Professional Documents

Culture Documents

Central Liquid Petrolium Gas System-Notes (UAE)

Uploaded by

imtiyaz94Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Central Liquid Petrolium Gas System-Notes (UAE)

Uploaded by

imtiyaz94Copyright:

Available Formats

1. As per NFPA the liquid filling line should be schedule 80 and vapor line should be sch 40.

Filling is

done at 15-17bar pressure.

2. For feeding to apartment gas pipes, it is preferred to have dedicated fire rated (2hr) shaft

(150x150 is min. 300x 300). If the dedicated shaft is open to sky then, pipe in pipe is not

required. Venting of shafts at bottom or above is not necessary.

3. If feeding to apartment gas pipe is running through a common shaft with other services, then it

should be pipe in pipe, or provide 150x150 calcium silicate partition with 2hr fire rating, or cover

the pipe in U shape with GI sheet coated with 2hr fire rated coating. Also Pipe in pipe is not

good as it will be difficult to identify the leak, hence enclosure is preferred.

4. Pipe running through the toilet above false ceiling (pipe in pipe) is rarely accepted by civil

defense. However it should be avoided.

5. The shaft for droppers should be either within the kitchen or adjacent to the kitchen, as pipes

are not allowed to run through any other space like living bedroom etc.

6. If the pipe running through a podium which is open on sides, still provide pipe in pipe.

7. LPG droppers chased in walls is not acceptable by DCD. Pipe risers should run in shafts only.

8. The gas filling line should be only on the external wall. Filling line cannot be in the core of the

building, even if you give dedicated open to sky shaft. But for aesthetic reasons, filling pipes can

be laid in a slot (400x150mm deep) on external wall and covered with a perforated non-

combustible material. Liquid gas expands 200 times the vapor gas and it is dangerous.

9. For Dubai, minimum 3 days storage is required. For up to 400 apartment, 1000gallons tank is

enough with 3 day refilling time.

10. For an apartment consider 0.5kg/hr (25000 btu/hr) as consumption. 0.25kg/hr can be

considered for studio. Also consider 60% (75%) diversity and 3hr duration of cooking.

11. For small restaurants like cafeteria consider 5kg/hr and for big restaurants take between 15-

20kg/hr. 6 hr working .

12.

13. 1Kg is equal to 1.8litres. 4 Ltr is equal to 1m/hr. 43000 btu/h is equal to 1kg/h.

14. As per Paul, for gas meters the maximum flow rate required in apartments for LPG is 2.5m/hr

and 4m/hr for SNG. Dedicated cabinet inside kitchen is preferred, which will be 400 wide x

500highx 250 deep. Generally cabinet are 400 deep which is also acceptable.

15. Tanks will have only 85% storage capacity. Also allow 15% as safety, for gas availability to

consumers while filling process is on.

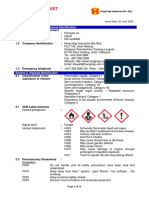

16. Electrical components (including solenoid valve) within 4.6m radius of tank installation should

be explosion proof.ATEX certificate is required.

17. The gallons indicated in UAE fire code is US gallons.

18. LPG cylinders located in places accessible to the public shall be protected and locked against

tampering and accidental damage by fencing of height not less than 1.8m (page 569).

19. The standard sizes of tanks available are , 2500, 2880, 3500, 4000, 4800, 5000, 6000, 7000, 7100

litres. These are the tank sizes. The storing capacity will be 15% less than the size, also the

usable gas volume in the tank will be only 70% of the tank size.

20. By increasing the size of the tank, vaporizer can be eliminated. Each cylinder has got a natural

vaporization rate. Like a 2000 liter tank at 40c has a natural vaporization rate of 15kg/hr. If the

hourly consumption is below 15kg/hr, then vaporizer is not essential. Similarly, the 7000 liter

storage tank at 15c as worst scenario in winter has 40-50kg/hr as natural vaporization rate

(30kg/hr @ 10c). If the consumption rate is below this , then vaporizer is not required.

21. Gas when stored as a liquid take up little volume.

22. As per Fadi, all droppers to be made from carbon steel, while branches to kitchens to be made

from copper.

23. Gas meters used in DAMAC projects are like prepaid, where a card has to be inserted in the

meter , which will allow gas until there is credit in the card.

24. The vaporizer is sized taking into account the natural vaporization rate. For example , if required

hourly rate is 70kg/hr, the 7000litre tank at 10c can give 30kg/hr vaporization rate, then for the

remaining 40kg/hr, provide vaporizer of 40kg/hr.

25. For aesthetic looks, gas tank can be covered on top with 2hr fire rated louvers having 50% free

area ratio. However at the solenoid/safety valve location on the tank 500x500 mm opening is

required to discharge gas vertically upwards.

26. As per NAGA

27. As per Mr. Paul, Generally in Dubai 95% of the installations limit the tank location to be 100m

above filling point. But there are suppliers who can fill the tank located at 200m also.

