Professional Documents

Culture Documents

Risk Assessment Form for Sand Blasting and Painting

Uploaded by

Rochdi BahiriOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment Form for Sand Blasting and Painting

Uploaded by

Rochdi BahiriCopyright:

Available Formats

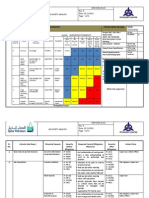

RISK ASSESSMENT FORM

Page 1 of 5

Location: Terga Date of Assessment: 17- 09 - 2009 Assessment No: 013 Rev - 0

Assessor(s): Biman Modak System/Activity: Sand Blasting and Painting.

P

r

o

b

a

b

i

l

i

t

y

&

F

r

e

q

u

e

n

c

y

Definite 5 5 10 15 20

High 4 4 8 12 16

Moderate 3 3 6 9 12

Low 2 2 4 6 8

Negligible 1 1 2 3 4

1 2 3 4

Minor Serious Major Catastrophic

Severity

Key to Priorities

Medium Priority (5 days) High Priority (2-3 days) Immediate

INTRODUCTION

The table below provides a simplified representation of the methodology used and the processes involved in this Hazard Identification & Risk Analysis Procedure (Risk

Management) to be undertaken by OCIA and all Subcontractors in order to initiate, act on, review and effectively manage project-related risks throughout the Construction

Phase.

IDENTIFICATION - Pre planning , Method

statement , Job safety analysis.

ASSESSMENT Impact, Risk factor,

Mitigation measure, Residual risk

IMPLEMENTATION &

COMMUNICATION

REVIEW & UP DATE

Identify activities , Identify hazards Assess Impacts, Analyze Risk ,

Establish Mitigation Measures.

Communication & Training Audit, Inspection & Up dating of Log.

RISK ASSESSMENT FORM

Page 2 of 5

Hazards Identified (include the exposed groups)

Probability

1 - 5

Severity

1 - 4

Risk

1 - 20

Control Measures to be Implemented

Probability

1 - 5

Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date Action

Completed

General concept about Sand Blasting and

Painting .

3 2 6

Sandblasting is a special physical

process that uses a stream of sand

propelled by water or compressed air

and applied on a surface. Texas

sandblasting creates a powerful

abrasive force that can act on any

surface worked on using this air-

propelled material. There are

alternative sandblast materials that can

be used depending on the requirement

of the work. These include iron

globules, emery and powdered quartz.

Sandblasting is commonly used for

cleaning the cast irons in foundry

shops. It is also the preparatory

process done on different kinds of

surfaces before enameling, painting

and during the process of galvanizing.

It is also a popular cleaning solution for

surfaces with hard to remove grime

and other debris that accumulate in the

concrete surfaces of buildings.

2 2 4

RISK ASSESSMENT FORM

Page 3 of 5

Personal protection equipments during

sand blasting and painting work.

3 3 9

It should be noted that sandblasting

and painting jobs can be hazardous as

workers are exposed to toxic elements

during the process. There are a wide

range of harmful particles which may

include zinc or lead which are common

components in coatings. When the

sandblast operations are being done ,

steps should be undertaken to protect

the operation group from the harmful

effects of the abrasive materials being

used. Protective gears like goggles and

appropriate clothing are extremely

important if the persons are going to

do sandblasting / painting work. The

potential harm and injury that can be

brought on the person doing the

sandblasting operations makes it

extremely important that safety

regulations are observed before and

during any sandblasting operation.

In any typical sandblasting / painting

operation, the standard air breathing

equipment must be used. This is

necessary as the operators need to

have a steady supply of clean air in a

workplace where there is a heavy

volume of toxic and harmful

contaminants. Before any sandblast

operation, it is imperative that the

concerned person must inspect the air

breathing apparatus to make sure that

it delivers a steady flow of clean air.

The operators are strongly advised to

remove the air breathing equipment

after operation only when they at a

safe distance from the work area as

harmful particulates remain suspended

in the air even after the sandblast

operations.

The crew must also wear standard

issue gloves and coveralls while within

2 3 6

RISK ASSESSMENT FORM

Page 4 of 5

3 3 9

Before undertaking any sandblast

jobs, it is important that the chosen

workplace will not pose any danger and

harm to the workers and the general

public. On top of the proper selection

of the appropriate workplace, it is also

essential that safety procedures are

observed with regard to the

appropriate sandblast / painting

machine / devices to be used. For the

details of the safety measures applied

to the machine, it is important that the

operator's instruction and safety

manual to be demonstrated to the

operator before any operation is

started.

