Professional Documents

Culture Documents

APW7159A

Uploaded by

Voicu AdrianOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

APW7159A

Uploaded by

Voicu AdrianCopyright:

Available Formats

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 1

ANPEC reserves the right to make changes to improve reliability or manufacturability without notice, and

advise customers to obtain the latest version of relevant information to verify before placing orders.

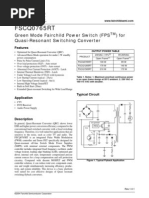

Dual Channel Synchronous Buck PWM Controller for SMPS

Features

Single 12V Power Supply Required

Excellent Output Voltage Regulation

- 1.0V0.8% Internal Reference Over Line and

Temperature

Simple Single Loop Control Design

- Voltage Mode PWM Control

0~100% Duty Ratio

Programmable Frequency Range from 50kHz to

400kHz (Constant 50kHz when Floating)

Integrated Soft-Start and Soft-Off (Patent Pending)

Support Pre-Biased Power-On

Both Channel with 180

o

Phase Shift

Integrated Boot-Strap Diode

Over-Current Protection

- Sense High Side MOSFETs R

DS(ON)

120% Over-Voltage Protection

50% Under-Voltage Protection

Over-Temperature Protection

Available in SOP-20 Package

Lead Free and Green Devices Available

(RoHS Compliant)

Applications

General Description

SMPS

Simplified Application Circuit

S

The APW7159A is a dual channel voltage mode and syn-

chronous PWM controller which drives dual N-channel

MOSFETs. The two channels are operated with 180 de-

gree phase shift.

The device integrates all of the control, monitoring, and

protecting functions into a single package; provides two

control l ed power output wi th over-vol tage, over-

temperature, and over-current protections.

The APW7159A provides excellent regulation for output

load variation. The internal 1.0V temperature-compen-

sated reference voltage provides high accuracy of 0.8%

over line and temperature. The device includes a 50kHz

free-running triangle-wave oscillator that is adjustable

from 50kHz to 400kHz.

PWM

Controller

1

PWM

Controller

2

APW7159A

V

OUT2

V

IN

V

OUT1

Phase Shift

The APW7159A has been equipped with excellent pro-

tection functions: POR, OCP, UVP, and OVP protections.

The Power-On-Reset (POR) circuit can monitor the VCC

and OCSET voltage to make sure the supply voltage ex-

ceeds their threshold voltage while the controller is

running. The Over-Current Protection (OCP) monitors the

output current by using the voltage drop across the high

side MOSFETs R

DS(ON)

. When the output current reaches

the trip point, the controller will be latched. Under-Voltage

Protection (UVP) and Over-Voltage Protection (OVP) moni-

tor the FB voltage to protect APW7159A from burnout when

output voltage is under 50% or over 120% of normal out-

put voltage. The APW7159A is available in SOP-20

package.

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 2

Ordering and Marking Information

Note: ANPEC lead-free products contain molding compounds/die attach materials and 100% matte tin plate termination finish; which

are fully compliant with RoHS. ANPEC lead-free products meet or exceed the lead-free requirements of IPC/JEDEC J-STD-020D for

MSL classification at lead-free peak reflow temperature. ANPEC defines Green to mean lead-free (RoHS compliant) and halogen

free (Br or Cl does not exceed 900ppm by weight in homogeneous material and total of Br and Cl does not exceed 1500ppm by

weight).

Pin Configuration

SOP-20

(Top View)

16

15

14

17

18

19

20 1

2

3

4

5

6

7

8

9

10 11

12

13

GND

UGATE1

VCC

COMP1

OCSET1

BOOT1

FB1

PHASE1

LGATE1

PGND

SS

FB2

UGATE2

COMP2

RT

OCSET2

BOOT2

NC

PHASE2

LGATE2

APW7159A

Handling Code

Temperature Range

Package Code

Assembly Material

APW7159A K: XXXXX - Date Code

Package Code

K : SOP-20

Operating Ambient Temperature Range

I : -40 to 85

o

C

Handling Code

TR : Tape & Reel

Assembly Material

G : Halogen and Lead Free Device

APW7159A

XXXXX

Absolute Maximum Ratings (Note 1)

Symbol Parameter Rating Unit

VVCC Input Bias Supply Voltage (VCC to GND) -0.3 ~ 16 V

VBOOT1/2 BOOT1/ BOOT2 to PHASE1/PHASE2 Voltage -0.3 ~ 16 V

<400ns pulse width -5 ~ VBOOT1/2+5 V

UGATE1/UGATE2 to PHASE1/PHASE2

>400ns pulse width -0.3 ~ VBOOT1/2+0.3 V

<400ns pulse width -5 ~ VVCC+0.3 V

LGATE1/LGATE2 to PGND Voltage

>400ns pulse width -0.3 ~ VVCC+0.3 V

<400ns pulse width -10 ~ 30 V

PHASE1/PHASE2 to PGND Voltage

>400ns pulse width -0.3 ~ 16 V

RT, SS, COMP1, COMP2, FB1, FB2 to GND Voltage -0.3 ~ 7 V

OCSET1, OCSET2 to GND -0.3 ~ VVCC+0.3 V

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 3

Absolute Maximum Ratings (Cont.) (Note 1)

Symbol Parameter Rating Unit

PGND to GND Voltage -0.3 ~ 0.3 V

PD Power Dissipation Internally Limited W

Maximum Junction Temperature 150

o

C

TSTG Storage Temperature -65 ~ 150

o

C

TSDR Maximum Lead Soldering Temperature, 10 Seconds 260

o

C

Thermal Characteristics

Symbol Parameter Typical Value Unit

JA

Junction-to-Ambient Thermal Resistance in Free Air

(Note 2)

SOP-20

100 C/W

Recommended Operating Conditions (Note 3)

Symbol Parameter Range Unit

VVCC Input Bias Supply Voltage (VCC to GND) 10 ~ 13.2 V

V

IN1

/V

IN2

Converter Input Voltage 2 ~ 13.2 V

VOUT1/VOUT2 Converter Output Voltage 1 ~ VIN1/VIN2 V

IOUT1/IOUT2 Converter Output Current 0 ~ 30 A

TA Ambient Temperature -40 ~ 85

o

C

TJ Junction Temperature -40 ~ 125

o

C

Note 3 : Refer to the typical application circuit

Note 1: Absolute Maximum Ratings are those values beyond which the life of a device may be impaired. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

Note 2:

JA

is measured with the component mounted on a high effective thermal conductivity test board in free air.

Unless otherwise specified, these specifications apply over VIN=12V, VOUT= 3.3V and TA= -40 ~ 85

o

C. Typical values are at TA=25

o

C.

APW7159A

Symbol Parameter Test Conditions

Min. Typ. Max.

