Professional Documents

Culture Documents

Pipe Flotation

Uploaded by

abhisheknharanghatCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Flotation

Uploaded by

abhisheknharanghatCopyright:

Available Formats

MINIMUM COVER TO PREVENT

EAGLE CORR PE

PIPE FLOATATION

TECHNICAL

BULLETIN

Building essentials

for a better tomorrow

MARCH 2010

Page 1 of 5

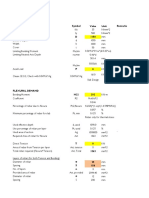

MINIMUM COVER REQUIRED PREVENTING FLOTATION

NOMINAL

DIAMETER

(IN)

APPROX.

OUTSIDE

DIAMETER (IN)

APPROX.

WEIGHT

(LBS/LF)

COVER (IN)

Dual 4 4.7 0.4 3

Wall 6 6.9 1.1 5

8 9.1 1.7 6

10 11.4 2.5 7

12 14.3 3.2 9

15 17.5 4.8 11

18 20.8 6.3 13

24 27.5 11.2 17

30 34.6 15.8 22

36 41.5 20.9 26

42 47.4 26.9 30

48 53.8 34.0 34

60 66.7 56.0 43

Single 4 4.7 0.4 3

Wall 6 6.9 1.1 5

8 9.1 1.7 6

Table 1

INTRODUCTION

This technical bulletin provides design guidance

for minimum burial depths necessary to prevent

flotation of Eagle Corr PE pipe. All types and sizes

of pipe, including RCP, can float under the right

conditions. The soil type, soil density, soil cover

height, location of the water table, pipe weight per

unit length, and the amount of effluent in the pipe

will all affect the flotation potential of pipe.

Pipe installed in areas where the groundwater

table regularly encroaches into the pipe zone is

pipe that must be installed to resist buoyancy.

Applications where Eagle Corr PE

will be sub-

jected to high groundwater tables or other consis-

tent submersion should be designed to prevent the

floatation of the pipe. These conditions may require

minimum cover requirements greater than those

specified in the Eagle Corr PE

installation manual.

MINIMUM COVER REQUIREMENTS

Table 1 summarizes the minimum burial depths of fill

over the top of Eagle Corr PE pipe to prevent flota-

tion. These minimum cover recommendations are

based on conservative assumptions for typical site

conditions and are summarized below. It should be

noted that in some cases the minimum burial depth

to prevent flotation is less than one foot. However,

structural considerations require a minimum of one

foot of cover for most H-25 traffic loading conditions.

Page 2 of 5

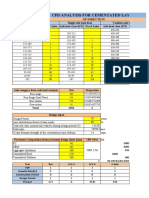

METHODOLOGY

Building essentials

for a better tomorrow

Table 1 is based on the following assumptions and

site conditions:

1. The pipe was assumed to be empty. This assump-

tion creates a conservative scenario. Empty pipe

is not likely unless the system is constructed with

watertight pipe.

2. Weight per unit length as shown in the Table 1.

3. A soil friction angle () of 90 degrees was used

for the analysis above which is an ultra conserva-

tive value resulting in a column soil load on the

pipe (see Figure 1a). A typical angle of 36.87

degrees is representative for most sand/gravel

mixture soils used in backfilling Eagle Corr PE

pipe and will yield conservative results. The load-

ing condition shown in Figure 1b is a more typical

loading scenario whereby soils outside of the

column immediately above the pipe are also used

in the downward soil forces.

4. The average of the inner and outer diameters was

used to determine soil and water displacement.

5. Soil density used was 120 pcf, which is typical for

many saturated soil mixtures. Soils of greater

densities will reduce the minimum cover neces-

sary to prevent flotation.

6. The depth of submerged soil (Hsat) or water

table was assumed to be at the ground surface

for a fully saturated soil condition. This assump-

tion created a worst case condition to yield

more conservative results. If effluent were in the

pipe, as would be likely in the case of a fully

saturated soil, its weight would reduce the mini-

mum burial depth.

7. Granular soils are recommended in most installa-

tions. Many soils do exhibit some degree of cohe-

sion which would reduce the effects of flotation;

however, this sample problem involved granular

or non cohesive soils.

It is noted, during installation the pipe should be cov-

ered at the end of the day. Unexpected rainfall events

or groundwater conditions may float the pipe in the

trench. This condition of water in the trench may

results in migration of soil and can affect the grade

and alignment.

Additionally, this technical bulletin provides design

guidance for an analytical methodology to evaluate

the potential for flotation for site conditions other

than those described above. Since other site condi-

tions may exist, the engineer is encouraged to evalu-

ate specific site conditions and make an indepen-

dent evaluation.