2 3 6

RISK ASSESSMENT FORM

Page 5 of 5

Safe access / egress . Work inside the

confined space.

3 3 9 All access routes to remain clear and

free from obstructions.

Area to be kept tidy at all times.

Adequate access ladders with fall arrest

system installed.

A pre tested and certified man basket

and scaffolding to be used to access

difficult areas.

Man basket to be checked daily by a

competent person prior to use.

The man basket must be checked each

time it is attached to the crane.

Shackles are secured and pinned.

Shackles and rings are not deformed

and pad eyes are not damaged.

Slings and rings in good condition.

Handrails are in good condition.

Floor plating and kick plates are in good

condition. A healthy working atmosphere

has to be maintained inside the confined

space keeping appropriate exhaust /

opening to pass out logged , entrapped

welding gases. Adequate lighting

arrangement has to be provided at the

work place.

2 3 6

Assessor Print : BIMAN MODAK Sign: Date: 17- 09 - 2009

RISK ASSESSMENT FORM

Page 6 of 5

You might also like

- Risk Assessment For Sand BlastingDocument8 pagesRisk Assessment For Sand BlastingRochdi Bahiri69% (16)

- Dar Al Hijra Painting Risk AssessmentDocument5 pagesDar Al Hijra Painting Risk Assessmentmakdel68% (22)

- Manual Tig Welding (RRC) - Job ProcedureDocument3 pagesManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- Jsa Grit BlastingDocument2 pagesJsa Grit BlastingHenryOdoh100% (3)

- QP Blasting JSADocument6 pagesQP Blasting JSAMohammed Mujahid100% (1)

- PEB Work Risk Assessment 17.4.17Document10 pagesPEB Work Risk Assessment 17.4.17Syed Ali HassanNo ratings yet

- JSA Blasting and Coating KP 69.4Document5 pagesJSA Blasting and Coating KP 69.4shinto Lawrence100% (6)

- JHA For Blasting Painting Works FinalDocument7 pagesJHA For Blasting Painting Works Finalrosevelvet50% (10)

- Abrasive Blasting S.O.P.7ADocument7 pagesAbrasive Blasting S.O.P.7AFerlie Indrapati100% (1)

- Risk Assessment Sand BlastingDocument7 pagesRisk Assessment Sand BlastingRohit Singh100% (7)

- 8.11. CR 29.H. Firefighting Equipment InspectorDocument3 pages8.11. CR 29.H. Firefighting Equipment InspectorGasa Security100% (2)

- Abrasive Sand-Blasting Procedure PDFDocument5 pagesAbrasive Sand-Blasting Procedure PDFEko Kurniawan100% (5)

- JHA For PWHT WorkDocument2 pagesJHA For PWHT WorkAzmi Fauzi77% (13)

- JSA For Painting Inside TankDocument2 pagesJSA For Painting Inside TankDilshad aliNo ratings yet

- Risk Asses 41-Blasting and Painting ControlDocument3 pagesRisk Asses 41-Blasting and Painting ControlRochdi Bahiri100% (1)

- JSA For Painting Works-Hazards ControlDocument4 pagesJSA For Painting Works-Hazards Controlkaleem0% (2)

- Refueling JSA 4 08 2019 Rev.03 Near WaterDocument9 pagesRefueling JSA 4 08 2019 Rev.03 Near Waterrisky indra antariNo ratings yet

- QP Painting JSADocument6 pagesQP Painting JSAMohammed Mujahid100% (2)

- JSA PaintingDocument1 pageJSA PaintingjonesNo ratings yet

- Task-Based Risk Assessment Painting WorksDocument6 pagesTask-Based Risk Assessment Painting Worksvinodhyper100% (2)

- Form JSA Lifting CraneDocument6 pagesForm JSA Lifting CraneYeti Srinurhayati100% (1)

- JSA Welding Confined SpaceDocument2 pagesJSA Welding Confined Spacegkmlal100% (4)

- Risk Assessment No. 25 PAINTING in GENERAL Rev. 02 20.03.09Document2 pagesRisk Assessment No. 25 PAINTING in GENERAL Rev. 02 20.03.09Devi Ratna Pratiwi89% (9)

- Method Statement Sandblasting Rev. 0Document7 pagesMethod Statement Sandblasting Rev. 0spazzbgt80% (10)

- JSA - Sand Blasting and PaintngDocument8 pagesJSA - Sand Blasting and PaintngJohn100% (1)

- JSA No. 9 - Safe Use of Pneumatic and Power ToolsDocument2 pagesJSA No. 9 - Safe Use of Pneumatic and Power ToolsAshok Suresh100% (1)