Unit

SUPPLY CURRENT

VCC Supply Current (Shutdown

Mode)

VVCC<5V, SS=GND - 0.5 1 mA

VCC Supply Current (Shutdown

Mode)

5V< VVCC <9V, SS=GND - 0.8 1.6 mA

IVCC VCC Supply Current

UGATE1/UGATE2 and

LGATE1/LGATE2 open

- 5 10 mA

POWER-ON-RESET (POR) AND LOCKOUT VOLTAGE THRESHOLDS

Rising VCC Threshold 9 9.5 10 V

Falling VCC Threshold 1 7.5 8 8.5 V

Falling VCC Threshold 2 - 4.6 - V

Rising VOCSET1/VOCSET2 Threshold - 1.6 - V

Falling VOCSET1/VOCSET2 Threshold - 1.0 - V

Electrical Characteristics

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 4

Unless otherwise specified, these specifications apply over VIN=12V, VOUT= 3.3V and TA= -40 ~ 85

o

C. Typical values are at TA=25

o

C.

APW7159A

Symbol Parameter Test Conditions

Min. Typ. Max.

Unit

OSCILLATOR

FOSC Free Running Frequency RT = NC, VVCC =12V 45 50 55 kHz

Programmable Frequency Range Connect Resistor from RT to GND 45 - 400 kHz

Total Frequency Accuracy Over-Temperature -10 - 10 %

VOSC Ramp Amplitude

(Note 4)

- 1.9 - V

Duty Cycle 0 - 100 %

REFERENCE VOLTAGE

VREF Reference Voltage - 1.0 - V

Reference Voltage Tolerance VVCC=10V~13.2V -0.8 - +0.8 %

Load Regulation

(Note 4)

IOUT1= IOUT2=0A~10A - 0.01 - %/A

PWM ERROR AMPLIFIERS

Open Loop Gain

(Note 4)

RL=10k, CL=10pF

(Note 4)

- 88 - dB

Unity-Gain Bandwidth

(Note 4)

RL=10k, CL=10pF

(Note 4)

- 15 - MHz

Slew Rate

(Note 4)

RL=10k, CL=10pF

(Note 4)

- 6 - V/s

FB1/FB2 Input Current VFB1/VFB2=1.0V - - 0.1 A

COMP1/COMP2 Source Current VCOMP=2V - 5 - mA

COMP1/COMP2 Sink Current VCOMP=2V - 5 - mA

BOOT-STRAP DIODE AND SOFT-START

VF Diode Forward Voltage IF=10mA - 0.8 - V

I

SS

Soft-Start Charge Current 24 30 36 A

GATE DRIVERS

IUGATE1/

IUGATE2

High Side Gate Source Current

VBOOT1=VBOOT2=12V,

VUGATE1-VPHASE1=2V/VUGATE2 VPHASE2=2V

- 1.7 - A

High Side Gate Sink Current

VBOOT1=VBOOT2=12V, VUGATE1-VPHASE1=

10V/VUGATE2 VPHASE2=10V

- 1.1 - A

ILGATE1/

ILGATE2

Low Side Gate Source Current VVCC=12V, VLGATE1=VLGATE2=2V - 1.9 - A

Low Side Gate Sink Current VVCC=12V,VLGATE1= VLGATE2=10V - 1.6 - A

Dead Time 1

(Note 4)

UGATE1/UGATE2 Falling to

LGATE1/LGATE2 Rising

- 40 - ns

Dead Time 2

(Note 4)

LGATE1/LGATE2 Falling to

UGATE1/UGATE2 Rising

- 40 - ns

PROTECTION

IOCSET1/

IOCSET2

OCSET1/OCSET2 Current Source 180 200 220 A

Over Voltage Protection Measure on FB1/FB2 115 120 125 %VREF

Under Voltage Protection Measure on FB1/FB2 45 50 55 %VREF

Over-Temperature Shutdown

(Note 4)

- 150 -

o

C

Over-Temperature Hysteresis

(Note 4)

- 40 -

o

C

Note 4: Guarantee by design, not production test

Electrical Characteristics (Cont.)

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 5

Typical Operating Characteristics

Reference Voltage vs. Junction

Temperature

Switching Frequency vs. Junction

Temperature

Junction Temperature

R

e

f

e

r

e

n

c

e

V

o

l

t

a

g

e

(

m

V

)

996

997

998

999

1000

1001

1002

1003

-40 -20 0 20 40 60 80 100 120

Junction Temperature

S

w

i

t

c

h

i

n

g

F

r

e

q

u

e

n

c

y

(

k

H

z

)

45

46

47

48

49

50

51

52

53

54

55

-40 -20 0 20 40 60 80 100 120

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 6

Operating Waveforms

Refer to the typical application circuit. The test condition is V

IN

=12V, T

A

= 25

o

C unless otherwise specified.

Power On Power Off

CH1: V

IN1

=V

IN2

=V

VCC

, 5V/Div

CH2: V

OUT1

, 2V/Div

Time: 2ms/Div

CH3: V

OUT2

, 2V/Div

1

3

2

V

IN1

= V

IN2

=V

vcc

V

OUT1

V

OUT2

1

2

3

V

IN1

= V

IN2

=V

VCC

, I

OUT

=0mA

V

OUT1

V

OUT2

CH1: V

IN1

=V

IN2

=V

VCC

, 5V/Div

CH2: V

OUT1

, 2V/Div

Time: 5ms/Div

CH3: V

OUT2

, 2V/Div

Enable Shutdown

CH1: V

SS

, 5V/Div

CH2: V

OUT1

, 2V/Div

CH3: V

OUT2

, 2V/Div

Time: 2ms/Div

CH1: V

SS

, 5V/Div

CH2: V

OUT1

, 2V/Div

CH3: V

OUT2

, 2V/Div

Time: 10ms/Div

1

3

2

V

SS

V

OUT1

V

OUT2

1

3

2

V

SS

V

OUT1

V

OUT2

R

LOAD1

=R

LOAD2

=10

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 7

Operating Waveforms (Cont.)

Refer to the typical application circuit. The test condition is V

IN

=12V, T

A

= 25

o

C unless otherwise specified.

Short-Circuit Protection Over-Current Protection

2

4

3

1

R

OCSET

=1k, R

DS

(high-side)=10m

V

IN

=V

VCC

V

OUT

V

PHASE

I

L

CH1: V

IN

=V

VCC

, 10V/Div

CH2: V

OUT

, 2V/Div

Time: 50A/Div

CH3: V

PHASE

, 10V/Div

CH4: I

L

, 10A/Div

CH1: V

IN

=V

VCC

, 10V/Div

CH2: V

OUT

, 2V/Div

Time: 10ms/Div

CH3: V

PHASE

, 10V/Div

CH4: I

L

, 10A/Div

2

4

3

1

V

IN

=V

vcc

V

OUT

V

PHASE

I

L

UGATE Falling UGATE Rising

1,2

3

I

OUT

=10A

V

UGATE

V

PHASE

V

LGATE

CH1: V

UGATE

, 10V/Div

CH2: V

LGATE

, 5V/Div

CH3: V

PHASE

, 10V/Div

Time: 20ns/Div

1,2

3

I

OUT

=10A

V

LGATE

V

PHASE

V

UGATE

CH1: V

UGATE

, 10V/Div

CH2: V

LGATE

, 5V/Div

CH3: V

PHASE

, 10V/Div

Time: 20ns/Div

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 8

Operating Waveforms (Cont.)

