Professional Documents

Culture Documents

Pneumatic Conveying

Uploaded by

Astri Ngent0 ratings0% found this document useful (0 votes)

47 views8 pagescalculation

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentcalculation

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

47 views8 pagesPneumatic Conveying

Uploaded by

Astri Ngentcalculation

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 8

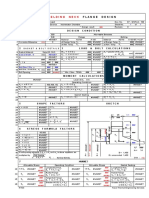

Chapter 15: Pneumatic Conveying

Rules of Thumb for Chemical Engineers, 5th Edition

by Stephen Hall

This Excel workbook includes Visual Basic for Application function subroutines.

Macros must be enabled for them to work.

ChemEng Software sells an Excel template called PIPESIZE.

www.chemengsoftware.com

PIPESIZE sizes pipes for gases and liquids. It includes a database of properties for piping materials, fluids,

roughness values, and recommended velocities. Order on-line or by telephone, 24-h/d; credit cards accepted.

Inputs

Conveying Fluid US Units

Conveying gas Air

Temperature F 70 C

Assumed supply psia 24.1 kPa

Discharge pressure psia 14.7 kPa

Minimum velocity ft/s 40 m/s

Solids

Solids rate lb/h 1,800 kg/h

Mean particle diameter ft 0.00025 m

Mass loading ratio 5

Slip factor 0.8

Solids friction factor 0.02

Solids density lb/ft3 155 kg/m3

Pipeline

Horizontal lengths ft 100 m

Vertical - up ft 30 m

Vertical - down ft - m

Hose ft - m

Divert valves -

Bends 2

Intermediate Values

Temperature K 294 K

Molecular weight 29.0

Viscosity cP 0.01842 mPa-s

Density lb/ft3 0.122 kg/m3

Gas flow rate lb/h 360 kg/h

Pipe diameter at Vmin in 1.94 mm

Pipe

Nominal diameter in 1.50 DN

Inside diameter in 1.500 mm

Roughness ft 0.00050 m

Actual velocity ft/s 67 m/s

Equivalent length ft 168 m/s

Calculations - Output

Gas Pressure Drop

Reynolds number 82,277

Friction factor 0.030

Calc'd discharge P psia 14.7 (0.00) kPa

Gas pressure drop psi 2.4 kPa

Solids Acceleration

Problem Statement:

Estimate the pressure drop for dilute phase pneumatic conveying

Acceleration pressure psi 0.47 kPa

Conveying Solids

Solids conveyance psi 6.08 kPa

Lifting through vertical psi 0.16 kPa

Through elbows psi 0.35 kPa

Total pressure drop psi 9.4 kPa

SI Units

Air

15.0

101.5

101.4

12.2

816

0.00008

5

0.8

0.02

2,483

30.5

9.1

-

-

-

2

288

29.0

0.01812

1.23

163

62.02

50

49.25

0.0001524

19

52

64,714

0.029

72.2

6.9

1.84

18.52

0.69

1.38

29.3

Conveying Fluids

Name MW C To mu

o

Air 29 120 291.15 0.00001827

Nitrogen 28.013 111 300.55 0.00001781

Pipe Wall Thickness for Schedule

Size Schedule O.D. Thickness I.D. DN 10 20 30

0.125 80 0.405 0.095 0.215 6 0.049 sched? sched?

0.250 80 0.540 0.119 0.302 8 0.065 sched? sched?

0.375 80 0.675 0.126 0.423 10 0.065 sched? sched?

0.500 80 0.840 0.147 0.546 15 0.083 sched? sched?

0.750 80 1.050 0.154 0.742 20 0.083 sched? sched?

1.000 80 1.315 0.179 0.957 25 0.109 sched? sched?

1.500 80 1.900 0.200 1.500 40 0.109 sched? sched?

2.000 80 2.375 0.218 1.939 50 0.109 sched? sched?

3.000 40 3.500 0.216 3.068 80 0.120 sched? sched?

4.000 40 4.500 0.237 4.026 100 0.120 sched? sched?

6.000 40 6.625 0.280 6.065 150 0.134 sched? sched?