- Jsa For Civil Confined Space EntryDocument11 pagesJsa For Civil Confined Space EntryKhuda BukshNo ratings yet

- Method Statement For Painting of All Metallic Piping: Form 000.653.F0100Document9 pagesMethod Statement For Painting of All Metallic Piping: Form 000.653.F0100narmathaNo ratings yet

- #15 Activity Based Risk Assessment For Painting of The Terror Club Compound and Roof Washing of T.C. BuildingsDocument14 pages#15 Activity Based Risk Assessment For Painting of The Terror Club Compound and Roof Washing of T.C. BuildingsSathish Insmile100% (1)

- JSA - Sand Blasting & PaintingDocument4 pagesJSA - Sand Blasting & Paintingsurendra behera100% (4)

- Vacuum Cleaner Checklist Ver0Document1 pageVacuum Cleaner Checklist Ver0Nair R RakeshNo ratings yet

- Lifting Operatio in Progress PDFDocument1 pageLifting Operatio in Progress PDFsubhanmusadiq100% (1)

- Abrasive Blasting Inspection ChecklistDocument1 pageAbrasive Blasting Inspection ChecklistRísês Ãfröz50% (2)

- Risk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEDocument12 pagesRisk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEnsadnan100% (4)

- 1 - HSE Violation Procedure Update - 23.05.2020Document11 pages1 - HSE Violation Procedure Update - 23.05.202036. Tengkea Ou100% (3)

- Hydro Jetting and Sludge RemovalDocument18 pagesHydro Jetting and Sludge Removalmarvin100% (1)

- HSE Violation & PenaltiesDocument5 pagesHSE Violation & PenaltiesVladimir RadovanovicNo ratings yet

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDocument9 pagesHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- Column Erection JSA AnalysisDocument6 pagesColumn Erection JSA AnalysisRaghava Richhu100% (2)

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- JSA - Fire Proofing WorksDocument5 pagesJSA - Fire Proofing WorksAnis Uddin100% (3)

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingRyanNo ratings yet

- Confined Spaces: Job Safety AnalysisDocument2 pagesConfined Spaces: Job Safety Analysismalimsaidi_160040895No ratings yet

- General Schools Risk Assessment: Part A. Assessment DetailsDocument8 pagesGeneral Schools Risk Assessment: Part A. Assessment Detailseng_hmaNo ratings yet

- Job Safety Analysis (Rolling For MS Plates)Document1 pageJob Safety Analysis (Rolling For MS Plates)Muhammad Ali100% (2)

- JSA Machinal PipingDocument7 pagesJSA Machinal PipingNaitik Desai48100% (1)

- Job Safety Analysis: Touch Up PaintDocument3 pagesJob Safety Analysis: Touch Up PaintMuhammad Umar GondalNo ratings yet

- Jsa Grinding W Angle GrinderDocument2 pagesJsa Grinding W Angle GrinderMichael Angelo SanteNo ratings yet

- Jsa Radiography ActivitiesDocument4 pagesJsa Radiography Activitiesnasar_mahsood80% (15)

- JSA For Working at HeightDocument1 pageJSA For Working at HeightSafety& Security Supervisor100% (1)

- Jsa Non Destructive TestingDocument2 pagesJsa Non Destructive Testingghulammohyuddin100% (1)

- Job Safety Analysis (Jsa)Document11 pagesJob Safety Analysis (Jsa)Noraini Binti Osman50% (2)

- Risk Assessment For Sand Blasting PDFDocument8 pagesRisk Assessment For Sand Blasting PDFOvais FarooqNo ratings yet

- Risk Assesment 16 - Pre - Assembly and Erection ofDocument7 pagesRisk Assesment 16 - Pre - Assembly and Erection ofRochdi BahiriNo ratings yet

- Storm Water Drainage Project in DammamDocument74 pagesStorm Water Drainage Project in DammamTATATAHERNo ratings yet

- Method Statement and Risk Assessment For Electrical Cable Trench ExcavationDocument8 pagesMethod Statement and Risk Assessment For Electrical Cable Trench Excavationfehmi-fjr469650% (2)

- Construction Safety Inspection ReportDocument6 pagesConstruction Safety Inspection ReportJoe PsNo ratings yet

- SP-12 - Ruble Soiling-R1Document3 pagesSP-12 - Ruble Soiling-R1shamshad ahamedNo ratings yet

- Installation of Cabinetry - JoineryDocument4 pagesInstallation of Cabinetry - JoineryJonas100% (2)

