Professional Documents

Culture Documents

FunctionalSafety V7666

Uploaded by

rufino.perea.20 ratings0% found this document useful (0 votes)

81 views12 pagesFunctionalSafety_V7666

Original Title

FunctionalSafety_V7666

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFunctionalSafety_V7666

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

81 views12 pagesFunctionalSafety V7666

Uploaded by

rufino.perea.2FunctionalSafety_V7666

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 12

Functional Safety Solutions

for the Process Control Industry

4

3-way pilot valves

Manual reset & redundant coil pilot valves

Redundant control pilot valve systems

w w w . a s c o v a l v e . c o m

1

ASCO solenoid pilot valves are an integral part of the final control element for any

safety instrumented system (SIS) or critical application. ASCO offers 3 solenoid pilot

valve solutions that are widely used in the process control industry; individual 3-way

pilot valves, manual reset valves, and redundant pilot valve systems. Each of these

solutions are proven in use as a pilot valve in critical applications and in safety

instrumented systems. Certified pilot valves per IEC 61508 Parts 1 and 2 are rated SIL

3 capable for domestic and international markets (ATEX). ASCO understands the need

to keep your process running, but also understands that the process must shut down

when commanded.

3-Way Pilot Valves

ASCO 3-way solenoids, 8314, 8316, and 8320 are the most widely used

solenoid pilot valves in the world. For your spring return actuator applications,

these valves are proven in use and have undergone 3rd party evaluation by

Exida per IEC 61508 Parts 1 & 2. All 3 series are certified SIL 3 capable.

Individual pilot valves are most commonly used in 1-out-of-1 voting archi-

tectures but can be easily piped into a 2-out-of-2 configuration. ASCO pilot

valves are used as the primary device for process valve actuation as well as

the shutdown valve when used with digital valve controllers for on-off and

control valve applications.

SIL 3 Certified

Redundant Control Pilot Valve Systems

The ASCO RCS is a redundant pilot valve system that acts as a single 3-way

valve. The added features of this system above an individual valve include the

ability to perform automatic online testing of the redundant solenoid valves,

automatic partial stroke testing of the process valve, and online maintenance

capabilities. This product is built for high reliability applications and functional

safety. The redundant solenoids can operate in 1-out-of-1 Hot Standby mode

or 2-out-of-2 Diagnostic mode. Both modes of operation are certified per IEC

61508 Parts 1 and 2 and are SIL 3 capable. To design an RCS product, please

visit www.ascovalve.com/RCSConfigurator for the RCS online configurator.

SIL 3 Certified, ATEX Approved

Manual Reset & Redundant Coil Pilot Valves

ASCO Manual Reset Pilot Valves are a process industry standard. For harsh

plant environments where reliability is a must, ASCO has the products to keep

your process going. Lever operated manual reset valves are designed with

corrosion resistant materials and industrial strength components. When you

need to manually engage the final control element of your process

system, ASCO has the proven solutions for your applications. Redundant coil

pilot valves are also available for your high availability applications.

FUNCTIONAL SAFETY SOLUTIONS

1

Process Valve

Fuel Gas Line

Process

Heater

Distillation

Column

Gas shut-off valves used in burner

applications for process heaters are

critical to the refining process. This is

one of the more common examples

of the need for functional safety. In

order for the refining process to run

without disruption, the valve cannot

trip spuriously, and must shut down

when commanded in order to avert

an unsafe condition.

2

3-Way Pilot Valves

ASCO IEC 61508 3-way pilot valves are typically piped in the following two configurations:

1 out-of 1

P

E

C

TO ACTUATOR / PROCESS VALVE

SUPPLY

PRESSURE

The 1 out-of 1 configuration is the most common pilot valve configuration used.

2 out-of 2

TO ACTUATOR / PROCESS VALVE

P

E

C

P

E

C

SUPPLY

PRESSURE

The 2 out-of 2 configurations are commonly used for high availability applications. In the case that one solenoid valve were

to spuriously trip, the second solenoid still maintains the position of the actuator/process valve at its operating state.

Both solenoids must close in order to shift the actuator/process valve to its non-operating state.

Redundant Coil Pilot Valves

Redundant coil pilot valves are used for high availability applications. There are two coils (solenoid operators) that are redundantly

keeping the main solenoid valve in the energized position, which in turn keeps the actuator/process valve in its operating position.

Both coils must be de-energized in order to return the actuator/process valve to its non-operating position.

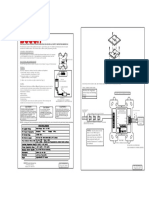

Tamper-Proof Manual Reset Valves

Electrically Tripped With the pilot valve solenoid de-energized, the handle is raised manually and latches the operator

in the up (latched) position. Upon energizing the pilot valve solenoid, the latch is tripped returning the operator to the

down (unlatched) position. If auxiliary air supply to the pilot valve is lost, the main valve will shift position.

No Voltage Release With the pilot valve solenoid energized, the handle is raised manually and latches the operator in the

up (latched) position. Upon loss of voltage, the latch is tripped returning the operator to the down (unlatched) position.

If the auxiliary air supply to the pilot valve is lost, the main valve will shift position.

Moving the handle while the valve is in its tripped state will not cause the actuator/process valve to shift.

(Applies to both tamper-proof manual reset valves)

High Shock Manual Reset Valves

Electrically Tripped With the pilot valve solenoid de-energized, the handle is raised manually and latches the operator

in the up (latched) position. Upon energizing the pilot valve solenoid, the latch is tripped returning the operator to the

down (unlatched) position.