8.000 40 8.625 0.322 7.981 200 0.148 0.250 0.277

10.000 30 10.750 0.307 10.136 250 0.165 0.250 0.307

12.000 30 12.750 0.330 12.090 300 0.180 0.250 0.330

14.000 30 14.000 0.375 13.250 350 0.188 0.312 0.375

16.000 30 16.000 0.375 15.250 400 0.188 0.312 0.375

18.000 30 18.000 0.438 17.124 450 0.188 0.312 0.438

20.000 30 20.000 0.500 19.000 500 0.218 0.375 0.500

24.000 30 24.000 0.562 22.876 600 0.250 0.375 0.562

30.000 20 30.000 0.500 29.000 750 0.312 0.500 0.625

1

2

40 80

0.068 0.095

0.088 0.119

0.091 0.126

0.109 0.147

0.113 0.154

0.133 0.179

0.145 0.200

0.154 0.218

0.216 0.300

0.237 0.337

0.280 0.432

0.322 0.500

0.365 0.594

0.406 0.688

0.438 0.750

0.500 0.844

0.562 0.938

0.594 1.031

0.688 1.219

sched? sched?

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Plate and Box Girder DesignDocument60 pagesPlate and Box Girder DesignKrishna ChandranNo ratings yet

- Spirax Sarco Design of Fluid Systems 2Document66 pagesSpirax Sarco Design of Fluid Systems 2mahonde100% (2)

- Flange Example CalcDocument14 pagesFlange Example CalcAstri NgentNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Over Head Water Tank DesignDocument5 pagesOver Head Water Tank DesignAstri Ngent100% (1)

- 26 Pressure Vessel.Document21 pages26 Pressure Vessel.mishtinil93% (14)

- Indoor Environmental QualityDocument29 pagesIndoor Environmental QualitykaigaNo ratings yet

- Standard Proctor Compaction TestDocument3 pagesStandard Proctor Compaction TestSami Sami80% (5)

- Motor Selection, Inertia PDFDocument6 pagesMotor Selection, Inertia PDFIswar Rauf Aboo 'AqilahNo ratings yet

- BP Energy Outlook 2019 Presentation SlidesDocument29 pagesBP Energy Outlook 2019 Presentation SlidesAJNo ratings yet

- Suspension Preheater 1998Document22 pagesSuspension Preheater 1998Sajal Gupta100% (2)

- 10 11Document9 pages10 11PrashannaNo ratings yet

- Data Dial IndikatorDocument2 pagesData Dial IndikatorAstri NgentNo ratings yet

- Bekomat Produk DisplayDocument4 pagesBekomat Produk DisplayAstri NgentNo ratings yet

- D Value CalcDocument5 pagesD Value CalcAstri NgentNo ratings yet

- Design of Welded ConnectionsDocument8 pagesDesign of Welded ConnectionsAstri NgentNo ratings yet

- Gantry Crane CalculatedDocument1 pageGantry Crane CalculatedAstri NgentNo ratings yet

- Mud Barge Sea ChestDocument1 pageMud Barge Sea ChestAstri NgentNo ratings yet

- Beam Desain1Document2 pagesBeam Desain1Astri NgentNo ratings yet

- Surge TankDocument4 pagesSurge TankAstri NgentNo ratings yet

- Assy Joint Pipa Line 1Document1 pageAssy Joint Pipa Line 1Astri NgentNo ratings yet

- Slide Bearing PTFE Tes ReportDocument6 pagesSlide Bearing PTFE Tes ReportAstri NgentNo ratings yet

- ZX 100 K-Truss Support PadDocument4 pagesZX 100 K-Truss Support PadAstri NgentNo ratings yet

- Bearing Layout PDFDocument1 pageBearing Layout PDFAstri NgentNo ratings yet

- Weld Analysis-IC Method v1.1Document5 pagesWeld Analysis-IC Method v1.1jefersonpimentelNo ratings yet

- Hydroelectric Hydro Power 4 3 1 DesignDocument28 pagesHydroelectric Hydro Power 4 3 1 DesignLouise UmaliNo ratings yet

- NTN Pillow BlockDocument54 pagesNTN Pillow BlockteguheafNo ratings yet

- Spherical Roller Thrust Bearing PDFDocument16 pagesSpherical Roller Thrust Bearing PDFAstri NgentNo ratings yet

- ValveDocument4 pagesValveAstri NgentNo ratings yet

- Calculating The Time Required To Empty A Vessel: ExamplesDocument1 pageCalculating The Time Required To Empty A Vessel: ExamplesKabir KhanNo ratings yet