- Safety and Health Work Place ProjectDocument30 pagesSafety and Health Work Place ProjectPrevindran KrishnanNo ratings yet

- A Case Study of 3-MW Scale Grid-Connected Solar Photovoltaic Power Plant at Kolar, KarnatakaDocument38 pagesA Case Study of 3-MW Scale Grid-Connected Solar Photovoltaic Power Plant at Kolar, KarnatakaAnant Joshi67% (3)

- Project Finance and Merchant PowerDocument76 pagesProject Finance and Merchant Powersimplyanks_5100% (2)

- Epc Contracts in The Power SectorDocument30 pagesEpc Contracts in The Power SectorIwan Anggara100% (2)

- What Is Quadrature Axis Reactance PDFDocument11 pagesWhat Is Quadrature Axis Reactance PDFRochdi BahiriNo ratings yet

- Primavera: Contract Manager Functional OverviewDocument22 pagesPrimavera: Contract Manager Functional OverviewIgor ČučekNo ratings yet

- Risk Asses23 - Generator RotorDocument3 pagesRisk Asses23 - Generator RotorRochdi BahiriNo ratings yet

- Readme 1 STDocument1 pageReadme 1 STRochdi BahiriNo ratings yet

- Audit of Power Purchase AgreementsDocument6 pagesAudit of Power Purchase AgreementsRochdi BahiriNo ratings yet

- Evaluate economic feasibility of power plant projectsDocument7 pagesEvaluate economic feasibility of power plant projectsfundu123No ratings yet

- Risk Asses 116 - Boiler Hydro Test LP3Document5 pagesRisk Asses 116 - Boiler Hydro Test LP3Rochdi BahiriNo ratings yet

- Power Electronics For Modern Wind Turbines-Frede Blaabjerg Zhe ChenDocument68 pagesPower Electronics For Modern Wind Turbines-Frede Blaabjerg Zhe Chennelber_xNo ratings yet

- Financing and Performance Contracting For EE Projects OutlineDocument1 pageFinancing and Performance Contracting For EE Projects OutlineRochdi BahiriNo ratings yet

- Risk Asses 118-Transformers Oil TreatmentDocument5 pagesRisk Asses 118-Transformers Oil TreatmentRochdi BahiriNo ratings yet

- TSA Appendices State - 16 09 2014 - WPDocument24,221 pagesTSA Appendices State - 16 09 2014 - WPRochdi BahiriNo ratings yet

- Pump Efficiency For Single Stage Centrifugal PumpsDocument8 pagesPump Efficiency For Single Stage Centrifugal PumpsPerrobast100% (1)

- Lettre Recommandation Orascom ConstructionDocument1 pageLettre Recommandation Orascom ConstructionRochdi BahiriNo ratings yet

- Install NotesDocument1 pageInstall NotesRochdi BahiriNo ratings yet

- Financial Analysis of Projects I - OutlineDocument2 pagesFinancial Analysis of Projects I - OutlineRochdi BahiriNo ratings yet

- 308 BeheraDocument6 pages308 BeheraRajneesh VachaspatiNo ratings yet

- 750-326 OM Blowdown Separator 04-10Document8 pages750-326 OM Blowdown Separator 04-10Rochdi BahiriNo ratings yet

- P6 Reference ManualDocument550 pagesP6 Reference Manualsaluthomas100% (22)

- BRD - Lean Manufacturing CaseDocument62 pagesBRD - Lean Manufacturing CaseRochdi BahiriNo ratings yet

- Hawk 4000 Controls: HAWK 4000 Boiler Control System Sample SpecificationsDocument4 pagesHawk 4000 Controls: HAWK 4000 Boiler Control System Sample SpecificationsRochdi BahiriNo ratings yet

- Primavera Project Planner p3Document300 pagesPrimavera Project Planner p3MARIANO100% (19)

- Wmu 2013 - PPT - FinalDocument103 pagesWmu 2013 - PPT - FinalRochdi BahiriNo ratings yet

- Dampers ExplanationDocument7 pagesDampers ExplanationRochdi BahiriNo ratings yet

- Project and O&M CostDocument2 pagesProject and O&M CostRochdi BahiriNo ratings yet

- Boiler Design StepDocument3 pagesBoiler Design StepRochdi BahiriNo ratings yet

- Risk Assesment 16 - Pre - Assembly and Erection ofDocument7 pagesRisk Assesment 16 - Pre - Assembly and Erection ofRochdi BahiriNo ratings yet

- Risk Asses23 - Generator RotorDocument3 pagesRisk Asses23 - Generator RotorRochdi BahiriNo ratings yet