Refer to the typical application circuit. The test condition is V

IN

=12V, T

A

= 25

o

C unless otherwise specified.

Load Transient Response Load Transient Response

PIN

NO. NAME

FUNCTION

1 FB1

Feedback Input of Channel 1. The Buck converter senses feedback voltage via FB1 and regulates the

FB1 voltage at 1.0V. Connecting FB1 with a resistor-divider from the output sets the output voltage of

the Buck converter.

2 COMP1

Error Amplifier Output of Channel 1. It is used to compensate the regulation control loop. Refer to the

section Application Information for details.

3 OCSET1

This pin is used to set the maximum inductor current of channel 1. Refer to the section in Function

Description for detail.

4 GND Signal Ground.

5 VCC

Power Supply Input. Connect a nominal 10V to 13.2V power supply voltage to this pin. A

power-on-reset function monitors the input voltage at this pin. It is recommended that a decoupling

capacitor (1 to 10F) should be connected to the GND for noise decoupling.

6 BOOT1

This pin provides the bootstrap voltage to the high-side gate driver for driving the N-channel MOSFET.

An external capacitor from PHASE1 to BOOT1, an internal diode, and the power supply voltage VCC,

generate the bootstrap voltage for the high-side gate driver (UGATE1).

7 UGATE1 High-Side Gate Driver Output of Channel 1. This pin is the gate driver for high-side MOSFET.

8 PHASE1

This pin is the return path for the high-side gate driver 1. Connect this pin to the high-side MOSFET

source and connect a capacitor to BOOT1 for the bootstrap voltage. This pin is also used to monitor

the voltage drop across the MOSFET for over-current protection.

Pin Description

2

1

V

IN2

=V

VCC

=12V, V

OUT2

=3.3V

I

OUT2

slew rate=10A/s

V

OUT2

I

OUT2

CH1: V

OUT2

, 200mV/Div

Time: 100s/Div

CH2: I

OUT2

, 5A/Div

CH1: V

OUT1

, 200mV/Div

Time: 100s/Div

CH2: I

OUT1

, 5A/Div

V

IN1

=V

VCC

=12V, V

OUT1

=5V

I

OUT1

slew rate=10A/s

V

OUT1

I

OUT1

2

1

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 9

PIN

NO. NAME

FUNCTION

9 LGATE1 Low-side Gate Driver Output of channel 1. This pin is connected to low-side MOSFET.

10 PGND

Power Ground of the Low-Side Gate Drivers. Use a separate track to connect this pin to Source of the

low-side MOSFET. The Source of the low-side MOSFET must be connected to system ground with

very low impedance. Connecting this pin to the GND.

11 NC No Connection.

12 LGATE2 Low-side Gate Driver Output of channel 2. This pin is the gate driver for low-side MOSFET.

13 PHASE2

This pin is the return path for the high-side gate driver of channel 2. Connect this pin to the high-side

MOSFET source and connect a capacitor to BOOT2 for the bootstrap voltage. This pin is also used to

monitor the voltage drop across the MOSFET for over-current protection.

14 UGATE2 High-side Gate Driver Output of Channel 2. This pin is connected to high-side MOSFET.

15 BOOT2

This pin provides the bootstrap voltage to the high-side gate driver for driving the N-channel

MOSFET. An external capacitor from PHASE2 to BOOT2, an internal diode, and the power supply

voltage VCC, generate the bootstrap voltage for the high-side gate driver (UGATE2).

16 OCSET2

This pin is used to set the maximum inductor current of channel 2. Refer to the section in Function

Description for detail.

17 COMP2

Error Amplifier Output of Channel 2. It is used to compensate the regulation control loop. Refer to the

section Application Information for details.

18 FB2

Feedback Input of Channel 2. The converter senses feedback voltage via FB2 and regulates the FB2

voltage at 1.0V. Connecting FB2 with a resistor-divider from the output sets the output voltage of the

Buck converter.

19 SS

Connect a capacitor to the GND and a 30A current source charges this capacitor to set the soft-start

time. The pin also integrates EN/Shutdown function. Pulling SS below 0.7V shuts down the IC.

20 RT

This pin allows adjusting the switching frequency. Connect a resistor from RT to the ground to

increase the switching frequency.

- Exposed Pad Connect the pad to the system ground plane on PCBs. The PCB will be a heat sink of the IC.

Pin Description (Cont.)

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 10

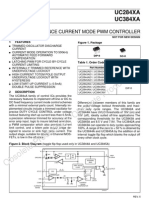

Block Diagram

PHASE1

UGATE1

BOOT1

GND

LGATE1

VCC

PGND1

FB1

V

REF

Error

Amplifier

1

PWM

Comparator

1

COMP1

Oscillator

Gate

Control

OCSET1

PHASE2

UGATE2

BOOT2

LGATE2

VCC

PGND2

FB2

V

REF

Error

Amplifier

2

PWM

Comparator

2

COMP2

Gate

Control

OCSET2

RT

I

OCSET1

I

OCSET2

VCC

Over-Current

Comparator

2

Over-Current

Comparator

1

I

SS

(30A typ.)

SS

Over-Voltage

Comparator

2

Over-Voltage

Comparator

1

1.2

Soft-Start

and

Fault Logic

V

REF

(1.0V typ.)

Regulator

Power-On-

Reset

15k

15k

15k

15k

1.2

0.5

Under-Voltage

Comparator

2

0.5

Under-Voltage

Comparator

1

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 11

Typical Application Circuit

V

IN

V

OUT2

3.3V/30A

BOOT2

UGATE2

PHASE2

LGATE2

PGND

COMP2

FB2

RT

SS

100nF

APM3109

APM3106

2200Fx2

ESR=30m

5.2k

12k

47nF

BOOT1

UGATE1

PHASE1

LGATE1

PGND

COMP1

FB1

VCC

GND

100nF

APM3109

APM3106

R

T

1F

APW7159

OCSET1

OCSET2

6.8nF

33nF

12k

6.8nF

33nF

12k

3k

12k

V

VCC

V

OUT1

5V/30A

L1

7.2H

L2

1nF

(option)

2k 2k

1.5nF

4R7

1.5nF

4R7

1k

15nF

1k

15nF

5R1

7.2H

2200Fx2

ESR=30m

470F

1F 10F 1F 10F

1nF

(option)

(option)

(option)

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 12

Function Description

VCC Power-On-Reset (POR)

The Power-On-Reset (POR) function of APW7159A con-

tinually monitors the voltage on VCC and OCSET1/

OCSET2 pin. When the voltage on VCC and OCSET1/

OCSET2 exceeds their rising POR threshold voltage re-

spectively (9.5V and 1.6V typical), the POR function ini-

tiates soft-start operation. Where the voltage at OCSET1/

OCSET2 pin is equal to V

IN1

/V

IN2

minus a fixed voltage

drop (V

OCSET1

/V

OCSET2

= V

IN1

/V

IN2

V

ROCSET1

/V

ROCSET2

). For op-

eration with a single +12V power source, V

IN1

/V

IN2

and

VCC are equivalent and the +12V power source must

exceed the rising VCC threshold. With all input supplies

above their POR thresholds, the device initiates a soft-

start interval.