- 6000 EN 00 04 Friction BearingDocument30 pages6000 EN 00 04 Friction BearingAstri NgentNo ratings yet

- Plugin Bushes PDFDocument3 pagesPlugin Bushes PDFAstri NgentNo ratings yet

- Reinforced PadDocument3 pagesReinforced PadAstri NgentNo ratings yet

- Hammer Product Data SheetDocument2 pagesHammer Product Data SheetAstri NgentNo ratings yet

- Limit State DesignDocument26 pagesLimit State DesignAstri NgentNo ratings yet

- Gang SawDocument55 pagesGang SawAstri NgentNo ratings yet

- Effects of El Nino and La Nina on Weather and ClimateDocument41 pagesEffects of El Nino and La Nina on Weather and ClimateK Sai maheswariNo ratings yet

- Environmental Degradation in Guwahati (Science)Document7 pagesEnvironmental Degradation in Guwahati (Science)SheenaHoqueNo ratings yet

- Newtons Laws of MotionDocument14 pagesNewtons Laws of MotionMakayla SalmonNo ratings yet

- Soil Report 1Document5 pagesSoil Report 1rekzziNo ratings yet

- TD Unit-1Document83 pagesTD Unit-1T Hari PrasadNo ratings yet

- Tutorial 3 Heat Exchanger PDFDocument22 pagesTutorial 3 Heat Exchanger PDFBipin GiriNo ratings yet

- Engineering Principles Lecture Notes Volume 2 Thermodynamics PropertiesDocument29 pagesEngineering Principles Lecture Notes Volume 2 Thermodynamics PropertiesAlbert LappiaNo ratings yet

- Physgen Unit 5Document13 pagesPhysgen Unit 5emji miraNo ratings yet

- What Are Various Environmental Segments?: FourDocument5 pagesWhat Are Various Environmental Segments?: Fourasim zebNo ratings yet

- General Chemistry 1: Learning Activity SheetsDocument11 pagesGeneral Chemistry 1: Learning Activity SheetsJeffrey Uy EscotoNo ratings yet

- Numericals XIIDocument17 pagesNumericals XIISyed Tanveer100% (1)

- Generator Power Factor Explained by YousseffaresDocument3 pagesGenerator Power Factor Explained by YousseffaresJoseph FaresNo ratings yet

- Chapter 4 Study Guide The Periodic Table Section 1Document2 pagesChapter 4 Study Guide The Periodic Table Section 1SyfensNo ratings yet

- Irjet V4i4259 PDFDocument4 pagesIrjet V4i4259 PDFArunRajNo ratings yet

- Stephen Hawking Reading ComprehensionDocument7 pagesStephen Hawking Reading ComprehensionJupiter MarsNo ratings yet

- Introduction To VolcanoDocument29 pagesIntroduction To Volcanoapi-266403636No ratings yet

- Industrial Instrumentation I Question Bank 1Document12 pagesIndustrial Instrumentation I Question Bank 1Feroz AhamedNo ratings yet

- Concrete Mix Design PDFDocument56 pagesConcrete Mix Design PDFYasir FahadNo ratings yet

- BTB PS CR LabDocument7 pagesBTB PS CR LabKathy XiangNo ratings yet

- Gravity and Energy Multiple Choice PracticeDocument11 pagesGravity and Energy Multiple Choice PracticeJohnNo ratings yet

- Environmental Impact Assessment of Ting Ting Hydroelectric Project, SikkimDocument18 pagesEnvironmental Impact Assessment of Ting Ting Hydroelectric Project, SikkimShreya MalikNo ratings yet

- Montalban Earth Dam: Permeability TestDocument20 pagesMontalban Earth Dam: Permeability TestMon MargalloNo ratings yet

- 5 One Dimensional Flow of Water Through SoilsDocument28 pages5 One Dimensional Flow of Water Through SoilsJenina LogmaoNo ratings yet

- Evaluating Nuclear Energy Risks vs Fossil FuelsDocument3 pagesEvaluating Nuclear Energy Risks vs Fossil FuelsShubham SinghNo ratings yet

- Pinch and Approach Point On HRSGDocument12 pagesPinch and Approach Point On HRSGluaguNo ratings yet