No Voltage Release With the pilot valve solenoid energized, the handle is raised manually and latches the operator in the

up (latched) position. Upon loss of voltage, the latch is tripped returning the operator to the down (unlatched) position.

Once tripped, the lever may be cycled causing the valve discs to open and close.

(Applies to both high shock manual reset valves)

3

Operational Specifications

Important

These solenoids are intended for use on clean, dry air or inert gas filtered to 50 microns or better. To prevent freezing,

the dew point of the media should be at least 18F (-8C) below the minimum temperature to which any portion of the clean

air or gas system could be exposed. Instrument air in compliance with ANSI/ISA Standard S7.3-1975 (R1981) exceeds

the above requirements and is, therefore, an acceptable medium for these valves.

Pipe

Size

(ins.)

Orifice

Size

(ins.)

Cv Flow

Factor

Operating Pressure

Differential (psi)

Fluid and

Ambient

Temp. F Brass Body Stainless Steel Body Air-Inert Gas

Pressure to

Cylinder

Cylinder to

Exhaust Min. Max. Min. Max. Catalog Number

Const.

Ref. Catalog Number

Const.

Ref.

UNIVERSAL OPERATION (Pressure at any port) with NBR Disc PFDAVG = 4.38 x 10

-4

1/4 1/16 .08 .08 0 150 -40 140 8314G300 4 8314G301 5

NORMALLY CLOSED (Closed when de-energized) with NBR Disc or FPM, as Listed PFDAVG = 7.01 x 10

-4

1/4 5/16 1.5 1.5 150 -4 140 8316G301 6 EV8316G381V 6

3/8 5/16 1.8 1.8 150 -4 140 8316G302 6 EV8316G382V 6

3/8 5/8 4 4 150 -4 140 8316G303 7 - -

1/2 5/8 4 4 150 -4 140 8316G304 7 EV8316G384V 7

3/4 11/16 5.5 5.5 10 150 -4 140 8316H374 8 - -

1 1 13 13 10 150 -4 140 8316G334 9 - -

IMPORTANT: A Minimum Operating Pressure Differential must be maintained between the pressure and exhaust ports. Supply and exhaust piping must be full area, unrestricted.

ASCO flow controls and other similar components must be installed in the cylinder lines only. See graph on page 7 for main line pressure vs. pilot line pressure.

Diaphragm and main disc FKM only (pilot is low-temperature NBR).

Zero minimum when valve selection gasket is in external position and proper auxiliary air pressure is applied. Minimum 15 psi Operating Pressure Differential when selection gasket

is in the internal position.

Can be used for dry natural gas service with the EF or EV prefix.

Pipe

Size

(ins.)

Orifice

Size

(ins.)

Cv

Flow

Factor

Operating Pressure

Differential (psi)

Min.

Fluid and

Ambient

Temp. F

Max.

Fluid

Temp. F

Max.

Ambient

Temp. F

Brass Body Stainless Steel Body

Watt Rating/

Class of Coil

Insulation Max. AC Max. DC

Catalog

Number

Const.

Ref.

Catalog

Number

Const.

Ref.

Air-Inert

Gas Water

Lt. Oil @

45 SSU

Air-Inert

Gas Water

Lt. Oil @

45 SSU AC DC AC DC AC DC

NORMALLY CLOSED (Closed when de-energized) PFDAVG = 4.38 x 10

-4

1/8 3/64 .04 230 230 230 120 140 135 32 200 104 125 104 8314G031 1 - - 10.1/F 11.6/F

1/4 3/64 .04 230 230 230 120 140 135 32 200 104 125 104 8314G034 2 - - 10.1/F 11.6/F

1/4 3/32 .15 150 100 100 60 70 30 32 200 104 125 104 8314G035 2 8314G121 x 3 10.1/F 11.6/F

1/4 1/8 .25 75 60 60 30 40 25 32 200 104 125 104 8314G036 2 - - 10.1/F 11.6/F

x Can be used for dry natural gas service with the EF prefix.

Pipe

Size

(ins.)

Orifice

Size

(ins.)

Cv

Flow

Factor

Operating Pressure

Differential (psi)

Min.

Fluid and

Ambient

Temp. F

Max.

Fluid

Temp. F

Max.

Ambient

Temp. F

Brass Body Stainless Steel Body

Watt Rating/

Class of Coil

Insulation y Max. AC Max. DC

Catalog

Number

Const.

Ref.

Catalog

Number

Const.

Ref.