Soft-Start

The SS pin controls the soft-start and enables/disables

the controller. Connect a soft-start capacitor from SS pin

to GND to set the soft-start interval. Figure1 shows the

soft-start interval. When VCC reaches its Power-On-Re-

set threshold (9.5V typical), a soft-start current source, I

SS

(30A typical), starts to charge the capacitor. When the

V

SS

reaches the threshold about 1V, the internal 1.0V ref-

erence starts to rise and follows the V

SS

; the error ampli-

fier output (V

COMP

) suddenly rises to 1.1V, which is the

valley of the triangle wave of the oscillator, leads the V

OUT1

/

V

OUT2

to start up. V

OUT1

and V

OUT2

have power on sequence

issue, V

OUT2

will start up after V

SS

rise up to 1.4V. The soft-

start time can be calculated as below:

The APW7159A does not have EN pin, pull SS low (SS

<0.7V) shut down the IC.

Where

C

SS

= external capacitor connected at SS pin

I

SS

= soft-start current, typical I

SS

current is 30A

Soft-Off (5V<VCC<9V)

(Note 5)

The APW7159A also integrates a soft-off circuitry. When

the voltage on VCC falls below the falling threshold1 (8V

typical), an internal current source, I

SS

(30A typical), starts

to discharge from SS. When the V

VCC

falls below the fall-

ing threshold2 (4.6V typical), the device is shutdown. The

APW7159A will initiate a soft-start process until re-cycle

power supply (9.5V typical).

Note 5: The mentioned soft-off function is patent pending by ANPEC

Over-Temperature Protection (OTP)

The over-temperature circuit limits the junction tempera-

ture of the APW7159A. When the junction temperature

exceeds 150

o

C, a thermal sensor pulls UGTAE1/UGATE2

and LGATE1/LGATE2 low, allowing the devices to cool.

The thermal sensor allows the converters to start a soft-

start process and to regulate the output voltage again

after the junction temperature cools by 40

o

C. The OTP is

designed with a 40

o

C hysteresis to lower the average

Junction Temperature (T

J

) during continuous thermal

overload conditions, increasing the lifetime of the device.

Over-Current Protection

The over-current function protects the switching converter

against over-current or short-circuit conditions. The con-

troller senses the inductor current by detecting the drain-

to-source voltage, which the product of the inductors cur-

rent and high side MOSFET on-resistance during its on-

state. This method enhances the converters efficiency

and reduces cost by eliminating a current sensing resis-

tor required.

1V

I

C

t t t t T

SS

SS

2 4 1 3 START SOFT

= = =

Figure 1. Soft-start timing sequence

Voltage

1.4

Time

t

0

1

V

SS

V

FB

1

V

FB2

t

1

t

2

t

3

t

4

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 13

Function Description (Cont.)

Over-Current Protection (Cont.)

A resistor (R

OCSET1

/R

OCSET2

) connected between OCSET1/

OCSET2 pin and the drain of the upper MOSFET will de-

termine the over-current limit. An internal current source

will flow through this resistor, creating a voltage drop,

which will be compared with the voltage across the up-

per MOSFET. When the voltage across the upper MOSFET

exceeds the voltage drop across the R

OCSET1

/R

OCSET2

, the

IC shuts off the entire gate drives. After a soft-start period

delay, the APW7159A initiates a new soft-start process.

After 3 times over-current events are counted continuously,

all devices and gate drivers (UGATE1/UGATE2/LGATE1/

LGATE2) were shutdown. Both outputs of the PWM con-

verter are latched to be floating. The threshold of the over-

current limit is therefore given by :

( ) side high R

R I

I

) ON ( DS

OCSET OCSET

LIMIT

=

For the over-current is never occurred in the normal oper-

ating load range; the variation of all parameters in the

above equation should be determined.

- The MOSFETs R

DS(ON)

is varied by temperature and

gate to source voltage, the user should determine the

maximum R

DS(ON)

in manufacturers datasheet.

-The minimum I

OCSET1

/I

OCSET2

(typical 200A) and mini-

mum R

OCSET1

/R

OCSET2

shoul d be used i n the above

equation.

-Note that the I

LIMIT

is the current flow through the up-

per MOSFET; I

LIMIT

must be greater than maximum output

current add the half of inductor ripple current.

The over-current protection will shut down the device and

discharge the C

SS

with a 30A sink current. If the R

OCSET1

/

R

OCSET2

is not connected or V

OCSET1

/V

OCSET2

is below 1.6V,

the APW7159A will not initiate soft-start process and force

device shutdown.

Over-Voltage Protection

The over-voltage protection monitors the FB voltage to

prevent the output from over-voltage. When the output

voltage rises to 120% of the nominal output voltage, the

APW7159A turns off all devices. The APW7159A will ini-

tiate a soft-start process until re-cycle power supply.

Adaptive Shoot-Through Protection

The gate driver incorporates adaptive shoot-through pro-

tection to high-side and low-side MOSFETs from con-

ducting simultaneously and shorting the input supply.

This is accomplished by ensuring the falling gate has

turned off one MOSFET before the other is allowed to

rise.

During turn-off of the low-side MOSFET, the LGATE1/

LGATE2 voltage is monitored until it reaches a 1.6V

threshold, at which time the UGATE is released to rise

after a constant delay. During turn-off of the high-side

MOSFET, the UGATE1/UGATE2 to PHASE1/PHASE2 volt-

age is also monitored until it reaches a 1.6V threshold, at

which time the LGATE1/LGATE2 is released to rise after

a constant delay.

Pre-Bias Power-On

When the APW7159A initiates the soft-start, the output

voltage will smoothly rising without discharged even the

voltage is not zero.

Switching Frequency

The APW7159A provides the oscillator switching fre-

quency adjustment. The device includes a 50kHz free-

running triangle wave oscillator. If operates in higher fre-

quency than 50kHz, connect a resistor from RT pin to the

ground to increase the switching frequency. Equation 1

and figure 2 shows the relationship between oscillation

frequency and RT resistance.

Under-Voltage Protection

The under-voltage function monitors the voltage on FB by

Under-Voltage comparator to protect the PWM converter

against short-circuit conditions. When the V

FB

falls below

the falling UVP threshold (50% V

REF

), a fault signal is in-

ternally generated and the device turns off high-side

and low-side MOSFETs. The converter is shutdown and

the output is latched to be floating.

( )

( )

+ =

k R

7550

50 kHz F

T

OSC

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 14

Function Description (Cont.)

