Professional Documents

Culture Documents

GE Oil & Gas Subsea Systems Torque and Tension Recommendations

Uploaded by

P Sandana NaraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GE Oil & Gas Subsea Systems Torque and Tension Recommendations

Uploaded by

P Sandana NaraCopyright:

Available Formats

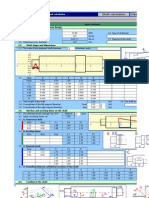

GE Oil & Gas

Subsea Systems

Doc. No

N042049-0001

Revision

Page

H

1 of 2

RECOMMENDED PRETENSION FORCE AND MAKE-UP TORQUE - METRIC FASTENERS

ISO 898-1

Gr. 8.8

ISO 898-2

Gr. 8

640

800

509

Bolt material (see note 2)

Nut material (see note 2)

SMYS [MPa]

Ultimate Strength [MPa]

Prestress [MPa]

DIM

M4

M5

M6

M8

M10

M12

M16

M20

M24

M30

M36

M42

M48

M52

M56

Outer

diameter

[mm]

4

5

6

8

10

12

16

20

24

30

36

42

48

52

56

Bolt utilization factor

Preload safety factor

Friction coefficient

Half the thread angle

Thread

pitch

[mm]

0.70

0.80

1.00

1.25

1.50

1.75

2.00

2.50

3.00

3.50

4.00

4.50

5.00

5.00

5.50

Stress

area

[mm^2]

8.8

14.2

20.1

36.6

58.0

84.3

156.7

244.8

352.5

560.6

816.7

1120.9

1473.1

1757.8

2030.0

ISO 3506-1

Gr. A4-80

ISO 3506-2

Gr. A4-80

600

800

420

ISO 3506-1

Gr. A4-70

ISO 3506-2

Gr. A4-70

450

700

315

ASTM A193/A320

Gr B7/L7

ASTM A194

Gr 2H/7

725

860

547

Preload

Torque

Preload

Torque

Preload

Torque

Preload

Torque

Preload

Torque

[kN]

4.5

7.2

10.2

18.6

29.5

42.9

79.8

124.6

179.5

285.4

415.8

570.6

750.0

894.9

1033

[Nm]

2.6

5.0

8.8

21

42

71

173

338

579

1151

2002

3180

4784

6117

7598

[kN]

3.7

6.0

8

15

24

35

66

103

148

[Nm]

2.1

4.2

7.2

18

34

59

143

279

478

[kN]

2.8

4.5

6

12

18

27

49

77

111

[Nm]

1.6

3.1

5.4

13

26

44

107

209

358

[kN]

4.8

7.8

11.0

20

32

46

86

134

193

307

447

613

806

962

1111

[Nm]

2.8

5.4

9.4

23

45

76

186

363

622

1237

2152

3418

5143

6576

8168

[kN]

3.9

6.2

8.8

16

25

37

69

107

155

246

359

492

647

772

891

[Nm]

2.2

4.3

7.6

18

36

61

149

291

499

993

1727

2743

4127

5276

6554

0.7

1.1

0.10

30

Notes

1. IMPORTANT: Bolt threads and bolt/nut contact area against support shall be lubricated with MOLYCOTE G-RAPID PLUS

2. For threaded connection with S355 type strutural steels, the make-up torque values are only valid provided that ENGAGED THREAD LENGTH 1.5 x DIAMETER.

If this requirement is not met and for all other materials with SMYS less than 300 MPa, separate calculations must be performed to determine correct make-up torque.

3. Bolts and nuts for subsea application shall be coated with electrodeposited zinc (ElZn, except ISO 3506 A4)

4. The recommended make-up torque values are based on a tolerance of maximum +/- 5%.

For slip resistant bolt connections using ISO 898-1 Gr. 8.8, incrase preload value by 10% and perform controlled make-up according to EN 1090-2 section 8.5.

5. Only recommended fastener dimensions are given in this table

6. For bolt connections with serrated washers, reduce torque values by 25%

7. For set screws (ISO 898-5 Gr 45H ), reduce torque value by 50% compared to ISO 898-1 Gr. 8.8

8. For set screws (ISO 3506-3 Gr 21H ), reduce torque value by 50% compared to ISO 3506-1 Gr. A4-70

9. To minimize bolt preload variations, a distributed tightening sequence should be considered.

Security

Level:

CONFIDENTIAL

STATE: RELEASED

REVIEWED BY: Gunner Kommisrud REVIEWED

REVISION PENDING: NO

APPROVED BY: Rolf Bastesen

ASTM A193/A320

Gr B7M/L7M

ASTM A194

Gr 2HM/7M

550

690

439

ON: 2014/04/03 13:42:04

APPROVED ON: 2014/04/04 07:54:39

VIEWED: 2014/05/21 20:09:24

DOCUMENT:

N042049-0001 | H

GE Oil & Gas

Subsea Systems

Doc. No

N042049-0001

Revision

Page

2 of 2

RECOMMENDED PRETENSION FORCE AND MAKE-UP TORQUE - UNIFIED COARSE FASTENERS

ISO 898-1

Gr. 8.8

ISO 898-2

Gr. 8

640

800

509

Bolt material (see note 2)

Nut material (see note 2)

SMYS [MPa]

Ultimate Strength [MPa]

Prestress [MPa]

DIM

[in]

1/4

3/8

1/2

9/16

5/8

3/4

7/8

1

1 1/8

1 1/4

1 3/8

1 1/2

1 3/4

2

2 1/2

3

Outer

diameter

[mm]

6.35

9.53

12.70

14.29

15.88

19.05

22.23

25.40

28.58

31.75

34.93

38.10

44.45

50.80

63.50

76.20

Bolt utilization factor

Preload safety factor

Friction coefficient

Half the thread angle

Threads

per inch

[-]

20

16

13

12

11

10

9

8

7

7

6

6

5

4.5

4

4

Stress

area

[mm^2]

20.5

50.0

91.5

117.4

145.8

215.8

297.9

390.8

492.4

625.2

745.1

906.6

1225.5

1611.8

2579.9

3849.9

ISO 3506-1

Gr. A4-80

ISO 3506-2

Gr. A4-80

600

800

420

ISO 3506-1

Gr. A4-70

ISO 3506-2

Gr. A4-70

450

700

315

ASTM A193/A320

Gr B7/L7

ASTM A194

Gr 2H/7

725

860

547

Preload

Torque

Preload

Torque

Preload

Torque

Preload

Torque

Preload

Torque

[kN]

10.5

25.5

46.6

59.8

74.2

109.9

151.7

199.0

250.7

318.3

379.3

461.5

623.9

820.5

1313.4

1960.0

[Nm]

10.0

35.6

86

121

169

296

477

713

1010

1408

1855

2439

3865

5809

11487

20240

[kN]

[Nm]

[kN]

[Nm]

[kN]

11.2

27.4

50.1

64.2

79.8

118.1

163.0

213.9

269.5

342.2

407.8

496.2

670.7

882.1

1411.9

2107.0

[Nm]

10.7

38.3

92

130

181

318

513

766

1086

1514

1994

2622

4155

6245

12349

21758

[kN]

9.0

22.0

40.2

51.5

64.0

94.7

130.8

171.6

216.2

274.5

327.2

398.1

538.1

707.7

1132.8

1690.5

[Nm]

8.6

30.7

74

105

145

255

412

615

872

1214

1600

2104

3334

5010

9908

17457

0.7

1.1

0.10

30

Notes

1. IMPORTANT: Bolt threads and bolt/nut contact area against support shall be lubricated with MOLYCOTE G-RAPID PLUS

2. For threaded connection with S355 type strutural steels, the make-up torque values are only valid provided that ENGAGED THREAD LENGTH 1.5 x DIAMETER.

If this requirement is not met and for all other materials with SMYS less than 300 MPa, separate calculations must be performed to determine correct make-up torque.

3. Bolts and nuts for subsea application shall be coated with electrodeposited zinc (ElZn, except ISO 3506 A4)

4. The recommended make-up torque values are based on a tolerance of maximum +/- 5%.

For slip resistant bolt connections using ISO 898-1 Gr. 8.8, incrase preload value by 10% and perform controlled make-up according to EN 1090-2 section 8.5.

5. For bolt connections with serrated washers, reduce torque values by 25%

6. To minimize bolt preload variations, a distributed tightening sequence should be considered.

Security

Level:

CONFIDENTIAL

STATE: RELEASED

REVIEWED BY: Gunner Kommisrud REVIEWED ON: 2014/04/03 13:42:04

REVISION PENDING: NO

APPROVED BY: Rolf Bastesen

ASTM A193/A320

Gr B7M/L7M

ASTM A194

Gr 2HM/7M

550

690

439

APPROVED ON: 2014/04/04 07:54:39

VIEWED: 2014/05/21 20:09:24

DOCUMENT:

N042049-0001 | H

You might also like

- Comp 2Document9 pagesComp 2YYo YudiNo ratings yet

- Analysis of Bolt Torquing CalculationsDocument6 pagesAnalysis of Bolt Torquing CalculationsBahtiar YudhistiraNo ratings yet