- Elma Combitest 419 Multifunctional Meter SpecificationsDocument4 pagesElma Combitest 419 Multifunctional Meter SpecificationscipriancordeaNo ratings yet

- Restricting TECO revoking after order settlementDocument4 pagesRestricting TECO revoking after order settlementMayank MevchaNo ratings yet

- Shubham Sonar CVDocument2 pagesShubham Sonar CVKuldip PardeshiNo ratings yet

- Cummins QuickServe Online2Document1 pageCummins QuickServe Online2Anugerah PradanaNo ratings yet

- C Terpillar®: D3C, D4C, and D5C Series III Power Shift TransmissionDocument12 pagesC Terpillar®: D3C, D4C, and D5C Series III Power Shift TransmissionAnta MursidikNo ratings yet

- 1 Conductor Characteristics PDFDocument20 pages1 Conductor Characteristics PDFjaimeNo ratings yet

- Lecture Notes 8b - Slope Deflection Frames No Sidesway PDFDocument12 pagesLecture Notes 8b - Slope Deflection Frames No Sidesway PDFShavin ChandNo ratings yet

- A210-Handheld: Operating InstructionsDocument24 pagesA210-Handheld: Operating InstructionsAleksandarNo ratings yet

- Heater TreaterDocument5 pagesHeater TreaterImmanuel100% (1)

- Microstructure of a lead-tin eutectic alloyDocument55 pagesMicrostructure of a lead-tin eutectic alloyThaya GanapathyNo ratings yet

- SAP Fiori Launchpad For Developers - Architecture OverviewDocument12 pagesSAP Fiori Launchpad For Developers - Architecture OverviewsanasriNo ratings yet

- How To Install and Root Your Android Emulator - Cyber Treat Defense On Security TutorialsDocument11 pagesHow To Install and Root Your Android Emulator - Cyber Treat Defense On Security TutorialsCarlos SanchezNo ratings yet

- 14EEMME00 - Darshna RamawatDocument31 pages14EEMME00 - Darshna Ramawatdatshna ramawatNo ratings yet

- Mini Esplit LGDocument76 pagesMini Esplit LGLEASUCNo ratings yet

- Router Table Fence Building PlansDocument11 pagesRouter Table Fence Building Plansleo100% (2)

- Avk Gate Valve, Flanged, Pn10/16 02/60-0045: EN 558-2 S.15/DIN F5, Clockwise To OpenDocument3 pagesAvk Gate Valve, Flanged, Pn10/16 02/60-0045: EN 558-2 S.15/DIN F5, Clockwise To OpenMohamed SayedNo ratings yet

- 7 FeedforwardDocument12 pages7 FeedforwardHamdi MakniNo ratings yet

- Fluidized Bed ReactorDocument10 pagesFluidized Bed ReactorDurgesh BondeNo ratings yet

- PRV Spirax Sarco 25P - 25PADocument17 pagesPRV Spirax Sarco 25P - 25PAwen.cokNo ratings yet

- D. Marriot - The Development of High-Performance Post-Tensioned Rocking Systems For The Seismic Design of StructuresDocument556 pagesD. Marriot - The Development of High-Performance Post-Tensioned Rocking Systems For The Seismic Design of Structuresedicson1aNo ratings yet

- Charles Correa 1Document21 pagesCharles Correa 1NupurAgrawalNo ratings yet

- Concrete Caissons For 2BMA - Large Scale Test of Design and Material 2019Document154 pagesConcrete Caissons For 2BMA - Large Scale Test of Design and Material 2019hjdNo ratings yet

- 3 28 19 NtapDocument199 pages3 28 19 Ntapfikri fikriNo ratings yet

- Metaltech-Automex-2019-Post-Show-Report CompressedDocument9 pagesMetaltech-Automex-2019-Post-Show-Report Compressedapi-480638034No ratings yet

- ResumeDocument2 pagesResumekoduruabhinavNo ratings yet

- Introduction To Electrical and Computer Engineering Lab ManualDocument124 pagesIntroduction To Electrical and Computer Engineering Lab Manualkstu1112No ratings yet

- Revision of existing site plan for residential propertyDocument1 pageRevision of existing site plan for residential propertyAndrew BydderNo ratings yet

- Optimized Induction Motor Design for Electrical VehiclesDocument12 pagesOptimized Induction Motor Design for Electrical Vehiclesmass72100% (1)

- Reporting and Analysis GuideDocument336 pagesReporting and Analysis GuidechanduNo ratings yet

- EDI MessageDocument3 pagesEDI Messagerameshkola1434No ratings yet