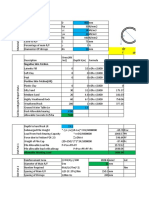

As shown in Figure 1 below, there are three major

forces affecting the potential for flotation (Fsoil, Fbuoyance

and Fpipe).

Building essentials

for a better tomorrow

Page 3 of 5

Figure 1:

FORCES AND VARIABLE DEFINITIONS AFFECTING FLOTATION

Figure 1a: Marstons, or column loading condition Figure 1b: Prism Loading condition

The minimum depth of cover (H) required to counteract the buoyant force of empty Eagle Corr PE pipe is cal-

culated for a static condition where the sum of the forces acting on the pipe is zero (see Equation 1). To obtain

a conservative minimum cover height recommendation, it is assumed that the soil friction angle is 90 degrees

which results in a column load (see Figure 1a) of the soil; not the more traditional prism load associated with a

friction angle less than 90 degrees (see Figure 1b). Equations used to derive the values found in Table 1, are

shown on the right.

Page 4 of 5

Building essentials

for a better tomorrow

The equation for weight of soils experienced by a pipe at various water depths, Wsoil, can be calculated from

Equation 1:

The hydrostatic uplift force, U, can be calculated from Equation 2, shown below:

In order to prevent pipe floatation from happening, the first step is to ensure that the hydrostatic uplift force is

less than the combined downward forces of the pipe, Wpipe and the soils, Wsoil. Equation 3 demonstrates this

basic principle.

Building essentials

for a better tomorrow

Page 5 of 5

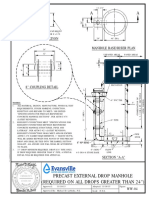

Figure 2:

Figure 2a Figure 2b

There are other methods to prevent soil floatation in the case that the pipe cannot be installed with adequate

soil cover. These methods include, but are not limited to, precast concrete weights (see Figure 2a), or anchor

assemblies (see Figure 2b). Precast concrete weights are used and installed over the top and sides of the pipe

to increase the downward forces around the pipe to prevent floatation. Anchors, alternatively, secure the pipe

more firmly to the bedding or surrounding trench walls. Flowable fill solutions are often used in pipe installation

applications. Due to the varying densities of flowable fills, floatation analysis should be performed for pipe

installed with this procedure.

Again, the engineer is encouraged to evaluate specific site conditions and make an independent evalua-

tion. For additional information or assistance for unique site conditions, please contact your local JM Eagle

sales representative.

You might also like

- Enhancing the Climate Resilience of Africa's Infrastructure: The Power and Water SectorsFrom EverandEnhancing the Climate Resilience of Africa's Infrastructure: The Power and Water SectorsNo ratings yet

- Pipe BendsDocument23 pagesPipe BendsabhisheknharanghatNo ratings yet

- Amex Seals Product Data SheetsDocument13 pagesAmex Seals Product Data SheetscloantafNo ratings yet

- Group 08 - Bio TowersDocument18 pagesGroup 08 - Bio TowersMeenu MariyamNo ratings yet

- Grain Size AnalyisDocument1 pageGrain Size AnalyisDNYANESHWAR PATILNo ratings yet

- Computation of Wind Force On Superstructure For Pier:-: Ref. Cl. 212.3 IRC: 6-1966 H V (KM/HR) P (KG/M)Document2 pagesComputation of Wind Force On Superstructure For Pier:-: Ref. Cl. 212.3 IRC: 6-1966 H V (KM/HR) P (KG/M)Mukhlish AkhatarNo ratings yet

- Field Engineer's Guide to Sewerage ProjectsDocument40 pagesField Engineer's Guide to Sewerage ProjectsSyed AliNo ratings yet

- Disclosure To Promote The Right To InformationDocument34 pagesDisclosure To Promote The Right To InformationArpan SahaNo ratings yet

- Indian Standard: Recommendatlons FOR Detailing of Reinforcement IN Reinforced Concrete WorksDocument31 pagesIndian Standard: Recommendatlons FOR Detailing of Reinforcement IN Reinforced Concrete Workssrtools1980yNo ratings yet

- Description Symbol Value Unit RemarksDocument1 pageDescription Symbol Value Unit RemarksRakesh SapkotaNo ratings yet

- Bundu WSS 2 Engineering Design 130608 PDFDocument173 pagesBundu WSS 2 Engineering Design 130608 PDFR V DesignersNo ratings yet

- SAFTA ProjectDocument9 pagesSAFTA ProjectMuhammad Mubasher Rafique100% (5)