- Clamp Design-2Document6 pagesClamp Design-2Harpreet SinghNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Blind Flange Design CalculationsDocument4 pagesBlind Flange Design CalculationsamaNo ratings yet

- AB 520 Finite Element Analysis FEA Requirements PDFDocument4 pagesAB 520 Finite Element Analysis FEA Requirements PDFbello imamNo ratings yet

- Facilities On Offshore Installations: Guide For Building and ClassingDocument209 pagesFacilities On Offshore Installations: Guide For Building and ClassingKarthick VenkatswamyNo ratings yet

- Analysis of a rectangular pressure vesselDocument7 pagesAnalysis of a rectangular pressure vesselPressure VesselNo ratings yet

- Welding SymbolsDocument12 pagesWelding SymbolsrsrtnjNo ratings yet

- Beams On Elastic FoundationsDocument3 pagesBeams On Elastic FoundationsIgnatius SamrajNo ratings yet

- Bolt Tensioning: What is it and how does it workDocument2 pagesBolt Tensioning: What is it and how does it work4jawwy markme026No ratings yet

- Asme Viii Calculation Xls PDF FreeDocument28 pagesAsme Viii Calculation Xls PDF FreeMisbachul ChoirNo ratings yet

- Design of lifting lug on spreader beamDocument2 pagesDesign of lifting lug on spreader beamSabrang LorNo ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- Trunnion 6 TonDocument3 pagesTrunnion 6 TonEngr Khurram Jaan RamayNo ratings yet

- SP-2069 Specification For Pressure VesselsDocument68 pagesSP-2069 Specification For Pressure Vesselsarjunprasannan7No ratings yet

- A-344, A-347 Master LinkDocument1 pageA-344, A-347 Master LinkAekJayNo ratings yet

- Stress analysis of buried cross-country pipingDocument3 pagesStress analysis of buried cross-country pipingSharon LambertNo ratings yet

- Technical DataDocument48 pagesTechnical Datashekhar2681No ratings yet

- Bolt Load Design CalculationDocument2 pagesBolt Load Design CalculationDamanpreet SinghNo ratings yet

- Synechron: Customer Name Date Created byDocument1 pageSynechron: Customer Name Date Created byneelNo ratings yet

- Calculation of Safety Factor Guarding Against Joint OpeningDocument12 pagesCalculation of Safety Factor Guarding Against Joint OpeningPandiyarajan RajuNo ratings yet

- Spreaer Beam&Lifting Line Beam p5Document2 pagesSpreaer Beam&Lifting Line Beam p5Sabrang LorNo ratings yet

- Welding Neck Flanges 1Document3 pagesWelding Neck Flanges 1bikkelbobNo ratings yet

- 7-12-0005 Rev6 (Skirt Opening Details)Document2 pages7-12-0005 Rev6 (Skirt Opening Details)sumit kumarNo ratings yet

- Teague's ShaftDocument145 pagesTeague's ShaftBUDAPESNo ratings yet

- Skirt Design - For Small VesselsDocument7 pagesSkirt Design - For Small VesselsSakthi VelNo ratings yet

- Marine Propulsion System Failures-A Review: Marine Science and EngineeringDocument14 pagesMarine Propulsion System Failures-A Review: Marine Science and EngineeringDavid NuñezNo ratings yet

- B Jack Nos For Cs Ss MaterialDocument12 pagesB Jack Nos For Cs Ss MaterialfahadfiazNo ratings yet

- Cone Weight CalculationDocument10 pagesCone Weight CalculationRajesh OwaiyarNo ratings yet

- Bolts Torque CalculatorDocument2 pagesBolts Torque CalculatorsopapilasNo ratings yet

- Mechanical Design SpreadsheetDocument1 pageMechanical Design SpreadsheetHoney TiwariNo ratings yet

- PDF2 L Hydraulic CylinderDocument56 pagesPDF2 L Hydraulic CylinderShyam Srinivasan100% (1)

- 0488a0vvgc001 06Document73 pages0488a0vvgc001 06AlienshowNo ratings yet

- Boiler and Pressure Vessel Engineering - Vessel Nozzle LoadingDocument7 pagesBoiler and Pressure Vessel Engineering - Vessel Nozzle Loadingvenkatrangan2003No ratings yet

- PV Elite Vessel Analysis Program: Input DataDocument30 pagesPV Elite Vessel Analysis Program: Input DatachampNo ratings yet

- PPD 199 - Lifting Fixture Engineering NoteDocument15 pagesPPD 199 - Lifting Fixture Engineering NoteWalterNo ratings yet