Air-Inert

Gas Water

Lt. Oil

@ 300

SSU

Air-Inert

Gas Water

Lt. Oil

@ 300

SSU AC DC AC DC AC DC

NORMALLY CLOSED (Closed when de-energized) PFD

AVG

= 4.38 x 10

-4

1/8 3/64 .06 200 200 200 200 200 200 32 180 120 125 104 8320G132 10 8320G142 10 6.1/F 10.6/F

1/8 1/16 .09 150 125 125 125 125 125 32 180 120 125 104 8320G013 10 8320G045 10 6.1/F 10.6/F

1/8 3/32 .12 100 100 100 100 100 100 32 180 120 125 104 8320G015 10 8320G047 10 6.1/F 10.6/F

1/8 1/8 .21 40 40 40 40 40 40 32 180 120 125 104 8320G017 10 8320G049 10 6.1/F 10.6/F

1/4 1/16 .09 210 225 225 160 160 160 32 200 150 125 104 8320G182 11 - - 17.1/F 11.6/F

1/4 3/32 .12 150 150 150 115 115 115 32 200 150 125 104 8320G184 11 8320G202 12 10.1/F 11.6/F

1/4 1/8 .25 85 85 85 60 60 60 32 200 150 125 104 8320G186 11 8320G203 12 10.1/F 11.6/F

1/4 11/64 .35 45 45 45 25 25 25 32 200 150 125 104 8320G188 11 - - 10.1/F 11.6/F

NORMALLY OPEN (Open when de-energized) PFDAVG = 5.04 x 10

-4

1/8 3/64 .06 200 200 200 200 200 200 32 180 120 125 104 8320G136 10 8320G146 10 6.1/F 10.6/F

1/8 1/16 .09 150 125 125 125 125 125 32 180 120 125 104 8320G027 10 8320G051 10 6.1/F 10.6/F

1/8 3/32 .12 100 100 100 100 100 100 32 180 120 125 104 8320G029 10 8320G053 10 6.1/F 10.6/F

1/8 1/8 .21 40 40 40 40 40 40 32 180 120 125 104 8320G031 10 8320G055 10 6.1/F 11.6/F

1/4 1/16 .09 250 250 250 160 160 160 32 200 150 125 104 8320G192 11 - - 17.1/F 11.6/F

1/4 3/32 .12 150 140 140 100 100 100 32 200 150 125 104 8320G194 11 8320G204 12 10.1/F 11.6/F

1/4 1/8 .25 70 70 70 55 55 55 32 200 150 125 104 8320G196 11 8320G205 12 10.1/F 11.6/F

1/4 11/64 .35 40 40 40 30 30 30 32 200 150 125 104 8320G198 11 - - 10.1/F 11.6/F

y On 50 hertz service, the watt rating for the 6.1/F solenoid is 8.1 watts; the watt rating for the 9.1/F solenoid is 11.1 watts.

Can be used for dry natural gas service with the EF or EV prefix.

3-Way Pilot Valves

4

3-Way Low Power Pilot Valves (1.4 W)

3-Way Pilot Valves

1 2

3

Const.

Ref. H K L P W

1

ins. 3.87 1.67 1.19 3.51 1.95

mm 98 42 30 89 50

2

ins. 4.21 1.80 1.25 3.79 1.95

mm 107 46 32 96 50

3

ins. 4.14 1.78 1.63 3.77 1.95

mm 105 45 41 96 50

IMPORTANT: Valves can be mounted in any position.

Const. Ref. 1, 2, 3

Const. Ref. 4, 5

Const. Ref. 7

Const. Ref. 6

5

Dimensions: inches [mm]

2 MOUNTING HOLES

.164 [4] THD CUTTING

SCREW

2

1

.44 [11]

R.09 [2.3]

4 PLACES

FOR MOUNTING

.44 [11]

1.19 [30]

.09 [2.3]

2 PLACES

1.30 [33]

.63 [16]

1/8 NPT

3 PLACES

3

1.32 [34]

1.69 [43]

2.18 [55]

3.15 [80]

1/2 NPT

1.69 [43]

.44 [11]

3.74 [95]

2.73 [69]

1.75 [45]

.37 [9]

2 MOUNTING HOLES

.31 [8] DEEP FOR

.164 [4] THD CUTTING SCREW

1/4 NPT

3 PLACES

1.40 [36]

.81 [21]

3

1.95 [50]

1/2 NPT

1

2

1.44 [37]

1.76 [45]

2.74 [70]

3.73 [95]

1.95 [50]

1/2 NPT

1/4 NPT

3 PLACES

.72 [18]

1.81 [46]

MOUNTING BRACKET

IS STANDARD ON THIS

CONSTRUCTION

*

MOUNTING BRACKET*

WITH .28 [7] HOLES

2 PLACES

1 2 3

Const. Ref. 10

Const. Ref. 11 Const. Ref. 12

6

Dimensions: inches [mm]

OPTIONAL MOUNTING

BRACKET WITH

.28 [ 7] HOLES

[4 PLACES] AVAILABLE

ON 3/4 SIZE ONLY

3.82 [97]

R

C

1.66 [42]

1/2 NPT

1/8 NPT

.45 [11]

H

P

K

PRESS P

3/4 NPT

3 PLACES

CYL

A

L

M

A

B

EXH

E

W N

Const. Ref. 8, 9

Const.

Ref. A B C H K L M N P R W

8

ins. 1.61 1.41 1.66 6.78 3.68 3.38 2.16 .53 5.09 .50 3.31

mm 41 36 42 172 93 86 55 13 129 13 84

9

ins. X 1.78 X 7.40 3.93 4.44 2.81 .87 5.34 1.74 5.31

mm X 45 X 188 100 113 71 22 136 44 135

Pipe

Size

(ins.)

Orifice

Size

(ins.)

Cv Flow

Factor

Operating Pressure

Differential (psi)

Fluid

Temp. F

Max.

Ambient

Temp. F

Catalog

Number

Const.

