limit State Design of ColumnsDocument7 pagesUnit IV - Limit State Design of ColumnsManikandanNo ratings yet

- Cement Treatment GIT 1Document12 pagesCement Treatment GIT 1Sparsh ShukalNo ratings yet

- Splash Works Water Parks Core Test Report PDFDocument1 pageSplash Works Water Parks Core Test Report PDFJahid HasanNo ratings yet

- History of Refrigeration and Early Artificial MethodsDocument39 pagesHistory of Refrigeration and Early Artificial MethodsKart01No ratings yet

- Vertical glandless pump installation guideDocument22 pagesVertical glandless pump installation guideYoutube For EducationNo ratings yet

- Air-Conditioning SystemDocument6 pagesAir-Conditioning SystemDay DreamerNo ratings yet

- Ramos DLP Lesson1Document10 pagesRamos DLP Lesson1Irah kabilingNo ratings yet

- Fisher 99 Instruction ManualDocument24 pagesFisher 99 Instruction ManualJosé de Jesús MartinezNo ratings yet

- History and Applications of Reinforced Brick MasonryDocument7 pagesHistory and Applications of Reinforced Brick MasonryAbhishek AggarwalNo ratings yet

- 132KV Pi and Sa Steel Support Structures NewDocument6 pages132KV Pi and Sa Steel Support Structures NewNNANYELU CHINWUBANo ratings yet

- AISC Comparison (2005 To 2010 To 2016) PDFDocument1 pageAISC Comparison (2005 To 2010 To 2016) PDFPrima AdhiyasaNo ratings yet

- Gundu Rao Sanc Plan - A2 SizeDocument1 pageGundu Rao Sanc Plan - A2 SizeBHARATH KUMARNo ratings yet

- Jeffrey Shulenburg Design PortfolioDocument30 pagesJeffrey Shulenburg Design PortfoliojeffreyshulenburgNo ratings yet

- We Deliver Ice Builders (Latent Heat Storage Units) To The HVAC, Dairy, and Food Processing IndustriesDocument4 pagesWe Deliver Ice Builders (Latent Heat Storage Units) To The HVAC, Dairy, and Food Processing IndustriesArlex Ricardo Guillen PetitNo ratings yet

- Rothoblaas - Wrt.technical Data Sheets - enDocument5 pagesRothoblaas - Wrt.technical Data Sheets - enAndrei GheorghicaNo ratings yet

- Energy Methods in Structural Analysis: Version 2 CE IIT, KharagpurDocument13 pagesEnergy Methods in Structural Analysis: Version 2 CE IIT, Kharagpurmathewsujith31No ratings yet

- Ressure Elief Alves: Model 7000 Model 7200 For Fire Sprinkler SystemsDocument1 pageRessure Elief Alves: Model 7000 Model 7200 For Fire Sprinkler SystemsrajeshNo ratings yet

- Reinforced Concrete Beams With Lightweight Concrete InfillDocument10 pagesReinforced Concrete Beams With Lightweight Concrete Infillcharvi shinyNo ratings yet

- Oceanic HW 443 Series: Key Benefits DescriptionDocument2 pagesOceanic HW 443 Series: Key Benefits Descriptions bNo ratings yet