Figure 2. Oscillator Frequency vs. RT Resistance

Switching Frequency (Cont.)

Oscillator Frequency vs. RT Resistance

O

s

c

i

l

l

a

t

o

r

F

r

e

q

u

e

n

c

y

(

k

H

z

)

RT Resistance (k)

0 100 200 300 400 500 600

0

100

200

300

400

500

600

700

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 15

Application Information

Output Voltage Selection

The output voltage can be programmed with a resistive

divider. Use 1% or better resistors for the resistive divider

is recommended. The FB pin is the inverter input of the

error amplifier, and the reference voltage is 1V. The out-

put voltage is determined by:

Where R

OUT

is the resistor connected from V

OUT

to FB and

R

GND

is the resistor connected from FB to the GND.

Output Inductor Selection

The inductor value determines the inductor ripple current

and affects the load transient response. Higher inductor

value reduces the inductors ripple current and induces

lower output ripple voltage. The ripple current and ripple

voltage can be approximated by:

where Fs is the switching frequency of the regulator.

Although increase of the inductor value and frequency

reduces the ripple current and voltage, a tradeoff will

exist between the inductors ripple current and the

regulator load transient response time.

A smaller inductor will give the regulator a faster load

transient response at the expense of higher ripple current.

Increasing the switching frequency (F

S

) also reduces the

ripple current and voltage, but it will increase the

switching loss of the MOSFET and the power dissipation

of the converter. The maximum ripple current occurs at

the maximum input voltage. A good starting point is to

choose the ripple current to be approximately 30% of

the maximum output current. Once the inductance value

has been chosen, select an inductor is capable of carry-

i ng the requi red peak current wi thout goi ng i nto

saturation. In some types of inductors, especially core

that is made of ferrite, the ripple current will increase

abruptly when it saturates. This will result in a larger out-

put ripple voltage.

IN

OUT

S

OUT IN

RIPPLE

V

V

L F

V V

I

=

ESR I V

RIPPLE OUT

=

Output Capacitor Selection

Higher capacitor value and lower ESR reduce the output

ripple and the load transient drop. Therefore, selecting high

performance low ESR capacitors is intended for switch-

ing regulator applications. In some applications, mul-

tiple capacitors have to be parallelled to achieve the

desired ESR value. A small decoupling capacitor in

parallel for bypassing the noise is also recommended,

and the voltage rating of the output capacitors also must

be considered. If tantalum capacitors are used, make

sure they are surge tested by the manufactures. If in doubt,

consult the capacitors manufacturer.

Input Capacitor Selection

The input capacitor is chosen based on the voltage rating

and the RMS current rating. For reliable operation, select

the capacitor voltage rating to be at least 1.3 times higher

than the maximum input voltage. The RMS current of the

bulk input capacitor is calculated as the following equation:

During power up, the input capacitors have to handle

large amount of surge current. If tantalum capacitors are

used, make sure t hey are surge t est ed by t he

manufactures. If i n doubt, consul t the capaci tors

manufacturer. For high frequency decoupling, a ceramic

capacitor 1F can be connected between the drain of

upper MOSFET and the source of lower MOSFET.

MOSFET Selection

The selection of the N-channel power MOSFETs are

determined by the R

DS(ON)

, reverse transfer capacitance

(C

RSS

) and maximum output current requirement. There

are two components of loss in the MOSFETs: conduction

loss and transition loss. For the upper and lower

MOSFET, the losses are approximately given by the fol-

lowing equations:

P

UPPER

= I

OUT

2

( 1+ TC)(R

DS(ON)

)D + (0.5)( I

OUT

)(V

IN

)( t

SW

)F

S

P

LOWER

= I

OUT

2

(1+ TC)(R

DS(ON)

)(1-D)

Where I

OUT

is the load current

TC is the temperature dependency of R

DS(ON)

F

S

is the switching frequency

t

SW

is the switching interval

D is the duty cycle

( ) D 1 D I I

OUT RMS

=

+ =

GND

OUT

OUT

R

R

1 1 V

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 16

Note that both MOSFETs have conduction loss while the

upper MOSFET includes an additional transition loss.

The switching internal, t

SW

, is the function of the reverse

transfer capacitance C

RSS

. The (1+TC) term is to factor

in the temperature dependency of the R

DS(ON)

and can be

extracted from the R

DS(ON)

vs Temperature curve of the

power MOSFET.

PWM Compensation

The output LC filter of a step down converter introduces a

double pole, which contributes with -40dB/decade gain

slope and 180 degrees phase shift in the control loop. A

compensation network among COMP, FB, and V

OUT

should be added. The compensation network is shown in

Figure 6. The output LC filter consists of the output induc-

tor and output capacitors. The transfer function of the LC

filter is given by:

Application Information (Cont.)

MOSFET Selection (Cont.)

The F

LC

is the double poles of the LC filter, and F

ESR

is the

zero introduced by the ESR of the output capacitor.

V

PHASE

L V

OUT

C

OUT

ESR

Figure 3. The Output LC Filter

Figure 4. The LC Filter GAIN and Frequency

The PWM modulator is shown in Figure 5. The input is

the output of the error amplifier and the output is the

PHASE node. The transfer function of the PWM modulator

is given by:

OUT

ESR

C ESR 2

1

F

=

F

LC

F

ESR

-40dB/dec

-20dB/dec

Frequency(Hz)

G

A

I

N

(

d

B

)

OSC

IN

PWM

V

V

GAIN

=

Figure 5. The PWM Modulator

Output of

Error Amplifier

GVOSC

PWM

Comparator

Driver

Driver

PHASE

VIN

OSC

The compensation network is shown in Figure 6. It

provides a close loop transfer function with the highest

zero crossover frequency and sufficient phase margin.

The transfer function of error amplifier is given by:

The poles and zeros of the transfer function are:

VREF

VOUT

VCOMP

R1

R3 C3 R2 C2

C1

FB

Figure 6. Compensation Network

( )

C3 R3 2

1

F

C2 C1

C2 C1

R2 2

1

F

C3 R3 R1 2

1

F

C2 R2 2

1

F

P2

P1

Z2

Z1

=

=

+

=

=

( )

+

+

+

+

+

=

+

= =

C3 R3

1

s

C2 C1 R2

C2 C1

s s

C3 R3 R1

1

s

C2 R2

1

s

C1 R3 R1

R3 R1

sC3

1

R3 R1//

sC2

1

R2 //

sC1

1

V

V

GAIN

OUT

COMP

AMP

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 17

The poles and zero of this transfer functions are:

Application Information (Cont.)

PWM Compensation (Cont.)

The closed loop gain of the converter can be written as:

GAIN

LC

X GAIN

PWM

X GAIN

AMP

Figure 7. shows the asymptotic plot of the closed loop

converter gain, and the following guidelines will help to

design the compensation network. Using the below

guidelines should give a compensation similars to the

curve plotted. A stable closed loop has a -20dB/ decade

slope and a phase margin greater than 45 degree.