28. If the tank is located at lower level it can supply gas upto 200m. In one of Pauls project he had

supplied gas from tank at ground to appt at 54

th

floor (185m). The gas travels by means of

specific gravity.

29. Mr. Paul has done underground installation also. For this, there should be 3m clearance all

around from building plot limit and building for capacity up to 7500litres. There should be sand

below if you dig up to 1.5m. You cannot have basements up to plot limit. For capacities above

7500 litres there should be 15m clearance all around.

30. If underground cannot be done then, Mounted type installation can be done. It is done above

ground. Around the tank civil brick work is done and the cavity is filled with sand. Same 3m

clearance is required here also.

31. As per Paul, It is normal practice to introduce LPG pipe above false ceiling and install meter,

regulator, valve etc. within upper cabinet of kitchen and drop the pipe in the corner and conceal

it with removable non flammable decorative material cover. It is not allowed to embed the pipe

in wall. Installation in lower cabinets is not preferred due to maintenance issues. As per Suhail,

the pipe from above can be made to run through a open channel chased in wall. This channel

can be covered with removable perforated nonflammable cover, which is usually stainless steel.

Pipe can also run along wall covered in PVC trunking.

32. At standard temperature and pressure (STP), propane is a gas. To become liquid, propane is

compressed and held inside tanks. This is done primarily to make a transportable fuel for

applications that require a "containerized" solution...remote homes, specialty transportation

like forklifts, and of course camp stoves and lanterns.

Inside a compressed propane tank, the space over the top of the liquid propane is filled with

propane gas. As the tank valve is opened, most applications are pulling off this gas which

reduces the pressure above the liquid causing more gas to vaporize and fill the space. As new

liquid vaporizes, it take in energy to satisfy the heat of vaporization which is why running

propane tanks feel cold. In some specialty applications, propane liquid will be fed to large

energy users, but those applications are rare.

When fuels evaporate this specifically refers to liquid fuels flashing over to the gaseous state.

Every fuel has a temperature at standard atmospheric pressure where this transition occurs.

This is called the fuel's flash point. Some fuels like gasoline have a very low flash point. This

means that at most temperatures, the liquid fuel is evaporating to a gas which can create a

flammable gaseous cloud above or near the liquid fuel. In other cases, like with diesel fuel, the

fuel has a much higher flash point. This means that at reasonable temperatures, the fuel will

remain a liquid and have a lower hazard of flammable vapors.

http://greenanswers.com/q/185158/energy-fuels/fossil-fuels/natural-gas/does-propane-

evaporate-really-quickly#ixzz287Sjx2TY

33. For all capacities minimum of 5.5m (10% reduction allowed) clearance required from all

services. 6.1m clearance is required from all air outlets and ducts. For upto 500gallon, 3m

clearance is required from parapet wall and 7.6m for above 500gallon. If you have 1000 gallon

tank split into 500gallon 2 nos, keep 3m from parapet and 7m to another tank. Special approval

is possible for ducts 3m away from tank subject to duct being fire rated, air tight and fire sealent

provided.

34. Size of LPG tank, 500gal- 1.9m x 1.2dia, and 1000gal- 4.44m x 1.0mdia.. Top of tank will be

1.65m (1.45m for 1000gal tank) from top of pedestal of 400mm, due to 20cm of tank leg and

25cm gap on top of tank for valves, cover etc.

35. As per Suhail the tank size of 1000gal is 3.5m length and 1.2dia, 500gal-2.4m l and 1m tank.

36. Access doors are not required in each apartment. While in case of LPG access door is required at

the bottom of shaft to maintain gas detector. In natural gas detector will be at the top both

inside kitchen and in shaft. SNG and LPG are almost same, while natural gas is different.

37. Louvers in shaft are not required for LPG and SNG.

http://www.algas-sdi.com/why-vaporizers.html

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- LPG Pipe SizingDocument2 pagesLPG Pipe Sizingimtiyaz94No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Danfoss Training Module 2 v3 Balancing Valves CompressedDocument51 pagesDanfoss Training Module 2 v3 Balancing Valves Compressedimtiyaz94No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Balancing BasicsDocument14 pagesBalancing BasicspbharrisNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Halton Design Guide enDocument54 pagesHalton Design Guide enimtiyaz94No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Danfoss Training Module 1 v2 Thermostatic Radiator Valves CompressedDocument45 pagesDanfoss Training Module 1 v2 Thermostatic Radiator Valves Compressedimtiyaz94No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Clean Agent System SizingDocument8 pagesClean Agent System Sizingimtiyaz94No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Balancing BasicsDocument14 pagesBalancing BasicspbharrisNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Drainage NotesDocument1 pageDrainage Notesimtiyaz94No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Water Demnd EstimateDocument6 pagesWater Demnd Estimateimtiyaz94100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Sizing Hot Water Circulation SystemsDocument1 pageSizing Hot Water Circulation Systemsimtiyaz94No ratings yet