- 7-12-0018 Rev 5Document1 page7-12-0018 Rev 5cynideNo ratings yet

- Jis g3456 Grade STPT 410 Pipes PDFDocument1 pageJis g3456 Grade STPT 410 Pipes PDFMitul MehtaNo ratings yet

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDocument5 pagesASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaNo ratings yet

- Lifting Lug DesignDocument7 pagesLifting Lug DesignJens SøndergaardNo ratings yet

- Tolerance CalculatorDocument4 pagesTolerance CalculatorAshok Kumar UppariNo ratings yet

- Earthquake load calculations as per IS1893-2002Document9 pagesEarthquake load calculations as per IS1893-2002irshad313No ratings yet

- S275JR PDFDocument1 pageS275JR PDFEmrahCayboylu100% (1)

- M 452 ContentDocument63 pagesM 452 ContentprasannaNo ratings yet

- Shear Strength of High-Strength BoltsDocument61 pagesShear Strength of High-Strength Boltsloox600No ratings yet

- Minimum tensile strength materials chartDocument8 pagesMinimum tensile strength materials chartTrishul Nath PallayNo ratings yet

- Oriental Engineering Works PVTDocument20 pagesOriental Engineering Works PVTDarshan DhimanNo ratings yet

- Study & Analysis of Transportation SkidDocument10 pagesStudy & Analysis of Transportation SkidJay PNo ratings yet

- MB 400 Base PlateDocument3 pagesMB 400 Base PlatePeace Rain100% (1)

- UCP 213 Y UCP 215 - FYHcat3300 PDFDocument1 pageUCP 213 Y UCP 215 - FYHcat3300 PDFFranz Alex Fernandez CeronNo ratings yet

- Analysis of structural frame with pinned base plate connectionDocument5 pagesAnalysis of structural frame with pinned base plate connectionwaweng22No ratings yet

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezNo ratings yet

- Body Flange Design-Appx-2Document4 pagesBody Flange Design-Appx-2Matthieu100% (1)

- Screw Type:: Hose Clamps (Uniform Load)Document2 pagesScrew Type:: Hose Clamps (Uniform Load)Tan JaiNo ratings yet

- Key Word Product Name Test File Name Method File Name Report Date Test Date Test Type Speed Shape No of Batches: Qty/BatchDocument2 pagesKey Word Product Name Test File Name Method File Name Report Date Test Date Test Type Speed Shape No of Batches: Qty/BatchSteven Otalora BernalNo ratings yet

- Din933 A4l 8 X 80 MMDocument1 pageDin933 A4l 8 X 80 MMM K ANBUDURAINo ratings yet

- Properties of Grade 8.8 Bolt & Nut (Iso)Document1 pageProperties of Grade 8.8 Bolt & Nut (Iso)Didik RahmadNo ratings yet

- Bolt Torque ASME B16.5 Flanges - Sheet Gaskets 02Document26 pagesBolt Torque ASME B16.5 Flanges - Sheet Gaskets 02bakelly100% (7)

- Traceability List: ProjectDocument16 pagesTraceability List: ProjectP Sandana NaraNo ratings yet

- Quality Manual for Machining, Fabrication and Testing ServicesDocument76 pagesQuality Manual for Machining, Fabrication and Testing ServicesP Sandana Nara100% (2)

- Remove The Welder No Remove and Put As "Refer To The Attached Drawing"Document4 pagesRemove The Welder No Remove and Put As "Refer To The Attached Drawing"P Sandana NaraNo ratings yet

- Bar Stock or Round BarDocument2 pagesBar Stock or Round BarP Sandana NaraNo ratings yet

- Arc Gouging Process GuideDocument6 pagesArc Gouging Process GuideP Sandana NaraNo ratings yet

- MR No Team Part No Item No Type Grade Standard Specification 140447-01,02, 140462-01-01 Cameron 235672-27/01 N/A Metal A36/S275JRASTM N/ADocument3 pagesMR No Team Part No Item No Type Grade Standard Specification 140447-01,02, 140462-01-01 Cameron 235672-27/01 N/A Metal A36/S275JRASTM N/AP Sandana NaraNo ratings yet

- MR No Team Part No Item No Type Grade Standard Specification 140447-01,02, 140462-01-01 Cameron 235672-27/01 N/A Metal A36/S275JRASTM N/ADocument3 pagesMR No Team Part No Item No Type Grade Standard Specification 140447-01,02, 140462-01-01 Cameron 235672-27/01 N/A Metal A36/S275JRASTM N/AP Sandana NaraNo ratings yet