1. Choose a value for R1, usually between 1K and 5K.

2. Select the desired zero crossover frequency

F

O

: (1/5 ~ 1/10) X F

S

>F

O

>F

ESR

Use the following equation to calculate R2:

3. Place the first zero F

Z1

before the output LC filter double

pole frequency F

LC

.

F

Z1

= 0.75 X F

LC

Calculate the C2 by the equation:

4. Set the pole at the ESR zero frequency F

ESR

:

F

P1

= F

ESR

Calculate the C1 by the equation:

5. Set the second pole F

P2

at the half of the switching

frequency and also set the second zero F

Z2

at the output LC

filter double pole F

LC

. The compensation gain should not

exceed the error amplifier open loop gain, check the

compensation gain at F

P2

with the capabilities of the error

amplifier.

F

P2

= 0.5 X F

S

F

Z2

= F

LC

Combine the two equations will get the following component

calculations:

R1

F

F

V

V

R2

LC

O

IN

OSC

=

0.75 F R2 2

1

C2

LC

=

1 F C2 R2 2

C2

C1

ESR

=

1 C ESR s C L s

C ESR s 1

GAIN

OUT OUT

2

OUT

LC

+ +

+

=

Figure 7. Converter Gain and Frequency

S

LC

S

OUT

LC

F R3

1

C3

1

F 2

F

R1

R3

C L 2

1

F

=

=

=

F

LC

Frequency(Hz)

G

A

I

N

(

d

B

)

20log

(R

2

/R

1

)

20log

(V

IN

/GV

OSC

)

F

Z1

F

Z2

F

P1

F

P2

F

ESR

PWM & Filter

Gain

Converter

Gain

Compensation

Gain

Layout Consideration

In any high switching frequency converter, a correct lay-

out is important to ensure proper operation of the

regulator. With power devices switching at 200kHz, the

resulting current transient will cause voltage spike across

the interconnecting impedance and parasitic circuit

elements. As an example, consider the turn-off transition

of the PWM MOSFET. Before turn-off, the MOSFET is car-

rying the full load current. During turn-off, current stops

flowing in the MOSFET and is free-wheeling by the lower

MOSFET and parasitic diode. Any parasitic inductance of

the circuit generates a large voltage spike during the

switching interval. In general, using short and wide printed

circuit traces should minimize interconnecting imped-

ances and the magnitude of voltage spike. And signal

and power grounds are to be kept separating till com-

bined using the ground plane construction or single point

grounding. Figure 8. illustrates the layout, with bold lines

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 18

Application Information (Cont.)

indicating high current paths; these traces must be short

and wide. Components along the bold lines should be

placed lose together. Below is a checklist for your layout:

Layout Consideration (Cont.)

- Keep the switching nodes (UGATE, LGATE, and PHASE)

away from sensitive small signal nodes since these

nodes are fast moving signals. Therefore, keep traces

to these nodes as short as possible.

- The traces from the gate drivers to the MOSFETs (UGATE

and LGATE) should be short and wide.

- Place the source of the high-side MOSFET and the drain

of the low-side MOSFET as close as possible. Minimiz-

ing the impedance with wide layout plane between the

two pads reduces the voltage bounce of the node.

- Decoupling capacitor, compensation component, the

resistor dividers, and boot capacitors should be close

their pins. (For example, place the decoupling ceramic

capacitor near the drain of the high-side MOSFET as

close as possible. The bulk capacitors are also placed

near the drain).

- The input capacitor should be near the drain of the up-

per MOSFET; the output capacitor should be near the

loads. The input capacitor GND should be close to the

lower MOSFET GND.

- The drain of the MOSFETs (VIN and PHASE nodes)

should be a large plane for heat sinking.

- The R

OCSET

resistance should be placed near the IC as

close as possible.

- The decoupling capacitor for VCC should be placed

near the VCC and GND. C

BOOT

should be connected as

close to the BOOT and PHASE pins as possible.

Figure 8. Layout Consideration

VCC

BOOT

PHASE

UGATE

LGATE

V

IN

V

OUT

L

O

A

D

APW7159A

R

OCSET

Close to IC

OCSET

GND

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 19

Package Information

SOP-20

0

L

VIEW A

0

.

2

5

SEATING PLANE

GAUGE PLANE

Note : 1. Follow from JEDEC MS-013 AC.

2. Dimension "D" does not include mold flash, protrusions

or gate burrs. Mold flash, protrusion or gate burrs shall not

exceed 6 mil per side.

3. Dimension "E" does not include inter-lead flash or protrusions.

Inter-lead flash and protrusions shall not exceed 10 mil per side.

D

E

1

E

e

b

A

A

1

A

2

S

Y

M

B

O

L

MIN. MAX.

2.65

0.10

0.20 0.33

0.30

A

A1

c

D

E

E1

e

h

L

MILLIMETERS

b 0.31 0.51

SOP-20

0.25 0.75

0.40 1.27

MIN. MAX.

INCHES

0.104

0.004

0.012 0.020

0.008 0.013

0.010 0.030

0.016 0.050

0 0

o

8

o

0

o

8

o

0.012

1.27 BSC 0.050 BSC

2.05 0.081 A2

12.60 13.00 0.496 0.512

10.10 10.50 0.398 0.413

7.40 7.60 0.291 0.299

SEE VIEW A

c

h

X

4

5

o

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 20

Application A H T1 C d D W E1 F

330.0 2.00 50 MIN.

24.40+2.00

-0.00

13.0+0.50

-0.20

1.5 MIN. 20.2 MIN. 24.0 0.30 1.75 0.10 11.5 0.10

P0 P1 P2 D0 D1 T A0 B0 K0 SOP-20

4.0 0.10 12.0 0.10 2.0 0.10

1.5+0.10

-0.00

1.5 MIN.

0.6+0.00

-0.40

10.9 0.20 13.3 0.20 3.1 0.20

(mm)

Carrier Tape & Reel Dimensions

A

E

1

A

B

W

F

T

P0

OD0

B

A0

P2

K0

B

0

SECTION B-B

SECTION A-A

OD1

P1

H

T1

A

d

Package Type Unit Quantity

SOP-20 Tape & Reel 1000

Devices Per Unit

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 21

Taping Direction Information

SOP-20

USER DIRECTION OF FEED

Classification Profile

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 22

Classification Reflow Profiles

Profile Feature Sn-Pb Eutectic Assembly Pb-Free Assembly

Preheat & Soak

Temperature min (Tsmin)

Temperature max (Tsmax)

Time (Tsmin to Tsmax) (ts)

100 C

150 C

60-120 seconds

150 C

200 C

60-120 seconds

Average ramp-up rate

(Tsmax to TP)

3 C/second max. 3C/second max.

Liquidous temperature (TL)

Time at liquidous (tL)

183 C

60-150 seconds

217 C

60-150 seconds

Peak package body Temperature

(Tp)*

See Classification Temp in table 1 See Classification Temp in table 2

Time (tP)** within 5C of the specified

classification temperature (Tc)

20** seconds 30** seconds

Average ramp-down rate (Tp to Tsmax) 6 C/second max. 6 C/second max.