Ref. Body Material Pilot Construction

Watt Rating/ Class

of Coil Insulation

per Solenoid

Pilot Min. Pilot Max. Main Max. Min. Max. AC DC

3/2 Redundant Coil Pilot Valves

1/4 3/64 .04 - - 150 -40 140 140 EV8323G352 13 Stainless Steel Normally Closed - 1.4/F

1/4 3/64 .04 - - 150 -40 140 140 EV8323G353 13 Stainless Steel Normally Open - 1.4/F

1/4 3/64 .04 - - 150 -4 200 125 EV8323G052 13 Stainless Steel Normally Closed 10.1/F -

1/4 3/64 .04 - - 150 -4 200 125 EV8323G053 13 Stainless Steel Normally Open 10.1/F -

1/4 5/16 1.5 x 150 150 -4 180 125 EF8323G060 14 Brass Normally Closed 10.1/F -

1/4 5/16 1.5 x 150 150 -4 180 125 EV8323G080 14 Stainless Steel Normally Closed 10.1/F -

1/4 5/16 1.5 x 150 150 -4 180 125 EV8323G082 14 Stainless Steel Normally Open 10.1/F -

1/4 5/16 1.5 x 150 150 -4 140 140 EV8323G380 14 Stainless Steel Normally Closed - 1.4/F

1/4 5/16 1.5 x 150 150 -4 140 140 EV8323G382 14 Stainless Steel Normally Open - 1.4/F

1/2 5/8 4 x 150 150 -4 180 125 EV8323G081 15 Stainless Steel Normally Closed 10.1/F -

1/2 5/8 4 x 150 150 -4 180 125 EV8323G083 15 Stainless Steel Normally Open 10.1/F -

1/2 5/8 4 x 150 150 -4 140 140 EV8323G381 15 Stainless Steel Normally Closed - 1.4/F

1/2 5/8 4 x 150 150 -4 140 140 EV8323G383 15 Stainless Steel Normally Open - 1.4/F

3/2 Tamper Proof Manual Reset Valves

1/4 5/16 1.5 25 125 150 -4 180 125 EV8308G060 16 Stainless Steel No Voltage Release (NVR) 10.1/F -

1/4 5/16 1.5 25 125 150 -4 140 140 EV8308G360 16 Stainless Steel No Voltage Release (NVR) - 1.4/F

1/2 5/8 4 25 125 150 -4 180 125 EV8308G061 17 Stainless Steel No Voltage Release (NVR) 10.1/F -

1/2 5/8 4 25 125 150 -4 140 140 EV8308G361 17 Stainless Steel No Voltage Release (NVR) - 1.4/F

3/2 High Shock Manual Reset Valves

3/8 1/4 0.45 25 125 125 -40 140 140 EV8308G385 18 Brass No Voltage Release (NVR) - 1.4/F

3/8 1/4 0.45 25 125 125 -40 140 140 EV8310G385 18 Brass Electrically Tripped (TSO) - 1.4/F

3/8 1/4 0.45 25 125 125 -4 200 125 EV8308G085 18 Brass No Voltage Release (NVR) 10.1/F -

3/8 1/4 0.45 25 125 125 -4 200 125 EV8310G085 18 Brass Electrically Tripped (TSO) 10.1/F -

3/8 1/4 0.45 25 125 125 -40 140 140 EV8308G386 18 Stainless Steel No Voltage Release (NVR) - 1.4/F

3/8 1/4 0.45 25 125 125 -40 140 140 EV8310G386 18 Stainless Steel Electrically Tripped (TSO) - 1.4/F

3/8 1/4 0.45 25 125 125 -4 200 125 EV8308G086 18 Stainless Steel No Voltage Release (NVR) 10.1/F -

3/8 1/4 0.45 25 125 125 -4 200 125 EV8310G086 18 Stainless Steel Electrically Tripped (TSO) 10.1/F -

x Zero minimum when valve selection gasket is in external position and proper auxiliary air pressure is applied.

See graph below for main line pressure vs. pilot line pressure. Minimum 15 psi operating pressure differential when selection gasket is in the internal position.

Manual Reset and Redundant Coil Pilot Valves

1.91 [48]

C

1.91 [48]

F

E

SOL B SOL A

CYL

1/4 ANPT

1/2 NPT CONDUIT

CONN 2 PLACES

3

TUBE CONNECTS

PORT '2' WITH

SOLENOID AT

POSITION '3'.

SOLENOID POSITION

MARKED '3'

PORT

MARKED '2'

2.04

[52]

EXH

PRESS

1.96 [50]

1.25 [32]

2 PLACES

7.28 [77]

4 MOUNTING HOLES

CONDUIT

L C OF

SOL A SOL B

AUX

CYL

BOTTOM VIEW

PILOT VALVE NOT SHOWN

4.67 [119]

4.05 [103]

.88 [22]

1.91 [48]

Const. Ref. 13

Const. Ref. 14

120

15

30

45

60

75

90

106

0

60 45 30 15 0 135 120 105 90 75 150

MAIN LINE PRESSURE vs. PILOT LINE PRESSURE

WHEN SELECTION GASKET IS IN EXTERNAL POSITION

P

I

L

O

T

L

I

N

E

P

R

E

S

S

U

R

E

(

p

s

i

)

MAIN LINE PRESSURE (psi)

7

Dimensions: inches [mm]

EXH

CF-8M

PRESS

AUX

4 MOUNTING HOLES

4.84 [123]

4.22 [107] .31 [8]

2.16 [55]

1.66 [42]

7.28 [77]

2 PLACES

PRESS EXH

CONDUIT

C OF L

.88 [22]

SOL A SOL B

CYL

BOTTOM VIEW

PILOT VALVE NOT SHOWN

1.91 [48]

`2'

`1'

`3'

`2'

`3'

`1'