- Settlememt Analysis For Shallow Foundations Based On N - ValuesDocument5 pagesSettlememt Analysis For Shallow Foundations Based On N - Valueskushaljp8989No ratings yet

- Chapter-III: Major Political Ideas of Acharya Narendra Deva: A Brief AppraisalDocument86 pagesChapter-III: Major Political Ideas of Acharya Narendra Deva: A Brief AppraisalBiddo Brahmin100% (1)

- Cement Testing Week No 37Document1 pageCement Testing Week No 37DNYANESHWAR PATILNo ratings yet

- 6 Scour Depth CalculationsDocument1 page6 Scour Depth CalculationsS N satyanarayanaNo ratings yet

- Essay Subhas Chandra BoseDocument30 pagesEssay Subhas Chandra BoseAnu BumraNo ratings yet

- Study The Effect of Different Load Combination That Will Lead To The Failure of The Structure and Hence Design For The Critical Combination of LoadDocument4 pagesStudy The Effect of Different Load Combination That Will Lead To The Failure of The Structure and Hence Design For The Critical Combination of LoadEditor IJTSRDNo ratings yet

- WB PWD Schedule-Sor NH 2015-16Document326 pagesWB PWD Schedule-Sor NH 2015-16lenkapradipta_200067% (3)

- RMT Periphery Works for 9.5m Excavation DepthDocument1 pageRMT Periphery Works for 9.5m Excavation DepthManan ParikhNo ratings yet

- ENCE 647 ENCE 647 Stability of Slopes Dr. Ahmet AydilekDocument23 pagesENCE 647 ENCE 647 Stability of Slopes Dr. Ahmet AydilekHoracioCruiseNo ratings yet

- Identity PoliticsDocument6 pagesIdentity PoliticsMeti MallikarjunNo ratings yet

- Thrust Block For C12 ZoneDocument6 pagesThrust Block For C12 ZonePrinkle SheteNo ratings yet

- Beam Design With Deflection CheckDocument2 pagesBeam Design With Deflection Checkbhavin_civilNo ratings yet

- Is 7894 1975 PDFDocument44 pagesIs 7894 1975 PDFLibin VargheseNo ratings yet

- Is 11150 1993 PDFDocument21 pagesIs 11150 1993 PDFExecutive EngineerNo ratings yet

- BeamDocument4 pagesBeamAnkit SuriNo ratings yet

- Water Tank Analysis Using STAAD PRODocument9 pagesWater Tank Analysis Using STAAD PROEr Bhavesh IngaleNo ratings yet

- CFD ANALYSISDocument14 pagesCFD ANALYSISPriyanka YadavNo ratings yet

- NIT of Alote Anicut Final 23 1 ..5.08Document84 pagesNIT of Alote Anicut Final 23 1 ..5.08a_kharyaNo ratings yet

- Pile Calculation 1BH1&BH2Document6 pagesPile Calculation 1BH1&BH2S SathiyarubanNo ratings yet

- Detailed Estimate of A G-3 Building in Excel - Part 13 - Concrete For WATER TANKDocument2 pagesDetailed Estimate of A G-3 Building in Excel - Part 13 - Concrete For WATER TANKmintu PatelNo ratings yet

- Column Biaxial ProblemsDocument25 pagesColumn Biaxial ProblemsRajanvmNo ratings yet

- Meyerhof bearing capacity equation analysisDocument18 pagesMeyerhof bearing capacity equation analysisSisay GashaNo ratings yet

- 40KL OhsrDocument6 pages40KL Ohsrnvijay_23No ratings yet

- Well SinkingDocument153 pagesWell SinkingHari Krishna AaryanNo ratings yet

- Chapter 7. Well Foundations: CE-471: Foundation EngineeringDocument31 pagesChapter 7. Well Foundations: CE-471: Foundation Engineeringmallikarjuna rao bodduNo ratings yet

- Design Coefficientsfor Three Cell Box CulvertDocument14 pagesDesign Coefficientsfor Three Cell Box CulvertteweldeNo ratings yet

- Intze Tank-175kL Design 18M STAGING BASI BLOCK - SMTDocument55 pagesIntze Tank-175kL Design 18M STAGING BASI BLOCK - SMTRajendra MittalNo ratings yet

- Approved Guidelines For Evaluation of ProposalsDocument13 pagesApproved Guidelines For Evaluation of ProposalsAbdullah Al JubayerNo ratings yet