Time 25C to peak temperature 6 minutes max. 8 minutes max.

* Tolerance for peak profile Temperature (Tp) is defined as a supplier minimum and a user maximum.

** Tolerance for time at peak profile temperature (tp) is defined as a supplier minimum and a user maximum.

Table 2. Pb-free Process Classification Temperatures (Tc)

Package

Thickness

Volume mm

3

<350

Volume mm

3

350-2000

Volume mm

3

>2000

<1.6 mm 260 C 260 C 260 C

1.6 mm 2.5 mm 260 C 250 C 245 C

2.5 mm 250 C 245 C 245 C

Table 1. SnPb Eutectic Process Classification Temperatures (Tc)

Package

Thickness

Volume mm

3

<350

Volume mm

3

350

<2.5 mm 235 C 220 C

2.5 mm 220 C 220 C

Reliability Test Program

Test item Method Description

SOLDERABILITY JESD-22, B102 5 Sec, 245C

HOLT JESD-22, A108 1000 Hrs, Bias @ 125C

PCT JESD-22, A102 168 Hrs, 100%RH, 2atm, 121C

TCT JESD-22, A104 500 Cycles, -65C~150C

HBM MIL-STD-883-3015.7 VHBM 2KV

MM JESD-22, A115 VMM 200V

Latch-Up JESD 78 10ms, 1tr 100mA

Copyright ANPEC Electronics Corp.

Rev. A.1 - Oct., 2009

APW7159A

www.anpec.com.tw 23

Customer Service

Anpec Electronics Corp.

Head Office :

No.6, Dusing 1st Road, SBIP,

Hsin-Chu, Taiwan, R.O.C.

Tel : 886-3-5642000

Fax : 886-3-5642050

Taipei Branch :

2F, No. 11, Lane 218, Sec 2 Jhongsing Rd.,

Sindian City, Taipei County 23146, Taiwan

Tel : 886-2-2910-3838

Fax : 886-2-2917-3838

You might also like

- APW7165Document20 pagesAPW7165Jorge BulacioNo ratings yet

- Apl 5336Document20 pagesApl 5336FlavianoSilvaNo ratings yet

- APW7120Document22 pagesAPW7120nishatiwari82No ratings yet

- Features General Description: 3A, 12V, Synchronous-Rectified Buck ConverterDocument20 pagesFeatures General Description: 3A, 12V, Synchronous-Rectified Buck ConverterDarien SanchezNo ratings yet

- APW7313Document20 pagesAPW7313Gabriel BeguiriztainNo ratings yet

- Features General Description: 3A, 12V, Synchronous-Rectified Buck ConverterDocument22 pagesFeatures General Description: 3A, 12V, Synchronous-Rectified Buck ConverterRichard MachadoNo ratings yet

- Amplificador LA42102Document8 pagesAmplificador LA42102SilvestrePalaciosLópezNo ratings yet

- Apl 5930Document17 pagesApl 5930zanaturNo ratings yet

- AP2182Document17 pagesAP2182ابراهيم السعيديNo ratings yet

- Features General Description: Advanced Dual PWM and Dual Linear Power ControllerDocument13 pagesFeatures General Description: Advanced Dual PWM and Dual Linear Power ControllerbehzadNo ratings yet

- Boost Controller With Power Factor CorrectionDocument14 pagesBoost Controller With Power Factor CorrectionChiseledPrawnNo ratings yet

- High Efficiency Low-Side N-Channel Controller For Switching RegulatorsDocument33 pagesHigh Efficiency Low-Side N-Channel Controller For Switching Regulatorssoft4gsmNo ratings yet

- Features General Description: USB Power-Distribution SwitchesDocument21 pagesFeatures General Description: USB Power-Distribution SwitchesgraynotNo ratings yet

- Universal DC/DC Converter: (Top View)Document11 pagesUniversal DC/DC Converter: (Top View)Engine Tuning UpNo ratings yet

- AP358 DatasheetDocument13 pagesAP358 DatasheetRafael OliveiraNo ratings yet

- Ap5002 - PWM Control 2a Step-Down ConverterDocument10 pagesAp5002 - PWM Control 2a Step-Down ConverterAmador Garcia IIINo ratings yet

- La 42205Document7 pagesLa 42205ban4444No ratings yet

- LTC 7138Document24 pagesLTC 7138MallickarjunaNo ratings yet

- LCD Bias Power Integrated With WLED Backlight Drivers: FeaturesDocument31 pagesLCD Bias Power Integrated With WLED Backlight Drivers: FeaturesJoseph BernardNo ratings yet

- 1.5A Power Switching Regulator: DescriptionDocument16 pages1.5A Power Switching Regulator: DescriptionPravin MevadaNo ratings yet

- LM5007 High Voltage (80V) Step Down Switching Regulator: FeaturesDocument17 pagesLM5007 High Voltage (80V) Step Down Switching Regulator: FeaturesbhushanchittaragiNo ratings yet

- Apl 5902Document21 pagesApl 5902kamran latifNo ratings yet

- LM3875TDocument19 pagesLM3875TJasten S DeleñaNo ratings yet

- TLP5214 Photocoupler 4A Gate Driver DatasheetDocument20 pagesTLP5214 Photocoupler 4A Gate Driver DatasheetandrewNo ratings yet

- Datasheet LM3429Document34 pagesDatasheet LM3429Bagus KrisviandikNo ratings yet

- La 42031Document7 pagesLa 42031Deyby GarciaNo ratings yet

- 3000W Single Output Power Supply Spec SheetDocument6 pages3000W Single Output Power Supply Spec SheetGrigoriu CodrutaNo ratings yet

- CQ 0765RTDocument24 pagesCQ 0765RTsonivitel100% (2)

- A 2918 SW Data SheetDocument8 pagesA 2918 SW Data SheetGustavo LunaNo ratings yet

- Tda 4601Document8 pagesTda 4601Mirko AleksicNo ratings yet

- Uc 3845Document23 pagesUc 3845Bahram RN100% (1)

- 1.5-A Peak Boost/Buck/Inverting Switching Regulators: FeaturesDocument23 pages1.5-A Peak Boost/Buck/Inverting Switching Regulators: FeaturesReinaldo VergaraNo ratings yet

- Constant Current Led DriverDocument27 pagesConstant Current Led DriverJubin JainNo ratings yet

- LM3478 High Efficiency Low-Side N-Channel Controller For Switching RegulatorDocument22 pagesLM3478 High Efficiency Low-Side N-Channel Controller For Switching RegulatorVinoth Kumar RajendranNo ratings yet

- Thb7128 InstructionsDocument9 pagesThb7128 InstructionsanhxcoNo ratings yet

- Iso 3082Document20 pagesIso 3082Nur ÇetinerNo ratings yet

- BM2596Document9 pagesBM2596Anton AdrianNo ratings yet

- EN5322QI: 2 A Voltage Mode Synchronous Buck PWM DC-DC Converter With Integrated InductorDocument16 pagesEN5322QI: 2 A Voltage Mode Synchronous Buck PWM DC-DC Converter With Integrated Inductorcatsoithahuong84No ratings yet