1/4 ANPT

1/4 TUBE

1/2 NPT

11.25 [286]

MAX

6.56 [167]

MAX

6.95 [177]

MAX

Const. Ref. 15

Const. Ref. 16

8

Dimensions: inches [mm]

SHOWN WITH

OPTIONAL POSITION

INDICATOR SWITCH

14.24 [362]

11.43 [290]

1/4 NPT

3.77 [96]

10.04 [255]

3.41 [87]

1.03 [26]

PORT

1

UNLATCHED

LATCHED

6.56 [167]

1.38 [35] 2.05 [52] 1/2 NPT

7.61

[193]

1.38

[35]

PORT

2

PORT

3

6.56 [167]

1.44 [36]

6.23

[158]

2.12 [54]

3/8 NPT

3 PLACES

2.00 [51]

R.17 [4]

2 PLACES

FOR MOUNTING

LATCHED

1/4 ANPT

11.50 [292]

MAX

6.38 [162] MAX

6.62 [168 ] MAX

`2'

`3'

`1'

`2'

`1'

`3'

1/8 NPT

1/2 NPT

1/4 TUBE

Const. Ref. 17

Const. Ref. 18

9

Dimensions: inches [mm]

Enter Catalog Number Reset View Details

Enter Catalog Number Reset View Details

5RC027BFQ4E2Z0C

Energized to Trip

De-Energized to Trip

1oo1HS De-Energized to Trip

2oo2 De-Energized to Trip

Common Alarm

Modbus 485 Communication

Local Initiation of Sov Test

Local Initiation of Partial Stroke Test

Local Manual Reset

Bypass Inidcation

Midstroke Limit Switch

Silver Contacts for Relay Logic

SIL Certification

Full Stroke Limit Switch

Dual Power Sources

Analog Input Module

Two Analog Input Modules

Cabinet Heater

Lever Type Bypass

Shutoff for Modulatd Control Valves

No Bypass

ATEX Certification

One Green Light

Two Green Lights

Three Green Lights

Four Green Lights

One Red Light

Two Red Lights

Three Red Lights

Four Red Lights

One Green & One Red Light

Two Green & One Red Light

Three Green & One Red Light

One Green & Two Red Lights

One Green & Three Red Lights

Two Green & Two Red Lights

One Push Button

Two Push Buttons

Three Push Buttons

Four Push Buttons

Additional Lights and Push Buttons

Optional Features

P

Design a Redundant Control System

Extended Temperature: -13F to 158F (-25C to 70C)

304 Stainless Steel

Composite (Fiberglass)

316 Stainless Steel

Standard: 32F to 131F (0C to 55C)

None

12 VDC

24 VDC

48 VDC

120 VDC

120/60-110/50

24 VDC Intrinsically Safe

230/50-240/50

Normally Closed

Normally Open

Double Acting

Configuration On board Diagnostic Processor

Enclosure Material System Voltage Operational Mode

Information

Indicates a required attribute

To ensure that you are familiar with the RCS product line, we recommend that you read the RCS catalog prior to designing a product.

*

*

* * *

*

ATEX Cert O&M Guide View Safety Manual View RCS Catalog

ASCO simplified the RCS product selection process with an online catalog number configurator. Once you have de-

termined the features required, you can easily construct a catalog number by clicking on each feature required and then

clicking the View Details button. A second screen appears providing the product catalog number, product attributes,

and various drawings. The configurator is programmed to accept only valid constructions.

In addition to creating a catalog number, the configurator can also decipher a catalog number. Type a valid 5RC or

5LC catalog number into the window next to the Enter Catalog Number button (CAPs only). The configurator

automatically highlights the appropriate construction features.

In order to use the online configurator go to: www.ascovalve.com/RCSConfigurator

10

Redundant Control Pilot Valve Systems

ASCO Val ve, I nc. 800. 972. 2726 www. ascoval ve. com

France

Tel (33) 1-47-14-32-00

Germany

Tel (49)-7237-9960

United Kingdom

Tel (44) 1695-713600

Australia

Tel (61) 2-9-451-7077

China

Tel (86-28) 8662-8833

Japan

Tel (81) 798-65-6361

Singapore

Tel (65) 6556-1100

Brazil

Tel (55) 11-4208-1660

Mexico

Tel (52-1) 728-28-51-238

Canada

Tel 519-758-2700

01/09 - V7666

You might also like

- General Control Valves.: Engineering Centre of Excellence Ecoe - Doha, Qatar Instrument Training - 16 July 2011Document42 pagesGeneral Control Valves.: Engineering Centre of Excellence Ecoe - Doha, Qatar Instrument Training - 16 July 2011ahmed messallamNo ratings yet

- Us 13520Document324 pagesUs 13520jashkishoreNo ratings yet

- 60a11 ReadingDocument19 pages60a11 Readingishu vohraNo ratings yet

- Up STP Build and Design Project PLC Detailed Wiring Diagram: PlantelligentDocument22 pagesUp STP Build and Design Project PLC Detailed Wiring Diagram: PlantelligentTimothy CorpusNo ratings yet

- OpticalCON Power Budget CalculatorDocument1 pageOpticalCON Power Budget CalculatorGuido MartinezNo ratings yet

- Chapter 7 - System Design ConsiderationDocument23 pagesChapter 7 - System Design ConsiderationFaizal EngintechNo ratings yet

- Flujo RosemountDocument42 pagesFlujo RosemountcristianNo ratings yet

- 3.2transmitters Guided Wave Radar 706xxxDocument58 pages3.2transmitters Guided Wave Radar 706xxxQuy le manhNo ratings yet