- 2007 - 01 Sewer Installation by Pipejacking in The Urban Areas of Hong Kong Part IDocument14 pages2007 - 01 Sewer Installation by Pipejacking in The Urban Areas of Hong Kong Part IAldro SopiohNo ratings yet

- Government of Madhya Prades1Document77 pagesGovernment of Madhya Prades1gourav.imsNo ratings yet

- PM Interaction CurvesDocument57 pagesPM Interaction CurvesSelvamChidambaramNo ratings yet

- Design Document For Centrifuge BLDGDocument76 pagesDesign Document For Centrifuge BLDGepe civil1100% (1)

- Unit III Trickling Filter DesignDocument1 pageUnit III Trickling Filter Designधीरज कुमारNo ratings yet

- International Codes-Is456 - Beam Design in STAAD Pro - V8iDocument5 pagesInternational Codes-Is456 - Beam Design in STAAD Pro - V8iUmesh ChikhlikarNo ratings yet

- Roughing Filter For Water Pre-Treatment TechnologyDocument10 pagesRoughing Filter For Water Pre-Treatment TechnologyFauzan AffifNo ratings yet

- Bhimgoda BarrageDocument2 pagesBhimgoda BarrageLuojisi CilNo ratings yet

- DESIGN OF BOX - CULVERT FOR ROAD CROSSING at CH 450 TO 500 (01-07-13)Document3,497 pagesDESIGN OF BOX - CULVERT FOR ROAD CROSSING at CH 450 TO 500 (01-07-13)kamal kumar MallikarjunaNo ratings yet

- Analysis of Raft Foundation Using Finite Element ApproachDocument15 pagesAnalysis of Raft Foundation Using Finite Element ApproachShadin Asari ArabaniNo ratings yet

- Seismic Analysis of Overhead Circular Water TanksDocument10 pagesSeismic Analysis of Overhead Circular Water TanksGiurcanas Andrei0% (1)

- SPT-BH 17Document1 pageSPT-BH 17Umesh MishraNo ratings yet

- External Drop Manhole DesignDocument1 pageExternal Drop Manhole DesignorganicspolybondNo ratings yet

- Is 9795 1 1981 PDFDocument18 pagesIs 9795 1 1981 PDFpranit jaiswalNo ratings yet

- Design PDF BommakurDocument113 pagesDesign PDF BommakurRama KrishnaNo ratings yet

- Larsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreDocument1 pageLarsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreOuseppachan AmbookenNo ratings yet

- 2.0 Sluice Valve Chamber Precast Panel DesignDocument2 pages2.0 Sluice Valve Chamber Precast Panel DesignGaurav BhabadNo ratings yet

- RCC Design Sheets 1Document437 pagesRCC Design Sheets 1Bang JoyNo ratings yet

- 7861 2 PDFDocument26 pages7861 2 PDFUdit Kumar SarkarNo ratings yet

- Design-Retaining Wall2 9555Document27 pagesDesign-Retaining Wall2 9555SureshSawantNo ratings yet

- A5.05 Pipe FlotationDocument5 pagesA5.05 Pipe Flotationlinamohdzhor4815No ratings yet

- Plate Load Test Determines 154kPa Soil Bearing CapacityDocument5 pagesPlate Load Test Determines 154kPa Soil Bearing CapacityJoseph Cloyd L. LamberteNo ratings yet

- Apptitude 1-10Document45 pagesApptitude 1-10abhisheknharanghatNo ratings yet

- Bends (Elbows) (ASME B31.3-2012 Para. 304.2.1) : Design ConditionsDocument1 pageBends (Elbows) (ASME B31.3-2012 Para. 304.2.1) : Design ConditionsabhisheknharanghatNo ratings yet

- L4 NotesDocument7 pagesL4 NotesBehin SamNo ratings yet

- Binomial DistributionDocument11 pagesBinomial DistributionAnjalee PrabhaNo ratings yet

- 31 3Document3 pages31 3abhisheknharanghatNo ratings yet

- Mm/dd/yy 5/4/1965 Enter Date of BirthDocument1 pageMm/dd/yy 5/4/1965 Enter Date of BirthabhisheknharanghatNo ratings yet

- HSE guide section on hot tapping safetyDocument4 pagesHSE guide section on hot tapping safetyabhisheknharanghat100% (1)

- Monitor Corrosion RatesDocument3 pagesMonitor Corrosion RatesbtjajadiNo ratings yet

- Acson Catalogue Air Handling Unit 1201 PDFDocument12 pagesAcson Catalogue Air Handling Unit 1201 PDFfaiz budiNo ratings yet

- ASME 2017 SA 312 Sublimentry RequirementsDocument2 pagesASME 2017 SA 312 Sublimentry RequirementsKathir VelNo ratings yet