- Duct DesignDocument9 pagesDuct DesignjaswanthNo ratings yet

- Plumbing MaterialDocument1 pagePlumbing Materialimtiyaz94No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Humidification Calculation ImtiyazDocument2 pagesHumidification Calculation Imtiyazimtiyaz94No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- HVAC Basic FormulaDocument4 pagesHVAC Basic FormulaAbdul NabiNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- A Guide To Rooftop GardeningDocument41 pagesA Guide To Rooftop GardeningdantranzNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Flammable Hazardous Materials 1Document64 pagesFlammable Hazardous Materials 1abdulla kasimNo ratings yet

- Flash Point by Small Scale Closed Cup Tester: Standard Test Methods ForDocument10 pagesFlash Point by Small Scale Closed Cup Tester: Standard Test Methods ForAbidin SyakirinNo ratings yet

- Chemical Storage Color CodesDocument6 pagesChemical Storage Color CodesMohan PrasadNo ratings yet

- Fires ExplosionsDocument61 pagesFires ExplosionsRitesh MokhadeNo ratings yet

- Safety Data Sheet: Product Name: MOBIL DTE 10 EXCEL 68Document10 pagesSafety Data Sheet: Product Name: MOBIL DTE 10 EXCEL 68RICHA CHOPRANo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Maintaining CNG Vehicles: A Guide to Engine, Fuel System and Cylinder CareDocument20 pagesMaintaining CNG Vehicles: A Guide to Engine, Fuel System and Cylinder CareEsmer Shokata HadzibegićNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- M 82-75 (2004) Cutback Asphalt (MC Type)Document2 pagesM 82-75 (2004) Cutback Asphalt (MC Type)WalticoZegarraHerrera100% (1)

- ASTM D 92 - 02b: Standard Test Method For Flash and Fire Points by Cleveland Open Cup TesterDocument10 pagesASTM D 92 - 02b: Standard Test Method For Flash and Fire Points by Cleveland Open Cup TesterShaheer AhmadNo ratings yet

- (NH4) 2SDocument6 pages(NH4) 2SGalih S'lalu SmartNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- MSDS 82111Document11 pagesMSDS 82111angel de mi guardaNo ratings yet

- SikaFix PU - (A-B) - E PDFDocument10 pagesSikaFix PU - (A-B) - E PDFNyu123456No ratings yet

- Ansi Z129 - 1 For Hazardous Industrial Chemicals - Precautionary LabelingDocument100 pagesAnsi Z129 - 1 For Hazardous Industrial Chemicals - Precautionary LabelingJuan Carlos Guerrero R0% (1)

- Astm D381Document6 pagesAstm D381Difany tsabita100% (2)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Publication 1 - 92 - A Study of Tank Farm Fires in KuwaitDocument122 pagesPublication 1 - 92 - A Study of Tank Farm Fires in KuwaitRafaelNo ratings yet

- Fundamentals of Combustible Gas DetectionDocument34 pagesFundamentals of Combustible Gas Detectionrobisiz7299No ratings yet

- Risk Assessment Thermal Power PlantDocument24 pagesRisk Assessment Thermal Power Plantfloayzav5684No ratings yet

- MSDS - Alkyd Enamel Paint (Cat Avian) PDFDocument11 pagesMSDS - Alkyd Enamel Paint (Cat Avian) PDFbumisetraNo ratings yet

- Fire Safety Unit 1Document102 pagesFire Safety Unit 1Raunaq AroraNo ratings yet

- 1910 HAZARDOUS MATERIALS: FLAMMABLE AND COMBUSTIBLE LIQUIDSDocument107 pages1910 HAZARDOUS MATERIALS: FLAMMABLE AND COMBUSTIBLE LIQUIDSelvis hidalgo100% (1)

- MSDS Crude Oil by JP Morgan. Rev 2013Document18 pagesMSDS Crude Oil by JP Morgan. Rev 2013Torero02No ratings yet

- TRX Oil Test PropertiesDocument48 pagesTRX Oil Test PropertiesbibhooNo ratings yet

- Heat Transfer Oil XW 15 HTDocument2 pagesHeat Transfer Oil XW 15 HTmk7718100% (1)

- Liquefied Petroleum Gas (Lpgas) : Safety Data SheetDocument8 pagesLiquefied Petroleum Gas (Lpgas) : Safety Data Sheetnuke apriyaniNo ratings yet

- SDS - HHI Pyrolysis Oil - Flash Point 10CDocument11 pagesSDS - HHI Pyrolysis Oil - Flash Point 10CKelly LimNo ratings yet

- Aromor Catalogue 2015Document70 pagesAromor Catalogue 2015shishirchem100% (1)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chapter 7 - Lubricants and Lubrication SystemsDocument34 pagesChapter 7 - Lubricants and Lubrication SystemsRi AlvesNo ratings yet

- Crude OilDocument51 pagesCrude OilwdfhbfsNo ratings yet

- ASTM D2071 Amine Value Fatty AminesDocument4 pagesASTM D2071 Amine Value Fatty Aminesrazamehdi3No ratings yet

- Engineering ManualDocument27 pagesEngineering ManualThousif Rahman67% (3)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)