- 1492 Aifm8 3 Con If8hDocument1 page1492 Aifm8 3 Con If8hLeonardo VillateNo ratings yet

- 55-052 Releasing Control Module: Installation InstructionsDocument2 pages55-052 Releasing Control Module: Installation Instructionsjunioralamo17No ratings yet

- Instrucalc BrochureDocument28 pagesInstrucalc BrochureShantanu100% (1)

- Ulusoy Elektrik's Metal Enclosed Modular SwitchgearsDocument71 pagesUlusoy Elektrik's Metal Enclosed Modular SwitchgearsKang RondaNo ratings yet

- Trusted Field Loop ConfigurationDocument56 pagesTrusted Field Loop Configurationjaysonlkh100% (1)

- Lect. 05 Che 185 - Dcs and PLC FundamentsDocument27 pagesLect. 05 Che 185 - Dcs and PLC FundamentsLuis Enrique PariapazaNo ratings yet

- 8512spec PDFDocument4 pages8512spec PDFbradmal89yahoo.comNo ratings yet

- Install STS-1 Security Tamper SwitchDocument2 pagesInstall STS-1 Security Tamper SwitchRobel MTNo ratings yet

- Manual Easy 412Document55 pagesManual Easy 412S Raúl Vargas100% (1)

- ASME B16.47 Series B Flanges Class 150 SpecsDocument1 pageASME B16.47 Series B Flanges Class 150 SpecsD.RameshkumarNo ratings yet

- Manual AlarmScout 910 117 - 4417900 - Rev00Document4 pagesManual AlarmScout 910 117 - 4417900 - Rev00Maribel CamachoNo ratings yet

- I56 3500 PDFDocument2 pagesI56 3500 PDFPedro VelozoNo ratings yet

- Isa ManometrosDocument1 pageIsa ManometrosVicent Rojas100% (1)

- 12P5403GDocument16 pages12P5403GMalik HamzaNo ratings yet

- Switchmatic Switchmatic 2: Advanced SettingsDocument6 pagesSwitchmatic Switchmatic 2: Advanced SettingsHay ThemNo ratings yet

- Bentley Instrumentation and Wiring Design Fundamentals V8i (Ss1) Edition TRN011660 10002 Megacad Ingenieria y Sistemas S.a.S. 18-Jul-2011Document434 pagesBentley Instrumentation and Wiring Design Fundamentals V8i (Ss1) Edition TRN011660 10002 Megacad Ingenieria y Sistemas S.a.S. 18-Jul-2011edwinchisNo ratings yet

- 3100/3150 - LTQ Limitorque Valve Actuator Master Module: Revision 1.7Document41 pages3100/3150 - LTQ Limitorque Valve Actuator Master Module: Revision 1.7Marcos VasconcelosNo ratings yet

- Severn Glocon 3Document10 pagesSevern Glocon 3Amit SurtiNo ratings yet

- Fatek Analogna - karticaB4AD enDocument3 pagesFatek Analogna - karticaB4AD enМилош ЈовановићNo ratings yet

- Appendix G - TRS 09082B - Inverter System Interface To Plant Computer (KIT) Rev 0Document14 pagesAppendix G - TRS 09082B - Inverter System Interface To Plant Computer (KIT) Rev 0pthakur234No ratings yet

- Installation Instructions For Flm-325-2I4 Dual Input Monitor ModuleDocument1 pageInstallation Instructions For Flm-325-2I4 Dual Input Monitor ModuleLuiyi Lazcano MontalvoNo ratings yet

- 12P6122DDocument4 pages12P6122DMalik HamzaNo ratings yet

- Cyl Tel CutsheetDocument2 pagesCyl Tel CutsheetaLeXiNNo ratings yet

- MMB 2Document8 pagesMMB 2albertoNo ratings yet

- 61a1 ReadingDocument7 pages61a1 Readingishu vohraNo ratings yet

- Manual Smar Tt301Document58 pagesManual Smar Tt301yo_soy_yvette100% (1)

- 2.0 VISION 2020i: 2.1 PrecautionsDocument3 pages2.0 VISION 2020i: 2.1 PrecautionsTran Van TienNo ratings yet

- Experion SCADA ILMS BrochureDocument4 pagesExperion SCADA ILMS BrochureFredy López VerezaluceNo ratings yet

- SIMATIC - 002-Demo Projects For LOGODocument4 pagesSIMATIC - 002-Demo Projects For LOGOJorge_Andril_5370No ratings yet

- SG 003a Multi Functional Signal Generator ManualDocument17 pagesSG 003a Multi Functional Signal Generator ManualbryanvelesacaNo ratings yet

- Password Reset Via SADP Tool v3Document2 pagesPassword Reset Via SADP Tool v3jose medinaNo ratings yet

- Digital Input Module SM 321 DI 16 X DC 24 V (6ES7321-1BH02-0AA0)Document3 pagesDigital Input Module SM 321 DI 16 X DC 24 V (6ES7321-1BH02-0AA0)Fabio CavalheiroNo ratings yet

- DelugeDocument4 pagesDelugeBogdan Axinte100% (1)

- ARUV050GSD0Document2 pagesARUV050GSD0MIGUELNo ratings yet

- Data TTG AcDocument5 pagesData TTG AcMya Diggory SikukangzNo ratings yet

- Temperature Probes Thermowells: Smith Meter® Electronic EquipmentDocument4 pagesTemperature Probes Thermowells: Smith Meter® Electronic EquipmentiptusNo ratings yet