- Ic 3843Document4 pagesIc 3843nishatiwari82No ratings yet

- Ca3130, Ca3130aDocument17 pagesCa3130, Ca3130aproctepNo ratings yet

- Tps 40057 PWPDocument33 pagesTps 40057 PWPcatsoithahuong84No ratings yet

- Ltc1629/Ltc1629-Pg Polyphase, High Efficiency, Synchronous Step-Down Switching RegulatorsDocument28 pagesLtc1629/Ltc1629-Pg Polyphase, High Efficiency, Synchronous Step-Down Switching Regulatorscatsoithahuong84No ratings yet

- 1565 RTDocument24 pages1565 RTJose Samuel Robelto RNo ratings yet

- PM 150 CSD 120Document7 pagesPM 150 CSD 120elecompinnNo ratings yet

- STRW6252Document15 pagesSTRW6252miltoncgNo ratings yet

- 3000W Single Output Power Supply: SeriesDocument7 pages3000W Single Output Power Supply: SeriesAlexander PekarovskiyNo ratings yet

- UC3842B/3843B: Unisonic Technologies Co., LTDDocument11 pagesUC3842B/3843B: Unisonic Technologies Co., LTDvannadioNo ratings yet

- Single Synchronous Buck PWM DC-DC ControllerDocument16 pagesSingle Synchronous Buck PWM DC-DC Controllerbachet56No ratings yet

- La 42102Document8 pagesLa 42102buyadiNo ratings yet

- CA3140Document20 pagesCA3140Brzata PticaNo ratings yet

- Precision Phase-Locked Loop: ... The Analog Plus CompanyDocument21 pagesPrecision Phase-Locked Loop: ... The Analog Plus Companykao08No ratings yet

- CD4047BC Low Power Monostable/Astable Multivibrator: General DescriptionDocument10 pagesCD4047BC Low Power Monostable/Astable Multivibrator: General DescriptionWillianNo ratings yet

- Isolated Flyback Switching Regulator W - 9V OutputDocument16 pagesIsolated Flyback Switching Regulator W - 9V OutputCasey DialNo ratings yet

- Uc3842b 3843BDocument10 pagesUc3842b 3843Bbob75No ratings yet

- Uc284xa Uc384xaDocument16 pagesUc284xa Uc384xayusufwpNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Daily Timecard Entry in HoursDocument20 pagesDaily Timecard Entry in HoursadnanykhanNo ratings yet

- Industrial Tour Report (JEWEL - MANAGEMENT-CU)Document37 pagesIndustrial Tour Report (JEWEL - MANAGEMENT-CU)Mohammad Jewel100% (2)

- Announcement: Inter-And Intra-Sectoral Dynamics For Transforming Indian AgricultureDocument8 pagesAnnouncement: Inter-And Intra-Sectoral Dynamics For Transforming Indian AgricultureEnamul HaqueNo ratings yet

- Real Estate Merger Motives PDFDocument13 pagesReal Estate Merger Motives PDFadonisghlNo ratings yet

- Machine Dynamics and Vibration-Forced Vibration AssignmentDocument4 pagesMachine Dynamics and Vibration-Forced Vibration AssignmentVijay ReddyNo ratings yet

- Uuee 17-2020Document135 pagesUuee 17-2020Tweed3ANo ratings yet

- Time Division Muliple AccessDocument4 pagesTime Division Muliple AccessAbhishek RanaNo ratings yet

- Antigua and Barbuda, Build Free Back LinksDocument7 pagesAntigua and Barbuda, Build Free Back LinkswaNo ratings yet

- LG Mini Split ManualDocument38 pagesLG Mini Split ManualMark ChaplinNo ratings yet

- Factors Supporting ICT Use in ClassroomsDocument24 pagesFactors Supporting ICT Use in ClassroomsSeshaadhrisTailoringNo ratings yet

- Naara Brochure AUSDocument4 pagesNaara Brochure AUSCatalin CosmaNo ratings yet

- VISIONARCHDocument3 pagesVISIONARCHJHON YDUR REMEGIONo ratings yet

- Crusher RC Classic RC-II OM FN 23830 (En)Document128 pagesCrusher RC Classic RC-II OM FN 23830 (En)julio cesarNo ratings yet

- Remedy Shortcut Keys: Home Solutions & Services Products Partners Support Education ConnectDocument2 pagesRemedy Shortcut Keys: Home Solutions & Services Products Partners Support Education Connectaert5683No ratings yet

- Tool Selection For Rough and Finish CNC Milling OpDocument4 pagesTool Selection For Rough and Finish CNC Milling Opmatic91No ratings yet

- CIT-Vs-NCR-Corporation-Pvt.-Ltd.-Karnataka-High-Court - ATMs Are ComputerDocument15 pagesCIT-Vs-NCR-Corporation-Pvt.-Ltd.-Karnataka-High-Court - ATMs Are ComputerSoftdynamiteNo ratings yet

- Public Arrest Report For 22jan2016Document4 pagesPublic Arrest Report For 22jan2016api-214091549No ratings yet

- Mining Operational ExcellenceDocument12 pagesMining Operational ExcellencegarozoNo ratings yet

- RPG One 1.5 2.5Document2 pagesRPG One 1.5 2.5YJ JangNo ratings yet

- Long Vowel SoundsDocument15 pagesLong Vowel SoundsRoselle Jane PasquinNo ratings yet

- ELEC 121 - Philippine Popular CultureDocument10 pagesELEC 121 - Philippine Popular CultureMARITONI MEDALLANo ratings yet

- Detection of Phising Websites Using Machine Learning ApproachesDocument9 pagesDetection of Phising Websites Using Machine Learning Approachesshresthabishal721No ratings yet

- Vim 101 - A Beginner's Guide To VimDocument5 pagesVim 101 - A Beginner's Guide To VimHuy TranNo ratings yet

- Netflix AccountsDocument2 pagesNetflix AccountsjzefjbjeNo ratings yet

- Pakistan Relations With EnglandDocument4 pagesPakistan Relations With Englandpoma7218No ratings yet

- Computer Programmer or Software Developer or C++ or Visual BasicDocument6 pagesComputer Programmer or Software Developer or C++ or Visual Basicapi-77734404No ratings yet

- Cement Lined Piping SpecificationDocument167 pagesCement Lined Piping SpecificationvenkateshwaranNo ratings yet

- Final IEQC MICRODocument10 pagesFinal IEQC MICROWMG NINJANo ratings yet

- Lesson 2 Empowerment MidtermDocument5 pagesLesson 2 Empowerment Midtermaronfranco223No ratings yet

- Zelio Plug-In Relays: RPM Power RangeDocument16 pagesZelio Plug-In Relays: RPM Power RangeSimon MouneNo ratings yet