- Chemical Engineering Test QuestionsDocument1 pageChemical Engineering Test Questionsjake dionisioNo ratings yet

- Domestic Timber Deck Design: Technical Design Guide Issued by Forest and Wood Products AustraliaDocument24 pagesDomestic Timber Deck Design: Technical Design Guide Issued by Forest and Wood Products AustraliaHaibo LVNo ratings yet

- Equipment, Design, and Installation of Closed-Circuit Ammonia Mechanical Refrigerating SystemsDocument100 pagesEquipment, Design, and Installation of Closed-Circuit Ammonia Mechanical Refrigerating Systemsᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔No ratings yet

- Design Basis Memorandum - Mechanical Equipment and SystemsDocument26 pagesDesign Basis Memorandum - Mechanical Equipment and SystemsLuojisi Cil50% (2)

- 2 Lateral-Load-Transfer Session-2 2perDocument56 pages2 Lateral-Load-Transfer Session-2 2perLuis CortesNo ratings yet

- Project ReportDocument599 pagesProject ReportFarzad DehghanNo ratings yet

- Tripole University: Glass-Ceramic "MME660"Document3 pagesTripole University: Glass-Ceramic "MME660"amnajamNo ratings yet

- Shear Force Diagram - Bending Moment DiagramDocument2 pagesShear Force Diagram - Bending Moment Diagrammoondonoo7No ratings yet

- Archive of SIDDocument13 pagesArchive of SIDmfhfhfNo ratings yet

- Fuselage DesignDocument4 pagesFuselage DesignIndra FurwitaNo ratings yet

- Mastic Asphalt Mix DesignDocument3 pagesMastic Asphalt Mix DesignRaghav100% (4)

- Condenser: Lesson 3 Lesson Title: Learning Outcomes: at The End of The Lesson, Students of BTLE Will Be Able ToDocument37 pagesCondenser: Lesson 3 Lesson Title: Learning Outcomes: at The End of The Lesson, Students of BTLE Will Be Able ToAliceNo ratings yet

- NORTHERN ARIZONA UNIVERSITY - Technical Standards: Project XX - XXX.XXX - Project NameDocument69 pagesNORTHERN ARIZONA UNIVERSITY - Technical Standards: Project XX - XXX.XXX - Project NameMEHDI FARROKHINo ratings yet

- Design of Self Compacting Lightweight Concrete Using Acidic Pumice With Different Powder MaterialsDocument5 pagesDesign of Self Compacting Lightweight Concrete Using Acidic Pumice With Different Powder MaterialsJames Daniel GarciaNo ratings yet

- Bridge Presentation FinalDocument38 pagesBridge Presentation FinalEngineeri TadiyosNo ratings yet

- Architextures - Barrisol Stretch Ceilings SpecDocument4 pagesArchitextures - Barrisol Stretch Ceilings SpecMohammed Abdul BaseerNo ratings yet

- Project Report Group 4Document28 pagesProject Report Group 4Akame TakashitaNo ratings yet

- Aroon v. Shenoy (Auth.) - Rheology of Filled Polymer Systems-Springer Netherlands (1999)Document483 pagesAroon v. Shenoy (Auth.) - Rheology of Filled Polymer Systems-Springer Netherlands (1999)Swetha100% (1)

- Renderoc PlugDocument3 pagesRenderoc Plugtalatzahoor100% (1)

- EJOT Crossfix Factsheet 2022 07 21 ENDocument1 pageEJOT Crossfix Factsheet 2022 07 21 ENEren GülayNo ratings yet

- 26071-100-GPP-GCX-00056-001 Concrete Repair ProcedureDocument25 pages26071-100-GPP-GCX-00056-001 Concrete Repair ProcedureAsril Sang Lentera Senja100% (1)

- Corosion Assignment FullDocument104 pagesCorosion Assignment FullVelavan KNo ratings yet

- Compile Timber Past YearDocument45 pagesCompile Timber Past YearEZZARYN ERRISHA FARAZASMADYNo ratings yet

- Descriptive Analysis of Advantages and Disadvantages of Expanded Polystyrene Monolytic Panels - EPSDocument11 pagesDescriptive Analysis of Advantages and Disadvantages of Expanded Polystyrene Monolytic Panels - EPSWilson Bryan RegaladoNo ratings yet

- G-R 25Document27 pagesG-R 25Duncan VanderwallNo ratings yet

- Princesa Bridge Narrative ReportDocument9 pagesPrincesa Bridge Narrative ReportRodelo OngNo ratings yet