- NTF-DS-CV-001 Data Sheet Control Valve Rev.BDocument4 pagesNTF-DS-CV-001 Data Sheet Control Valve Rev.BRicardo NapitupuluNo ratings yet

- 32-00076 Slate Modules PDFDocument8 pages32-00076 Slate Modules PDFManuel CorralesNo ratings yet

- Siemens CZM1 Remote Conventional Zone ModuleDocument6 pagesSiemens CZM1 Remote Conventional Zone ModuleBruno VellinhaNo ratings yet

- Solid State RelayDocument4 pagesSolid State RelaymysisterandmeNo ratings yet

- SMC Flex With Datalinks - D735 Devicenet - OptionDocument5 pagesSMC Flex With Datalinks - D735 Devicenet - OptionSergio SuarezNo ratings yet

- Components For Pneumatic Automation: Five ONEDocument26 pagesComponents For Pneumatic Automation: Five ONEamNo ratings yet

- 1019 A8 Card Datasheet PDFDocument2 pages1019 A8 Card Datasheet PDFbahmanNo ratings yet

- Fenwalnet 8000-Ml: Protection SystemsDocument12 pagesFenwalnet 8000-Ml: Protection SystemsricardopelezinhoNo ratings yet

- Total Plant Solutions Overview TP01100 PDFDocument64 pagesTotal Plant Solutions Overview TP01100 PDFEMC RoboticsNo ratings yet

- A52/A53 RS-422 and RS-485 converter installation guideDocument2 pagesA52/A53 RS-422 and RS-485 converter installation guideJan Der VarNo ratings yet

- ParadoxDocument7 pagesParadoxLisa FloresNo ratings yet

- N 259Document3 pagesN 259Rafael GarciaNo ratings yet

- Catalog Functional Safety Solutions Asco en 5084612Document16 pagesCatalog Functional Safety Solutions Asco en 5084612alejomariana03No ratings yet

- SRC Alpha Version1 PDFDocument26 pagesSRC Alpha Version1 PDFRajat JainNo ratings yet

- Allenair Catalog 4 Way ValvesDocument5 pagesAllenair Catalog 4 Way ValvesEddie WallsNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Smartplant Review: Hardware and Software RecommendationsDocument4 pagesSmartplant Review: Hardware and Software Recommendationsrufino.perea.2No ratings yet

- Integrating Switching and Routing As A SolutionDocument1 pageIntegrating Switching and Routing As A Solutionrufino.perea.2No ratings yet

- CH 18 NFPA 1 HandbookDocument7 pagesCH 18 NFPA 1 Handbookrufino.perea.2No ratings yet

- About RTOs Banks Engineering 10-8-2007Document9 pagesAbout RTOs Banks Engineering 10-8-2007rufino.perea.2No ratings yet

- Designing and Planning Laboratories PDFDocument60 pagesDesigning and Planning Laboratories PDFPaul Karija100% (1)

- Hydrogen Sulfide Fact SheetDocument2 pagesHydrogen Sulfide Fact Sheetdarrd2010No ratings yet

- Electrical Installations in Hazardous Areas - New Brazillian DirectivesDocument4 pagesElectrical Installations in Hazardous Areas - New Brazillian DirectivesJimBoringNo ratings yet

- Good Lab Safety 2009Document86 pagesGood Lab Safety 2009rufino.perea.2No ratings yet

- FunctionalSafety V7666Document12 pagesFunctionalSafety V7666rufino.perea.2No ratings yet

- Guidance For Monitoring Enclosed FlaresDocument74 pagesGuidance For Monitoring Enclosed Flaresrufino.perea.2No ratings yet

- In Oxid AbleDocument20 pagesIn Oxid Ablerufino.perea.2No ratings yet

- Chapter 7: Design and Operation of Steam-Assisted FlaresDocument44 pagesChapter 7: Design and Operation of Steam-Assisted FlaresBre WirabumiNo ratings yet

- Material Grade Comparison ChartDocument1 pageMaterial Grade Comparison ChartMiorita_13No ratings yet

- enDocument16 pagesenrufino.perea.2No ratings yet

- Aermod MepDocument41 pagesAermod Meprufino.perea.2No ratings yet

- Ufc 3 520 01Document42 pagesUfc 3 520 01carlcrowNo ratings yet

- Push Buttons MASTER 1Document26 pagesPush Buttons MASTER 1rufino.perea.2No ratings yet

- E-F Brooks MLG-810Document12 pagesE-F Brooks MLG-810rufino.perea.2No ratings yet

- Manifold Actuation Arrangement Kit For 225-Lb. and 395-Lb. Cylinder SystemsDocument2 pagesManifold Actuation Arrangement Kit For 225-Lb. and 395-Lb. Cylinder Systemsrufino.perea.2No ratings yet

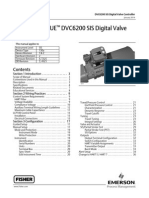

- Fisher R Fieldvue DVC6200 SIS Digital Valve Controller: Instruction ManualDocument108 pagesFisher R Fieldvue DVC6200 SIS Digital Valve Controller: Instruction Manualrufino.perea.2No ratings yet

- WP Large DeltaVSIS SystemsDocument12 pagesWP Large DeltaVSIS Systemsiman562No ratings yet