- Approved SMDL Copy of Worksheetin4500541788-40-Smdlrev00 - 20130911043508.141 - XDocument2 pagesApproved SMDL Copy of Worksheetin4500541788-40-Smdlrev00 - 20130911043508.141 - XP Sandana NaraNo ratings yet

- Material TestDocument9 pagesMaterial TestP Sandana NaraNo ratings yet

- No Smoking PolicyDocument1 pageNo Smoking PolicyP Sandana NaraNo ratings yet

- 1367 1 PDFDocument6 pages1367 1 PDFGaurav AgarwalNo ratings yet

- Technical Information RE100Document11 pagesTechnical Information RE100akilshaikhNo ratings yet

- IsoDocument9 pagesIsoEgemet Satis0% (1)

- BC1 2008 Design Guide On Use of Structural SteelDocument89 pagesBC1 2008 Design Guide On Use of Structural SteelfongheeNo ratings yet

- HS FNT02 00000080aec - DDocument4 pagesHS FNT02 00000080aec - DMarcoNo ratings yet

- Is 1364 Part 2 or ISO 4017Document19 pagesIs 1364 Part 2 or ISO 4017santhosh kumarNo ratings yet

- Iso 4034 2012Document9 pagesIso 4034 2012vishnuNo ratings yet

- Iso 21670 2003 PDFDocument9 pagesIso 21670 2003 PDFGiuseppeNo ratings yet

- TYP-E-E - PETRO-C-XG-002 - Gen Spec For Steel WorksDocument31 pagesTYP-E-E - PETRO-C-XG-002 - Gen Spec For Steel WorksLumy NastaseNo ratings yet

- Iso 4035-1999 (Din439)Document9 pagesIso 4035-1999 (Din439)GorkaNo ratings yet

- List of ISO StandardsDocument22 pagesList of ISO StandardsLaster JauodNo ratings yet

- ISO2003Document379 pagesISO2003Yulia RachmawatiNo ratings yet

- BS EN - 15048 2 2007 Non Preloaded Structural Bolting Assemblies Part 2 Suitability Test PDFDocument14 pagesBS EN - 15048 2 2007 Non Preloaded Structural Bolting Assemblies Part 2 Suitability Test PDFPaco100% (1)

- Is 7483 2005Document13 pagesIs 7483 2005sarath6725100% (1)

- Iso 4014Document16 pagesIso 4014Emílio BeckerNo ratings yet

- BS en 26157-1-1992Document18 pagesBS en 26157-1-1992islamfarag2No ratings yet

- Is 1367 1 2002 PDFDocument9 pagesIs 1367 1 2002 PDFBsc Aditya Singh DinkarNo ratings yet

- Cmpl-Bolt and Torque Specifications UsDocument3 pagesCmpl-Bolt and Torque Specifications UsYanina CamonesNo ratings yet

- Metric, Hex Thin Nuts, DIN 936, Plain: Page 1 of 1 REV-03 Date: October 9, 2015 M.936.PDocument1 pageMetric, Hex Thin Nuts, DIN 936, Plain: Page 1 of 1 REV-03 Date: October 9, 2015 M.936.PSatnam Rachna FastenersNo ratings yet

- Hex Socket Head Screws Is 2269Document17 pagesHex Socket Head Screws Is 2269Rajasekaran MuruganNo ratings yet

- Wa 950 PDFDocument2 pagesWa 950 PDFRico Malibiran0% (1)

- Hexagon Lock Nuts DIN 439 - 2Document2 pagesHexagon Lock Nuts DIN 439 - 2Idehen Kelvin100% (1)

- BS en 14399-7 2007Document24 pagesBS en 14399-7 2007Kristina KaskNo ratings yet

- Tabel Kekuatan BautDocument94 pagesTabel Kekuatan BautJuweni 65100% (2)

- JDM A17.1 - Rev. 11-2013Document10 pagesJDM A17.1 - Rev. 11-2013Romulo EduardoNo ratings yet

- Hexagon NutsDocument2 pagesHexagon NutsHoang LynafNo ratings yet

- ZPS-1037252 08-09-2020Document35 pagesZPS-1037252 08-09-2020Ronald AraujoNo ratings yet

- China Fastener TestingDocument1 pageChina Fastener TestingAbdullah AnsariNo ratings yet

- Null ADMSNo 304591v1nullDocument16 pagesNull ADMSNo 304591v1nullThanga PandiNo ratings yet

- TM-0026M-F (Property Requirements of Externally-Threaded Fasteners, Steel)Document5 pagesTM-0026M-F (Property Requirements of Externally-Threaded Fasteners, Steel)方綵樺100% (1)