- Design Guideline - ABC BuildingsDocument7 pagesDesign Guideline - ABC Buildingsrufino.perea.2No ratings yet

- Strength Tables For Special Seismic and Blast Design Tech Note TSNDocument10 pagesStrength Tables For Special Seismic and Blast Design Tech Note TSNrufino.perea.2No ratings yet

- Fire Alarm Training ManualDocument34 pagesFire Alarm Training Manualmmahmad1989No ratings yet

- 640829554Document5 pages640829554rufino.perea.2No ratings yet

- DN 60533Document2 pagesDN 60533osto72No ratings yet

- VEL MS 2003aDocument28 pagesVEL MS 2003arufino.perea.2No ratings yet

- Wireguide TecDocument14 pagesWireguide Tecrufino.perea.2No ratings yet

- Operating Instruction For The Thermowell Calculation Program According To ASME PTC 19.3 TW-2010Document18 pagesOperating Instruction For The Thermowell Calculation Program According To ASME PTC 19.3 TW-2010ferrari.edgardo646No ratings yet

- CEN 305 - IntroductionDocument46 pagesCEN 305 - IntroductionAyush Kishore100% (1)

- Electrical NotesDocument1 pageElectrical NotesKenneth MarcosNo ratings yet

- Herramientas Bombas PDFDocument172 pagesHerramientas Bombas PDFrgb0906No ratings yet

- DME 1 Assignment 3Document3 pagesDME 1 Assignment 3AnilNo ratings yet

- Glass Industry Vocabulary - Learn What Glass Industry Terms Mean - Signa SystemDocument15 pagesGlass Industry Vocabulary - Learn What Glass Industry Terms Mean - Signa SystemkrajasrinivasNo ratings yet

- Ce2252 - Strength of MaterialsDocument4 pagesCe2252 - Strength of Materialsmuru0105No ratings yet

- Stock-Material-and-Febricated-Material SOR-2016-17Document35 pagesStock-Material-and-Febricated-Material SOR-2016-17souvikbesu89No ratings yet

- SkylightsDocument77 pagesSkylightszameer72790% (1)

- Max-3 Plus (420-2700) Technical Information & Assembly Instructions Manual PDFDocument60 pagesMax-3 Plus (420-2700) Technical Information & Assembly Instructions Manual PDFFlorentina SanduNo ratings yet

- Sanitary FixturesDocument47 pagesSanitary FixturesAneesh SulliaNo ratings yet

- Condensate Recovery SystemsDocument14 pagesCondensate Recovery SystemsLuis Felipe Zuñiga100% (1)

- Fire: en 13501 The European Standard Owacoustic Ceilings Reaction To Fire Fire ResistanceDocument12 pagesFire: en 13501 The European Standard Owacoustic Ceilings Reaction To Fire Fire Resistanceradubotinesteanu100% (3)

- BFab/2 EC 8-0+0(U) W 1.5 mm DatasheetDocument1 pageBFab/2 EC 8-0+0(U) W 1.5 mm DatasheetGerente OperacionesNo ratings yet

- Soil Investigation Report: Item Page NoDocument6 pagesSoil Investigation Report: Item Page NoWai LinnNo ratings yet

- Base PlateDocument34 pagesBase PlaterohitnrgNo ratings yet

- Nabard Rural Godown PDFDocument6 pagesNabard Rural Godown PDFVivek KhandelwalNo ratings yet

- Aisc TearoutsDocument11 pagesAisc Tearoutsclam2014No ratings yet

- 74f9b9a3-8170-4821-a9ae-9dbeb60bf676Document9 pages74f9b9a3-8170-4821-a9ae-9dbeb60bf676Swamy Dhas DhasNo ratings yet

- Parameters of Courtyard Design affecting the Energy Efficiency of buildingsDocument10 pagesParameters of Courtyard Design affecting the Energy Efficiency of buildingsGaurav GangwarNo ratings yet

- (PDF) Design Standards - CONFERENCE BUILDINGS, EXHIBITION & RESEARCH BUILDINGS - Muath Humaid - Academia - Edu PDFDocument110 pages(PDF) Design Standards - CONFERENCE BUILDINGS, EXHIBITION & RESEARCH BUILDINGS - Muath Humaid - Academia - Edu PDFatchaya gopalsamyNo ratings yet

- CV VijayDocument2 pagesCV VijayVijayaragavan SakthivelNo ratings yet

- Boq Gisu OkDocument61 pagesBoq Gisu OkYedid Amq100% (2)

- Super Asia Mds Limited Service Centre, LahoreDocument40 pagesSuper Asia Mds Limited Service Centre, Lahoresohailakhtar5No ratings yet

- Design of CorbelDocument3 pagesDesign of CorbelAkshay KumarNo ratings yet

- Ref & AC SystemDocument60 pagesRef & AC SystemJeffcaster ComelNo ratings yet

- Revised Final Year Project TopicsDocument3 pagesRevised Final Year Project TopicsIan KahuthiaNo ratings yet

- Harga Satuan 2023Document12 pagesHarga Satuan 2023Ratih MelatiNo ratings yet

- DMW 3305 30116 1 3305 602 - Is00Document1 pageDMW 3305 30116 1 3305 602 - Is00nuramirah2023No ratings yet

- Technical Specification SG-45Document7 pagesTechnical Specification SG-45KrunoslavNo ratings yet

- S01L02 S Eskesen PDFDocument101 pagesS01L02 S Eskesen PDFmodest_dhuNo ratings yet